Centrifugal Pump Rotating Impeller . Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Can a centrifugal pump handle. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. How it works, its components, design, advantages, disadvantages and applications. Learn about the rotating centrifugal pump impeller! The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point.

from www.steel-foundry.com

The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. How it works, its components, design, advantages, disadvantages and applications. Learn about the rotating centrifugal pump impeller! Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Can a centrifugal pump handle.

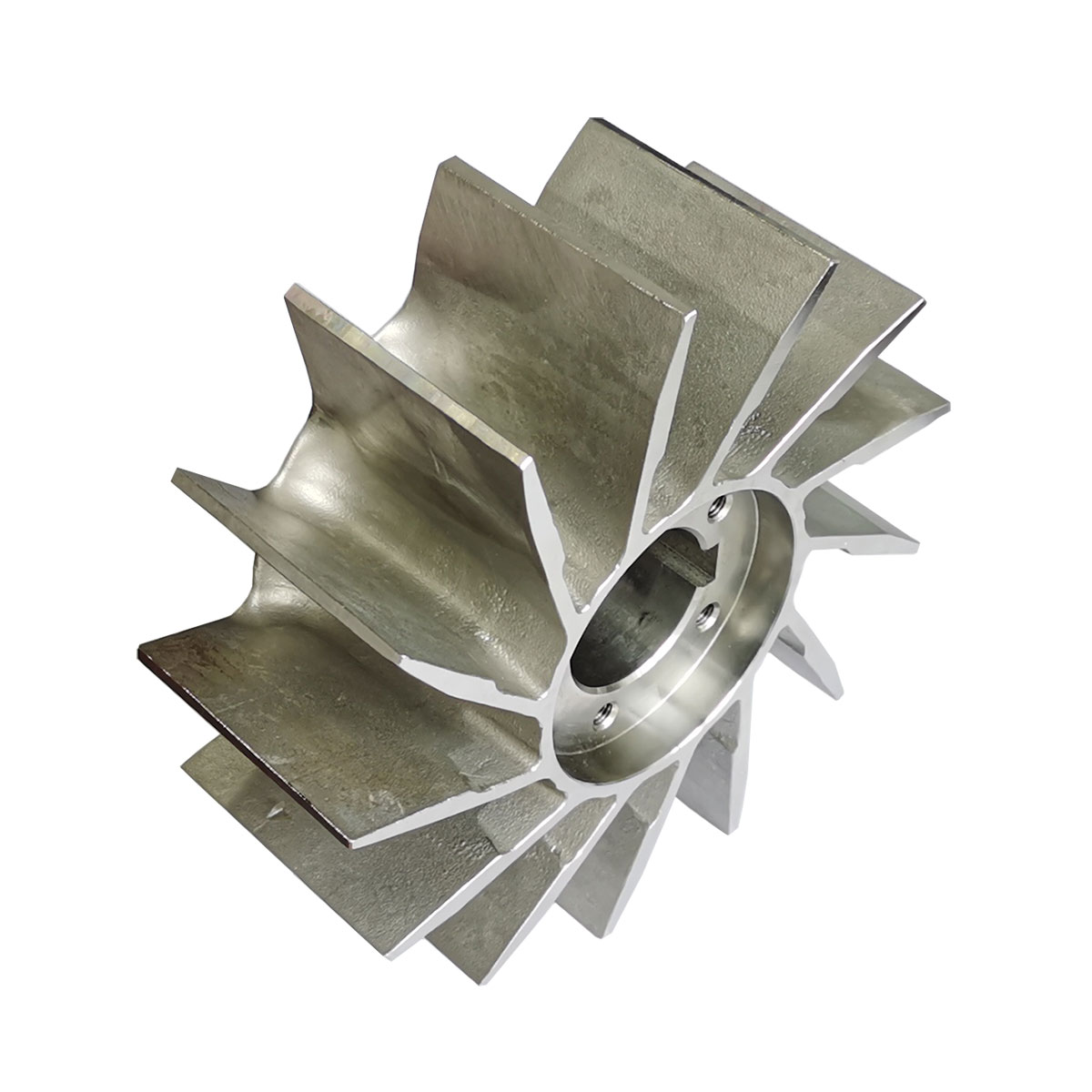

Centrifugal Pump Vane Impeller Steel Casting Factory Grey Iron

Centrifugal Pump Rotating Impeller The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Can a centrifugal pump handle. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. How it works, its components, design, advantages, disadvantages and applications. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn about the rotating centrifugal pump impeller! Impellers are the link between the power input (motor) and power output (fluid movement) of pumps.

From www.zillionsbuyer.com

What is Principle And Working Of Centrifugal Pump Zillions Buyer Centrifugal Pump Rotating Impeller Can a centrifugal pump handle. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Impellers are the link between the power input (motor) and power output (fluid movement). Centrifugal Pump Rotating Impeller.

From savree.com

Centrifugal Pump Explained saVRee Centrifugal Pump Rotating Impeller The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The impeller is the rotating component of the pump that is responsible. Centrifugal Pump Rotating Impeller.

From ph.pinterest.com

Centrifugal Physics concepts, Centrifugal pump, Engineering Centrifugal Pump Rotating Impeller Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Learn about the rotating centrifugal pump impeller! Impellers are the link between the power input. Centrifugal Pump Rotating Impeller.

From marinersgalaxy.com

Centrifugal Pump and Overhauling Centrifugal Pump marinersgalaxy Centrifugal Pump Rotating Impeller How it works, its components, design, advantages, disadvantages and applications. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Can a centrifugal pump handle. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The fluid is drawn into. Centrifugal Pump Rotating Impeller.

From anekakuncibengkel.blogspot.com

39+ Centrifugal Pump Semi Open Impeller Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! Can a centrifugal pump handle. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and.. Centrifugal Pump Rotating Impeller.

From madetechnical.blogspot.com

Centrifugal Pump Beginner Guide Centrifugal Pump Rotating Impeller The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and. Centrifugal Pump Rotating Impeller.

From www.electroniclinic.com

Centrifugal Pump Working with impeller types explained Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. How it works, its components, design, advantages, disadvantages and applications. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller,. Centrifugal Pump Rotating Impeller.

From ar.inspiredpencil.com

Centrifugal Pump Impeller Types Centrifugal Pump Rotating Impeller The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Can a centrifugal pump handle. How it works, its components, design, advantages,. Centrifugal Pump Rotating Impeller.

From www.ny-engineers.com

Main Types of Pumps Centrifugal and Positive Displacement Centrifugal Pump Rotating Impeller Can a centrifugal pump handle. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Centrifugal pump impellers work by rotating rapidly. Centrifugal Pump Rotating Impeller.

From alatdanmesinperkakas.blogspot.com

42+ Centrifugal Pump Wear Ring Centrifugal Pump Rotating Impeller Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Impellers are the link between the power input (motor) and power output. Centrifugal Pump Rotating Impeller.

From www.steel-foundry.com

Centrifugal Pump Vane Impeller Steel Casting Factory Grey Iron Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps.. Centrifugal Pump Rotating Impeller.

From www.youtube.com

Centrifugal Pump Working YouTube Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. How it works, its components, design, advantages, disadvantages and applications. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The impeller is. Centrifugal Pump Rotating Impeller.

From www.tec-science.com

How does a centrifugal pump work? tecscience Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Can a centrifugal pump handle. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump. Centrifugal Pump Rotating Impeller.

From ladybird.beauty

Centrifugal Pump Impeller Types Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! Can a centrifugal pump handle. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The fluid is drawn into centrifugal or aerodynamic pumps by a. Centrifugal Pump Rotating Impeller.

From www.youtube.com

CENTRIFUGAL PUMP IMPELLER MOVEMENT YouTube Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Learn about the rotating centrifugal pump impeller! How it works, its components, design, advantages, disadvantages and applications. The fluid. Centrifugal Pump Rotating Impeller.

From www.nuclear-power.com

Cavitation in Centrifugal Pumps Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Can a centrifugal pump handle. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and.. Centrifugal Pump Rotating Impeller.

From koharambotuo.blogspot.com

Rotating Equipment Collection CENTRIFUGAL API 610 PUMP Centrifugal Pump Rotating Impeller Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. How it works, its components, design, advantages, disadvantages and applications. Centrifugal pump impellers work by. Centrifugal Pump Rotating Impeller.

From www.indiamart.com

Stainless Steel SS Centrifugal Pump Impeller, Size/ Dimensions 90 Mm Centrifugal Pump Rotating Impeller The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being.. Centrifugal Pump Rotating Impeller.

From blog.thepipingmart.com

Overview of Centrifugal Pumps Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Can a centrifugal pump handle. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. The impeller is the rotating component of the pump that is responsible for transferring the. Centrifugal Pump Rotating Impeller.

From mungfali.com

Centrifugal Pump Impeller Design Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being.. Centrifugal Pump Rotating Impeller.

From www.youtube.com

( हिन्दी ) CENTRIFUGAL PUMP WORKING & TYPES OF IMPELLER ANUNIVERSE Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and.. Centrifugal Pump Rotating Impeller.

From ar.inspiredpencil.com

Centrifugal Pump Impeller Types Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Can a centrifugal. Centrifugal Pump Rotating Impeller.

From www.researchgate.net

Centrifugal pump components (Static and Rotor) Download Scientific Centrifugal Pump Rotating Impeller The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that. Centrifugal Pump Rotating Impeller.

From mungfali.com

Centrifugal Pump Impeller Design Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps.. Centrifugal Pump Rotating Impeller.

From bertrem.com

Centrifugal Pumps Bertrem Products Inc. Centrifugal Pump Rotating Impeller The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Can a centrifugal pump handle. Learn about the rotating centrifugal pump impeller! How it works, its components, design, advantages, disadvantages and applications. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the. Centrifugal Pump Rotating Impeller.

From www.theengineersperspectives.com

What Is A Centrifugal Pump? The Engineer's Perspective Centrifugal Pump Rotating Impeller Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Learn about the rotating centrifugal pump impeller! Impellers are the link between the power input. Centrifugal Pump Rotating Impeller.

From www.youtube.com

What are the Rotary and Stationary Parts of the Centrifugal Pump (Part Centrifugal Pump Rotating Impeller Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn about the rotating centrifugal pump impeller! Can a centrifugal pump handle. Impellers are the link. Centrifugal Pump Rotating Impeller.

From mungfali.com

Centrifugal Pump Impeller Design Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers. Centrifugal Pump Rotating Impeller.

From techblog.ctgclean.com

Pumps Centrifugal Pumps CTG Technical Blog Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Centrifugal pump impellers work by rotating rapidly within a volute casing to create pressure and flow within the liquid being. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and.. Centrifugal Pump Rotating Impeller.

From electricalworkbook.com

What is Centrifugal Pump? Working, Parts, Diagram & Types Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Can a centrifugal pump handle. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s. Centrifugal Pump Rotating Impeller.

From www.mechanicaltutorial.com

Centrifugal Pump Different Types And Application Of Centrifugal Pump Centrifugal Pump Rotating Impeller Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. Learn about the rotating centrifugal pump impeller! The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates. Centrifugal Pump Rotating Impeller.

From mungfali.com

Centrifugal Pump Impeller Design Centrifugal Pump Rotating Impeller Learn about the rotating centrifugal pump impeller! Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Centrifugal pump impellers work by rotating rapidly within a volute casing to create. Centrifugal Pump Rotating Impeller.

From www.youtube.com

Types of impellers in centrifugal pumps YouTube Centrifugal Pump Rotating Impeller How it works, its components, design, advantages, disadvantages and applications. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Can a centrifugal pump handle. The impeller is the rotating. Centrifugal Pump Rotating Impeller.

From www.youtube.com

How does a Centrifugal pump work ? YouTube Centrifugal Pump Rotating Impeller Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that uses impellers and diffusers to increase fluid kinetic and. Impellers are the link between the power input (motor) and power output (fluid movement) of pumps. Can a centrifugal pump handle. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also. Centrifugal Pump Rotating Impeller.

From cartoondealer.com

Impeller From A Centrifugal Compressor Stock Photography Centrifugal Pump Rotating Impeller The impeller is the rotating component of the pump that is responsible for transferring the energy from the motor to the. The fluid is drawn into centrifugal or aerodynamic pumps by a rotating impeller, which also accelerates the fluid’s exit from the pump’s outlet point. Learn the design and operation of centrifugal pumps, a common type of rotodynamic pump that. Centrifugal Pump Rotating Impeller.