Corner Chamfer Vs Corner Radius . Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. What is a break edge? as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Corner radius end mills are different flutes and. — corner chamfer vs. Chamfers do not have to be a 45. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Considering all factors, the 0.030” corner chamfer proved to be. — table of contents. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Notice the difference in the picture above. — corner radius end mills are suitable for the die and mold industry.

from www.mscdirect.com

— table of contents. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Corner radius end mills are different flutes and. Notice the difference in the picture above. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Considering all factors, the 0.030” corner chamfer proved to be. Chamfers do not have to be a 45. as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner.

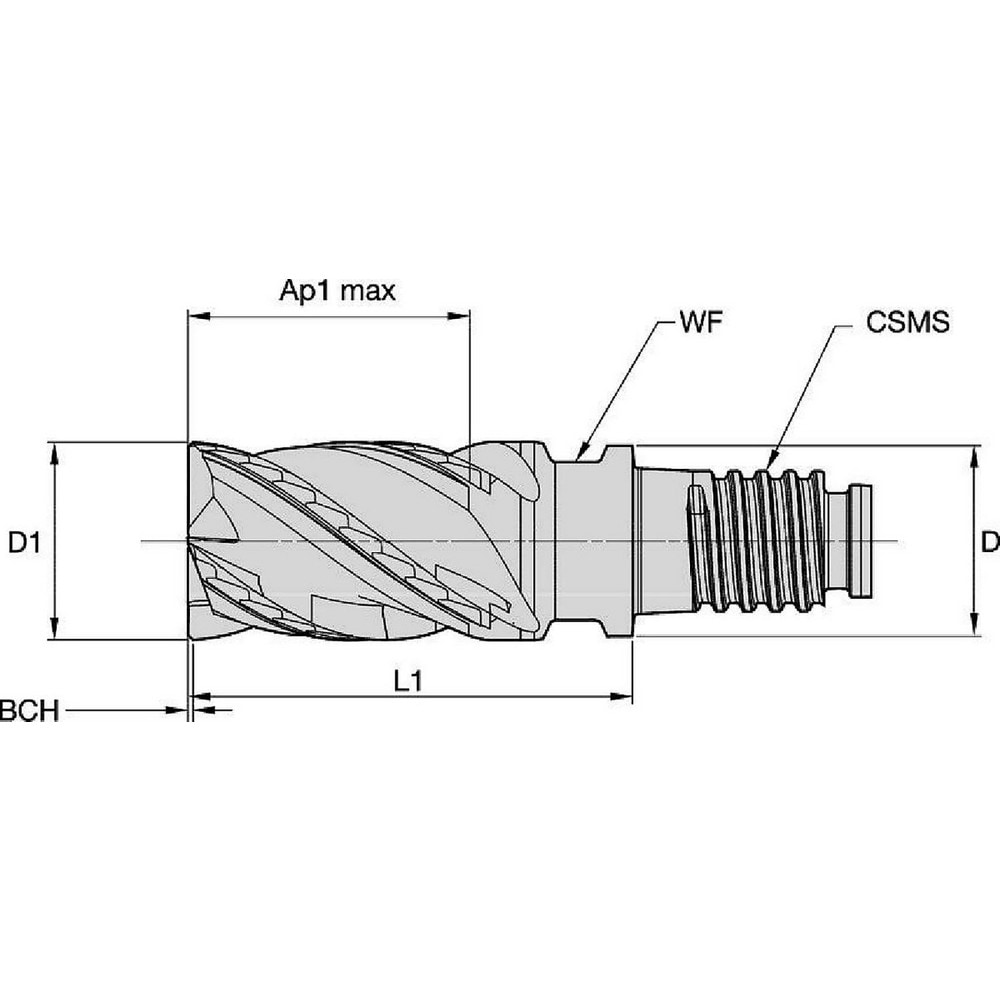

Kennametal Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 20.00; Chamfer

Corner Chamfer Vs Corner Radius Notice the difference in the picture above. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Notice the difference in the picture above. — table of contents. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. — corner chamfer vs. — corner radius end mills are suitable for the die and mold industry. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. Chamfers do not have to be a 45. What is a break edge? Corner radius end mills are different flutes and. as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. Considering all factors, the 0.030” corner chamfer proved to be.

From www.3qmachining.com

Difference Between a Fillet and Chamfer, Everything You Need To Know Corner Chamfer Vs Corner Radius Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. — corner radius end mills are suitable for. Corner Chamfer Vs Corner Radius.

From exoikxuuh.blob.core.windows.net

Chamfer Strip Sizes at Jenny Noble blog Corner Chamfer Vs Corner Radius Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. Corner radius end mills are different flutes and. — table of contents. What is a break edge? Considering all factors, the 0.030” corner chamfer proved to be. — corner. Corner Chamfer Vs Corner Radius.

From waykenrm.com

Fillet vs Chamfer A Complete Guide for Applications WayKen Corner Chamfer Vs Corner Radius as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. — corner chamfer vs. Chamfers do not have to be a 45. A break edge means the removal. Corner Chamfer Vs Corner Radius.

From thelibraryofmanufacturing.com

Design And Applications Of Powder Processes Corner Chamfer Vs Corner Radius Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. What is a break edge? Corner radius end mills are different flutes and. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Chamfers. Corner Chamfer Vs Corner Radius.

From www.slideserve.com

PPT Dimensioning Standards PowerPoint Presentation, free download ID6594909 Corner Chamfer Vs Corner Radius Considering all factors, the 0.030” corner chamfer proved to be. What is a break edge? — table of contents. — corner chamfer vs. Chamfers do not have to be a 45. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Machining a surface will often leave a corner which can. Corner Chamfer Vs Corner Radius.

From www.precastconcretemagnet.com

The Complete Guide to Chamfering Concrete Edges Knowledge Corner Chamfer Vs Corner Radius A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. — table of contents. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. — corner chamfer vs. Notice the difference in the picture above. Chamfers do not have. Corner Chamfer Vs Corner Radius.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria Corner Chamfer Vs Corner Radius — corner chamfer vs. — table of contents. Notice the difference in the picture above. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. Chamfers do not have to be a 45. What is a break edge? A break edge means the removal of material, usually in. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Kennametal Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 20.00; Chamfer Corner Chamfer Vs Corner Radius — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Chamfers do not have to be a 45. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. What is a break edge? A break edge means the removal of material, usually in. Corner Chamfer Vs Corner Radius.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Corner Chamfer Vs Corner Radius as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. — corner radius end mills are suitable for the die and mold industry. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge.. Corner Chamfer Vs Corner Radius.

From dxoonkbug.blob.core.windows.net

What Does Chamfer Mean In English at Mary Burcham blog Corner Chamfer Vs Corner Radius A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Notice the difference in the picture above. Considering all factors, the 0.030” corner chamfer proved to be. — corner radius end mills are suitable for the die and mold industry. — table of contents. What is. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Kennametal Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 20.00; Chamfer Corner Chamfer Vs Corner Radius Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. — corner chamfer vs. — table of contents. . Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Corner Radius End Mill 3/8" Dia, 1" LOC, 0.03" Radius, 5 Flutes, Solid Carbide 3" OAL, 3/8 Corner Chamfer Vs Corner Radius A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. — a fillet is a rounded or radiused. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Seco Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 10.00; Mill Diameter Corner Chamfer Vs Corner Radius as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. Chamfers do not have to be a 45. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. — table of contents. — corner radius end mills. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Ingersoll Cutting Tools Corner Radius & Corner Chamfer End Mill Heads; Chamfer Width (Decimal Corner Chamfer Vs Corner Radius Chamfers do not have to be a 45. — corner radius end mills are suitable for the die and mold industry. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Corner radius end mills are different flutes and. — corner chamfer vs. What is a. Corner Chamfer Vs Corner Radius.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. Corner Chamfer Vs Corner Radius — corner radius end mills are suitable for the die and mold industry. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Corner radius end mills are different flutes and. Chamfers do not have to be a 45. as with radii, a uniform wall thickness. Corner Chamfer Vs Corner Radius.

From www.youtube.com

Solid Edge How to dimension chamfer with corner intersection? YouTube Corner Chamfer Vs Corner Radius — a fillet is a rounded or radiused corner and a chamfer is a straight cut. What is a break edge? Considering all factors, the 0.030” corner chamfer proved to be. — corner chamfer vs. Corner radius end mills are different flutes and. Notice the difference in the picture above. A break edge means the removal of material,. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Ingersoll Cutting Tools Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 16. Corner Chamfer Vs Corner Radius Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. — table of contents. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. as with radii, a uniform wall thickness is. Corner Chamfer Vs Corner Radius.

From www.penntoolco.com

Made in USA Corner Chamfer/Corner Radius End Mill SM6F500 030R 43814243 Penn Tool Co., Inc Corner Chamfer Vs Corner Radius Corner radius end mills are different flutes and. — table of contents. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. Notice the difference in the picture above. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. A break edge. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Ingersoll Cutting Tools Corner Radius & Corner Chamfer End Mill Heads; Number Of Flutes 5 Corner Chamfer Vs Corner Radius Chamfers do not have to be a 45. Corner radius end mills are different flutes and. — table of contents. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Considering all factors, the 0.030” corner chamfer proved to be. as with radii, a uniform wall. Corner Chamfer Vs Corner Radius.

From thecontentauthority.com

Chamfer vs Corner The Main Differences And When To Use Them Corner Chamfer Vs Corner Radius Corner radius end mills are different flutes and. Considering all factors, the 0.030” corner chamfer proved to be. — corner radius end mills are suitable for the die and mold industry. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. as with radii, a uniform. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Sandvik Coromant Corner Radius & Corner Chamfer End Mill Heads 99025801 MSC Industrial Supply Corner Chamfer Vs Corner Radius Corner radius end mills are different flutes and. Considering all factors, the 0.030” corner chamfer proved to be. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. Notice the difference in the picture above. — a fillet is a. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Titan USA Corner Radius & Corner Chamfer End Mills; Mill Diameter (Inch) 1/2 ; Mill Diameter Corner Chamfer Vs Corner Radius Chamfers do not have to be a 45. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Notice the difference in the picture above. — table of contents. — corner chamfer vs. . Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Corner Chamfer End Mill 5.00 mm Dia, 30.00 mm LOC, 4 Flute(s), 0.10 mm Chamfer Width, Solid Corner Chamfer Vs Corner Radius — corner chamfer vs. Corner radius end mills are different flutes and. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts. What is a break edge? Machining a surface will often leave a corner which can be dangerous for. Corner Chamfer Vs Corner Radius.

From www.slideserve.com

PPT WELD JOINT GEOMETERY AND WELDING SYMBOLS PowerPoint Presentation ID5664585 Corner Chamfer Vs Corner Radius — corner radius end mills are suitable for the die and mold industry. — corner chamfer vs. as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. Corner radius end mills are different flutes and. Considering all factors, the 0.030” corner chamfer proved to. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Micro 100 Corner Radius & Corner Chamfer End Mills; Mill Diameter (Inch) 1/2 ; Mill Diameter Corner Chamfer Vs Corner Radius — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Notice the difference in the picture above. Corner radius end mills are different flutes and. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting. Corner Chamfer Vs Corner Radius.

From www.madearia.com

Fillet vs Chamfer Basic Operations & Cad Design Features 2022 Corner Chamfer Vs Corner Radius as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. What is a break edge? Corner radius end mills are different flutes and. — corner chamfer vs. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. . Corner Chamfer Vs Corner Radius.

From eziil.com

Chamfering 101 Types, Dimensions & Callout Corner Chamfer Vs Corner Radius Chamfers do not have to be a 45. as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. What is a break edge? — table of contents. Considering. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Seco Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 10.00; Chamfer Width Corner Chamfer Vs Corner Radius Corner radius end mills are different flutes and. as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. What is a break edge? . Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Seco Corner Radius & Corner Chamfer End Mill Heads; Mill Diameter (mm) 10.00; Length of Cut Corner Chamfer Vs Corner Radius — a fillet is a rounded or radiused corner and a chamfer is a straight cut. Considering all factors, the 0.030” corner chamfer proved to be. Chamfers do not have to be a 45. A break edge means the removal of material, usually in the form of a chamfer or radius to remove the sharp edge. Corner radius end. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Ingersoll Cutting Tools Corner Radius & Corner Chamfer End Mill Heads; Chamfer Width (Decimal Corner Chamfer Vs Corner Radius Considering all factors, the 0.030” corner chamfer proved to be. — a fillet is a rounded or radiused corner and a chamfer is a straight cut. — corner chamfer vs. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. Corner radius end mills are different flutes and.. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Titan USA Corner Radius & Corner Chamfer End Mills; Mill Diameter (Inch) 3/4 ; Mill Diameter Corner Chamfer Vs Corner Radius — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Notice the difference in the picture above. — table of contents. Considering all factors, the 0.030” corner chamfer proved to be. — corner chamfer vs. — a fillet is a rounded or radiused corner and a chamfer is a straight. Corner Chamfer Vs Corner Radius.

From www.mscdirect.com

Micro 100 Corner Radius & Corner Chamfer End Mills; Mill Diameter (Inch) 1/2 ; Mill Diameter Corner Chamfer Vs Corner Radius — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Machining a surface will often leave a corner which can be dangerous for both the part and the part handler. Considering all factors, the 0.030” corner chamfer proved to be. — corner radius end mills are suitable for the die and mold. Corner Chamfer Vs Corner Radius.

From www.smlease.com

Fillet vs Chamfer What is the difference Between a Fillet and Chamfer Corner Chamfer Vs Corner Radius as with radii, a uniform wall thickness is preferred, so a chamfer on an outer edge should be copied on the inner corner. Notice the difference in the picture above. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit of mating or connecting parts.. Corner Chamfer Vs Corner Radius.

From www.bharatagritech.com

Radius, Fillet, Bevel And Chamfer Explained!, 42 OFF Corner Chamfer Vs Corner Radius — a fillet is a rounded or radiused corner and a chamfer is a straight cut. — corner radius end mills are suitable for the die and mold industry. — table of contents. Engineers typically design radii to improve a part’s safety and enhance its appearance, though, like chamfers, radii can also improve the assembly and fit. Corner Chamfer Vs Corner Radius.

From www.scribd.com

Chamfer Radius Cordinates PDF Corner Chamfer Vs Corner Radius — a fillet is a rounded or radiused corner and a chamfer is a straight cut. — a radius replaces a raw corner with a rounded edge rather than a chamfered edge. Notice the difference in the picture above. Considering all factors, the 0.030” corner chamfer proved to be. What is a break edge? — corner radius. Corner Chamfer Vs Corner Radius.