Difference Between Sheet Metal Operations . The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. Let we will discuss the types of sheet metal operations in detail. One of the oldest and most straightforward. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Most of the sheet metal cutting processes discussed can be performed on both sheet. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. What are the basic properties of sheet metal? However, there are two categories of sheet metal operations: Cutting and forming thin sheets of metal usually performed as cold working. Before we read the sheet metal operations in detail, we must have to get familiar.

from www.slideshare.net

Before we read the sheet metal operations in detail, we must have to get familiar. Under the two subcategories, there are nine other processes that make up sheet metal. However, there are two categories of sheet metal operations: Most of the sheet metal cutting processes discussed can be performed on both sheet. What are the basic properties of sheet metal? Let we will discuss the types of sheet metal operations in detail. Cutting and forming thin sheets of metal usually performed as cold working. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. One of the oldest and most straightforward.

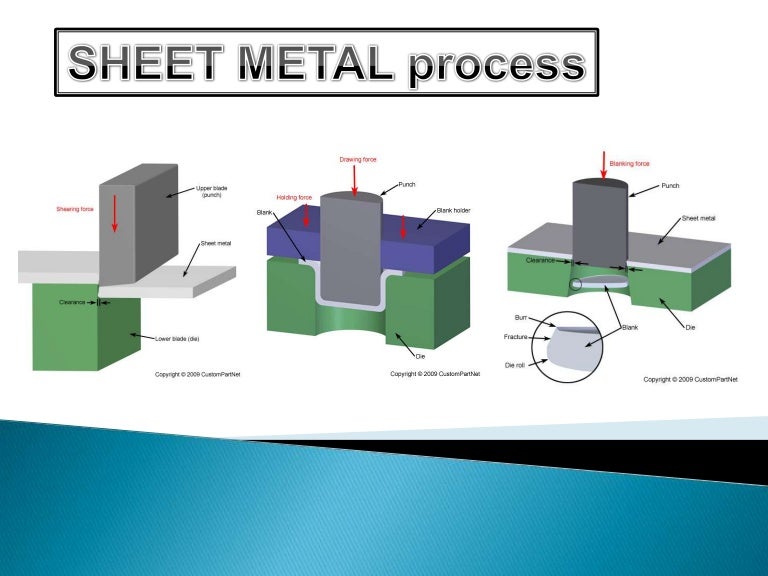

Sheet metaloperations

Difference Between Sheet Metal Operations The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Cutting and forming thin sheets of metal usually performed as cold working. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Let we will discuss the types of sheet metal operations in detail. Most of the sheet metal cutting processes discussed can be performed on both sheet. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. What are the basic properties of sheet metal? One of the oldest and most straightforward. However, there are two categories of sheet metal operations: Before we read the sheet metal operations in detail, we must have to get familiar. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Under the two subcategories, there are nine other processes that make up sheet metal.

From calsteel.com

What Are the Different Sheet Metal Operations? Difference Between Sheet Metal Operations The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Most of the sheet metal cutting processes discussed can be performed on both sheet. Under the two subcategories, there are nine other processes. Difference Between Sheet Metal Operations.

From caddesignr.com

8 common sheet metal operations Cad Designer Difference Between Sheet Metal Operations One of the oldest and most straightforward. Most of the sheet metal cutting processes discussed can be performed on both sheet. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Let we will discuss the types of sheet metal operations in detail. What are the basic properties of sheet metal? Under the two. Difference Between Sheet Metal Operations.

From www.theengineerspost.com

9 Different Types of Sheet Metal Operations with Diagram & PDF Difference Between Sheet Metal Operations Before we read the sheet metal operations in detail, we must have to get familiar. Let we will discuss the types of sheet metal operations in detail. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and. Difference Between Sheet Metal Operations.

From workshopinsider.com

The Last Guide to Sheet Metal Forming You Will Ever Need Difference Between Sheet Metal Operations One of the oldest and most straightforward. Before we read the sheet metal operations in detail, we must have to get familiar. However, there are two categories of sheet metal operations: What are the basic properties of sheet metal? Most of the sheet metal cutting processes discussed can be performed on both sheet. The common types of sheet metal operations. Difference Between Sheet Metal Operations.

From www.scribd.com

Different Types of Sheet Metal Operations Are 1. Shearing Operation PDF Sheet Metal Difference Between Sheet Metal Operations Under the two subcategories, there are nine other processes that make up sheet metal. Most of the sheet metal cutting processes discussed can be performed on both sheet. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. What are the basic properties of sheet metal? One of the oldest and. Difference Between Sheet Metal Operations.

From www.slideserve.com

PPT SHEET METAL OPERATIONS PowerPoint Presentation, free download ID9684631 Difference Between Sheet Metal Operations However, there are two categories of sheet metal operations: Most of the sheet metal cutting processes discussed can be performed on both sheet. Under the two subcategories, there are nine other processes that make up sheet metal. One of the oldest and most straightforward. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending,. Difference Between Sheet Metal Operations.

From www.slideserve.com

PPT Sheet Metal Forming PowerPoint Presentation, free download ID5354499 Difference Between Sheet Metal Operations The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. Cutting and forming thin sheets of metal usually performed as cold working. Most of the sheet metal cutting processes discussed can be performed on both sheet. Read. Difference Between Sheet Metal Operations.

From www.machinemfg.com

Sheet Metal Forming Processes and Equipment MachineMfg Difference Between Sheet Metal Operations Cutting and forming thin sheets of metal usually performed as cold working. Before we read the sheet metal operations in detail, we must have to get familiar. What are the basic properties of sheet metal? Let we will discuss the types of sheet metal operations in detail. One of the oldest and most straightforward. Read on and explore the different. Difference Between Sheet Metal Operations.

From www.studocu.com

Sheet metal operations Sheet Metal Operations Following are the 9 different types of sheet Difference Between Sheet Metal Operations Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. However, there are two categories of sheet. Difference Between Sheet Metal Operations.

From www.scribd.com

Sheet Metal Operations PDF Sheet Metal Procedural Knowledge Difference Between Sheet Metal Operations Under the two subcategories, there are nine other processes that make up sheet metal. What are the basic properties of sheet metal? The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Cutting. Difference Between Sheet Metal Operations.

From guidebytips.com

Different Types of Sheet Metal Operations with Diagrams GuideByTips Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Before we read the sheet metal operations in detail, we must have to get familiar. Most of the sheet metal cutting processes discussed can be performed on both sheet.. Difference Between Sheet Metal Operations.

From www.themachinedesign.com

Sheet Metal Operations Definition and Types The Machine Design Difference Between Sheet Metal Operations Before we read the sheet metal operations in detail, we must have to get familiar. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Cutting and forming thin sheets of metal usually performed as cold working. Read on and explore the different sheet metal operations to develop a comprehensive understanding of. Difference Between Sheet Metal Operations.

From www.youtube.com

Sheet Metal Operations Explained in Detail (বাংলায়) SolidWorks YouTube Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. What are the basic properties of sheet metal? Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Cutting and forming thin sheets of metal usually performed as cold working. Most of the sheet metal cutting processes discussed can be performed on. Difference Between Sheet Metal Operations.

From www.slideserve.com

PPT SHEET METAL OPERATIONS PowerPoint Presentation, free download ID9684631 Difference Between Sheet Metal Operations The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. What are the basic properties of sheet metal? Cutting and forming thin sheets of metal usually performed as cold working. One of the oldest and most straightforward.. Difference Between Sheet Metal Operations.

From www.slideserve.com

PPT Sheet Metalworking PowerPoint Presentation, free download ID6713883 Difference Between Sheet Metal Operations The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Most of the sheet metal cutting processes discussed can be performed on both sheet. Before we read the sheet metal operations in detail,. Difference Between Sheet Metal Operations.

From www.themachinedesign.com

Sheet Metal Operations Definition and Types The Machine Design Difference Between Sheet Metal Operations What are the basic properties of sheet metal? Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Cutting and forming thin sheets of metal usually performed as cold working. Let we will discuss the types of sheet metal operations in detail. Under the two subcategories, there are nine other processes that make up. Difference Between Sheet Metal Operations.

From www.slideshare.net

Sheet metaloperations Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Cutting and forming thin sheets of metal usually performed as cold working. Before we read the sheet metal operations in detail, we must have to get familiar. Most of. Difference Between Sheet Metal Operations.

From www.scribd.com

Sheet Metal Operations PDF Sheet Metal Mechanical Engineering Difference Between Sheet Metal Operations Under the two subcategories, there are nine other processes that make up sheet metal. Cutting and forming thin sheets of metal usually performed as cold working. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending,. Difference Between Sheet Metal Operations.

From www.studypool.com

SOLUTION Sheet metal operations Studypool Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. What are the basic properties of sheet metal? However, there are two categories of sheet metal operations: Cutting and forming thin sheets of metal usually performed as cold working. One of the. Difference Between Sheet Metal Operations.

From www.scribd.com

Sheet Metal Operations Sheet Metal Metalworking Difference Between Sheet Metal Operations The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Let we will discuss the types of sheet metal operations in detail. Before we read the sheet metal operations in detail, we must have to get familiar. However, there are two categories of sheet metal operations: One of the oldest and most. Difference Between Sheet Metal Operations.

From www.cnclathing.com

CNC Sheet Metal Operation Walkthrough All You Need To Know About The Sheet Metal Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. Before we read the sheet metal operations in detail, we must have to get familiar. One of the oldest and most straightforward. Under the two subcategories, there are nine other processes that make up sheet metal. Read on and explore the different sheet metal operations to develop a. Difference Between Sheet Metal Operations.

From learnmech.com

Metal Forming Basic, Types , Diagram , Classification Difference Between Sheet Metal Operations Under the two subcategories, there are nine other processes that make up sheet metal. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. However, there are two categories of sheet metal operations: Cutting and forming thin sheets of metal usually performed as cold working. Let we will discuss the types of. Difference Between Sheet Metal Operations.

From www.slideshare.net

sheet metal operations part 2 Difference Between Sheet Metal Operations Before we read the sheet metal operations in detail, we must have to get familiar. Most of the sheet metal cutting processes discussed can be performed on both sheet. Cutting and forming thin sheets of metal usually performed as cold working. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Under. Difference Between Sheet Metal Operations.

From www.youtube.com

Bending, Drawing, Slitting, Trimming, Shaving Process Working Animation Metal forming Difference Between Sheet Metal Operations Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Under the two subcategories, there are nine other processes that make up sheet metal. The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. Cutting and forming thin sheets of metal usually performed as cold working.. Difference Between Sheet Metal Operations.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending operations YouTube Difference Between Sheet Metal Operations However, there are two categories of sheet metal operations: Before we read the sheet metal operations in detail, we must have to get familiar. What are the basic properties of sheet metal? Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. The common types of sheet metal operations are shearing, blanking, punching, piercing,. Difference Between Sheet Metal Operations.

From in.pinterest.com

Different Types of Sheet Metal Operations [Explained] Sheet metal fabrication, Metal sheet Difference Between Sheet Metal Operations Let we will discuss the types of sheet metal operations in detail. Under the two subcategories, there are nine other processes that make up sheet metal. Before we read the sheet metal operations in detail, we must have to get familiar. However, there are two categories of sheet metal operations: One of the oldest and most straightforward. Most of the. Difference Between Sheet Metal Operations.

From www.youtube.com

Bending And Its Types (Sheet Metal Operation) हिन्दी YouTube Difference Between Sheet Metal Operations Most of the sheet metal cutting processes discussed can be performed on both sheet. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. Before we read the sheet metal operations in detail, we must have to. Difference Between Sheet Metal Operations.

From www.themachinedesign.com

Sheet Metal Operations Definition and Types The Machine Design Difference Between Sheet Metal Operations Before we read the sheet metal operations in detail, we must have to get familiar. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Cutting and forming thin sheets of metal usually performed as cold working. Most of the sheet metal cutting processes discussed can be performed on both sheet. However, there are. Difference Between Sheet Metal Operations.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI Difference Between Sheet Metal Operations Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. However, there are two categories of sheet metal operations: The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. Cutting and. Difference Between Sheet Metal Operations.

From www.slideserve.com

PPT Sheet Metalworking PowerPoint Presentation, free download ID6713883 Difference Between Sheet Metal Operations Most of the sheet metal cutting processes discussed can be performed on both sheet. However, there are two categories of sheet metal operations: Let we will discuss the types of sheet metal operations in detail. Cutting and forming thin sheets of metal usually performed as cold working. Under the two subcategories, there are nine other processes that make up sheet. Difference Between Sheet Metal Operations.

From www.studocu.com

Dies in Sheet metal operations 5+ Types of Dies used in Sheet Metal Operations Definition of Difference Between Sheet Metal Operations What are the basic properties of sheet metal? Most of the sheet metal cutting processes discussed can be performed on both sheet. Under the two subcategories, there are nine other processes that make up sheet metal. Let we will discuss the types of sheet metal operations in detail. Cutting and forming thin sheets of metal usually performed as cold working.. Difference Between Sheet Metal Operations.

From www.youtube.com

SHEARING PROCESS SHEARING MECHANISM SHEAR FORCE SHEAR STRENGTH SHEET METAL OPERATION Difference Between Sheet Metal Operations Under the two subcategories, there are nine other processes that make up sheet metal. Before we read the sheet metal operations in detail, we must have to get familiar. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. The difference is that sheet metal is under 1/4 inch (6mm) in. Difference Between Sheet Metal Operations.

From www.studypool.com

SOLUTION Sheet metal operations Studypool Difference Between Sheet Metal Operations The difference is that sheet metal is under 1/4 inch (6mm) in thickness, while plate metal is thicker. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Under the two subcategories, there are nine other processes that make up sheet metal. Read on and explore the different sheet metal operations. Difference Between Sheet Metal Operations.

From studentlesson.com

Understanding Sheet Metal Operations with Diagram student lesson Difference Between Sheet Metal Operations The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. What are the basic properties of sheet metal? However, there are two categories of sheet metal operations: Let we will discuss the types of sheet metal operations in detail. Cutting and forming thin sheets of metal usually performed as cold working.. Difference Between Sheet Metal Operations.

From slideplayer.com

Manufacturing Processes ppt download Difference Between Sheet Metal Operations Cutting and forming thin sheets of metal usually performed as cold working. However, there are two categories of sheet metal operations: Read on and explore the different sheet metal operations to develop a comprehensive understanding of each. Under the two subcategories, there are nine other processes that make up sheet metal. What are the basic properties of sheet metal? Most. Difference Between Sheet Metal Operations.