Brazing Pin Holes . Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Take care not to damage the lug. With a simplified system and ergonomic design, the electrobraze pin. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer.

from www.youtube.com

Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Take care not to damage the lug. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as.

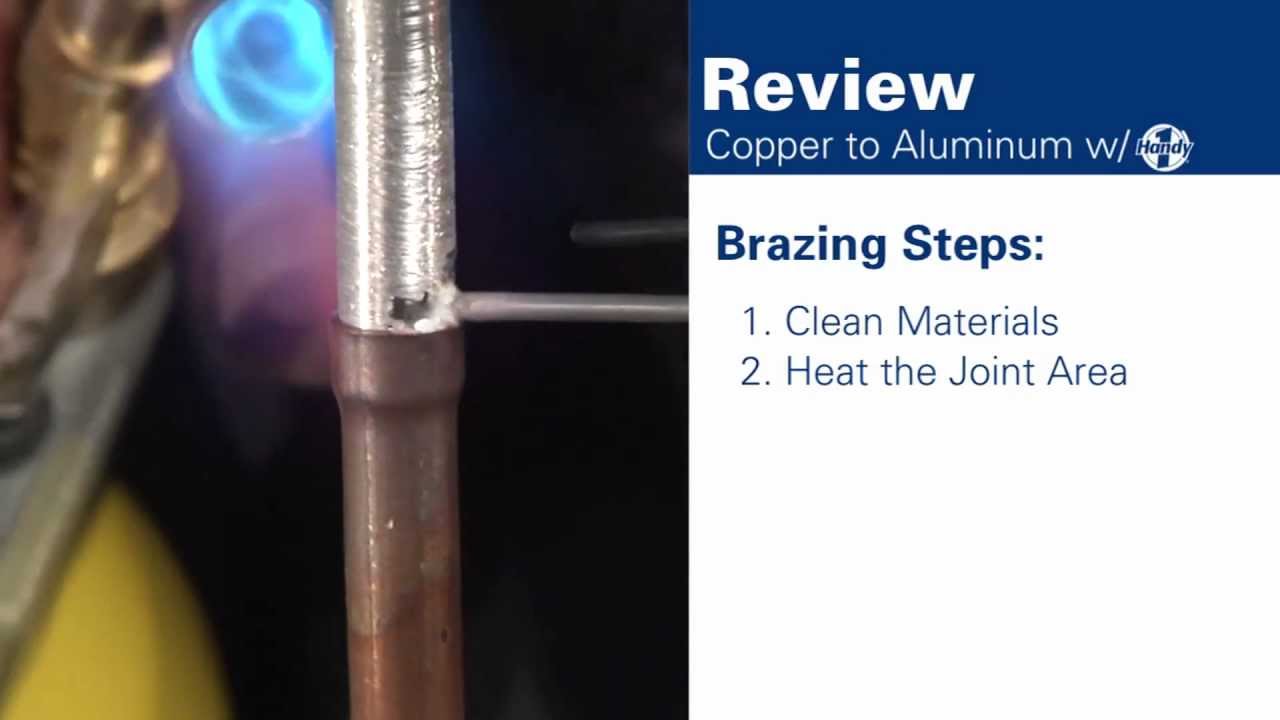

How to Braze Aluminum to Copper YouTube

Brazing Pin Holes Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Take care not to damage the lug. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. With a simplified system and ergonomic design, the electrobraze pin.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider Brazing Pin Holes Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. With a simplified system and ergonomic design, the electrobraze pin. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. With the earth device in place the gun trigger depressed and after approximately. Brazing Pin Holes.

From www.slideserve.com

PPT PinBrazing PowerPoint Presentation, free download ID1043224 Brazing Pin Holes Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Brazing. Brazing Pin Holes.

From www.electronicsandyou.com

Pin Hole & Blow Hole Soldering Defects and Remedies on Solder Joint Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Take care not to damage the lug. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin. Brazing Pin Holes.

From www.youtube.com

Induction Brazing a Steel Pin to a Steel Plate YouTube Brazing Pin Holes With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Take care not to damage the lug. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Pin brazing is a simple,. Brazing Pin Holes.

From www.youtube.com

PinBrazing with Safetrack digitized equipment, ECONECT, on pipeline Brazing Pin Holes Take care not to damage the lug. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Easybond pin brazing is ideally suited for many applications. Brazing Pin Holes.

From www.youtube.com

Pin Brazing for Cathodic Protection Applications A Beginner's Guide Brazing Pin Holes Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin with a. Brazing Pin Holes.

From www.ramchargercentral.com

Brazing pinholes and electro plating questions Dodge RamCharger Central Brazing Pin Holes Take care not to damage the lug. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and. Brazing Pin Holes.

From www.cathodic-protection.net

Brazing Pin,Welding Pin,Cable Connector,Ceramic Ferrule Brazing Pin Holes With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Take care not to damage the lug. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and. Brazing Pin Holes.

From www.instructables.com

How to Fix a Pinhole With Plumbing Solder 3 Steps Instructables Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of. Brazing Pin Holes.

From www.bacgroup.com

Pin Brazing Technical Brazing Pin Holes Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Pin brazing is. Brazing Pin Holes.

From popasia.net

เชื่อมอุดรู อลูมิเนียม/เหล็ก/สแตนเลส/ทองเหลือง/ทองแดง/Pin hole brazing Brazing Pin Holes Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Take care not to damage the lug. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Test direct braze pins by carefully breaking off the. Brazing Pin Holes.

From www.youtube.com

How to Braze Aluminum to Copper YouTube Brazing Pin Holes Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Easybond pin. Brazing Pin Holes.

From www.youtube.com

Induction Brazing of stainless steel pin to a steel base YouTube Brazing Pin Holes With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as. Brazing Pin Holes.

From weldingheadquarters.com

Welding Headquarters Learn Welding Basics Brazing Pin Holes Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Take care not to damage the lug. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures,. Brazing Pin Holes.

From www.ramchargercentral.com

Brazing pinholes and electro plating questions Dodge RamCharger Central Brazing Pin Holes With a simplified system and ergonomic design, the electrobraze pin. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. It is used in cathodic protection systems in which electricity is used to protect. Brazing Pin Holes.

From xpressmobilewelding.com

What Causes Pinholes in MIG Welding? Brazing Pin Holes Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Pin brazing is a simple, metallurgically safe. Brazing Pin Holes.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Brazing Pin Holes Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Take care not to damage the lug. Pin brazing is a simple, metallurgically safe method for making electrical connections to. Brazing Pin Holes.

From www.youtube.com

cathodic protection pin brazing using safetrack machine YouTube Brazing Pin Holes Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. With a simplified system and ergonomic design, the electrobraze pin. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. It is used in cathodic protection systems in. Brazing Pin Holes.

From dw-inductionheater.com

Handheld Induction Brazing Copper Tubing and Fitting Brazing Pin Holes With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel. Brazing Pin Holes.

From www.researchgate.net

MIG/MAG braze welding [4] Download Scientific Diagram Brazing Pin Holes Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Take care not to damage the lug. Pin brazing is a metallurgically safe and easy process of making electrical. Brazing Pin Holes.

From www.superradiatorcoils.com

Brazing Defects Flux Entrapment Overview and Causes The Super Blog Brazing Pin Holes Take care not to damage the lug. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Easybond pin brazing is ideally suited for many applications including continuity bonding. Brazing Pin Holes.

From www.moneypit.com

Best Way to Repair Pinhole Leaks in Copper Pipe » The Money Pit Brazing Pin Holes With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Test direct braze pins by carefully breaking off the shank of the plain pin. Brazing Pin Holes.

From corrosion-group.com

PinBrazing Equipment Cathodic Protection Corrosion Group Brazing Pin Holes Take care not to damage the lug. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Brazing is a fascinating process that connects metals using a filler material heated. Brazing Pin Holes.

From kaybrazing.com

Centerline Eutectics in NiBrazing Kay & Associates Brazing Consultants Brazing Pin Holes With a simplified system and ergonomic design, the electrobraze pin. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Take care not to damage the lug. With the earth device in place the gun. Brazing Pin Holes.

From www.youtube.com

Alloy Braze Pin hole repair on Trophy truck radiator for Baja 1000 Brazing Pin Holes Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other. Brazing Pin Holes.

From www.bacgroup.com

Easybond Pin Brazing Consumables Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Take care not to damage the lug. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing. Brazing Pin Holes.

From www.electrobraze.com

Pin Brazing Hole Punch Cable Terminal Repair Tool Brazing Pin Holes Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Take care not to damage the lug. With a simplified system and ergonomic design, the electrobraze pin. It is used in cathodic protection systems in. Brazing Pin Holes.

From www.youtube.com

Soldering Through Hole Tips & Tricks (4K) YouTube Brazing Pin Holes Take care not to damage the lug. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Easybond pin brazing is ideally suited for. Brazing Pin Holes.

From www.youtube.com

How to Braze Copper to Copper with 0 Silver Brazing Rods YouTube Brazing Pin Holes With a simplified system and ergonomic design, the electrobraze pin. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Brazing is a fascinating process that connects metals using a filler material heated to a specific temperature range. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across. Brazing Pin Holes.

From www.slideserve.com

PPT PinBrazing PowerPoint Presentation, free download ID1043224 Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. With a simplified system and ergonomic. Brazing Pin Holes.

From simpleweld.com

Copper Brazing Rod A Beginner's Guide Simpleweld Brazing Pin Holes Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. With the earth device in place the gun trigger depressed and after approximately 1.5 to 2 seconds the circuit is mechanically broken as. With a simplified system and ergonomic design, the electrobraze pin. It is used in. Brazing Pin Holes.

From www.manufacturingguide.com

Pin brazing Find suppliers, processes & material Brazing Pin Holes Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. With a simplified system and ergonomic design, the electrobraze pin. Pin brazing is a simple, metallurgically safe method for making electrical connections. Brazing Pin Holes.

From www.youtube.com

Pin brazing YouTube Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Pin brazing is a metallurgically safe and easy process of making electrical connections to metallic structures, such as steel and ductile. Test direct braze pins by carefully breaking off the shank of the plain pin with a hammer. With the earth device. Brazing Pin Holes.

From www.youtube.com

How to Braze Air Conditioning Copper YouTube Brazing Pin Holes Easybond pin brazing is ideally suited for many applications including continuity bonding between pipes, across flanges, connection of cathodic. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Take care not to damage the lug. With a simplified system and ergonomic design, the electrobraze pin. With. Brazing Pin Holes.

From midsouthsupply.com

Guide to Aluminum Brazing Mid South Supply Brazing Pin Holes It is used in cathodic protection systems in which electricity is used to protect the substrate from corrosion. Pin brazing is a simple, metallurgically safe method for making electrical connections to steel and iron pipelines as well as other metallic structures. Take care not to damage the lug. Brazing is a fascinating process that connects metals using a filler material. Brazing Pin Holes.