Surface Roughness Values In Inches . Ra = roughness average in micrometers or microinches. Sr = (ra + rz) / 2. The formula for calculating surface roughness (sr) is: It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. The value of e indicates a minimum material removal. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Machining process ra [ micro inches ] Learn the value of surface quality and. The following charts and tables convert surface finish or roughness between selected industry standard units. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Here, “ra” represents the average roughness,.

from www.engineersedge.com

The formula for calculating surface roughness (sr) is: The following charts and tables convert surface finish or roughness between selected industry standard units. Here, “ra” represents the average roughness,. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Learn the value of surface quality and. The value of e indicates a minimum material removal. Sr = (ra + rz) / 2. Machining process ra [ micro inches ] The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve.

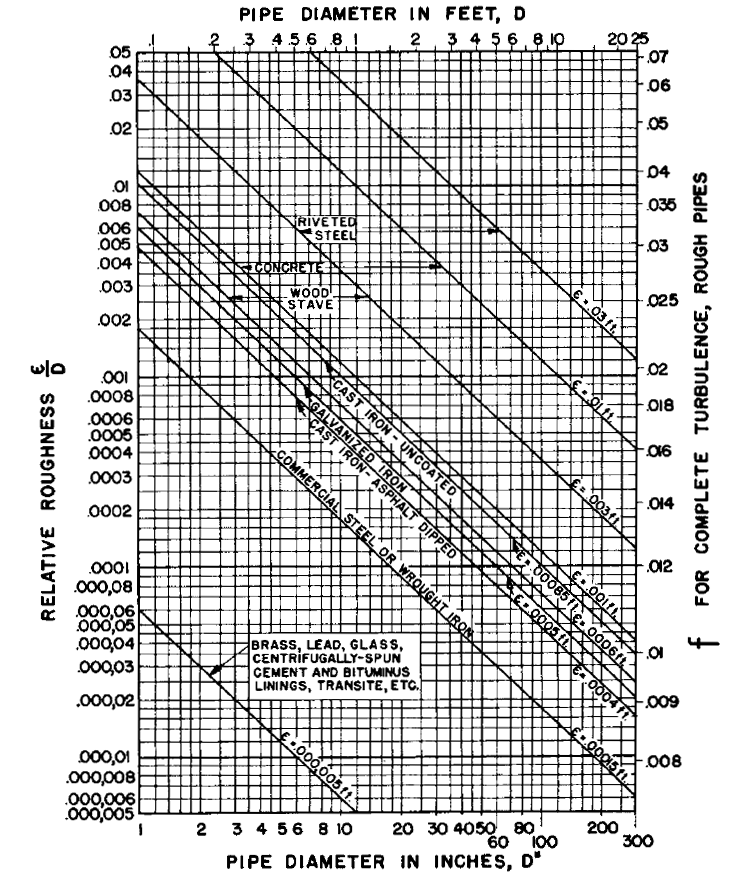

Pipe Roughness Coefficients Table Charts HazenWilliams Coefficient Manning Factor

Surface Roughness Values In Inches It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Learn the value of surface quality and. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. The following charts and tables convert surface finish or roughness between selected industry standard units. Here, “ra” represents the average roughness,. Sr = (ra + rz) / 2. Machining process ra [ micro inches ] Ra = roughness average in micrometers or microinches. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. The formula for calculating surface roughness (sr) is: Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The value of e indicates a minimum material removal. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve.

From michmet.com

Typical Average Roughness values for various machining operations Michigan Metrology Surface Roughness Values In Inches Sr = (ra + rz) / 2. Here, “ra” represents the average roughness,. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Ra = roughness average in micrometers or microinches. The formula for calculating surface roughness (sr) is: The letter c provides the roughness sampling length in millimeters or inches, while. Surface Roughness Values In Inches.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Values In Inches The following charts and tables convert surface finish or roughness between selected industry standard units. Here, “ra” represents the average roughness,. The formula for calculating surface roughness (sr) is: The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Learn the value of surface quality and. Explore the unique. Surface Roughness Values In Inches.

From proleantech.com

Surface Roughness Everything You Need to Know Surface Roughness Values In Inches Here, “ra” represents the average roughness,. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The following charts and tables convert surface finish or roughness between selected industry standard units.. Surface Roughness Values In Inches.

From www.suginocorp.com

Surface Roughness for Lathe Turning Surface Roughness Values In Inches In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Sr = (ra + rz) / 2. The following charts and tables convert surface finish or roughness between selected industry standard units. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction. Surface Roughness Values In Inches.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards, and Charts Surface Roughness Values In Inches Sr = (ra + rz) / 2. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. The following charts and tables convert surface finish or. Surface Roughness Values In Inches.

From www.researchgate.net

Surface roughness values, mm Download Table Surface Roughness Values In Inches Ra = roughness average in micrometers or microinches. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Sr = (ra + rz) / 2. The formula for. Surface Roughness Values In Inches.

From www.researchgate.net

Description of surface and evaluated average capacitive roughness values. Download Table Surface Roughness Values In Inches Sr = (ra + rz) / 2. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Here, “ra” represents the average roughness,. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Ra = roughness average in micrometers. Surface Roughness Values In Inches.

From gahess.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect (2022) Surface Roughness Values In Inches Machining process ra [ micro inches ] Here, “ra” represents the average roughness,. Ra = roughness average in micrometers or microinches. The following charts and tables convert surface finish or roughness between selected industry standard units. The value of e indicates a minimum material removal. The formula for calculating surface roughness (sr) is: Learn the value of surface quality and.. Surface Roughness Values In Inches.

From informacionpublica.svet.gob.gt

Complete Surface Finish Chart, Symbols Roughness Conversion Surface Roughness Values In Inches The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Here, “ra” represents the average roughness,. The following charts and tables convert surface finish or roughness between selected industry standard units. Machining process ra [ micro inches ] Ra = roughness average in micrometers or microinches. Learn the value. Surface Roughness Values In Inches.

From mavink.com

Roughness Conversion Chart Surface Roughness Values In Inches Sr = (ra + rz) / 2. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Ra = roughness average in micrometers or microinches. Machining. Surface Roughness Values In Inches.

From www.cnccookbook.com

Surface Finish Symbols and Roughness Conversion Chart Tables Surface Roughness Values In Inches It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Ra = roughness average in micrometers or microinches. Learn the value of surface quality and. The value of e indicates a minimum material removal. Here, “ra” represents the average roughness,. Machining process ra [ micro inches ]. Surface Roughness Values In Inches.

From mavink.com

Surface Roughness Comparison Chart Surface Roughness Values In Inches Learn the value of surface quality and. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Here, “ra” represents the average roughness,. Machining process ra. Surface Roughness Values In Inches.

From www.tpsearchtool.com

Surface Roughness Chart Iso Finishing Images Surface Roughness Values In Inches The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. The formula for calculating surface roughness (sr) is: Ra = roughness average in micrometers or microinches. Here, “ra” represents the average roughness,. It is a part of the texture of the surface and is often shortened to “roughness.” it. Surface Roughness Values In Inches.

From www.engineersedge.com

Pipe Roughness Coefficients Table Charts HazenWilliams Coefficient Manning Factor Surface Roughness Values In Inches Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Ra = roughness average in micrometers or microinches. Sr = (ra + rz) / 2. The following charts and tables convert surface finish or roughness between selected industry standard units. It is a part of the texture of the surface and is. Surface Roughness Values In Inches.

From www.researchgate.net

Surface roughness values before and after Download Scientific Diagram Surface Roughness Values In Inches In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Learn the value of surface quality and. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Explore the unique characteristics of surface roughness, including its. Surface Roughness Values In Inches.

From mavink.com

Surface Roughness Comparison Chart Surface Roughness Values In Inches The value of e indicates a minimum material removal. The formula for calculating surface roughness (sr) is: Sr = (ra + rz) / 2. The following charts and tables convert surface finish or roughness between selected industry standard units. Here, “ra” represents the average roughness,. Learn the value of surface quality and. Explore the unique characteristics of surface roughness, including. Surface Roughness Values In Inches.

From mungfali.com

Ra Surface Roughness Chart Surface Roughness Values In Inches It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. The formula for calculating surface roughness (sr) is: Sr = (ra + rz) / 2. The following charts and tables convert surface finish or roughness between selected industry standard units. Explore the unique characteristics of surface roughness,. Surface Roughness Values In Inches.

From mungfali.com

Surface Finish Roughness Chart Surface Roughness Values In Inches Sr = (ra + rz) / 2. Learn the value of surface quality and. Ra = roughness average in micrometers or microinches. The value of e indicates a minimum material removal. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Machining process ra [ micro inches ] The. Surface Roughness Values In Inches.

From www.scribd.com

Surface Roughness Tables The onestop source for all your METRIC HARDWARE needs! Surface Roughness Values In Inches Learn the value of surface quality and. Here, “ra” represents the average roughness,. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. The following charts and tables convert surface finish or roughness between selected industry standard units. The formula for calculating surface roughness (sr) is: Ra. Surface Roughness Values In Inches.

From www.researchgate.net

A selection of surface roughness values listed under different cutting... Download Table Surface Roughness Values In Inches Machining process ra [ micro inches ] Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Here, “ra” represents the average roughness,. Sr = (ra + rz) / 2. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much. Surface Roughness Values In Inches.

From www.researchgate.net

Surface roughness (R a is in µinch) measurement results. Download Scientific Diagram Surface Roughness Values In Inches Learn the value of surface quality and. Sr = (ra + rz) / 2. In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. The following charts and tables convert surface finish or roughness between selected industry standard units. Machining process ra [ micro inches ] It is a. Surface Roughness Values In Inches.

From www.china-machining.com

Understand the Surface Roughness Chart and Make Great Parts Surface Roughness Values In Inches The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Machining process ra [ micro inches ] Ra = roughness average in micrometers or microinches. The formula for calculating surface roughness (sr) is: In the chart below, you can find the lowest surface roughness (best surface finish) that the. Surface Roughness Values In Inches.

From labbyag.es

Pipe Roughness Chart Labb by AG Surface Roughness Values In Inches It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The value of e indicates a minimum material removal. Ra = roughness average in micrometers or microinches. Here, “ra”. Surface Roughness Values In Inches.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Roughness Values In Inches Machining process ra [ micro inches ] Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Sr = (ra + rz) / 2. The following charts and tables convert surface finish or roughness between selected industry standard units. In the chart below, you can find the lowest surface roughness (best surface. Surface Roughness Values In Inches.

From www.americanmachinist.com

SurfaceFinish Conversion Tips American Machinist Surface Roughness Values In Inches Sr = (ra + rz) / 2. Learn the value of surface quality and. Machining process ra [ micro inches ] In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. It is a part of the texture of the surface and is often shortened to “roughness.” it is. Surface Roughness Values In Inches.

From mavink.com

Surface Roughness Comparison Chart Surface Roughness Values In Inches Machining process ra [ micro inches ] Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The formula for calculating surface roughness (sr) is: The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. In the chart below, you can. Surface Roughness Values In Inches.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Surface Roughness Values In Inches It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Machining process ra [ micro inches ] The following charts and tables convert surface finish or roughness between selected industry standard units. Ra = roughness average in micrometers or microinches. The value of e indicates a minimum. Surface Roughness Values In Inches.

From facfox.com

Selecting right surface roughness for CNC machining FacFox Docs Surface Roughness Values In Inches In the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The value of e indicates a minimum material removal. Learn the value of surface quality and. Machining process ra [ micro. Surface Roughness Values In Inches.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Roughness Values In Inches The formula for calculating surface roughness (sr) is: Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The following charts and tables convert surface finish or roughness between selected industry standard units. Sr = (ra + rz) / 2. Learn the value of surface quality and. Machining process ra [ micro. Surface Roughness Values In Inches.

From www.researchgate.net

Surface roughness values (µm), mean ±standard deviations Download Table Surface Roughness Values In Inches Here, “ra” represents the average roughness,. Machining process ra [ micro inches ] The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. The following charts and tables convert surface finish or roughness between selected industry standard units. Sr = (ra + rz) / 2. Explore the unique characteristics. Surface Roughness Values In Inches.

From www.vrogue.co

Surface Roughness Conversion Chart Tables vrogue.co Surface Roughness Values In Inches Here, “ra” represents the average roughness,. The following charts and tables convert surface finish or roughness between selected industry standard units. It is a part of the texture of the surface and is often shortened to “roughness.” it is measured by how much its. Machining process ra [ micro inches ] Sr = (ra + rz) / 2. Ra =. Surface Roughness Values In Inches.

From www.nextgentooling.com

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING Surface Roughness Values In Inches The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Here, “ra” represents the average roughness,. Ra = roughness average in micrometers or microinches. Learn the value of surface quality and. The formula for calculating surface roughness (sr) is: Explore the unique characteristics of surface roughness, including its exact. Surface Roughness Values In Inches.

From michmet.com

Average Roughness basics Michigan Metrology Surface Roughness Values In Inches Machining process ra [ micro inches ] The following charts and tables convert surface finish or roughness between selected industry standard units. Here, “ra” represents the average roughness,. Learn the value of surface quality and. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The letter c provides the roughness sampling. Surface Roughness Values In Inches.

From mungfali.com

Surface Roughness Conversion Chart Surface Roughness Values In Inches Machining process ra [ micro inches ] Learn the value of surface quality and. Ra = roughness average in micrometers or microinches. Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. Here, “ra” represents the average roughness,. The letter c provides the roughness sampling length in millimeters or inches, while d. Surface Roughness Values In Inches.

From mungfali.com

Surface Finish Roughness Chart Surface Roughness Values In Inches Explore the unique characteristics of surface roughness, including its exact measuring methods, applicable industry standards, and roughness charts. The letter c provides the roughness sampling length in millimeters or inches, while d gives the direction of the surface lay. Ra = roughness average in micrometers or microinches. Here, “ra” represents the average roughness,. The following charts and tables convert surface. Surface Roughness Values In Inches.