Shielding Gas Helium Welding . Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. If you want a general shielding gas for tig welding, most welders will use 100% ar. When used as a shielding gas in gas tungsten arc welding or tig. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases.

from www.open.edu

When used as a shielding gas in gas tungsten arc welding or tig. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for tig welding, most welders will use 100% ar. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process.

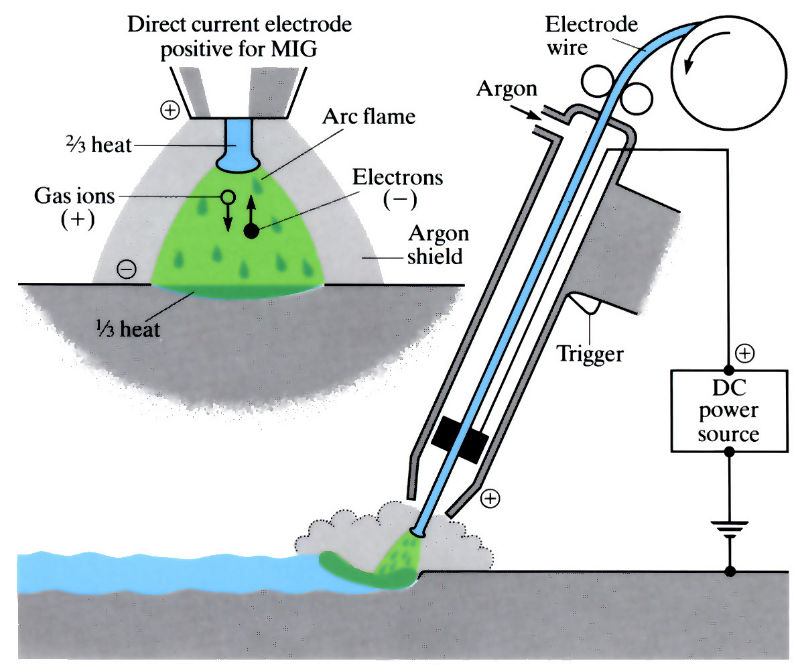

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open

Shielding Gas Helium Welding One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you want a general shielding gas for tig welding, most welders will use 100% ar. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. When used as a shielding gas in gas tungsten arc welding or tig. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix.

From www.schuettemetals.com

Fab Times What is the Best Shielding Gas for Welding and Their Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. When used as a shielding gas in gas tungsten arc welding or tig. If you want a general shielding gas for tig welding, most welders will use 100% ar. But, if you need to modify the arc characteristics to achieve better. Shielding Gas Helium Welding.

From www.researchgate.net

Laser welding with helium as a bottomshielding gas. (a) Variations in Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. One of. Shielding Gas Helium Welding.

From yeswelder.com

Tig Welding Shielding Gas Overview |YesWelder Shielding Gas Helium Welding The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on. Shielding Gas Helium Welding.

From wiscoonline.com

Industrial Gases Welding Gas, Shielding Gas, Compressed Gas Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. If you want a general shielding gas for tig welding, most welders will use 100% ar. When used as a shielding gas in gas tungsten arc welding or tig. The three most common shielding gas options for. Shielding Gas Helium Welding.

From www.youtube.com

Differences between Gas Shielding and Flux Shielding for Arc Welding Shielding Gas Helium Welding One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. If you want a general shielding gas for tig welding, most welders will use 100% ar. When used as a shielding gas in gas tungsten arc welding or tig. Perhaps the biggest hope for welders looking to live. Shielding Gas Helium Welding.

From hongyundagas.en.made-in-china.com

Superconducting Shielding Gas in Welding Processes Gas Helium Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to. Shielding Gas Helium Welding.

From sigvn.com

How to Choose Shielding Gas in Welding Technology Khí công nghiệp Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. Shielding gas is an essential. Shielding Gas Helium Welding.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests. Shielding Gas Helium Welding.

From ronsonstorch.com

Selecting the Right Shielding Gas For Your Welding Process RonSon’s Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. One of the main benefits of using helium in welding is its ability to augment penetration and heat. Shielding Gas Helium Welding.

From yeswelder.com

Welding Shielding Gas Overview YesWelder Shielding Gas Helium Welding The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the. Shielding Gas Helium Welding.

From www.gascylindertank.com

Cool Gas for superconducting and shielding gas in welding Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for tig welding, most welders will use 100% ar. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. The three. Shielding Gas Helium Welding.

From shcmc123.en.made-in-china.com

Superconducting and Shielding Gas in Welding Processes Gas Shielding Gas Helium Welding One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. When used as a shielding gas in gas tungsten arc welding or tig. In some. Shielding Gas Helium Welding.

From fitwelding.com

What is Shielding Gas & How does it work? Fit Welding Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. But, if you need to modify the arc characteristics to achieve better penetration or oxide. Shielding Gas Helium Welding.

From www.fabricatingandmetalworking.com

How Shielding Gas Affects Filler Metal Performance Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. The three. Shielding Gas Helium Welding.

From yeswelder.com

Tig Welding Shielding Gas Overview |YesWelder Shielding Gas Helium Welding When used as a shielding gas in gas tungsten arc welding or tig. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for. Shielding Gas Helium Welding.

From weldingvalue.com

What Shielding Gas for TIG Welding? Welding Value Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an. Shielding Gas Helium Welding.

From www.hobartbrothers.com

Welding Procedures Shielding Gases Used For MIG And TIG Welding Shielding Gas Helium Welding When used as a shielding gas in gas tungsten arc welding or tig. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. But, if. Shielding Gas Helium Welding.

From welderplanet.com

Shielding Gas In Welding Welder Shielding Gas Helium Welding If you want a general shielding gas for tig welding, most welders will use 100% ar. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the process. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. Shielding gas. Shielding Gas Helium Welding.

From www.tws.edu

What's Welding Shielding Gases & Why are They Important? TWS Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for tig welding, most welders will use 100% ar. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. Perhaps the biggest hope for welders looking to live. Shielding Gas Helium Welding.

From tooliom.com

Shielding Gas For TIG Welding Tooliom Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. When used as a shielding gas in gas tungsten arc welding or tig. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding process, serving to. Shielding Gas Helium Welding.

From www.wcwelding.com

Shielding Gas Guide Shielding Gas Helium Welding When used as a shielding gas in gas tungsten arc welding or tig. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for tig welding, most welders will use 100% ar. The three most common shielding gas options for gtaw are 100 percent. Shielding Gas Helium Welding.

From weldingpros.net

MIG Welding With Helium Shielding Gas Shielding Gas Helium Welding The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire. Shielding Gas Helium Welding.

From weldingpros.net

MIG Welding With Helium Shielding Gas Shielding Gas Helium Welding Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. When used as a shielding gas in gas tungsten arc welding or tig. One of the main benefits of using helium in welding is its ability to augment penetration and heat input during the. Shielding Gas Helium Welding.

From weldingvalue.com

What Shielding Gas for TIG Welding? Welding Value Shielding Gas Helium Welding If you want a general shielding gas for tig welding, most welders will use 100% ar. When used as a shielding gas in gas tungsten arc welding or tig. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. In some applications, hydrogen or nitrogen is added to a mixture with one or two. Shielding Gas Helium Welding.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. When used as a shielding gas in gas tungsten arc welding. Shielding Gas Helium Welding.

From www.digitaljournal.com

Welding Gas and Shielding Gas Market 2023 Competitive Insights The Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. One of the main benefits of using helium in welding is its ability to augment penetration and heat. Shielding Gas Helium Welding.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you want a general shielding gas for tig welding, most welders will use 100% ar. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. The three most common shielding. Shielding Gas Helium Welding.

From www.slideserve.com

PPT TIG Welding Introduction PowerPoint Presentation, free download Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you want a general shielding gas for tig welding, most welders will use 100% ar. When used as a shielding. Shielding Gas Helium Welding.

From weldingpros.net

MIG Welding With Helium Shielding Gas Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. But, if you need to modify the arc characteristics to achieve. Shielding Gas Helium Welding.

From www.researchgate.net

Timeresolved images of the weld performed using a shielding gas Shielding Gas Helium Welding In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you. Shielding Gas Helium Welding.

From sea.itwwelding.com

ITW Welding Singapore Shielding Gas and Welding Filler Metal Performance Shielding Gas Helium Welding But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you want a general shielding gas for tig welding, most welders will use 100% ar. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. Shielding gas is an essential component of the welding. Shielding Gas Helium Welding.

From www.adamsgas.co.uk

Shielding Gas Basics for MIG Welding Adams Gas Shielding Gas Helium Welding Shielding gas is an essential component of the welding process, serving to protect the weld from atmospheric gases that can cause defects and. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for tig welding, most welders will use 100% ar. One of. Shielding Gas Helium Welding.

From www.weldfabworld.com

Common Shielding Gases For Arc Welding Welding Fabrication World Shielding Gas Helium Welding The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. But, if you need to modify the arc characteristics to achieve better penetration or oxide removal,. If you want a general shielding gas for tig welding, most welders will use 100% ar. Perhaps the biggest hope for welders looking to. Shielding Gas Helium Welding.

From weldinganswers.com

Effects of Shielding Gases in GMAW WELDING ANSWERS Shielding Gas Helium Welding The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. When used as a shielding gas in gas tungsten arc welding or tig. In some applications, hydrogen or nitrogen is added to a mixture with one or two of the basic gases. If you want a general shielding gas for. Shielding Gas Helium Welding.

From sheetstainlesssteel.com

What Gas to Use for TIG Welding Stainless Steel Your Guide Shielding Gas Helium Welding Perhaps the biggest hope for welders looking to live without, or at least with less, helium rests on the ability to tailor the entire gas metal. The three most common shielding gas options for gtaw are 100 percent argon, 100 percent helium and an argon/helium mix. One of the main benefits of using helium in welding is its ability to. Shielding Gas Helium Welding.