Grinding Surface Properties . Machine operators use abrasive media to remove material from the surface. Grinding surface quality is a key indicator to determine. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Typically resulting in a smoother finish and improved dimensional accuracy. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Making it the best method to use when. Zhaohui deng & mingtao wu. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. This precision is achieved by. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces.

from pt.slideshare.net

Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Grinding surface quality is a key indicator to determine. Making it the best method to use when. This precision is achieved by. Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Machine operators use abrasive media to remove material from the surface. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface.

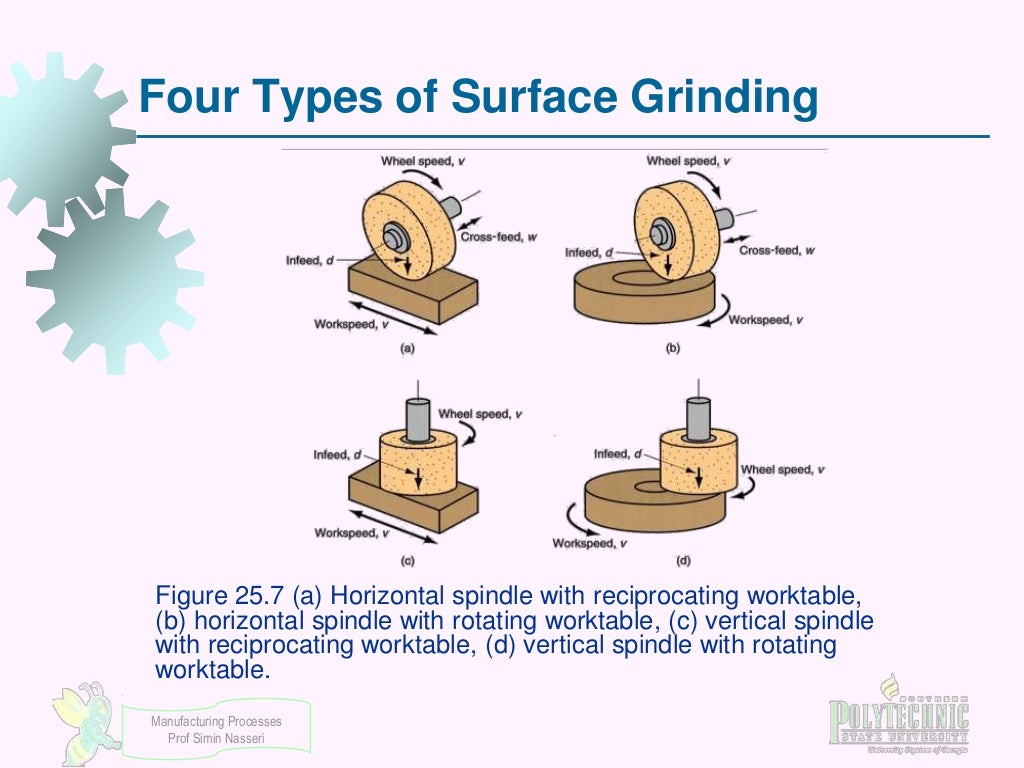

Chapter 25 (grinding)

Grinding Surface Properties Making it the best method to use when. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. This precision is achieved by. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Grinding surface quality is a key indicator to determine. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Making it the best method to use when. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Machine operators use abrasive media to remove material from the surface.

From www.mdpi.com

JMMP Free FullText Modelling and Analysis of Topographic Surface Grinding Surface Properties This precision is achieved by. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Zhaohui deng & mingtao wu. Machine operators use abrasive media to remove material from the surface. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an ideal method to. Grinding Surface Properties.

From www.researchgate.net

Surface topography before and after grinding. a Surface topography of Grinding Surface Properties Making it the best method to use when. Grinding surface quality is a key indicator to determine. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Zhaohui deng. Grinding Surface Properties.

From deanabraxton.blogspot.com

surface grinding machine parts and functions Deana Braxton Grinding Surface Properties Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Zhaohui deng & mingtao wu. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. This precision is achieved by. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an ideal method. Grinding Surface Properties.

From www.researchgate.net

Simulation process of internal grinding surface topography Download Grinding Surface Properties Grinding surface quality is a key indicator to determine. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Making it the best method to use when. Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Machine operators use abrasive media to. Grinding Surface Properties.

From www.researchgate.net

(PDF) Effects of a New Type of Grinding Wheel with MultiGranular Grinding Surface Properties Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Typically resulting in a smoother finish and improved dimensional accuracy. Zhaohui deng & mingtao wu. Making it. Grinding Surface Properties.

From grindall.com

Surface Grinding Grind All Inc. Grinding Surface Properties Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Machine operators use abrasive. Grinding Surface Properties.

From www.lach-diamant.de

Grinding & Surface Finishing Lach Diamant Grinding Surface Properties This precision is achieved by. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Machine operators use abrasive media to remove material from the surface. Typically resulting in a. Grinding Surface Properties.

From myslide.ru

Abrasive materials. Classification, structure, properties and applications Grinding Surface Properties Grinding surface quality is a key indicator to determine. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. This precision is achieved by. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using. Grinding Surface Properties.

From www.researchgate.net

Typical cutting edge geometry obtained ((ac) after grinding; (d) after Grinding Surface Properties Zhaohui deng & mingtao wu. This precision is achieved by. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically resulting in a smoother finish and improved dimensional accuracy. Grinding. Grinding Surface Properties.

From www.youtube.com

What are the Rotary Surface Grinding Parameters? Rotary Surface Grinding Surface Properties Zhaohui deng & mingtao wu. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Typically resulting in a smoother finish and improved dimensional accuracy. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Both the t i and t s properties determine how well. Grinding Surface Properties.

From www.researchgate.net

shows the grinding surface morphology and its surface roughness under Grinding Surface Properties Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Grinding surface quality is a key indicator to determine. Machine operators use abrasive media to remove material from the surface. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Making it the best method to. Grinding Surface Properties.

From pgisteel.com

Surface Grinding Precision Grinding, Inc. Grinding Surface Properties Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Grinding surface quality is a key indicator to determine. Making it the best method to use when. Grinding is essential for flotation. Grinding Surface Properties.

From allan-liddle-steel.co.uk

Surface Grinding Grinding Surface Properties Typically resulting in a smoother finish and improved dimensional accuracy. Machine operators use abrasive media to remove material from the surface. Grinding surface quality is a key indicator to determine. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Making it the best method. Grinding Surface Properties.

From allan-liddle-steel.co.uk

Surface Grinding Grinding Surface Properties Zhaohui deng & mingtao wu. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. This precision is achieved by. Making it the best method to use when. Machine operators use abrasive media to remove material from the surface. Typically resulting in a smoother finish and improved. Grinding Surface Properties.

From pgisteel.com

Surface Grinding Precision Grinding, Inc. Grinding Surface Properties Machine operators use abrasive media to remove material from the surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Grinding surface quality is a key indicator to. Grinding Surface Properties.

From pt.slideshare.net

Chapter 25 (grinding) Grinding Surface Properties This precision is achieved by. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Machine operators use abrasive media to remove material from the surface. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Making it the best. Grinding Surface Properties.

From www.precision-surface.com

What is Surface Grinding & Reciprocating grinding? Grinding Surface Properties Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Machine operators use abrasive media to remove material from the surface. Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Making it the best method to use when. Surface grinding is. Grinding Surface Properties.

From www.youtube.com

How Surface Grinding Works Part 1? YouTube Grinding Surface Properties Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Zhaohui deng & mingtao wu. This precision is achieved by. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning. Grinding Surface Properties.

From www.researchgate.net

(PDF) Lubricating properties of grinding fluids Comparison of fluids Grinding Surface Properties Machine operators use abrasive media to remove material from the surface. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Zhaohui deng & mingtao wu. Typically resulting in a smoother finish and improved dimensional accuracy. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral.. Grinding Surface Properties.

From www.researchgate.net

Grinding surface SEM topography with different cutting depths Grinding Surface Properties Typically resulting in a smoother finish and improved dimensional accuracy. Machine operators use abrasive media to remove material from the surface. Making it the best method to use when. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Zhaohui deng & mingtao wu. Both the t i and t s properties. Grinding Surface Properties.

From www.researchgate.net

The microstructure below the grinding surface with different feed rates Grinding Surface Properties Machine operators use abrasive media to remove material from the surface. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Zhaohui deng & mingtao wu. Grinding surface quality is a key indicator to determine. Normal grinding. Grinding Surface Properties.

From issuu.com

Different Types Surface Grinding Machine How To Select? by Grinding Surface Properties Machine operators use abrasive media to remove material from the surface. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Typically resulting in a smoother finish and improved dimensional accuracy. Grinding surface quality is a key indicator to determine. Grinding is essential for flotation separation, and the. Grinding Surface Properties.

From www.researchgate.net

Surface roughness obtained by different grinding methods Download Grinding Surface Properties Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Machine operators use abrasive media to remove material from the surface. Both the t i and t s properties determine how well a grinding wheel can. Grinding Surface Properties.

From www.youtube.com

SURFACE GRINDING part 2, accurate grinding, squaring up a block Grinding Surface Properties Grinding surface quality is a key indicator to determine. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its surface. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Making it the best method to use when. Grinding is essential for flotation. Grinding Surface Properties.

From www.researchgate.net

Grains and wheel grinding surface of gear grinding Download Grinding Surface Properties Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. This precision is achieved by. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Both the t i and t s properties determine how well a grinding wheel can resist. Grinding Surface Properties.

From www.researchgate.net

Microstructure of grinding surface Download Scientific Diagram Grinding Surface Properties Typically resulting in a smoother finish and improved dimensional accuracy. Zhaohui deng & mingtao wu. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Making it the best method to use when. This precision is achieved by. Normal grinding force, grinding surface temperature, and. Grinding Surface Properties.

From www.researchgate.net

(a) Sketch of a typical surface grinding process, showing the process Grinding Surface Properties Making it the best method to use when. Typically resulting in a smoother finish and improved dimensional accuracy. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of. Grinding Surface Properties.

From allan-liddle-steel.co.uk

Surface Grinding Grinding Surface Properties Grinding surface quality is a key indicator to determine. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Making it the best method to use when. Machine operators use abrasive media to remove material from. Grinding Surface Properties.

From leadrp.net

What Is Surface Grinding LEADRP Rapid Prototyping And Manufacturing Grinding Surface Properties Zhaohui deng & mingtao wu. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Grinding surface quality is a key indicator to determine. Typically resulting in a smoother finish and improved dimensional accuracy. Making it. Grinding Surface Properties.

From www.researchgate.net

Metallographic structure of grinding surface (a) matrix, (b) ground Grinding Surface Properties Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Typically resulting in a smoother finish and improved dimensional accuracy. This precision is achieved by. Zhaohui deng & mingtao wu. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Surface grinding is an abrasive machining. Grinding Surface Properties.

From www.precisiongroundbars.com

Surface Grinding The Essential Guide for Precision and Quality Grinding Surface Properties Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Both the t i and t s properties determine how well a grinding wheel can resist wear and, consequently, retain its. Grinding Surface Properties.

From www.researchgate.net

Comparison of the actual and simulated grinding surface topography from Grinding Surface Properties Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties including surface. Surface grinding is an ideal method to use when you wish to have a reference surface due to its ability to produce distinct flat surfaces. Typically resulting in a smoother finish and improved dimensional accuracy. Making it the best method to use when. Zhaohui. Grinding Surface Properties.

From www.mdpi.com

Grinding Force and Surface Formation Mechanisms of 17CrNi2MoVNb Alloy Grinding Surface Properties Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Typically resulting in a smoother finish and improved dimensional accuracy. This precision is achieved by. Grinding surface quality is a key indicator to determine. Surface grinding is an ideal method to use when you wish to have. Grinding Surface Properties.

From www.youtube.com

Surface Grinding Stainless Steel Discs on the Okamoto CNC YouTube Grinding Surface Properties Typically resulting in a smoother finish and improved dimensional accuracy. Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Surface grinding is an abrasive machining process, creating flat, smooth finishes on workpieces using a spinning wheel with rough particles, essential for precision. Grinding surface quality is a key indicator to determine.. Grinding Surface Properties.

From autoplasticsworld.com

Surface Grinding Machine Techniques, Technologies & Trends Grinding Surface Properties Grinding is essential for flotation separation, and the shape of grinding media impacts the morphological characteristics of mineral. Machine operators use abrasive media to remove material from the surface. Grinding surface quality is a key indicator to determine. Making it the best method to use when. Normal grinding force, grinding surface temperature, and metal removal rate were measured, surface properties. Grinding Surface Properties.