What Is The Typical Design Burst Pressure For A Rupture Disk . “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. The tolerance associated with the marked burst pressure within which the disc is expected to burst. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure.

from www.idealspectroscopy.com

“the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. The tolerance associated with the marked burst pressure within which the disc is expected to burst. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure.

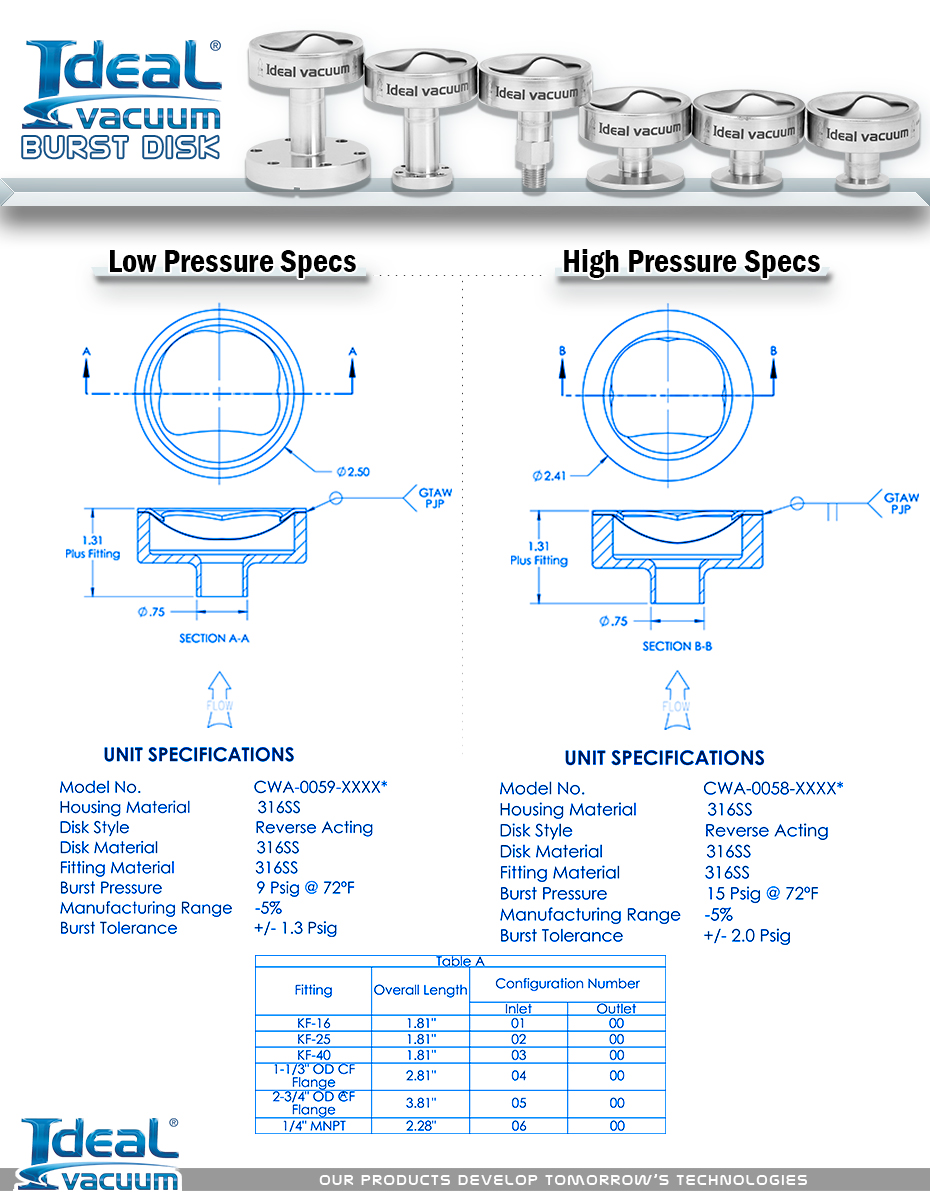

Ideal Spectroscopy Burst Disk CF 1.33 Inches Flange, Ultra High

What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. The tolerance associated with the marked burst pressure within which the disc is expected to burst. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular.

From blog.zookdisk.com

Double Rupture Disk Assembly is a Great Solution for Severe Process What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for. What Is The Typical Design Burst Pressure For A Rupture Disk.

From chemicalengineeringworld.com

Rupture Disks Function Chemical Engineering World What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.slideshare.net

Rupture Disc Burst Rating Types What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.scribd.com

NB18 Specification of Rupture Disk Burst Pressure Temperature What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. To find the maximum allowable specified burst pressure, the process engineer first needs to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From mechasource.blogspot.com

Rupture Discs introduction and study What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. To find the maximum allowable specified burst pressure, the process engineer. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.pinterest.com

We are proud to offer Pressure Burst Discs from Allectra! Allectra What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. When sizing pressure relief devices,. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.youtube.com

Installation and test of burst (rupture) disks for vacuum systems What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. The tolerance associated with the marked burst pressure within which the disc is expected to burst. When sizing pressure relief devices, the code defines. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.plantautomation-technology.com

MRB High Pressure Rupture Disk (Bursting Disc) Industrial Valves BS What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From staging-osecoelfab.webflow.io

What happens when a rupture disc bursts? Forward acting discs What Is The Typical Design Burst Pressure For A Rupture Disk It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum. What Is The Typical Design Burst Pressure For A Rupture Disk.

From whatispiping.com

Rupture Disc Definition, Types, Components, Selection, Sizing What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers. What Is The Typical Design Burst Pressure For A Rupture Disk.

From kara-consulting.nl

Rupture Disks Kara Consulting What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. The tolerance associated with the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.idealspectroscopy.com

Ideal Spectroscopy Burst Disk CF 1.33 Inches Flange, Ultra High What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. It is important to work closely with the rupture disk manufacturer at. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.slideshare.net

Rupture Disks for Process Engineers What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. It. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.idealspectroscopy.com

Ideal Spectroscopy Burst Disk CF 2.75 inches Flange, Ultra High What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. The tolerance associated with the marked burst pressure within which the disc is expected to burst. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure,. What Is The Typical Design Burst Pressure For A Rupture Disk.

From instrumentationtools.com

Why is a Rupture Disc required? Functions & Selections What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.electricalvolt.com

Rupture DISK Its Working, Specifications, benefits & Usage What Is The Typical Design Burst Pressure For A Rupture Disk To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. The tolerance associated with the marked burst pressure within which the disc is expected to burst. It is. What Is The Typical Design Burst Pressure For A Rupture Disk.

From whatispiping.com

Rupture Disc Definition, Types, Components, Selection, Sizing What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. When sizing pressure relief devices,. What Is The Typical Design Burst Pressure For A Rupture Disk.

From mechasource.blogspot.com

Rupture Discs introduction and study What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. The tolerance associated with the marked burst pressure within which the disc is expected to burst. When sizing. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.researchgate.net

Scored TensionLoaded Rupture Disk (Courtesy of API, from API RP 520 I What Is The Typical Design Burst Pressure For A Rupture Disk To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From whatispiping.com

Rupture Disc Definition, Types, Components, Selection, Sizing What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. It is important to work closely with the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.youtube.com

What is Rupture Disk Working Principle? YouTube What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. The tolerance associated with the marked burst pressure within which the disc is expected to burst. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. “the manufacturing design range is a range of. What Is The Typical Design Burst Pressure For A Rupture Disk.

From inchbyinch.de

INCH Technical English rupture disc What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. “the manufacturing design range is. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk The tolerance associated with the marked burst pressure within which the disc is expected to burst. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From calculator.academy

Rupture Disk Burst Pressure Calculator Calculator Academy What Is The Typical Design Burst Pressure For A Rupture Disk It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. Asme refers to marked burst pressure and ce/ped refers to minimum. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk Asme refers to marked burst pressure and ce/ped refers to minimum burst pressure. The tolerance associated with the marked burst pressure within which the disc is expected to burst. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work closely with the rupture disk manufacturer at. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.measurement-solutions.com

RUPTURE DISCS (Bursting Discs) Australian Agent for CDC and LaMOT What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. The tolerance associated with the marked burst pressure within which the disc is expected to burst. When sizing. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.contdisc.com

Mintrx Rupture Disc Operate at 90 Rated Burst Pressure What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From dokumen.tips

(PDF) RUPTURE DISK STANDARD BODY DESIGNS MPIRUPTURE DISK with BURST What Is The Typical Design Burst Pressure For A Rupture Disk It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. The tolerance associated with the marked burst pressure within which the disc is expected to burst. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.mdpi.com

Processes Free FullText Influence of Moulding Pressure on the What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. The tolerance associated with the marked burst pressure within which the. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.zeusfilter.com

Over pressure burst disc/ rupture disk & explosion panel/ bursting What Is The Typical Design Burst Pressure For A Rupture Disk “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. To find the maximum allowable specified burst pressure, the process engineer first needs to define a vessel design pressure. It is important to work closely with the rupture disk manufacturer at the end of this process to. What Is The Typical Design Burst Pressure For A Rupture Disk.

From www.researchgate.net

Conventional Rupture Disk (Courtesy of API, from API RP 520 I What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. “the manufacturing design range is a range of pressure within which the marked burst pressure must fall to be acceptable for a particular. It is important to work closely with the rupture disk manufacturer at the end. What Is The Typical Design Burst Pressure For A Rupture Disk.

From blog.zookdisk.com

The Perfect Combination A Rupture Disk with a Safety Valve Blog What Is The Typical Design Burst Pressure For A Rupture Disk When sizing pressure relief devices, the code defines the maximum pressure that may build up in the pressure vessel while the device is. It is important to work closely with the rupture disk manufacturer at the end of this process to achieve the best results before making the final. The tolerance associated with the marked burst pressure within which the. What Is The Typical Design Burst Pressure For A Rupture Disk.