Sealing Face Flange . A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Flat face flanges should not be bolted to raised face flanges. The flange face surface is the area where the sealing element (gasket) is installed. Asme b16.5 and b16.47 define various. The most common flange face surface designs are. Raised face flanges are available in all pressure classes and therefore. The material of the gasket seats over the flange face and creates an effective sealing under pressure. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint.

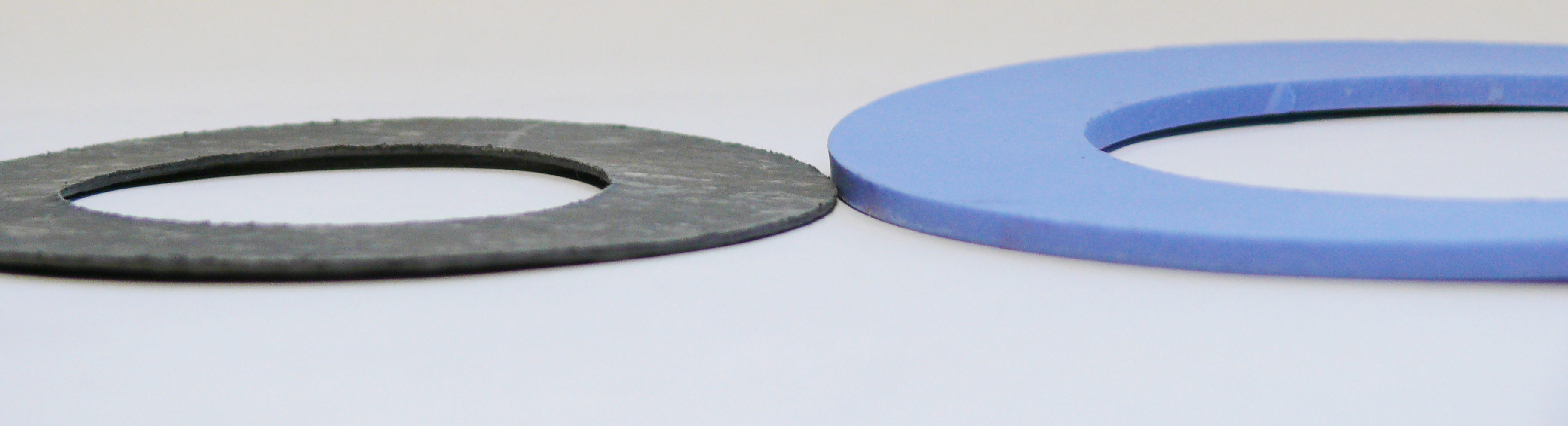

from trianglefluid.com

Flat face flanges should not be bolted to raised face flanges. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. The flange face surface is the area where the sealing element (gasket) is installed. The most common flange face surface designs are. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Raised face flanges are available in all pressure classes and therefore. The material of the gasket seats over the flange face and creates an effective sealing under pressure. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt.

Sealing Worn Flange Faces Triangle Fluid Controls Ltd.

Sealing Face Flange The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Flat face flanges should not be bolted to raised face flanges. Raised face flanges are available in all pressure classes and therefore. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The most common flange face surface designs are. The material of the gasket seats over the flange face and creates an effective sealing under pressure. Asme b16.5 and b16.47 define various. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. The flange face surface is the area where the sealing element (gasket) is installed.

From www.youtube.com

Piping Flange Types, Faces, and Surfaces Explained! YouTube Sealing Face Flange Asme b16.5 and b16.47 define various. Raised face flanges are available in all pressure classes and therefore. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Flat face flanges should not be bolted to raised face flanges. The flange face surface is the area where the sealing element (gasket) is. Sealing Face Flange.

From www.atlasuhv.com

Aluminum Face Seal ATCR Fitting, VCR Fitting Atlas Technologies Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. Raised face flanges are available in all pressure classes and therefore. The most common flange face surface designs are. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. The flange. Sealing Face Flange.

From savree.com

Flange Face Surfaces Explained (Serrated and Smooth) saVRee Sealing Face Flange Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Flat face flanges should not be bolted to raised face flanges. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Raised face flanges are available in all pressure classes and. Sealing Face Flange.

From richpipefitting.en.made-in-china.com

Flange Sealing Face FF RF FM TF GF Rtj Tj Rj Flange China Sealing Face Flange Raised face flanges are available in all pressure classes and therefore. The most common flange face surface designs are. Asme b16.5 and b16.47 define various. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. One of the key aspects of flange design is the flange face, which. Sealing Face Flange.

From www.precisionpipingproducts.com

Adhesive Flange Face Protection Self Adhesive Flange Protector Sealing Face Flange The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Raised face flanges are available in all pressure classes and therefore. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. The most common flange face surface designs are. Asme b16.5 and b16.47 define various. One of. Sealing Face Flange.

From trianglefluid.com

Sealing Worn Flange Faces Triangle Fluid Controls Ltd. Sealing Face Flange Raised face flanges are available in all pressure classes and therefore. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Asme b16.5 and b16.47 define various. Flat face flanges should. Sealing Face Flange.

From ballvalvegrinding.en.made-in-china.com

Machine for Flange Face Sealing Surface Repair, Flanges Facing, Flange Sealing Face Flange A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Asme b16.5 and b16.47 define various. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. The flange face refers to the surface area of a flange that comes into direct contact with the mating. Sealing Face Flange.

From hardhatengineer.com

10 Most Used Types of Pipe Flanges Their Features, Uses, and Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. Flat face flanges should not be bolted to raised face flanges. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Asme b16.5 and b16.47 define various. Raised face flanges are. Sealing Face Flange.

From engineeringlearn.com

12 Types of Flanges Design, Functions & Flange Face [with Pictures Sealing Face Flange The most common flange face surface designs are. Asme b16.5 and b16.47 define various. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. One of the key aspects of flange. Sealing Face Flange.

From savree.com

Flange Assembly Explained saVRee Sealing Face Flange The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Asme b16.5 and b16.47 define various. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Different types of flange faces are used as the contact surfaces to seat. Sealing Face Flange.

From www.vrogue.co

What Is Serration On Flange Face Smooth And Serrated vrogue.co Sealing Face Flange The most common flange face surface designs are. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. Flat face flanges should not be bolted to. Sealing Face Flange.

From indonesian.roller-ball-bearing.com

Sealing Face Long Weld Neck Flange, Koneksi Perempuan Flensa Baja Ditempa Sealing Face Flange The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Flat face. Sealing Face Flange.

From www.industrimigas.com

Flange Corrosion Protection Isolating the Sealing Face IndustriMigas Sealing Face Flange Asme b16.5 and b16.47 define various. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of. Sealing Face Flange.

From www.vrogue.co

Flange Face Finish vrogue.co Sealing Face Flange A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Flat face flanges should not be bolted to raised face flanges. The material of the gasket seats over the flange face and creates an effective sealing under pressure. The most common flange face surface designs are. Different types of flange faces. Sealing Face Flange.

From www.belzona.co.uk

Belzona Kit For damaged flanges Sealing Face Flange The flange face is designed per the asme b16.5 for flanges up to 24 inches and. The material of the gasket seats over the flange face and creates an effective sealing under pressure. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Asme b16.5 and b16.47 define various. A flat face flange. Sealing Face Flange.

From www.htpipe.com

304 Raised Face Blind Flange Sealing FaceZhengzhou Huitong Pipeline Sealing Face Flange Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Raised face flanges are available in all pressure classes and therefore. The most common flange face surface designs are. The flange face surface is the area where the sealing element (gasket) is installed. Flat face flanges should not be bolted to raised face. Sealing Face Flange.

From chinesefittings.en.made-in-china.com

ANSI 150 Slip on 3.26.3ra Stock Finished Seal Face Raised Face Flange Sealing Face Flange The flange face is designed per the asme b16.5 for flanges up to 24 inches and. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Asme b16.5 and b16.47 define various. The most common flange face surface designs are. One of the key aspects of flange design is the flange. Sealing Face Flange.

From www.htpipe.com

Raised Face Flange Sealing Face S31803 SteelZhengzhou Huitong Sealing Face Flange The flange face surface is the area where the sealing element (gasket) is installed. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Flat face flanges should not be bolted to raised face flanges. Raised face flanges are available in all pressure classes and therefore. One of the key aspects of flange. Sealing Face Flange.

From www.industrimigas.com

Flange Corrosion Protection Isolating the Sealing Face IndustriMigas Sealing Face Flange The most common flange face surface designs are. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. Asme b16.5 and b16.47 define various. Flat face flanges should not be bolted to raised face flanges. The flange face is designed per the asme b16.5 for flanges up to. Sealing Face Flange.

From trianglefluid.com

Sealing Worn Flange Faces Triangle Fluid Controls Ltd. Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. The flange face surface is the area where the sealing element (gasket) is installed. The most common flange face surface designs. Sealing Face Flange.

From www.industrimigas.com

Flange Corrosion Protection Isolating the Sealing Face IndustriMigas Sealing Face Flange A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Flat face flanges should not be bolted to raised face flanges. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Different types of flange faces are used as the contact surfaces to seat the. Sealing Face Flange.

From www.htpipe.com

DIN 2527 Blind Flange Sealing Face Stainless Steel 304LZhengzhou Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. The most common flange face surface designs are. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of. Sealing Face Flange.

From www.htpipe.com

150 300 400Groove Face Blind Flange Sealing FaceZhengzhou Huitong Sealing Face Flange Asme b16.5 and b16.47 define various. Raised face flanges are available in all pressure classes and therefore. The material of the gasket seats over the flange face and creates an effective sealing under pressure. The most common flange face surface designs are. The flange face surface is the area where the sealing element (gasket) is installed. One of the key. Sealing Face Flange.

From www.industrimigas.com

Flange Corrosion Protection Isolating the Sealing Face IndustriMigas Sealing Face Flange The flange face surface is the area where the sealing element (gasket) is installed. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Raised face flanges are available in all pressure classes and therefore. The most common flange face surface designs are. A flat face flange has a sealing surface in the. Sealing Face Flange.

From www.vrogue.co

What Is Flange Face Types Of Flange Faces And Flange vrogue.co Sealing Face Flange Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Asme b16.5 and b16.47 define various. The flange face surface is the area where the sealing element (gasket) is installed. Raised face flanges are. Sealing Face Flange.

From www.youtube.com

Flange Face Types Different Types of Flange Faces as per ASME B16.5 Sealing Face Flange Asme b16.5 and b16.47 define various. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. The most common flange face surface designs are. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Different types of flange faces. Sealing Face Flange.

From www.haihaoflange.com

Selecting the right flange face finish to improve the sealing Sealing Face Flange The flange face surface is the area where the sealing element (gasket) is installed. The material of the gasket seats over the flange face and creates an effective sealing under pressure. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The flange face refers to the surface area of a. Sealing Face Flange.

From www.cndcrubber.com

Type Classification Of Flange Sealing Faces News Xinxiang City Ding Sealing Face Flange One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Asme b16.5 and b16.47 define various. The material of the gasket seats over the flange face and creates an. Sealing Face Flange.

From www.mepskills.com

Three Common Types of Pipeline Flange Faces Sealing Face Flange A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The material of the gasket seats over the flange face and creates an effective sealing under pressure. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Asme b16.5. Sealing Face Flange.

From chunhuanfzp.en.made-in-china.com

Hot Sale Expanded PTFE Full Face Flange Gasket Sealing Products China Sealing Face Flange The most common flange face surface designs are. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. The material of the gasket seats over the flange face and creates an effective sealing under pressure. One of the key aspects of flange design is the flange face, which directly affects the sealing performance. Sealing Face Flange.

From savree.com

Flange Faces Explained (Flat, Raised, etc) saVRee Sealing Face Flange The flange face is designed per the asme b16.5 for flanges up to 24 inches and. The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. Asme b16.5 and b16.47 define. Sealing Face Flange.

From trianglefluid.com

Sealing Worn Flange Faces Triangle Fluid Controls Ltd. Sealing Face Flange Asme b16.5 and b16.47 define various. A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. The material of the gasket seats over the flange face and creates an effective sealing under pressure. The most common flange face surface designs are. Different types of flange faces are used as the contact. Sealing Face Flange.

From www.weldflange.com

Proper packing methods for flanges and pipe fittings China Hebei Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. One of the key aspects of flange design is the flange face, which directly affects the sealing performance of the flange joint. Flat face flanges should. Sealing Face Flange.

From blog.enerpac.com

Guide to Flange Face Finish Types Enerpac Blog Sealing Face Flange A flat face flange has a sealing surface in the same plane as the circumferential surface of the bolt. Raised face flanges are available in all pressure classes and therefore. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Asme b16.5 and b16.47 define various. The material of the gasket seats over the. Sealing Face Flange.

From blog.thepipingmart.com

Why Is Flange Face Protection Important? Sealing Face Flange The material of the gasket seats over the flange face and creates an effective sealing under pressure. Asme b16.5 and b16.47 define various. Flat face flanges should not be bolted to raised face flanges. The flange face is designed per the asme b16.5 for flanges up to 24 inches and. Different types of flange faces are used as the contact. Sealing Face Flange.