Bending Sheet Metal Pdf . Auto body parts, beverage cans,. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. By the end of today you should be able to. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight axis. Many metal components are formed by bending a sheet of metal in one or more places. .describe different forming processes, when they might be used, and compare their. During bending operation, the metal on the inner side of the. Short lengths of metal can be bent by using die sets.

from www.mech4study.com

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the. Many metal components are formed by bending a sheet of metal in one or more places. By the end of today you should be able to. Cutting and forming thin sheets of metal usually performed as cold working. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Short lengths of metal can be bent by using die sets. Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Auto body parts, beverage cans,.

Different Sheet Metal Bending Process mech4study

Bending Sheet Metal Pdf Cutting and forming thin sheets of metal usually performed as cold working. Short lengths of metal can be bent by using die sets. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Auto body parts, beverage cans,. During bending operation, the metal on the inner side of the. Cutting and forming thin sheets of metal usually performed as cold working. Metallic sheet typically < 6 mm thick. .describe different forming processes, when they might be used, and compare their. Many metal components are formed by bending a sheet of metal in one or more places. Sheet bending is defined as the straining of the metal around a straight axis. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. By the end of today you should be able to.

From thelibraryofmanufacturing.com

Sheet Metal Bending Bending Sheet Metal Pdf Many metal components are formed by bending a sheet of metal in one or more places. Metallic sheet typically < 6 mm thick. During bending operation, the metal on the inner side of the. .describe different forming processes, when they might be used, and compare their. Short lengths of metal can be bent by using die sets. Sheet metal =. Bending Sheet Metal Pdf.

From www.protocase.com

Sheet Metal Bending Tolerances Bending Sheet Metal Pdf .describe different forming processes, when they might be used, and compare their. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually performed as cold working. By the end of today you should be able to. Auto body. Bending Sheet Metal Pdf.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Sheet bending is defined as the straining of the metal around a straight axis. By the end of today you should be able to. Metallic sheet typically < 6 mm thick. Short lengths of metal can be bent by using die sets. Cutting and forming thin sheets of metal. Bending Sheet Metal Pdf.

From angelenekaydn.blogspot.com

44+ sheet metal bending calculation formula pdf AngeleneKaydn Bending Sheet Metal Pdf By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their. Many metal components are formed by bending a sheet of metal in one or more places. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Short lengths of metal can be bent by using die sets. Bend. Bending Sheet Metal Pdf.

From www.hardwareinterviews.fyi

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Short lengths of metal can be bent by using die sets. By the end of today you should be. Bending Sheet Metal Pdf.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Bending Sheet Metal Pdf Many metal components are formed by bending a sheet of metal in one or more places. During bending operation, the metal on the inner side of the. Metallic sheet typically < 6 mm thick. .describe different forming processes, when they might be used, and compare their. Bend allowance is a term which describes how much material is needed between two. Bending Sheet Metal Pdf.

From www.madearia.com

Sheet metal fabrication design guide Bending Aria Online Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Cutting and forming thin sheets of metal usually performed as cold working. .describe different forming processes, when they might be used, and compare their. By the end of today you should be able to. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Auto body parts, beverage cans,.. Bending Sheet Metal Pdf.

From www.youtube.com

SolidWorks Tutorial Sheet Metal Part Design Bend Allowance YouTube Bending Sheet Metal Pdf Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Short lengths of metal can be bent by using die sets. During bending operation, the metal on the inner side of the. Auto body parts, beverage cans,. Metallic sheet typically. Bending Sheet Metal Pdf.

From www.protocase.com

Sheet Metal Bending Tolerances Bending Sheet Metal Pdf Auto body parts, beverage cans,. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. During bending operation, the metal on the inner side of the. Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually performed as. Bending Sheet Metal Pdf.

From www.smlease.com

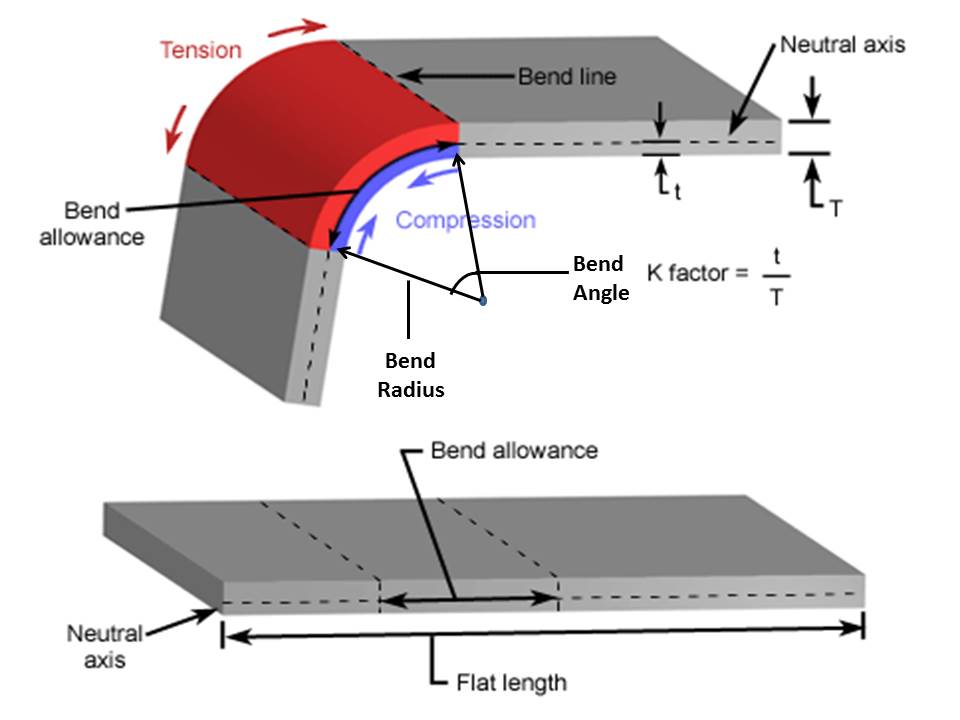

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Cutting and forming thin sheets of metal usually performed as cold working. Auto body parts, beverage cans,. During bending operation, the metal on the inner side of the. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight axis.. Bending Sheet Metal Pdf.

From metalmaq.shop

The metal sheet bending table are the basis of the operation of the metal Bending Sheet Metal Pdf By the end of today you should be able to. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Auto body parts, beverage cans,. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the. Bending Sheet Metal Pdf.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Bending Sheet Metal Pdf Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. By the end of today you should be able to. Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the. .describe different forming processes, when they might be used, and compare their. Cutting and forming. Bending Sheet Metal Pdf.

From www.protocase.co.uk

Sheet Metal Bending Tolerances Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Auto body parts, beverage cans,. Many metal components are formed by bending a sheet of metal in one or more places. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. During bending operation, the metal on the inner side of the. Sheet bending is defined as the straining. Bending Sheet Metal Pdf.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. .describe different forming processes, when they might be used, and compare their. Sheet bending is defined as the straining of the metal around a straight axis. Auto body parts, beverage cans,. Cutting and forming thin sheets of metal usually performed as cold working. Bend allowance is a term which. Bending Sheet Metal Pdf.

From www.protocase.co.uk

Sheet Metal Bending Tolerances Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Auto body parts, beverage cans,. Many metal components are formed by bending a sheet of metal in one or more places. Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal. Bending Sheet Metal Pdf.

From www.scribd.com

Bend Radius Bend Angle Bending Is A Metal Forming Process in Which A Bending Sheet Metal Pdf Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet bending is defined as the straining of the metal around a straight axis. .describe different forming processes, when they might be used, and compare their. Metallic sheet typically < 6 mm thick. Cutting and forming thin sheets of metal usually performed as cold working. By the end of today. Bending Sheet Metal Pdf.

From www.mac-tech.com

7 Tips for Bending Long Pieces of Sheet Metal Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Auto body parts, beverage cans,. .describe different forming processes, when they might be used, and compare their. Cutting and forming thin sheets of metal usually performed as cold working. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight. Bending Sheet Metal Pdf.

From cncfirst.com

How To Bend Sheet Metal? cncfirst Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually. Bending Sheet Metal Pdf.

From www.javelin-tech.com

Learn Sheet Metal Design Terminology including Bend Deduction Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. During bending operation, the metal on the. Bending Sheet Metal Pdf.

From exomwibmm.blob.core.windows.net

Sheet Metal Bending Exercises Pdf at Rosa Coffey blog Bending Sheet Metal Pdf Sheet bending is defined as the straining of the metal around a straight axis. Short lengths of metal can be bent by using die sets. Cutting and forming thin sheets of metal usually performed as cold working. During bending operation, the metal on the inner side of the. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. By the. Bending Sheet Metal Pdf.

From www.youtube.com

Solidworks sheet metal Lofted Bend YouTube Bending Sheet Metal Pdf Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Short lengths of metal can be bent by using die sets. Sheet bending is defined as the straining of the metal around a straight axis. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. .describe different forming processes, when. Bending Sheet Metal Pdf.

From www.vrogue.co

Sheet Metal Bend Chart vrogue.co Bending Sheet Metal Pdf .describe different forming processes, when they might be used, and compare their. By the end of today you should be able to. Short lengths of metal can be bent by using die sets. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Many metal components are formed by bending a sheet of metal in one or more places. Auto. Bending Sheet Metal Pdf.

From www.engineersrule.com

sheet metal Archives Engineers Rule Bending Sheet Metal Pdf Sheet bending is defined as the straining of the metal around a straight axis. Auto body parts, beverage cans,. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Short lengths of metal can be bent by using die sets. By the end of today you should be able to. Metallic sheet typically < 6 mm thick. Many metal components. Bending Sheet Metal Pdf.

From www.rocheindustry.com

The Basics of Bending Sheet Metal You Should Know Bending Sheet Metal Pdf Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. .describe different forming processes, when they might be used, and compare their. Cutting and forming thin sheets of metal usually performed as cold working. Short lengths of metal can be bent by using die sets. Many metal components are formed. Bending Sheet Metal Pdf.

From www.conic.co.jp

vol.3 PREPARATION FOR BENDING 1 TECHNICAL GUIDE CONIC Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Cutting and forming thin sheets of metal usually performed as cold working. .describe different forming processes, when they might be used, and compare their. Bend allowance is a term which describes how much material is needed between two panels. Bending Sheet Metal Pdf.

From www.youtube.com

Sheet Metal Bending Basics, Allowances, and Tips for Best Results Bending Sheet Metal Pdf Many metal components are formed by bending a sheet of metal in one or more places. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Cutting and forming thin sheets of metal usually performed as cold working. Metallic sheet typically < 6 mm thick. By the end of today. Bending Sheet Metal Pdf.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Auto body parts, beverage cans,. Cutting and forming thin sheets of metal usually performed as cold working. Sheet bending is defined as the straining of the metal around a straight axis. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Bend allowance is a term which describes how. Bending Sheet Metal Pdf.

From www.javelin-tech.com

Sheet Metal Bend Deduction Calculations with Switching Directions Bending Sheet Metal Pdf Many metal components are formed by bending a sheet of metal in one or more places. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Sheet bending is defined as the straining of the metal around a straight axis.. Bending Sheet Metal Pdf.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Bending Sheet Metal Pdf Many metal components are formed by bending a sheet of metal in one or more places. .describe different forming processes, when they might be used, and compare their. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. By the end of today you should be able to. Sheet bending. Bending Sheet Metal Pdf.

From www.shenchong.com

Sheet Metal Bending Design Guidelines Bending Sheet Metal Pdf Sheet bending is defined as the straining of the metal around a straight axis. Cutting and forming thin sheets of metal usually performed as cold working. Short lengths of metal can be bent by using die sets. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Metallic sheet typically. Bending Sheet Metal Pdf.

From www.choonngaiengineering.com

Metal Guidelines Methods of Sheet Metal Bending Bending Sheet Metal Pdf Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Short lengths of metal can be bent by using die sets. Metallic sheet typically < 6 mm thick. Cutting and forming thin sheets of metal usually performed as cold working.. Bending Sheet Metal Pdf.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Bending Sheet Metal Pdf Short lengths of metal can be bent by using die sets. Cutting and forming thin sheets of metal usually performed as cold working. By the end of today you should be able to. Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. .describe different forming processes, when they might be used, and. Bending Sheet Metal Pdf.

From www.youtube.com

18 types of bending operations in sheet metal Sheet metal bending Bending Sheet Metal Pdf Metallic sheet typically < 6 mm thick. Auto body parts, beverage cans,. Sheet bending is defined as the straining of the metal around a straight axis. Short lengths of metal can be bent by using die sets. .describe different forming processes, when they might be used, and compare their. Bend allowance is a term which describes how much material is. Bending Sheet Metal Pdf.

From cadinfield.com

Sheet Metal Fabrication Fundamental Cad Infield Bending Sheet Metal Pdf During bending operation, the metal on the inner side of the. Many metal components are formed by bending a sheet of metal in one or more places. Metallic sheet typically < 6 mm thick. Sheet bending is defined as the straining of the metal around a straight axis. Short lengths of metal can be bent by using die sets. By. Bending Sheet Metal Pdf.

From xometry.eu

Sheet Metal Design Tips For Bending Xometry Europe Bending Sheet Metal Pdf .describe different forming processes, when they might be used, and compare their. Metallic sheet typically < 6 mm thick. By the end of today you should be able to. Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Sheet bending is defined as the straining of the metal around. Bending Sheet Metal Pdf.