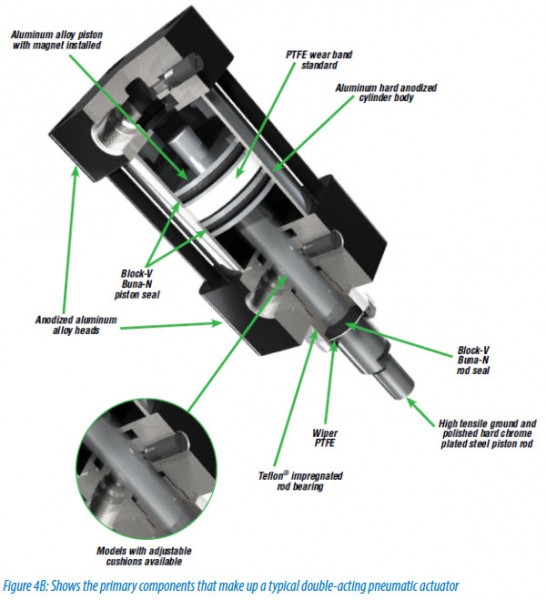

Pneumatic Piston Diagram . Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. A tube that is closed on both ends with a cap and head. Most of the cylinders with a piston rod contain the following parts: The main parts of pneumatic cylinders are the barrel, piston, and piston rod. The mechanical energy produces linear or rotary motion. Different types of attachments are normally connected to the piston of a cylinder that can perform work. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Design of pneumatic cylinder is explained in this video with relevant animations. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Inside the tube seen below a piston rod moves with a drive. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. There are seals in place to prevent air leakage.

from library.automationdirect.com

Most of the cylinders with a piston rod contain the following parts: Inside the tube seen below a piston rod moves with a drive. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. There are seals in place to prevent air leakage. Different types of attachments are normally connected to the piston of a cylinder that can perform work. The mechanical energy produces linear or rotary motion. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. A tube that is closed on both ends with a cap and head. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. The main parts of pneumatic cylinders are the barrel, piston, and piston rod.

Pneumatic Actuator/Air Cylinder Basics Library.AutomationDirect

Pneumatic Piston Diagram There are seals in place to prevent air leakage. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Inside the tube seen below a piston rod moves with a drive. Most of the cylinders with a piston rod contain the following parts: The mechanical energy produces linear or rotary motion. There are seals in place to prevent air leakage. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Design of pneumatic cylinder is explained in this video with relevant animations. Different types of attachments are normally connected to the piston of a cylinder that can perform work. A tube that is closed on both ends with a cap and head. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages:

From www.linquip.com

3 Main Types of Pneumatic Cylinders With Application Linquip Pneumatic Piston Diagram Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: There are seals in place to prevent air leakage. Most of the cylinders with a piston rod contain the following parts: Inside the tube seen below a piston rod moves with a drive. Different types of attachments are normally connected to the piston of a cylinder. Pneumatic Piston Diagram.

From www.youtube.com

Hydraulic cylinder design. How does the hydraulic cylinder work? YouTube Pneumatic Piston Diagram A tube that is closed on both ends with a cap and head. The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Design of pneumatic cylinder is explained in this video with relevant animations. Different types of attachments are normally connected to the piston of a cylinder that can perform work. Here’s a double acting pneumatic. Pneumatic Piston Diagram.

From schematicmanualwilliam.z13.web.core.windows.net

Pneumatic Rotary Actuator Diagram Pneumatic Piston Diagram The mechanical energy produces linear or rotary motion. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Inside the tube seen below a piston rod moves with a drive. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Most of the cylinders with a piston rod contain the following parts: A. Pneumatic Piston Diagram.

From wiringdbdoorframe.z13.web.core.windows.net

Diagram Of Pneumatic Pistons In F1 Cars Pneumatic Piston Diagram Design of pneumatic cylinder is explained in this video with relevant animations. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Most of the cylinders with a piston rod contain the following parts: Inside the tube seen below a piston rod moves with a drive. Seals, cushioning systems, sensors, guide rings, and tie rods enhance. Pneumatic Piston Diagram.

From www.pbslearningmedia.org

How Does a Pneumatic Piston Work? PBS LearningMedia Pneumatic Piston Diagram Different types of attachments are normally connected to the piston of a cylinder that can perform work. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: A tube that is closed on both ends with a cap and head. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. There are. Pneumatic Piston Diagram.

From www.psireland.ie

Pneumatic Symbols explained Pneumatics & Sensors Ireland Pneumatic Piston Diagram A tube that is closed on both ends with a cap and head. Design of pneumatic cylinder is explained in this video with relevant animations. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: There are seals in place to prevent air leakage. The main parts of pneumatic cylinders are the barrel, piston, and piston. Pneumatic Piston Diagram.

From slidingmotion.com

Guide to Understand Hydraulic Cylinder Parts Names & Diagram Pneumatic Piston Diagram Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. The mechanical energy produces linear or rotary motion. Inside the tube seen below a piston rod moves with a drive. The main parts of pneumatic cylinders are the barrel, piston, and piston rod. There are. Pneumatic Piston Diagram.

From manualmanualella.z6.web.core.windows.net

How To Read Pneumatic Schematics Pneumatic Piston Diagram Most of the cylinders with a piston rod contain the following parts: A tube that is closed on both ends with a cap and head. The mechanical energy produces linear or rotary motion. Inside the tube seen below a piston rod moves with a drive. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Air or. Pneumatic Piston Diagram.

From enginelibraryeisenhauer.z19.web.core.windows.net

Pneumatic Cylinder Circuit Diagram Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. A tube that is closed on both ends with a cap and head. Most of the cylinders with a. Pneumatic Piston Diagram.

From schematicgalionisuq6s.z21.web.core.windows.net

Pneumatic Cylinder Circuit Diagram Pneumatic Piston Diagram Inside the tube seen below a piston rod moves with a drive. There are seals in place to prevent air leakage. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Different types of attachments are normally connected to the piston of a cylinder that. Pneumatic Piston Diagram.

From ar.inspiredpencil.com

Hydraulic Piston Diagram Pneumatic Piston Diagram The mechanical energy produces linear or rotary motion. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Design of pneumatic cylinder is explained in this video with relevant. Pneumatic Piston Diagram.

From slidetodoc.com

PNEUMATIC CIRCUITS 1 Working of SINGLE acting cylinder Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. There are seals in place to prevent air leakage. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: The mechanical energy produces linear or rotary motion. Most of the cylinders with a piston rod contain the following parts: Design of pneumatic. Pneumatic Piston Diagram.

From britannicaweb.com

A Pneumatic Cylinder is a device which generates reciprocating linear Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Design of pneumatic cylinder is explained in this video with relevant animations. Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Most of the cylinders with a piston. Pneumatic Piston Diagram.

From www.researchgate.net

Schematic of the hydraulic cylinder (a) assembly structure, (b) piston Pneumatic Piston Diagram The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Design of pneumatic cylinder is explained in this video with relevant animations. Inside the tube seen below a piston rod moves with a drive. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in. Pneumatic Piston Diagram.

From instrumentationtools.com

Working Principle of Pneumatic Actuators Parts of Pneumatic Actuator Pneumatic Piston Diagram Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Design of pneumatic cylinder is explained in this video with relevant animations. Inside the tube seen below a piston rod moves with a drive. Different types of attachments are normally connected to the piston of a cylinder that can perform work. Seals, cushioning systems, sensors, guide. Pneumatic Piston Diagram.

From www.e-pneumatic.com

How Pneumatic Cylinder Work? Described Instructions EPneumatic Blog Pneumatic Piston Diagram Most of the cylinders with a piston rod contain the following parts: The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is. Pneumatic Piston Diagram.

From www.omchele.com

Understanding Pneumatic Cylinder Diagrams omchele Pneumatic Piston Diagram Inside the tube seen below a piston rod moves with a drive. A tube that is closed on both ends with a cap and head. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Most of the cylinders with a piston rod contain the following parts: Pneumatic cylinders work when air or liquid is forced. Pneumatic Piston Diagram.

From www.youtube.com

How does a pneumatic cylinder work? Pneumatic cylinder design YouTube Pneumatic Piston Diagram Different types of attachments are normally connected to the piston of a cylinder that can perform work. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Design of pneumatic cylinder is explained in this video with relevant animations. Most of the cylinders with a. Pneumatic Piston Diagram.

From enginedatanichered.z21.web.core.windows.net

Pneumatic Cylinder Diagram Pneumatic Piston Diagram Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Most of the cylinders with a piston rod contain the following parts: Design of pneumatic cylinder is explained in this video. Pneumatic Piston Diagram.

From www.researchgate.net

Schematic diagram of pneumatic cylinder [14]. Download Scientific Diagram Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Design of pneumatic cylinder is explained in this video with relevant animations. Here’s a double acting pneumatic cylinder diagram with the. Pneumatic Piston Diagram.

From www.wiringview.co

Pneumatic Circuit Diagram To Control A Single Acting Cylinder Wiring Pneumatic Piston Diagram Inside the tube seen below a piston rod moves with a drive. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder. Design of pneumatic cylinder is explained in this video. Pneumatic Piston Diagram.

From library.automationdirect.com

Pneumatic Actuator/Air Cylinder Basics Library.AutomationDirect Pneumatic Piston Diagram Different types of attachments are normally connected to the piston of a cylinder that can perform work. Inside the tube seen below a piston rod moves with a drive. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Most of the cylinders with a piston rod contain the following parts: The mechanical energy produces linear. Pneumatic Piston Diagram.

From userlibrarybernard.z13.web.core.windows.net

Pneumatic Cylinder Circuit Diagram Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. There are seals in place to prevent air leakage. The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Design of pneumatic cylinder is explained in this video with relevant animations. Pneumatic cylinders work when air or liquid is forced into the body. Pneumatic Piston Diagram.

From www.iqsdirectory.com

Pneumatic Cylinder What Is It? How Does It Work? Types Of Pneumatic Piston Diagram There are seals in place to prevent air leakage. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Most of the cylinders with a piston rod contain the following parts: Different types of attachments are normally connected to the piston of a. Pneumatic Piston Diagram.

From www.researchgate.net

Components of the pneumatic cylinder assembly. Download Scientific Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Most of the cylinders with a piston rod contain the following parts: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Here’s a double acting pneumatic cylinder diagram with. Pneumatic Piston Diagram.

From www.iqsdirectory.com

Pneumatic Cylinder What Is It? How Does It Work? Types Of Pneumatic Piston Diagram The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Inside the tube seen below a piston rod moves with a drive. A tube that is closed on both ends with a cap and head. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed. Pneumatic Piston Diagram.

From wiringlistcolucci.z19.web.core.windows.net

Pneumatic Circuit Diagram For Double Acting Cylinder Pneumatic Piston Diagram The mechanical energy produces linear or rotary motion. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Most of the cylinders with a piston rod contain the following parts: Air or pneumatic cylinders are devices that transform compressed air power into mechanical. Pneumatic Piston Diagram.

From circuitlistadrienne.z13.web.core.windows.net

Pneumatic Circuit Diagram For Single Acting Cylinder Pneumatic Piston Diagram There are seals in place to prevent air leakage. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Different types of attachments are normally connected to the piston of a cylinder that can perform work. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Inside the tube seen below a. Pneumatic Piston Diagram.

From www.airlane.co.uk

Pneumatic Circuit Design Airlane Pneumatics Limited Pneumatic Piston Diagram Different types of attachments are normally connected to the piston of a cylinder that can perform work. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Most of the cylinders with a piston rod contain the following parts: The mechanical energy produces linear or rotary motion. Pneumatic cylinders work when air or liquid is forced. Pneumatic Piston Diagram.

From www.researchgate.net

Pneumatic circuit schematic diagram of multicylinder single Pneumatic Piston Diagram Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: The main parts of pneumatic cylinders are the barrel, piston, and piston rod. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston. Pneumatic Piston Diagram.

From ar.inspiredpencil.com

Pneumatic Actuator Diagram Pneumatic Piston Diagram Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. There are seals in place to prevent air leakage. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Most of the cylinders with a piston rod contain the following parts: Design of pneumatic cylinder is explained in this video with relevant. Pneumatic Piston Diagram.

From valveman.com

Pneumatic Automation Explained by the ValveMan Valve Store Pneumatic Piston Diagram Inside the tube seen below a piston rod moves with a drive. Design of pneumatic cylinder is explained in this video with relevant animations. There are seals in place to prevent air leakage. Most of the cylinders with a piston rod contain the following parts: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. A tube. Pneumatic Piston Diagram.

From www.vrogue.co

Working Principle Of Pneumatic Actuator How Pneumatic vrogue.co Pneumatic Piston Diagram Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. Air or pneumatic cylinders are devices that transform compressed air power into mechanical energy. The mechanical energy produces linear or rotary motion. Pneumatic cylinders work when air or liquid is forced into the body of the cylinder which moves a piston that is housed in the cylinder.. Pneumatic Piston Diagram.

From pneumaticmfg.com

What Are Pneumatic Components? Working Principle & Function Pneumatic Piston Diagram Most of the cylinders with a piston rod contain the following parts: Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Seals, cushioning systems, sensors, guide rings, and tie rods enhance the performance and. A tube that is closed on both ends with a cap and head. Air or pneumatic cylinders are devices that transform. Pneumatic Piston Diagram.

From www.omchele.com

Understanding Pneumatic Cylinder Diagrams omchele Pneumatic Piston Diagram There are seals in place to prevent air leakage. A tube that is closed on both ends with a cap and head. Here’s a double acting pneumatic cylinder diagram with the extension stroke and other stages: Inside the tube seen below a piston rod moves with a drive. Different types of attachments are normally connected to the piston of a. Pneumatic Piston Diagram.