What Is Line Of Balancing . line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line balancing isn’t just a manufacturing buzzword; This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. It’s a powerful strategy that can revolutionize your production processes. This is done by breaking. what is line balancing? line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. Here the takt time is.

from www.allaboutlean.com

In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line balancing isn’t just a manufacturing buzzword; line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. It’s a powerful strategy that can revolutionize your production processes. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. Here the takt time is. what is line balancing? This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste.

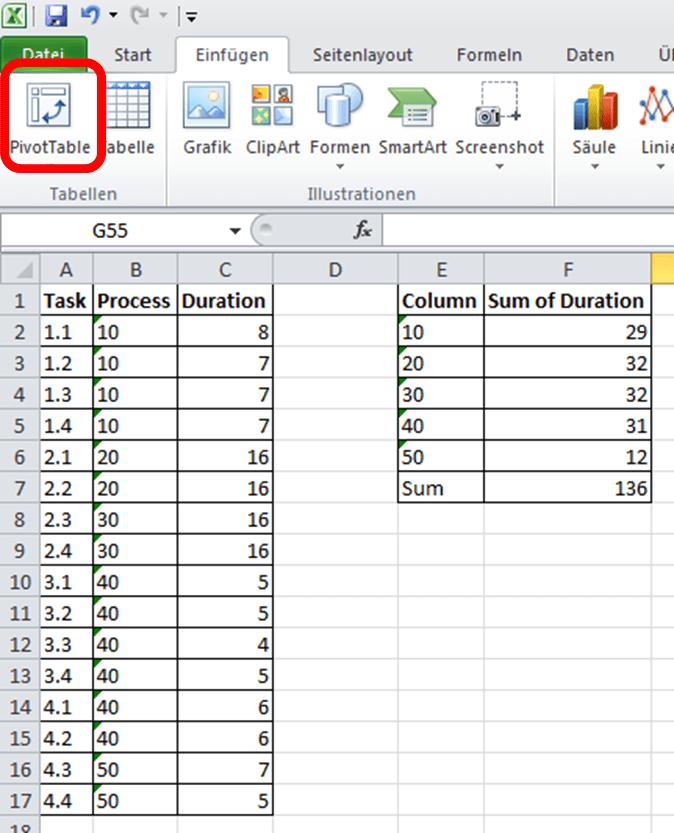

Line Balancing in Excel

What Is Line Of Balancing line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. what is line balancing? line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. Here the takt time is. line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. This is done by breaking. line balancing isn’t just a manufacturing buzzword; It’s a powerful strategy that can revolutionize your production processes. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time.

From www.taktiq.de

Line Balancing TAKTIQ GmbH & Co. KG What Is Line Of Balancing It’s a powerful strategy that can revolutionize your production processes. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing isn’t just a manufacturing buzzword;. What Is Line Of Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download What Is Line Of Balancing what is line balancing? line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. It’s a powerful strategy that can revolutionize your production processes. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator. What Is Line Of Balancing.

From www.youtube.com

Line Balancing by METHODS APPAREL CONSULTANCY.avi YouTube What Is Line Of Balancing what is line balancing? In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. line balancing is a process that involves analyzing the production line and determining the ideal workload for. What Is Line Of Balancing.

From www.taktiq.de

Line Balancing TAKTIQ GmbH & Co. KG What Is Line Of Balancing line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. Here the takt time is. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient. What Is Line Of Balancing.

From www.desertcart.ae

Buy Importance Of Line Balancing What Is Line Balancing And Cycle Time What Is Line Of Balancing Here the takt time is. what is line balancing? In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. line balancing is a production strategy that involves balancing operator and machine. What Is Line Of Balancing.

From collectionperformance.com

Maximizing Efficiency A Guide to Line Balancing in Production What Is Line Of Balancing This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints. What Is Line Of Balancing.

From www.mas-software.com

5 Cara Menerapkan Line Balancing untuk Industri Manufaktur What Is Line Of Balancing line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. line balancing isn’t just a manufacturing buzzword; In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and. What Is Line Of Balancing.

From www.acsco.com

Line Balancing Large Image Timer Pro Professional What Is Line Of Balancing In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. . What Is Line Of Balancing.

From kledo.com

Line Balancing Ketahui Pengertian Lengkap pada Proses Produksi What Is Line Of Balancing line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. line balancing isn’t just a manufacturing buzzword; line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in. What Is Line Of Balancing.

From www.youtube.com

Line Balancing Example YouTube What Is Line Of Balancing It’s a powerful strategy that can revolutionize your production processes. line balancing isn’t just a manufacturing buzzword; line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation.. What Is Line Of Balancing.

From www.proplanner.com

Line Balancing Software Generates Assignment of Tasks to Operator What Is Line Of Balancing This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. Here the takt time is. line balancing is a process that involves analyzing. What Is Line Of Balancing.

From www.simul8.com

Implementing Line Balancing Methods with Simulation SIMUL8 What Is Line Of Balancing This is done by breaking. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient. What Is Line Of Balancing.

From www.onlineclothingstudy.com

Line Balancing Tool Based on Operator Skill Matrix What Is Line Of Balancing line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing is a production strategy that involves balancing operator and machine. What Is Line Of Balancing.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron What Is Line Of Balancing line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. By minimizing waste, reducing inventory, adapting to change, and. What Is Line Of Balancing.

From www.allaboutlean.com

Line Balancing in Excel What Is Line Of Balancing By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and. What Is Line Of Balancing.

From www.youtube.com

line balancing YouTube What Is Line Of Balancing line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. It’s a powerful strategy that can revolutionize your production processes. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing isn’t just a manufacturing buzzword; line balancing is. What Is Line Of Balancing.

From www.onlineclothingstudy.com

Line Balancing Tool Based on Operator Skill Matrix What Is Line Of Balancing line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. line balancing isn’t just a manufacturing buzzword; It’s a powerful strategy that. What Is Line Of Balancing.

From zh.scribd.com

Examples Line Balancing Applied Mathematics Mathematics What Is Line Of Balancing line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. Here the takt time is. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing involves arranging the production line so that each assembler or machine. What Is Line Of Balancing.

From shakehandwithlife.blogspot.com

Shakehand with Life Line Balancing Vs Line of Balance What Is Line Of Balancing line balancing isn’t just a manufacturing buzzword; In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. Here the takt time is. line balancing, or production leveling, is a process whereby. What Is Line Of Balancing.

From studylib.net

Line Balancing What Is Line Of Balancing It’s a powerful strategy that can revolutionize your production processes. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line. What Is Line Of Balancing.

From knowindustrialengineering.com

Line Balancing How to do it Know Industrial Engineering What Is Line Of Balancing line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible.. What Is Line Of Balancing.

From kledo.com

Line Balancing Ketahui Pengertian Lengkap pada Proses Produksi What Is Line Of Balancing line balancing isn’t just a manufacturing buzzword; It’s a powerful strategy that can revolutionize your production processes. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. line balancing, or production leveling, is a process whereby operator time and machine. What Is Line Of Balancing.

From pt.slideshare.net

assembly line balancing What Is Line Of Balancing In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. This is done by breaking.. What Is Line Of Balancing.

From www.youtube.com

04 Assembly Line Balancing YouTube What Is Line Of Balancing line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. It’s a powerful strategy that can revolutionize your production processes. line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient. What Is Line Of Balancing.

From www.scribd.com

Line Balancing Sheet Technology Business What Is Line Of Balancing It’s a powerful strategy that can revolutionize your production processes. This is done by breaking. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and. What Is Line Of Balancing.

From shakehandwithlife.blogspot.com

Shakehand with Life Line Balancing Vs Line of Balance What Is Line Of Balancing This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. Here the takt time is. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. what is line balancing? It’s a powerful strategy that can revolutionize your production. What Is Line Of Balancing.

From wave20.blogspot.com

LINE BALANCING ARTI DAN TUJUAN MENURUT AHLI Wave20 Lean What Is Line Of Balancing line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. what is line balancing? line balancing involves arranging the production line so that each assembler or. What Is Line Of Balancing.

From www.erp-information.com

Definition of Line balancing ERP Information What Is Line Of Balancing line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time, minimizing downtime and reducing bottlenecks. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can. What Is Line Of Balancing.

From www.taktiq.de

Line Balancing TAKTIQ GmbH & Co. KG What Is Line Of Balancing In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. Here the takt time is. line balancing, or production leveling, is a process whereby operator time and machine time are optimized to. What Is Line Of Balancing.

From shakehandwithlife.blogspot.com

Shakehand with Life Line Balancing Vs Line of Balance What Is Line Of Balancing what is line balancing? line balancing is a process that involves analyzing the production line and determining the ideal workload for each workstation. line balancing isn’t just a manufacturing buzzword; It’s a powerful strategy that can revolutionize your production processes. Here the takt time is. line balancing is a technique to distribute the product manufacturing processes. What Is Line Of Balancing.

From www.allaboutlean.com

Line Balancing Parallel Process What Is Line Of Balancing By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste.. What Is Line Of Balancing.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download What Is Line Of Balancing line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time. In the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible.. What Is Line Of Balancing.

From www.taktiq.de

Line Balancing TAKTIQ GmbH & Co. KG What Is Line Of Balancing This ensures that the workflow moves smoothly from one operation to the next, maximizing productivity and reducing waste. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. . What Is Line Of Balancing.

From www.leanvlog.com

What is Line Balancing Lean Vlog What Is Line Of Balancing line balancing isn’t just a manufacturing buzzword; line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address constraints and use capacity in the most efficient way possible. line balancing involves arranging the production line so that each assembler or machine completes its task in the same amount of time,. What Is Line Of Balancing.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing What Is Line Of Balancing Here the takt time is. By minimizing waste, reducing inventory, adapting to change, and boosting profits, line balancing can unlock value for your organization. line balancing is a technique to distribute the product manufacturing processes at various manufacturing stations to achieve the best talk time. It’s a powerful strategy that can revolutionize your production processes. line balancing involves. What Is Line Of Balancing.