Headspace Oxygen Measurement . Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. If necessary or of interest,. Initial headspace is 1 atm of air (20.9% oxygen). Produce empty stoppered & crimped vials with the process.

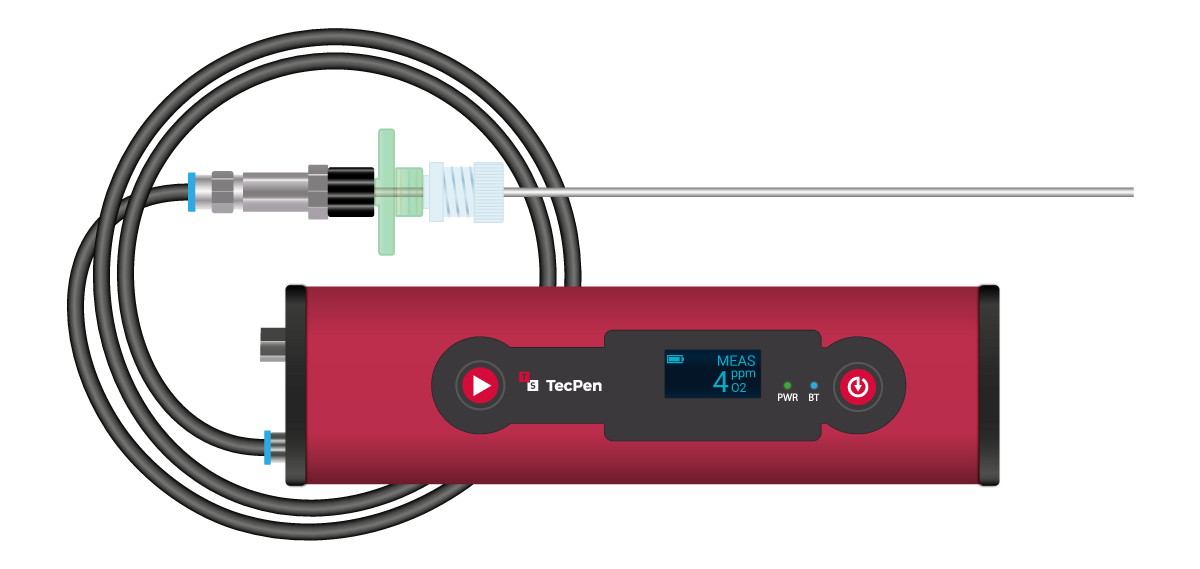

from techotrix.com.au

Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. If necessary or of interest,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately.

Laboratory Headspace Oxygen Measurement Techotrix

Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Produce empty stoppered & crimped vials with the process. Initial headspace is 1 atm of air (20.9% oxygen). High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. If necessary or of interest,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability.

From www.youtube.com

Headspace Oxygen Analyzer YouTube Headspace Oxygen Measurement Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. If necessary or of interest,. Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace oxygen levels are consistently low. Headspace Oxygen Measurement.

From www.mdpi.com

Sensors Free FullText The Development of a Novel Headspace O2 Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Initial headspace is 1 atm of air (20.9% oxygen). If necessary or of interest,. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered. Headspace Oxygen Measurement.

From typeset.io

(Open Access) Headspace Oxygen Concentration Measurement for Headspace Oxygen Measurement If necessary or of interest,. Initial headspace is 1 atm of air (20.9% oxygen). Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. A wide. Headspace Oxygen Measurement.

From jiuyinchengdu.en.made-in-china.com

Map Package Check Portable Headspace Gas Oxygen CO2 Nitrogen Analyzer Headspace Oxygen Measurement Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Produce empty stoppered & crimped vials with the process. A wide variety of techniques can be employed to verify that. Headspace Oxygen Measurement.

From www.thelabworldgroup.com

Quantek Instruments 905 Headspace Oxygen Analyzer Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. If necessary or of interest,. Using. Headspace Oxygen Measurement.

From www.labthinkinstruments.com

Headspace Oxygen Measurement for Food Packages Manufacturer at Best Price Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Produce empty stoppered & crimped vials with the process.. Headspace Oxygen Measurement.

From www.researchgate.net

Headspace oxygen concentrations, biomass measurements and transcript Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). If necessary or of interest,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. A wide variety of techniques can be employed to. Headspace Oxygen Measurement.

From www.giveandtech.fr

Give and Tech Produits > Headspace oxygen analysis Headspace Oxygen Measurement Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. If necessary or of interest,. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. A wide variety of techniques can be employed to verify that a leak is present and to identify its location.. Headspace Oxygen Measurement.

From www.mdpi.com

Sensors Free FullText The Development of a Novel Headspace O2 Headspace Oxygen Measurement Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. If necessary or of interest,. Initial headspace. Headspace Oxygen Measurement.

From www.pharmaceutical-networking.com

IV Bag Headspace Oxygen Measurements Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Using a fast and robust oxygen monitoring method significantly streamlines. Headspace Oxygen Measurement.

From serrax.in

Oxygen Headspace MAP Analyzer Serrax Technologies Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. Initial headspace is 1 atm of air (20.9% oxygen). High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. A wide variety of techniques can be employed to verify. Headspace Oxygen Measurement.

From www.youtube.com

Quick Operation Procedure of Headspace Oxygen Analyser HA One Plus by Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Produce empty stoppered & crimped vials. Headspace Oxygen Measurement.

From testinstruments.net.au

Quantek 905 Headspace Oxygen Analyser Test Instruments Headspace Oxygen Measurement If necessary or of interest,. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can. Headspace Oxygen Measurement.

From typeset.io

(Open Access) Headspace Oxygen Concentration Measurement for Headspace Oxygen Measurement If necessary or of interest,. Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as. Headspace Oxygen Measurement.

From techotrix.com.au

Laboratory Headspace Oxygen Measurement Archives Techotrix Headspace Oxygen Measurement Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Produce empty stoppered & crimped vials with the process. Ensuring that headspace oxygen levels are consistently low becomes crucial for. Headspace Oxygen Measurement.

From www.instrumentsservice.com

Oxygen Analyzer Headspace Oxygen Analyser Manufacturer from Coimbatore Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Initial headspace is 1 atm of air (20.9% oxygen). Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. A. Headspace Oxygen Measurement.

From www.thelabworldgroup.com

Quantek Instruments 905 Headspace Oxygen Analyzer Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Initial headspace is 1 atm of air (20.9% oxygen). Produce empty stoppered & crimped vials with the process. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace. Headspace Oxygen Measurement.

From www.mdpi.com

Sensors Free FullText The Development of a Novel Headspace O2 Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Produce empty stoppered & crimped vials with the process. Initial headspace is 1 atm of air (20.9% oxygen). Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Using a fast and robust oxygen monitoring method significantly streamlines. Headspace Oxygen Measurement.

From serrax.in

Headspace Oxygen Analyzer MAP550 Serrax Technologies Headspace Oxygen Measurement If necessary or of interest,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts. Headspace Oxygen Measurement.

From packagingguruji.com

Fast & accurate the headspace oxygen measurement device by Gasporox Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. If necessary or of interest,. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Intuitively, oxygen headspace analysis can be used. Headspace Oxygen Measurement.

From us.vinventions.com

System to measure headspace oxygen for TPO control at wine bottling Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. High sensitivity for headspace oxygen was demonstrated, allowing for. Headspace Oxygen Measurement.

From www.quantekinstruments.com

Model 901 Headspace Oxygen Analyzer Quantek Instruments Headspace Oxygen Measurement Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Initial. Headspace Oxygen Measurement.

From labstuff.eu

labstuff.eu Orbisphere 3650 Pharmaceutical package headspace oxygen Headspace Oxygen Measurement If necessary or of interest,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Produce empty stoppered & crimped vials with the process. Intuitively, oxygen headspace analysis can be used to detect. Headspace Oxygen Measurement.

From www.rycobel.com

Oxygen and carbon dioxide headspace gas analyzer GS6000 Rycobel Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). A wide variety of techniques can be employed to verify that a leak is present and to identify its location. If necessary or of interest,. Produce empty stoppered & crimped vials with the process. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling. Headspace Oxygen Measurement.

From www.indiamart.com

Headspace Oxygen Analyzer at Rs 265000/piece Headspace Analyzer in Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). Produce empty stoppered & crimped vials with the process. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can be used to detect. Headspace Oxygen Measurement.

From www.thelabworldgroup.com

Quantek Instruments 905 Headspace Oxygen Analyzer Headspace Oxygen Measurement Initial headspace is 1 atm of air (20.9% oxygen). Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. A wide variety of techniques can be employed to verify that a leak is. Headspace Oxygen Measurement.

From dokumen.tips

(PDF) Headspace Gas Analysis · 2020. 2. 22. · measurement of container Headspace Oxygen Measurement High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. If necessary or of interest,. Produce empty stoppered & crimped vials with the process. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can be used to detect. Headspace Oxygen Measurement.

From www.youtube.com

coffee capsule headspace oxygen analysis with LEGEND O2 YouTube Headspace Oxygen Measurement Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Intuitively, oxygen headspace analysis can be used to detect a leak in containers that starts with an altered headspace (e.g., purged vials,. Produce empty stoppered & crimped vials with. Headspace Oxygen Measurement.

From www.packagetestingequipment.com

Electronic Oxygen Headspace Analyzer , Oxygen And Carbon Dioxide Headspace Oxygen Measurement If necessary or of interest,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Using a fast. Headspace Oxygen Measurement.

From www.mdpi.com

Sensors Free FullText The Development of a Novel Headspace O2 Headspace Oxygen Measurement If necessary or of interest,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Initial headspace is 1 atm of air (20.9% oxygen). High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Produce empty stoppered & crimped vials with the process.. Headspace Oxygen Measurement.

From www.indiamart.com

UNIPHOS Portable Headspace Oxygen & CO2 Analyzer, 230 V, Model Name Headspace Oxygen Measurement If necessary or of interest,. Produce empty stoppered & crimped vials with the process. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Ensuring that headspace oxygen levels are consistently. Headspace Oxygen Measurement.

From www.indiamart.com

Headspace Oxygen Analyzer at Rs 180000/piece O2 Analyzer, O2 Monitor Headspace Oxygen Measurement A wide variety of techniques can be employed to verify that a leak is present and to identify its location. Initial headspace is 1 atm of air (20.9% oxygen). Produce empty stoppered & crimped vials with the process. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can be used to detect. Headspace Oxygen Measurement.

From testinstruments.net.au

Quantek 901 Portable O2 Analyzer Test Instruments Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. If necessary or of interest,. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Initial headspace is 1 atm of air (20.9% oxygen). Intuitively, oxygen headspace analysis can be. Headspace Oxygen Measurement.

From www.scribd.com

Headspace Oxygen Measurement in Vials and Ampoules PDF Sensor Oxygen Headspace Oxygen Measurement If necessary or of interest,. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Using a fast and robust oxygen monitoring method significantly streamlines the characterization, optimization, and validation of filling lines. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can. Headspace Oxygen Measurement.

From techotrix.com.au

Laboratory Headspace Oxygen Measurement Techotrix Headspace Oxygen Measurement Produce empty stoppered & crimped vials with the process. High sensitivity for headspace oxygen was demonstrated, allowing for levels of oxygen as low as 0.03% to be accurately. Initial headspace is 1 atm of air (20.9% oxygen). If necessary or of interest,. Ensuring that headspace oxygen levels are consistently low becomes crucial for product stability. Intuitively, oxygen headspace analysis can. Headspace Oxygen Measurement.