Calibration Plan Format . Typically, there are three options for companies to consider when deciding on a formal calibration program. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The equipment calibration plan template provides a structured method for managing calibration and. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. Iso 9001 has become a standard for quality management. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration.

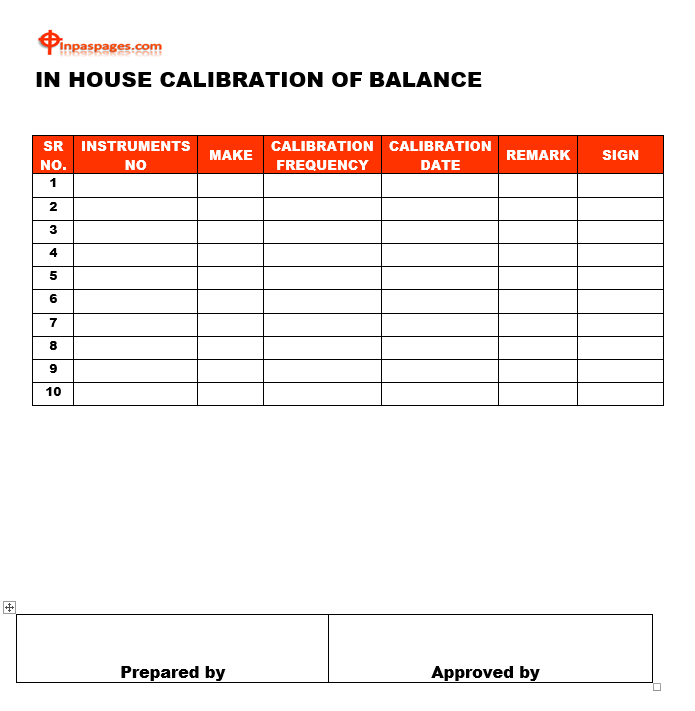

from www.inpaspages.com

The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and Iso 9001 has become a standard for quality management. Typically, there are three options for companies to consider when deciding on a formal calibration program. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The equipment calibration plan template provides a structured method for managing calibration and. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy.

In house calibration format

Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Typically, there are three options for companies to consider when deciding on a formal calibration program. This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The equipment calibration plan template provides a structured method for managing calibration and. Iso 9001 has become a standard for quality management.

From www.vertex42.com

Equipment Calibration Log for Excel Calibration Plan Format The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The equipment calibration and maintenance plan template helps organizations meet this standard by providing. Calibration Plan Format.

From www.scribd.com

Calibration Format Report Instrumentation Calibration Calibration Plan Format Iso 9001 has become a standard for quality management. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. The equipment calibration plan template provides a structured method for managing calibration and. Typically, there are three options for companies to consider when deciding on a formal calibration program.. Calibration Plan Format.

From calibrationawareness.com

Preventive Maintenance in Calibration Calibration Awareness Calibration Plan Format This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is. Calibration Plan Format.

From www.inpaspages.com

Measuring Instrument / Equipment Calibration Compliance Report Format Calibration Plan Format Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The purpose of the equipment calibration. Calibration Plan Format.

From instrumentationtools.com

How to Create Calibration Records? Instrumentation and Control Calibration Plan Format Iso 9001 has become a standard for quality management. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. The plan. Calibration Plan Format.

From www.scribd.com

Calibration Format Measuring Instrument Tools Free 30day Trial Calibration Plan Format Typically, there are three options for companies to consider when deciding on a formal calibration program. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The equipment calibration plan template provides a structured method for managing calibration and. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment. Calibration Plan Format.

From www.luztemplates.com

Calibration Control Sheet for Measuring Instruments Excel Spreadsheet Calibration Plan Format This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The calibration master plan. Calibration Plan Format.

From www.glzy8.com

快递收发登记表模板_快递收发登记表模板XLS表格下载_管理资源吧 Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The plan describes procedures for. Calibration Plan Format.

From www.sheqxel.com

SHEQXEL Equipment Calibration Tracker Calibration Plan Format The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and Typically, there are three options for companies to consider when deciding on a formal calibration program. This workflow describes the planning process involved in conducting calibration,. Calibration Plan Format.

From www.inpaspages.com

Calibration Calendar for Instruments Calibration Plan Format The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. This workflow. Calibration Plan Format.

From www.bizmanualz.com

ISO Calibration Record ISO Template Calibration Plan Format Typically, there are three options for companies to consider when deciding on a formal calibration program. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for. Calibration Plan Format.

From www.scribd.com

02Calibration Plan 2016.doc Scientific Observation Measuring Calibration Plan Format The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity,. Calibration Plan Format.

From www.scribd.com

Instrument Calibration Test Report Format Calibration Accuracy And Calibration Plan Format The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. Iso 9001 has become a standard for quality management. The outlines of the sop for calibration master plan are the procedures for creating. Calibration Plan Format.

From www.inpaspages.com

Daily Calibration Report Calibration Plan Format The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. Typically, there are three options for companies to consider when deciding on a formal. Calibration Plan Format.

From instrumentationbasic.com

Instrument Calibration Report Instrumentation basics Calibration Plan Format The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program. Calibration Plan Format.

From qcqa.industrialguide.co.in

SOP for Calibration of Hardness Tester Calibration Plan Format Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. The. Calibration Plan Format.

From old.sermitsiaq.ag

Equipment Maintenance Schedule Template Calibration Plan Format This workflow describes the planning process involved in conducting calibration, including setting up the required tools (i.e., test equipment, standards, engineering design. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The calibration master plan. Calibration Plan Format.

From www.scribd.com

RMC Plant Calibration Report PDF Calibration Weight Calibration Plan Format The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. Adhering. Calibration Plan Format.

From freewordtemplates.net

Equipment Calibration Form Calibration Plan Format The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The equipment calibration plan template provides a structured method for managing calibration and. The purpose of. Calibration Plan Format.

From www.bizmanualz.com

Calibration Log ISO Template Calibration Plan Format Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. Iso 9001 has become a standard for quality management. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities. Calibration Plan Format.

From www.ge.com

Calibration Management Calibration Planning Workflow Calibration Plan Format The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. This. Calibration Plan Format.

From studylib.net

Calibration Log Calibration Plan Format The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. Iso 9001 has become. Calibration Plan Format.

From pharmablog.in

Handling of Out Of Calibration (OOC) SOP PharmaBlog Calibration Plan Format The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. The equipment calibration plan template provides a structured method for managing calibration and. Iso 9001 has become a standard for quality management. This workflow describes the planning process involved in conducting calibration, including setting up the required tools. Calibration Plan Format.

From www.signnow.com

Speedometer Calibration 20172024 Form Fill Out and Sign Printable Calibration Plan Format The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. Iso 9001 has become a standard for quality management. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The calibration master plan aims to ensure that all measuring and test. Calibration Plan Format.

From www.slideteam.net

Machine Calibration Quality Assurance Plan Standard Ppt Powerpoint Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. Typically, there are three options for companies to consider when deciding on a formal calibration program. The outlines of the sop for calibration. Calibration Plan Format.

From www.inpaspages.com

In house calibration format Calibration Plan Format The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The purpose of the equipment calibration master plan sop is to define the requirements necessary for establishing and implementing an effective calibration control program. The equipment calibration plan template provides a structured method for managing calibration and. The calibration master plan aims to ensure that. Calibration Plan Format.

From inpaspages.com

Calibration Status Verification Report format Excel PDF Sample Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. Iso 9001 has become a standard for quality management. Adhering. Calibration Plan Format.

From smartofficetemplates.myinstamojo.com

Excel template equipment's calibration, inward & outward management Calibration Plan Format The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as. Calibration Plan Format.

From pharmadekho.com

sop for calibration policy Pharma Dekho Calibration Plan Format Iso 9001 has become a standard for quality management. Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. Typically, there are three options for companies to consider when deciding on a formal calibration program. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a. Calibration Plan Format.

From www.inpaspages.com

Calibration Standard Record Calibration Plan Format Without a calibration schedule, users rely on memory, or worse, intuition, to determine when their equipment is due for calibration. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and Iso 9001 has become a standard. Calibration Plan Format.

From www.pinterest.com

Equipment Calibration Form Download this Equipment Calibration table Calibration Plan Format The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. Without a. Calibration Plan Format.

From pharmabeginers.com

SOP for Instrument Calibration (Internal & Third Party) Pharma Beginners Calibration Plan Format The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as a comprehensive framework for managing the calibration activities of instruments and The equipment calibration plan template provides a structured method for managing calibration and. This workflow describes the planning process involved in conducting calibration, including setting up. Calibration Plan Format.

From www.scribd.com

Calibration Plan 2016 (3).doc Calibration Plan Format Iso 9001 has become a standard for quality management. The plan describes procedures for assessing instrument criticality, establishing calibration periodicity, documenting calibration records, and. Adhering to the calibration schedule you create helps to ensure that critical weighing & measurement equipment continues to produce accurate readings and is properly maintained. The equipment calibration plan template provides a structured method for managing. Calibration Plan Format.

From www.scribd.com

Annual Calibration Plan PDF Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. Typically, there are three options for companies to consider when deciding on a formal calibration program. The equipment calibration and maintenance plan template helps organizations meet this standard by providing a structured approach for managing equipment calibration and. The calibration master plan aims to ensure that all. Calibration Plan Format.

From www.slideserve.com

PPT Calibration Plan During BASIC Science PowerPoint Presentation Calibration Plan Format The equipment calibration plan template provides a structured method for managing calibration and. The calibration master plan aims to ensure that all measuring and test equipment (m&te) included in the program are calibrated to the manufacturer’s accuracy. The outlines of the sop for calibration master plan are the procedures for creating and maintaining a calibration master plan, which serves as. Calibration Plan Format.