Gas Recirculation Fan . Effective fans for hot processes. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. Higher plant efficiency is accomplished by reducing the. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. We can accommodate a wide range of systems and offer a variety of airfoil designs for. The power (rate of energy utilization) of a fan is a product. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system.

from www.slideshare.net

We can accommodate a wide range of systems and offer a variety of airfoil designs for. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. Effective fans for hot processes. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Higher plant efficiency is accomplished by reducing the. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The power (rate of energy utilization) of a fan is a product.

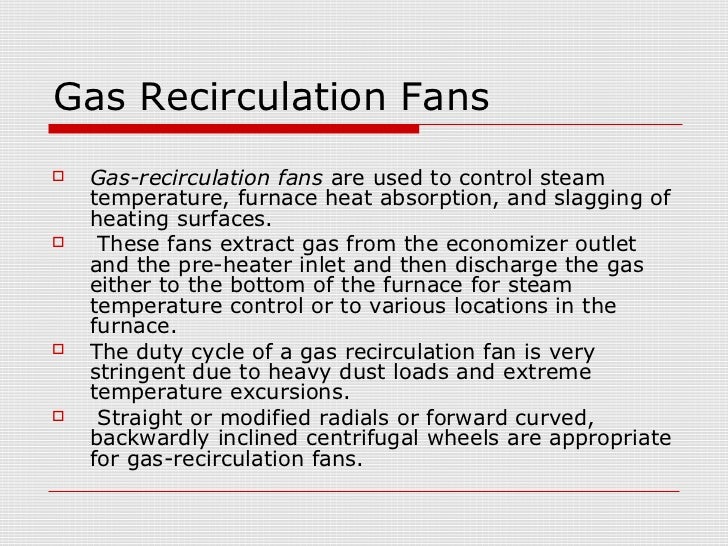

Fans in thermal power plants

Gas Recirculation Fan Effective fans for hot processes. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Higher plant efficiency is accomplished by reducing the. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. Effective fans for hot processes. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. The power (rate of energy utilization) of a fan is a product. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans.

From science-hamza.blogspot.com

Electricity , Power generation ,Thermal power plant , Solar Energy Gas Recirculation Fan The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces,. Gas Recirculation Fan.

From www.cibsejournal.com

Module 106 Natural gas boiler flue gas recirculation to reduce NOx Gas Recirculation Fan Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The power (rate of energy utilization) of a fan is a product. We can accommodate a wide range of systems and offer a variety of airfoil designs for. One main advantage of an overfire air and flue gas recirculation system. Gas Recirculation Fan.

From barkerbille.com

Combustion Air Fans for Ship Boilers Marine Industry BarkerBille Gas Recirculation Fan Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. Effective fans for hot processes. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. One main advantage of an overfire air and flue gas recirculation system is better. Gas Recirculation Fan.

From www.kelvion.com

ExhaustGas Recirculation Coolers Kelvion Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. We can accommodate a wide range of systems and offer a. Gas Recirculation Fan.

From www.venti-oelde.com

Hot gas circulation fans Gas Recirculation Fan Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. The power (rate of energy utilization) of a fan is a product. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Our circulating fans can withstand temperatures of. Gas Recirculation Fan.

From jintonglingtech.en.made-in-china.com

Gas Recirculation Fan D Series Centrifugal Blower with Good Workmanship Gas Recirculation Fan Effective fans for hot processes. The power (rate of energy utilization) of a fan is a product. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. Flue gas recirculation (fgr) is. Gas Recirculation Fan.

From www.researchgate.net

3 Whirl map for the anode offgas recirculation fan journal bearings Gas Recirculation Fan Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. One main advantage of an overfire air and flue gas recirculation system is. Gas Recirculation Fan.

From science-hamza.blogspot.com

Electricity , Power generation ,Thermal power plant , Solar Energy Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Effective fans for hot processes. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. The flue gas recirculation system (fgr). Gas Recirculation Fan.

From www.iqsdirectory.com

Industrial Oven What is it? Uses, Types & Use, How It Works Gas Recirculation Fan The power (rate of energy utilization) of a fan is a product. Effective fans for hot processes. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. We can accommodate. Gas Recirculation Fan.

From science-hamza.blogspot.com

Electricity , Power generation ,Thermal power plant , Solar Energy Gas Recirculation Fan Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. The power (rate of energy utilization) of a fan is a product. One main advantage of an. Gas Recirculation Fan.

From en.ntalborz.com

Circulation Fans Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system. The power (rate of energy. Gas Recirculation Fan.

From www.cqtygroup.com

China High Quality Hot Gas Circulation Fans Suppliers, Manufacturers Gas Recirculation Fan Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The power (rate of energy utilization) of a fan is a product. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Effective fans for hot processes. The flue gas recirculation process requires a. Gas Recirculation Fan.

From ritmindustry.com

Centrifugal fan / for air circulation / industrial RITM Industry Gas Recirculation Fan Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The power (rate of energy utilization) of a fan is a product. We can accommodate a wide range of systems and offer a variety of airfoil designs for. The flue gas recirculation process requires a fan to recirculate flue gas. Gas Recirculation Fan.

From www.pinterest.com

Pin on Our Products Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Some of the larger fan applications are the. Gas Recirculation Fan.

From www.techexplorist.com

A novel way to increase fuelcell efficiency and lifespan Gas Recirculation Fan Effective fans for hot processes. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. Higher plant efficiency is accomplished by reducing the. The power (rate of energy utilization) of a fan is a product. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary. Gas Recirculation Fan.

From emcombustion.es

Flue gas recirculation clean environment emissions reduction Gas Recirculation Fan The power (rate of energy utilization) of a fan is a product. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or. Gas Recirculation Fan.

From www.mdpi.com

Atmosphere Free FullText Investigation and Evaluation of Flue Gas Gas Recirculation Fan Effective fans for hot processes. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and. Gas Recirculation Fan.

From www.morseairsystems.com.au

Industrial Recirculation Fans Supplier Manufacturer Repairer Melbourne Gas Recirculation Fan The power (rate of energy utilization) of a fan is a product. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. One main advantage of an overfire air and flue. Gas Recirculation Fan.

From www.linkedin.com

Forced Draft Fans & Flue Gas Recirculation Fans Gas Recirculation Fan The power (rate of energy utilization) of a fan is a product. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Higher plant efficiency is accomplished by reducing the. Effective fans for hot processes. The flue gas recirculation process requires a. Gas Recirculation Fan.

From barkerbille.com

Industrial fans for Marine & Offshore BarkerBille Gas Recirculation Fan The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. Effective fans for hot processes. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The power (rate of energy utilization). Gas Recirculation Fan.

From www.slideshare.net

Fans in thermal power plants Gas Recirculation Fan The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. We can accommodate a wide range of systems and offer a variety of airfoil designs for. One main advantage. Gas Recirculation Fan.

From www.youtube.com

Principle of Exhaust Gas Recirculation (EGR) YouTube Gas Recirculation Fan Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The power (rate of energy utilization) of a fan is a product. The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the. Gas Recirculation Fan.

From ritmindustry.com

Centrifugal fan / circulation / hightemperature / furnace RITM Industry Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. We can accommodate a wide range of systems and offer a variety of airfoil designs for. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and. Gas Recirculation Fan.

From www.google.nl

Patent US8329125 Flue gas recirculation system Google Patenten Gas Recirculation Fan The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. We can accommodate a wide range of systems and offer a variety of airfoil designs for. One. Gas Recirculation Fan.

From www.youtube.com

Reducing Boiler Emissions with Flue Gas Recirculation Boiling Point Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. We can accommodate a wide range of systems and offer a variety of airfoil designs for. The flue gas recirculation system (fgr) is a. Gas Recirculation Fan.

From www.researchgate.net

Schematic diagram of the airgas flow path of the TPP210А boiler unit Gas Recirculation Fan The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. The power (rate of energy utilization) of a fan is a product. Higher plant efficiency is accomplished by reducing the. We can accommodate a wide range of systems and offer a variety of airfoil designs for. One main advantage of an. Gas Recirculation Fan.

From solucionesdecombustion.com

Flue gas recirculation helps to keep our environment clean Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. We can accommodate a wide range of systems and offer a variety of airfoil designs for. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a. Gas Recirculation Fan.

From www.crazyengineers.com

Boiler AIR AND FLUE GAS SYSTEM CrazyEngineers Gas Recirculation Fan Effective fans for hot processes. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. We can accommodate a wide range of systems. Gas Recirculation Fan.

From www.researchgate.net

3 Whirl map for the anode offgas recirculation fan journal bearings Gas Recirculation Fan The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. The power (rate of energy utilization) of a fan is a product. Some of the larger fan applications are. Gas Recirculation Fan.

From extension.okstate.edu

Dehydrator Exhaust Recirculation for Energy Savings Oklahoma State Gas Recirculation Fan Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. The power (rate of energy utilization) of a fan is a product. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. We can accommodate a wide range. Gas Recirculation Fan.

From jintonglingtech.en.made-in-china.com

Preheater Gas Recirculation D Series Centrifugal Fan with Latest Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. The power (rate of energy utilization) of a fan is a product. The flue gas recirculation system (fgr) is a technique to reduce nox. Gas Recirculation Fan.

From www.scheuch-components.com

Hotgas radial fan Flexible application Scheuch COMPONENTS Gas Recirculation Fan Higher plant efficiency is accomplished by reducing the. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. We can accommodate a wide range of systems and offer a variety of airfoil designs for. The power (rate of energy utilization) of a fan is a product. Flue gas recirculation (fgr). Gas Recirculation Fan.

From www.mdpi.com

Energies Free FullText Analysis of Gas Recirculation Influencing Gas Recirculation Fan Some of the larger fan applications are the forced draft (fd), induced draft (id), primary air (pa), booster and gas recirculation fans. Higher plant efficiency is accomplished by reducing the. Effective fans for hot processes. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a. Gas Recirculation Fan.

From 360.lubrizol.com

How it Works Exhaust Gas Recirculation Gas Recirculation Fan The power (rate of energy utilization) of a fan is a product. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. Our circulating fans can withstand temperatures of up to 1,000°c and are used for tempering, annealing and hardening furnaces, as. Some of the larger fan applications are the forced. Gas Recirculation Fan.

From science-hamza.blogspot.com

Electricity , Power generation ,Thermal power plant , Solar Energy Gas Recirculation Fan The flue gas recirculation system (fgr) is a technique to reduce nox emissions which is increasingly spreading thanks to the growing. The flue gas recirculation process requires a fan to recirculate flue gas air back into the supply air stream. One main advantage of an overfire air and flue gas recirculation system is better efficiency for the boiler system. Higher. Gas Recirculation Fan.