Soldering Nickel Plated Copper . Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. What you’ll need before you begin, make sure you have all the necessary materials on hand. Before beginning any soldering project, ensure you have all the On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. When you use that, say to 120 c, the. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. This includes solder flux, rosin core solder, and a

from www.alibaba.com

This includes solder flux, rosin core solder, and a When you use that, say to 120 c, the. Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. What you’ll need before you begin, make sure you have all the necessary materials on hand. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Before beginning any soldering project, ensure you have all the

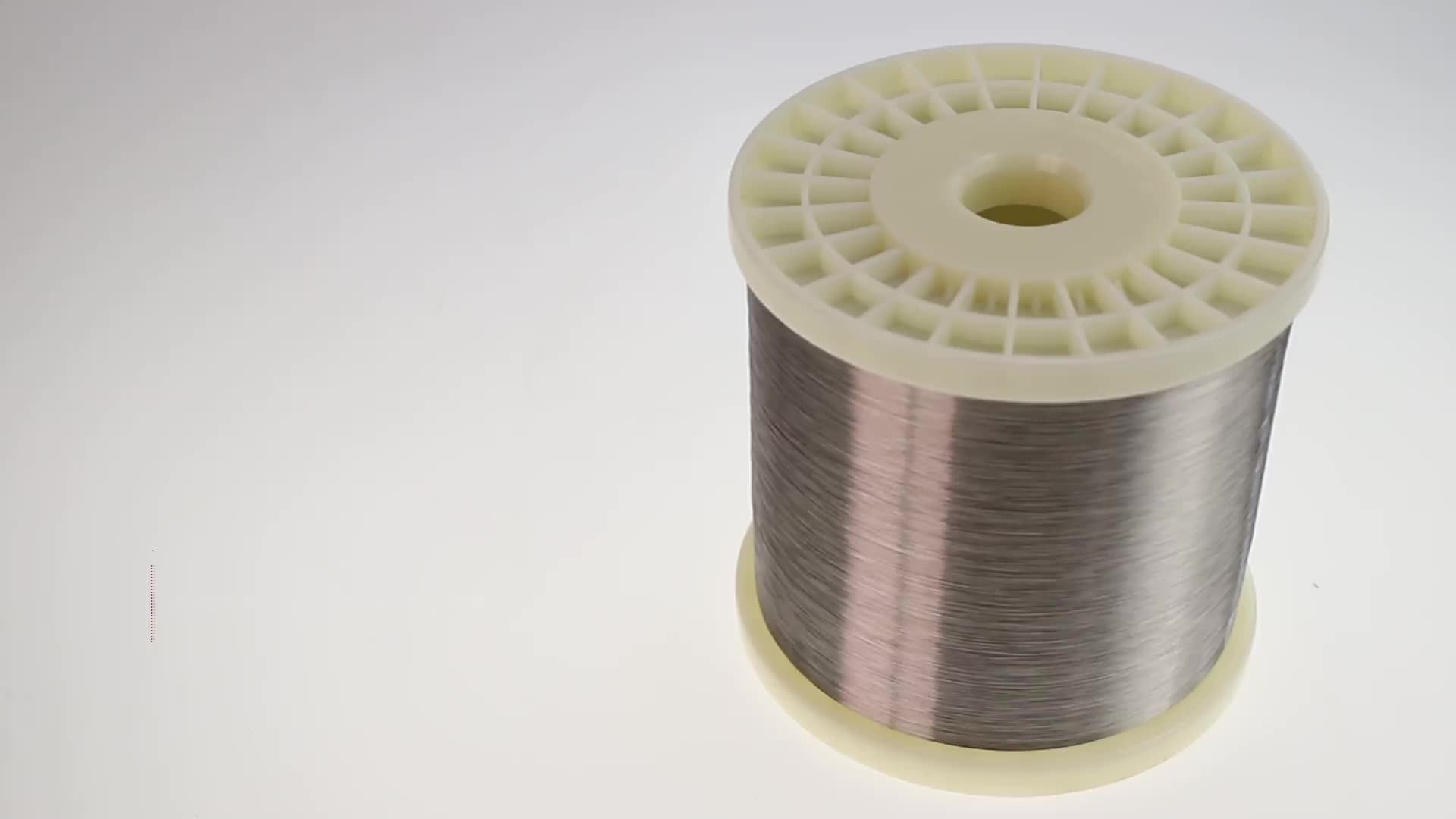

Heating Resistance Solid Soldering Nickel Plated Copper Wire Square

Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. This includes solder flux, rosin core solder, and a Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. Before beginning any soldering project, ensure you have all the What you’ll need before you begin, make sure you have all the necessary materials on hand. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. When you use that, say to 120 c, the.

From blog.thepipingmart.com

Differences between Nickel Plating and Tin Plating Copper Soldering Nickel Plated Copper Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. When you use that, say to 120 c, the. What you’ll need before you begin, make sure you have all the. Soldering Nickel Plated Copper.

From hackspark.fr

flux soldering of copper, silver, zinc and nickel plated Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. What you’ll need before you begin, make sure you have all the necessary materials on hand. On my prototypes i. Soldering Nickel Plated Copper.

From www.nickel-strips.com

Soldering Nickel Plated 18650 Battery Connector For Power Battery Soldering Nickel Plated Copper There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. Before beginning any soldering project, ensure you have all the What you’ll need. Soldering Nickel Plated Copper.

From www.shtc-wire.com

Soldering Nickel Plated Copper Wire Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. This includes solder flux, rosin core solder, and a What you’ll need before you begin, make sure you have all the necessary materials on hand. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to. Soldering Nickel Plated Copper.

From advancedplatingtech.com

Heavy Build Copper Plating of Bullets and Projectiles Soldering Nickel Plated Copper There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. Before beginning any soldering project, ensure you have all the When you use that, say to 120 c, the. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. You can electroplate the. Soldering Nickel Plated Copper.

From www.shtc-wire.com

China Excellent quality Soldering Nickel Plated Copper Wire Soldering Nickel Plated Copper Before beginning any soldering project, ensure you have all the There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. Soldering nickel plated copper with a highly active solder/flux can be challenging without. Soldering Nickel Plated Copper.

From www.youtube.com

DIY nickel electroplated copper busbars YouTube Soldering Nickel Plated Copper Before beginning any soldering project, ensure you have all the On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. What you’ll need before you begin, make sure you have all the necessary materials on hand. You can electroplate the nickel plated surface with selective. Soldering Nickel Plated Copper.

From blog.thepipingmart.com

How to Solder NickelPlated Copper Wire? Soldering Nickel Plated Copper What you’ll need before you begin, make sure you have all the necessary materials on hand. Before beginning any soldering project, ensure you have all the You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Soldering nickel plated copper with a highly active solder/flux. Soldering Nickel Plated Copper.

From bangteng.en.made-in-china.com

DIY OEM Battery Pack Soldering Busbar Stamping Nickel Plated Copper Soldering Nickel Plated Copper There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. On my prototypes i used nickel plate on brass, but the plating did. Soldering Nickel Plated Copper.

From corporate.sterenusa.com

40 Watt Soldering Iron Nickelplated Tip Steren USA Steren Solutions Soldering Nickel Plated Copper You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. This includes solder flux, rosin core solder, and a Before beginning any soldering project, ensure you have all the What you’ll need before you begin, make sure you have all the necessary materials on hand.. Soldering Nickel Plated Copper.

From reloaders.eu

FMJ vs Copper Plated Bullets what's the difference? Reloaders EU Soldering Nickel Plated Copper On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. When you use that, say to 120 c, the. Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. This includes solder flux, rosin core solder, and a. Soldering Nickel Plated Copper.

From www.rajasthanwires.com

Nickel Copper Wire Nickel Plated Copper Wire Manufacturer from Jaipur Soldering Nickel Plated Copper On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. What you’ll need before you begin, make sure you have all the necessary materials on hand. When you use that, say to 120 c, the. This includes solder flux, rosin core solder, and a You. Soldering Nickel Plated Copper.

From www.sumi-pac.com

Nickelplated copper wire SumiPac Corporation Soldering Nickel Plated Copper Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. What you’ll need before you begin, make sure you have all the necessary materials on hand. When you. Soldering Nickel Plated Copper.

From www.indiamart.com

Noel NickelCopper Plated Tip 50 Watt Soldering Iron Constant Tip Soldering Nickel Plated Copper When you use that, say to 120 c, the. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. Before beginning any soldering project, ensure you have all the Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct. Soldering Nickel Plated Copper.

From dir.indiamart.com

Nickel Plated Copper Wire at Best Price in India Soldering Nickel Plated Copper There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. When you use that, say to 120 c, the. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. You can electroplate the nickel plated surface with selective tin plating at the tail. Soldering Nickel Plated Copper.

From bangteng.en.made-in-china.com

DIY OEM Battery Pack Soldering Busbar Stamping Nickel Plated Copper Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. This includes solder flux, rosin core solder, and a When you use that, say to 120 c, the. You can. Soldering Nickel Plated Copper.

From www.indiamart.com

NOEL Nickel Copper Plated Tip 25 Watt Soldering Iron at Rs 45/piece Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. You can electroplate the nickel plated surface with selective tin plating at. Soldering Nickel Plated Copper.

From blog.thepipingmart.com

How to Solder Nickel Plated Copper Wire An Overview Soldering Nickel Plated Copper There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. This includes solder flux, rosin core solder, and a Soldering nickel plated copper. Soldering Nickel Plated Copper.

From blog.thepipingmart.com

Copper Nickel Plating Process An Overview Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Before beginning any. Soldering Nickel Plated Copper.

From www.parts-express.com

Weller ETA 1/16" Screwdriver Soldering Tip for WES51 Soldering Nickel Plated Copper You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. When you use that, say to 120 c, the. What. Soldering Nickel Plated Copper.

From blog.thepipingmart.com

Nickel Plating on Copper An Overview Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. What you’ll need before you begin, make sure you have all the necessary materials on hand. When you use that, say to 120 c, the. Before. Soldering Nickel Plated Copper.

From www.shtc-wire.com

14 Awg Nickel Plated Copper Wire Soldering Nickel Plated Copper You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. This includes solder flux, rosin core solder, and a What you’ll need before you begin, make sure you have all the necessary materials on hand. In scottiebabe's case, where a large copper plain is required,. Soldering Nickel Plated Copper.

From www.alibaba.com

Heating Resistance Solid Soldering Nickel Plated Copper Wire Square Soldering Nickel Plated Copper When you use that, say to 120 c, the. Before beginning any soldering project, ensure you have all the This includes solder flux, rosin core solder, and a On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. There is a metallurgy issue with soldering. Soldering Nickel Plated Copper.

From www.spcproducts.in

Nickel Plated Copper Wire Manufacturers and Suppliers, Stranded Nickel Soldering Nickel Plated Copper When you use that, say to 120 c, the. Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. Before beginning any soldering project, ensure you have all the You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you. Soldering Nickel Plated Copper.

From www.zjyipu.com

China Bare Copper Wire Supplier, Manufacturer and Factory Yipu Soldering Nickel Plated Copper Before beginning any soldering project, ensure you have all the What you’ll need before you begin, make sure you have all the necessary materials on hand. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. On my prototypes i used nickel plate on brass,. Soldering Nickel Plated Copper.

From www.searsoutlet.com

Craftsman 54021 2 pc. NickelPlated Copper Soldering Iron Tip Set Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. In scottiebabe's case, where a large copper plain is. Soldering Nickel Plated Copper.

From www.alibaba.com

Diy Oem Battery Pack Soldering Busbar Stamping Nickel Plated Copper Soldering Nickel Plated Copper On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Before beginning any soldering project, ensure you have all the. Soldering Nickel Plated Copper.

From www.nickel-strips.com

Welding Nickel Plated Copper Strip For 18650 Lithium Battery Connection Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final. Soldering Nickel Plated Copper.

From www.shtc-wire.com

China Excellent quality Soldering Nickel Plated Copper Wire Soldering Nickel Plated Copper Before beginning any soldering project, ensure you have all the When you use that, say to 120 c, the. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. This includes solder flux, rosin core solder, and a You can electroplate the nickel plated surface. Soldering Nickel Plated Copper.

From www.shtc-wire.com

Soldering Nickel Plated Copper Wire Soldering Nickel Plated Copper You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Before beginning any soldering project, ensure you have all the Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. When you use that, say to 120 c,. Soldering Nickel Plated Copper.

From www.shtc-wire.com

China China Manufacture Wholesale Silver Plated Copper Stranded Solder Soldering Nickel Plated Copper In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. You can electroplate the nickel plated surface with selective tin plating at the tail side where you are trying to solder it or you can. Before beginning any soldering project, ensure you have all the Soldering nickel plated copper with a highly active solder/flux can. Soldering Nickel Plated Copper.

From www.nickel-strips.com

T2 C1100 Nickel Plated Copper Strip Electronic Nickel Plated Copper Foil Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. Soldering nickel plated copper with a highly active solder/flux can be. Soldering Nickel Plated Copper.

From www.shtc-wire.com

44 Awg Silver Plated Copper Wire Soldering Nickel Plated Copper This includes solder flux, rosin core solder, and a In scottiebabe's case, where a large copper plain is required, a preheater can do wonders. When you use that, say to 120 c, the. There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. Before beginning any soldering project,. Soldering Nickel Plated Copper.

From www.shtc-wire.com

China Excellent quality Soldering Nickel Plated Copper Wire Soldering Nickel Plated Copper Soldering nickel plated copper with a highly active solder/flux can be challenging without using the correct technique. What you’ll need before you begin, make sure you have all the necessary materials on hand. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so i was esentially soldering onto brass. Before beginning. Soldering Nickel Plated Copper.

From www.aliexpress.com

DisposableLighterSolderWeldingWireSolderingTinWireStainless Soldering Nickel Plated Copper When you use that, say to 120 c, the. Before beginning any soldering project, ensure you have all the There is a metallurgy issue with soldering to nickel plated surfaces and depending upon the thickness of the final tin/lead coating, the. On my prototypes i used nickel plate on brass, but the plating did not extend into the tube so. Soldering Nickel Plated Copper.