Air Gauge Vs Bore Gauge . Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. The physics of the process produces a sweet spot for range and performance. The air tooling has no moving parts and therefore has a very long and dependable service life. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. Air gaging is a comparative, short range, high magnification measuring system. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. Should one use an air gage or a dial bore gage? Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. As clearance increases, air flow also. When it comes to precision measurement in the manufacturing industry, a common debate often arises:

from precisecalibration.in

As clearance increases, air flow also. Air gaging is a comparative, short range, high magnification measuring system. Should one use an air gage or a dial bore gage? Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. When it comes to precision measurement in the manufacturing industry, a common debate often arises: The physics of the process produces a sweet spot for range and performance. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. The air tooling has no moving parts and therefore has a very long and dependable service life.

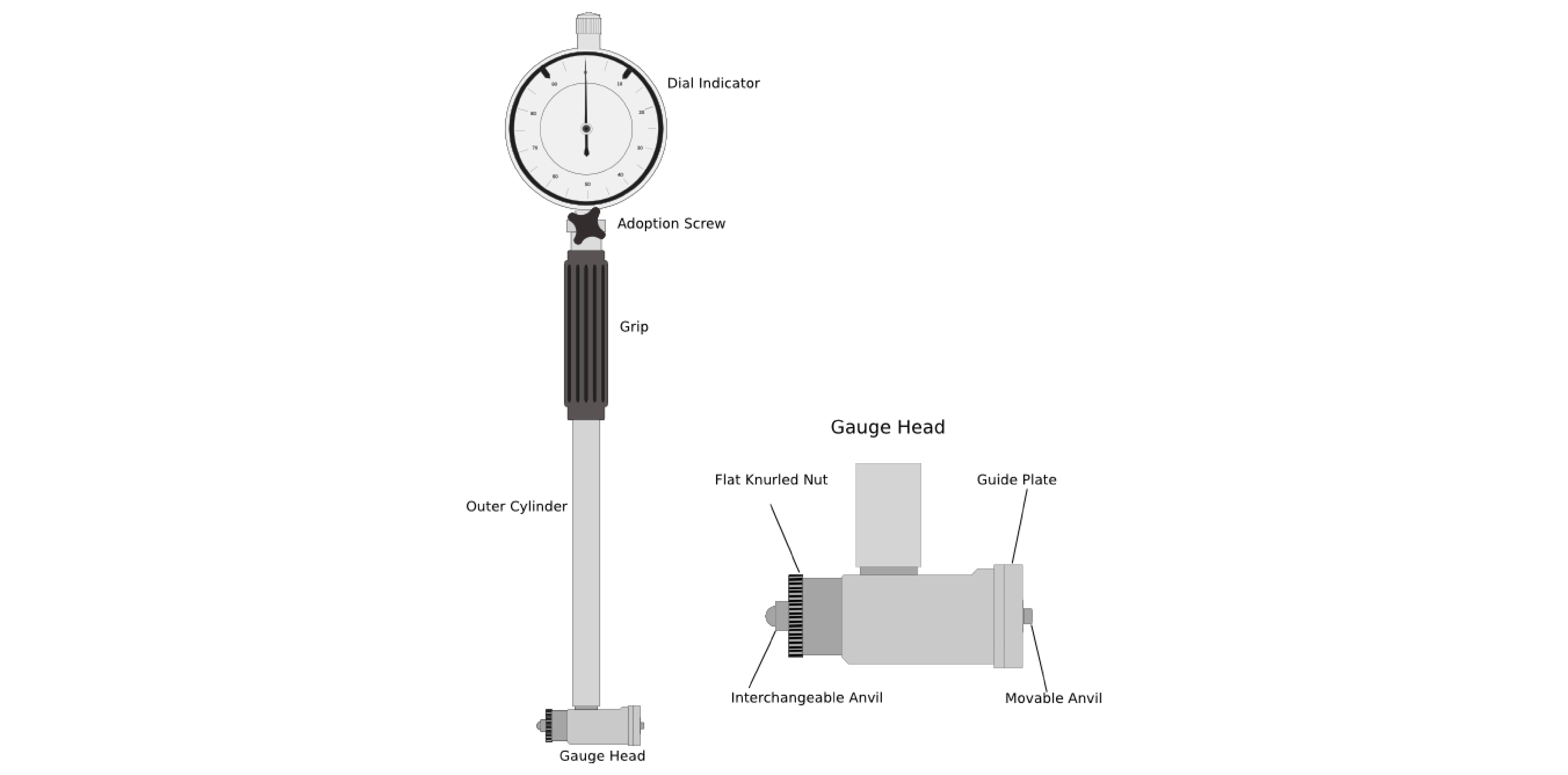

BoreGauge

Air Gauge Vs Bore Gauge Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. The physics of the process produces a sweet spot for range and performance. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. When it comes to precision measurement in the manufacturing industry, a common debate often arises: The air tooling has no moving parts and therefore has a very long and dependable service life. As clearance increases, air flow also. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. Should one use an air gage or a dial bore gage? Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. Air gaging is a comparative, short range, high magnification measuring system. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use.

From www.ammunitiontogo.com

28 Gauge vs 410 Bore Small Shotgun Showdown Air Gauge Vs Bore Gauge Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air gaging is a comparative, short range, high magnification measuring system. The air tooling has no moving parts and therefore has a very long and dependable service life. Air gaging systems operate at air pressures that. Air Gauge Vs Bore Gauge.

From www.ramsagauges.com.mx

BORE GAUGE Ramsa Air Gauge Vs Bore Gauge Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air gaging is a comparative, short range, high magnification measuring system. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. The flexibility of air gaging means it. Air Gauge Vs Bore Gauge.

From precisecalibration.in

BoreGauge Air Gauge Vs Bore Gauge Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure. Air Gauge Vs Bore Gauge.

From www.indiamart.com

1835 0.01mm Dial Bore Gauge at Rs 5500/piece in Chennai ID 21590018748 Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air gaging is a comparative, short range, high magnification measuring system. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air does not have the versatility of a micrometer, but it is. Air Gauge Vs Bore Gauge.

From www.practicalmachinist.com

Sunnen Dial Bore Gages F/S Air Gauge Vs Bore Gauge The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. When it comes to precision measurement in the manufacturing industry, a common debate often arises: The physics of the process produces a sweet spot for range and performance. Air gaging is a comparative, short. Air Gauge Vs Bore Gauge.

From www.indiamart.com

Stainless Steel 3 Point Bore Gauge Vs Air Gauge at Rs 1125/piece in Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling.. Air Gauge Vs Bore Gauge.

From precisecalibration.in

BoreGauge Air Gauge Vs Bore Gauge The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. The air tooling has no moving parts and therefore has. Air Gauge Vs Bore Gauge.

From www.desertcart.ae

Buy Accusize Industrial Tools Dial Bore Gauge Set, 1.46 inch Measuring Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Should one use an air gage or a dial bore gage? When it comes to precision measurement in the manufacturing industry, a common debate often arises: Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of. Air Gauge Vs Bore Gauge.

From ammo.com

16ga vs 12ga Shotgun Gauge Comparison by Experts at Air Gauge Vs Bore Gauge Should one use an air gage or a dial bore gage? The air tooling has no moving parts and therefore has a very long and dependable service life. Air gaging is a comparative, short range, high magnification measuring system. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. The flexibility of. Air Gauge Vs Bore Gauge.

From alchetron.com

Bore gauge Alchetron, The Free Social Encyclopedia Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for. Air Gauge Vs Bore Gauge.

From jinyiboyiqi.en.made-in-china.com

Air Bore Gauge, Digital Air Gauge Unit Air Micrometer and Electronic Air Gauge Vs Bore Gauge To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. As clearance increases, air flow also. Should one use an air gage or a dial bore gage? Air does not have the versatility of a micrometer, but it is faster, more accurate. Air Gauge Vs Bore Gauge.

From precisecalibration.in

BoreGauge Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on. Air Gauge Vs Bore Gauge.

From www.survivalistboards.com

20g vs.12g..thoughts? Survivalist Forum Air Gauge Vs Bore Gauge The air tooling has no moving parts and therefore has a very long and dependable service life. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on. Air Gauge Vs Bore Gauge.

From accud.com.au

Dial Bore Gauges Accud Australia Air Gauge Vs Bore Gauge Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. To achieve this measurement, it relies on the laws of physics, which. Air Gauge Vs Bore Gauge.

From www.practicalmachinist.com

Sunnen Dial Bore Gages F/S Air Gauge Vs Bore Gauge The air tooling has no moving parts and therefore has a very long and dependable service life. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. Air gaging is a comparative, short range, high magnification measuring system. Air does not have the versatility. Air Gauge Vs Bore Gauge.

From www.youtube.com

BORE GAUGE को USE करना सीखें BY GOPAL SIR । रहना फ्री viral bore Air Gauge Vs Bore Gauge When it comes to precision measurement in the manufacturing industry, a common debate often arises: The air tooling has no moving parts and therefore has a very long and dependable service life. As clearance increases, air flow also. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. To achieve this measurement,. Air Gauge Vs Bore Gauge.

From www.walmart.com

Dial Bore Gauge Set 1.4"6" with case Air Gauge Vs Bore Gauge Air gaging is a comparative, short range, high magnification measuring system. When it comes to precision measurement in the manufacturing industry, a common debate often arises: Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. Air gaging is a technology. Air Gauge Vs Bore Gauge.

From sheffieldmetals.com

24Gauge vs. 26Gauge Metal Roofing Which Is Better for Your Project Air Gauge Vs Bore Gauge The air tooling has no moving parts and therefore has a very long and dependable service life. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. When it comes to precision measurement in the manufacturing industry, a common debate often arises: Both air gages and. Air Gauge Vs Bore Gauge.

From www.indiamart.com

Digital Air Gauge at Rs 290000 Digital Air Gauge in Pune ID Air Gauge Vs Bore Gauge Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The air tooling has no moving parts and therefore has a very long and dependable service life. Should one use. Air Gauge Vs Bore Gauge.

From eatingthewild.com

16 Gauge vs 12 Gauge What’s the Difference Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air gaging is a comparative, short range, high magnification measuring system. When it comes to precision measurement in the manufacturing industry, a common debate often arises: Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. To achieve this. Air Gauge Vs Bore Gauge.

From www.sisco.com

50160mm Dial Bore Gauge, 0.01mm Air Gauge Vs Bore Gauge When it comes to precision measurement in the manufacturing industry, a common debate often arises: Air gaging is a comparative, short range, high magnification measuring system. Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. Air gaging is a technology that employs the use of air flow volumes and air pressure. Air Gauge Vs Bore Gauge.

From hupshenghardware.com

Insize 285210 Bore Gauge for Small Hole with Dial Indicator, 610mm Air Gauge Vs Bore Gauge Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. When it comes to precision measurement in the manufacturing industry, a common debate often arises: Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. As clearance. Air Gauge Vs Bore Gauge.

From www.indiamart.com

10 Meter Stainless Steel Digital Bore Gauge at Rs 10395/piece in Air Gauge Vs Bore Gauge Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. The flexibility of air gaging means it can be used to measure flatness, roundness, squareness, taper, straightness and matching between pairs of joined surfaces, on connector. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and. Air Gauge Vs Bore Gauge.

From www.recoilweb.com

12Gauge vs 20Gauge Shotguns Does Size Matter? RECOIL Air Gauge Vs Bore Gauge Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The air tooling has no moving parts and therefore has a very long and dependable service life. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. Air gaging. Air Gauge Vs Bore Gauge.

From www.youtube.com

DYNAMIC Gauges VS ADVANCED Gauges! (Greenville) YouTube Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. The air tooling has no moving. Air Gauge Vs Bore Gauge.

From www.desertcart.ie

Buy Bonvoisin Hotwire Anemometer Handheld CFM/CMM Air Flow Velocity Air Gauge Vs Bore Gauge To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. When it comes to precision measurement in the manufacturing industry,. Air Gauge Vs Bore Gauge.

From www.indiamart.com

Digital Bore Gauge at Rs 5000/piece Bore Gauge ID 14804885448 Air Gauge Vs Bore Gauge Air gaging is a comparative, short range, high magnification measuring system. Should one use an air gage or a dial bore gage? When it comes to precision measurement in the manufacturing industry, a common debate often arises: Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. To achieve this measurement, it. Air Gauge Vs Bore Gauge.

From www.youtube.com

How to Use Bore Gauge in Hindi ! How to Use Bore Gauge Lever Type l Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to each other. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will. Air Gauge Vs Bore Gauge.

From anthropology.iresearchnet.com

Thickness Detection Tool 50160X0.01 mm Inner Diameter Gauge Measuring Air Gauge Vs Bore Gauge As clearance increases, air flow also. The physics of the process produces a sweet spot for range and performance. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Should one use an air gage or a dial bore gage? When it comes to precision measurement. Air Gauge Vs Bore Gauge.

From www.practicalmachinist.com

Sunnen Dial Bore Gages F/S Air Gauge Vs Bore Gauge Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. As clearance increases, air flow also. Both air gages and bore gages are precise types of instruments to measure internal dimensions such as a bore or inside diameter. The flexibility of. Air Gauge Vs Bore Gauge.

From www.youtube.com

Bore gauge !How to use bore gauge ! Bore gauge kaise check kare ! Bore Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air gaging is a. Air Gauge Vs Bore Gauge.

From www.allendale-metrology.co.uk

10 to 18mm Dial Bore gauge allendalemetrology.co.uk Allendale Air Gauge Vs Bore Gauge The physics of the process produces a sweet spot for range and performance. Air gaging is a technology that employs the use of air flow volumes and air pressure to determine the size of measured part dimensions. Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. Air gaging is a. Air Gauge Vs Bore Gauge.

From www.themeateater.com

12 Gauge vs. 20 Gauge Understanding Shotgun Gauges MeatEater Hunting Air Gauge Vs Bore Gauge Since you need a specific set of tools to perform boring operations, hole measurement also requires specific tooling. The air tooling has no moving parts and therefore has a very long and dependable service life. The physics of the process produces a sweet spot for range and performance. Air does not have the versatility of a micrometer, but it is. Air Gauge Vs Bore Gauge.

From repairfixindijanacaq.z22.web.core.windows.net

410 Bore Vs 410 Gauge Air Gauge Vs Bore Gauge When it comes to precision measurement in the manufacturing industry, a common debate often arises: Air does not have the versatility of a micrometer, but it is faster, more accurate and easier to use. To achieve this measurement, it relies on the laws of physics, which state that flow and pressure are directly proportionate to clearance and react inversely to. Air Gauge Vs Bore Gauge.

From www.indiamart.com

Air Gauge Unit at Rs 19500 Air Gauge Unit in Satara ID 23346733533 Air Gauge Vs Bore Gauge Should one use an air gage or a dial bore gage? Air gaging is a comparative, short range, high magnification measuring system. Air gaging systems operate at air pressures that can remove contaminates such as abrasive particles and coolant, which will eliminate the need for a separate cleaning in most applications. When it comes to precision measurement in the manufacturing. Air Gauge Vs Bore Gauge.