Plasma Cutter Air Pressure Chart . How to set the correct air pressure and amperage for your plasma cutter. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Orifice hole size 1mm =.03937. Find tips, tricks and guidelines. In this article, we will provide you with. Cut50 plasma cutter suggested amperage & air setting cutter chart. Plasma cutters need compressed air. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Here is a summary of the recommended parameters for different thicknesses of materials and. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages.

from multicameast.com

To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Plasma cutters need compressed air. In this article, we will provide you with. Find tips, tricks and guidelines. Here is a summary of the recommended parameters for different thicknesses of materials and. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Cut50 plasma cutter suggested amperage & air setting cutter chart. How to set the correct air pressure and amperage for your plasma cutter. Orifice hole size 1mm =.03937. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut.

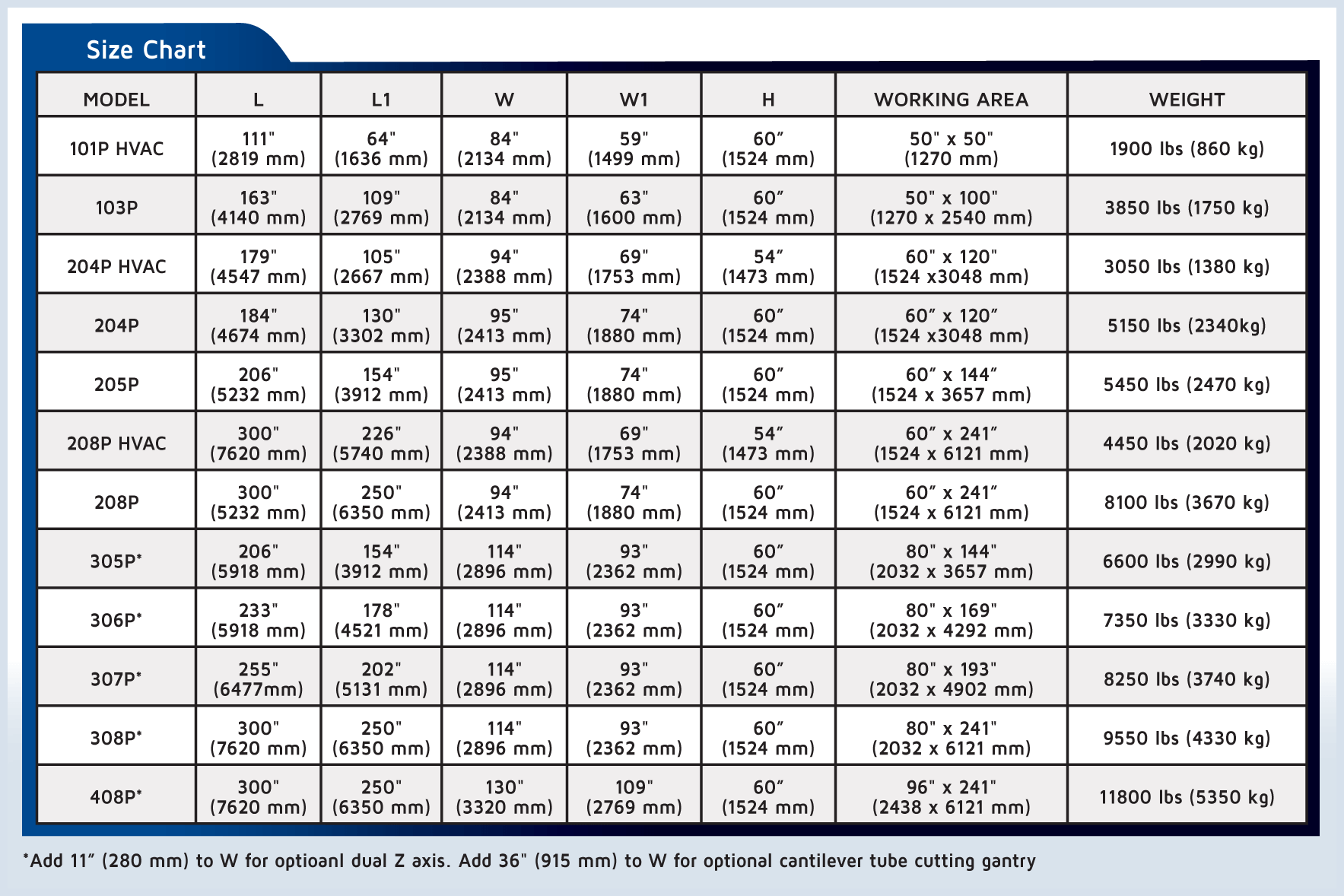

Plasma Cutting Machine 3000 Series MultiCam East, Shrewsbury PA

Plasma Cutter Air Pressure Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Plasma cutters need compressed air. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. How to set the correct air pressure and amperage for your plasma cutter. Cut50 plasma cutter suggested amperage & air setting cutter chart. Here is a summary of the recommended parameters for different thicknesses of materials and. In this article, we will provide you with. Orifice hole size 1mm =.03937. Find tips, tricks and guidelines.

From www.geardefine.com

How Much Air Pressure Does Your Plasma Cutter Need? GearDefine Plasma Cutter Air Pressure Chart Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Here is a summary of the recommended parameters for different thicknesses of materials and. How to set the correct. Plasma Cutter Air Pressure Chart.

From settingaid.com

Cut 50 Plasma Cutter Settings Chart Best Guides Ever Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. Plasma cutters need compressed air. How to set the correct air pressure and amperage for your plasma cutter. Here is a summary of the recommended parameters for different thicknesses of materials and. Find tips, tricks and guidelines. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to. Plasma Cutter Air Pressure Chart.

From aircompressorinsider.com

What Size Air Compressor For Plasma Cutter Complete Guide 2023 Air Compressor Insider Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. Here is a summary of the recommended parameters for different thicknesses of materials and. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. In. Plasma Cutter Air Pressure Chart.

From www.thefabricator.com

A check list for a plasma cutting table retrofit The Fabricator Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. How to set the correct air pressure and amperage for your plasma cutter. Plasma cutters need compressed air. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Cut50 plasma cutter suggested amperage & air setting cutter chart. Here is a summary of the recommended parameters. Plasma Cutter Air Pressure Chart.

From studylib.net

Cutting Speed Chart Victor Technologies Plasma Cutter Air Pressure Chart Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Find tips, tricks and guidelines. Learn how to adjust air pressure and. Plasma Cutter Air Pressure Chart.

From www.jasic.co.uk

Jasic Guide to Plasma Cutting Jasic Blog Plasma Cutter Air Pressure Chart Find tips, tricks and guidelines. Here is a summary of the recommended parameters for different thicknesses of materials and. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Orifice hole size 1mm =.03937. In this article, we will provide you with. Various plasma cutters will require differing air pressures depending on the thickness of. Plasma Cutter Air Pressure Chart.

From woodworkingset.com

Optimal Plasma Cutter Air Pressure A Comprehensive Guide in 2023 Plasma Cutter Air Pressure Chart In this article, we will provide you with. How to set the correct air pressure and amperage for your plasma cutter. Orifice hole size 1mm =.03937. Cut50 plasma cutter suggested amperage & air setting cutter chart. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Plasma cutters need compressed air. This is what i. Plasma Cutter Air Pressure Chart.

From www.geardefine.com

How Much Air Pressure Does Your Plasma Cutter Need? GearDefine Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. In this article, we will provide you with. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Plasma cutters. Plasma Cutter Air Pressure Chart.

From settingaid.com

Plasma Cutter Settings Chart Best Guides From Expert Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. In this article, we will provide you with. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Learn how to adjust. Plasma Cutter Air Pressure Chart.

From infographiclabs.com

A Guide to Plasma Cutting Plasma Cutter Air Pressure Chart Plasma cutters need compressed air. Orifice hole size 1mm =.03937. Here is a summary of the recommended parameters for different thicknesses of materials and. How to set the correct air pressure and amperage for your plasma cutter. Cut50 plasma cutter suggested amperage & air setting cutter chart. Find tips, tricks and guidelines. You can develop your own charts and reference. Plasma Cutter Air Pressure Chart.

From bamil.lewisburgdistrictumc.org

hypertherm 45xp cut chart Bamil Plasma Cutter Air Pressure Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Plasma cutters need compressed air. Here is a summary of the recommended parameters for different thicknesses of materials and. You can develop your own charts and reference those in the future to save yourself time and frustration when. Plasma Cutter Air Pressure Chart.

From engweld.co.uk

Plasma Cutters Guide Engweld Talk Plasma Cutter Air Pressure Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Cut50 plasma cutter suggested amperage & air setting cutter chart. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Plasma cutters need compressed air. In this article, we will provide you with. You can develop your. Plasma Cutter Air Pressure Chart.

From forum.langmuirsystems.com

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma Cutters Langmuir Systems Forum Plasma Cutter Air Pressure Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. How to set the correct air pressure and amperage for your plasma cutter. In this article, we will provide you with. Find tips, tricks and guidelines. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Learn how. Plasma Cutter Air Pressure Chart.

From www.researchgate.net

Atmospheric pressure plasma jet (APPJ) and its characteristics. (a)... Download Scientific Diagram Plasma Cutter Air Pressure Chart Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Cut50 plasma cutter suggested amperage & air setting cutter chart. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. How to set the correct air pressure and amperage for your plasma cutter. Orifice. Plasma Cutter Air Pressure Chart.

From www.engineering-machinery.ie

Hypertherm Powermax 125 Consumables Engineering Machinery & Services UK & Ireland Plasma Cutter Air Pressure Chart Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Cut50 plasma cutter suggested amperage & air setting cutter chart. Orifice hole size 1mm =.03937. Find tips, tricks and guidelines. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately.. Plasma Cutter Air Pressure Chart.

From woodworkingset.com

Optimal Plasma Cutter Air Pressure A Comprehensive Guide in 2023 Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. How to set the correct air pressure and amperage for your plasma cutter. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. To optimize your cutting results with the cut. Plasma Cutter Air Pressure Chart.

From giaiphapthienlong.vn

LGK 100 Plasma Cutter Plasma Cutter Air Pressure Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. How to set the correct air pressure and amperage for your plasma cutter. Cut50 plasma cutter suggested. Plasma Cutter Air Pressure Chart.

From morganthorpe.z13.web.core.windows.net

Plasma Cutter Air Pressure Chart Plasma Cutter Air Pressure Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table.. Plasma Cutter Air Pressure Chart.

From smithbuddy.com

Plasma Cutter Amps Thickness Chart (PDF Download) Plasma Cutter Air Pressure Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. Orifice hole size 1mm =.03937. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. In this article, we will provide you with. How to set the correct air pressure and. Plasma Cutter Air Pressure Chart.

From www.maverickcnc.com

Understanding air pressure and air flow in plasma cutting Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. Here is a summary of the recommended parameters for different thicknesses of materials and. Find tips, tricks and guidelines. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses.. Plasma Cutter Air Pressure Chart.

From wiki.opensourceecology.org

CNC Torch Table 2/Control Overview Open Source Ecology Plasma Cutter Air Pressure Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. In this article, we will provide you with. Here is a summary of the recommended parameters for different thicknesses of materials and. You. Plasma Cutter Air Pressure Chart.

From smithbuddy.com

Plasma Cutter Amps Thickness Chart (PDF Download) Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Cut50 plasma cutter suggested amperage & air setting cutter chart. How to set the correct air pressure and amperage for your plasma cutter. To optimize your cutting results with the cut. Plasma Cutter Air Pressure Chart.

From michaelfarmer.z21.web.core.windows.net

Plasma Cutter Thickness Chart Plasma Cutter Air Pressure Chart Orifice hole size 1mm =.03937. Cut50 plasma cutter suggested amperage & air setting cutter chart. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Here is a summary of the recommended parameters for different thicknesses of materials and. Plasma cutters need compressed air. To optimize your cutting. Plasma Cutter Air Pressure Chart.

From unimig.com.au

The Ultimate Guide to Plasma Cutting UNIMIG Welding Guides & Tutorials Plasma Cutter Air Pressure Chart In this article, we will provide you with. Orifice hole size 1mm =.03937. Plasma cutters need compressed air. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Here is a summary of. Plasma Cutter Air Pressure Chart.

From www.electrotechnicproducts.com

Featured Article LowTemperature Atmospheric Pressure Plasmas ElectroTechnic Products Plasma Cutter Air Pressure Chart Here is a summary of the recommended parameters for different thicknesses of materials and. How to set the correct air pressure and amperage for your plasma cutter. Plasma cutters need compressed air. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma. Plasma Cutter Air Pressure Chart.

From chartexamples.com

Pressure Conversion Chart Bar To Psi Chart Examples Plasma Cutter Air Pressure Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. In this article, we will provide you with. Plasma cutters need compressed air. Cut50 plasma cutter suggested amperage & air setting cutter chart. You can develop your own charts and reference those in the future to save yourself. Plasma Cutter Air Pressure Chart.

From www.hypertherm.com

Improve cut quality with these CNC steel and metal cutting tips Plasma Cutter Air Pressure Chart Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. Orifice hole size 1mm =.03937. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Here is a summary of the recommended parameters for different thicknesses of materials and. Plasma. Plasma Cutter Air Pressure Chart.

From schematicmodelers.z13.web.core.windows.net

Cut 60 Plasma Cutter Manual Plasma Cutter Air Pressure Chart Here is a summary of the recommended parameters for different thicknesses of materials and. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Plasma cutters need compressed air. Find tips, tricks and guidelines.. Plasma Cutter Air Pressure Chart.

From gabrielbruce.z19.web.core.windows.net

Plasma Cutting Settings Chart Plasma Cutter Air Pressure Chart Plasma cutters need compressed air. Orifice hole size 1mm =.03937. Find tips, tricks and guidelines. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. Here is a summary of the recommended parameters for different thicknesses of materials and. Various plasma cutters will require differing air pressures depending on the thickness of the metal you. Plasma Cutter Air Pressure Chart.

From www.perfectwelders.com

Understanding Cut Charts An Essential Guide,You gotta get know these plasma cutter,plasma Plasma Cutter Air Pressure Chart Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. How to set the correct air pressure and amperage for your plasma cutter. Cut50 plasma cutter suggested amperage & air setting cutter chart. You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come. Plasma Cutter Air Pressure Chart.

From multicameast.com

Plasma Cutting Machine 3000 Series MultiCam East, Shrewsbury PA Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. How to set the correct air pressure and amperage for your plasma cutter. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to. Plasma Cutter Air Pressure Chart.

From www.submarineboat.com

CNC Plasma Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Find tips, tricks and guidelines. Various plasma cutters will require differing air pressures depending on the thickness of the metal you wish to cut. In this article, we will provide you. Plasma Cutter Air Pressure Chart.

From charlottejohnson.z19.web.core.windows.net

Plasma Cutter Air Pressure Chart Plasma Cutter Air Pressure Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Cut50 plasma cutter suggested amperage & air setting cutter chart. Orifice hole size 1mm =.03937. In this article, we will provide you with. Learn how to adjust air pressure and amperage for plasma cutting different materials and thicknesses. How to set the correct air pressure and. Plasma Cutter Air Pressure Chart.

From gotorch.com

Plasma Cutter Comparison CNC Plasma Cutter Comparison Plasma Cutter Air Pressure Chart Find tips, tricks and guidelines. How to set the correct air pressure and amperage for your plasma cutter. In this article, we will provide you with. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Various plasma cutters will require differing air pressures depending on the thickness. Plasma Cutter Air Pressure Chart.

From www.svseeker.com

CNC Plasma Cutting SV Seeker Plasma Cutter Air Pressure Chart You can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. To optimize your cutting results with the cut 50 plasma cutter, it is essential to understand and adjust the settings appropriately. This is what i have found to work with most. Plasma Cutter Air Pressure Chart.