Gas Analysis Additive Manufacturing . In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in.

from thermalprocessing.com

However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in.

Additive manufacturing and gas technology applications Thermal

Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy.

From www.asap.nl

Gas analyzers for process control and laboratory ASaP Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This paper offers a condensed. Gas Analysis Additive Manufacturing.

From ferditraining.com

DISSOLVED GAS ANALYSIS TRAINING PROGRAM Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors. Gas Analysis Additive Manufacturing.

From www.symmetryelectronics.com

Defining Additive Manufacturing Symmetry Electronics Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal. Gas Analysis Additive Manufacturing.

From advintegrity.com

Something to Add Validating Additive Manufacturing for Critical Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of the implications. Gas Analysis Additive Manufacturing.

From www.devicemed.fr

De l’importance du gaz dans la fabrication additive DeviceMed.fr Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which. Gas Analysis Additive Manufacturing.

From esegas.com

Effective Gas Analysis Solutions How Manufacturers are Transforming Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive. Gas Analysis Additive Manufacturing.

From www.mdpi.com

Metals Free FullText DiffractionBased Residual Stress Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. This paper offers. Gas Analysis Additive Manufacturing.

From www.researchgate.net

4.7. Online FTIR gas analysis system. Download Scientific Diagram Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Suboptimal. Gas Analysis Additive Manufacturing.

From www.bruker.com

Gas Analysis Bruker Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This paper offers a condensed review of energy. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can. Gas Analysis Additive Manufacturing.

From www.designworldonline.com

OPEN MIND Technologies to highlight ADDITIVE Manufacturing Capability Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock. Gas Analysis Additive Manufacturing.

From www.researchgate.net

Typical GC signal of endgas analysis Download Scientific Diagram Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of. Gas Analysis Additive Manufacturing.

From mavink.com

Additive Manufacturing Process Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of. Gas Analysis Additive Manufacturing.

From www.metal-am.com

Additive Manufacturing for oil, gas and maritime Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images. Gas Analysis Additive Manufacturing.

From www.voestalpine.com

Additive Manufacturing Solutions for Oil and Gas Industry Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal process parameters and entrapped gas content in powder feedstock. Gas Analysis Additive Manufacturing.

From www.researchgate.net

Schematics of additive manufacturing (AM) by selective laser melting Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which. Gas Analysis Additive Manufacturing.

From www.nano-di.com

The Future of Additive Manufacturing in Engineering Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. However, the energy consumption inherent in am processes necessitates an understanding of the implications. Gas Analysis Additive Manufacturing.

From www.researchgate.net

(PDF) The Effect of ElectroInduced MultiGas Modification on Polymer Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Suboptimal. Gas Analysis Additive Manufacturing.

From www.startus-insights.com

5 Top Additive Manufacturing Startups Impacting the Oil & Gas Industry Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. This paper offers a condensed review of energy. In this study, a monitoring system was developed to collect the weld pool images. Gas Analysis Additive Manufacturing.

From www.cambridge-sensotec.co.uk

Oxygen Gas Analyser Gas Analysis Gas Analysis Equipment Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of. Gas Analysis Additive Manufacturing.

From www.cee.ed.tum.de

Additive Manufacturing process simulation Chair of Computational Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors. Gas Analysis Additive Manufacturing.

From www.researchandmarkets.com

Impact of Additive Manufacturing Technologies in Oil and Gas Gas Analysis Additive Manufacturing However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal. Gas Analysis Additive Manufacturing.

From birthdaywishes77.com

The Definitive Guide to Designing for Additive Manufacturing Advanced Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of. Gas Analysis Additive Manufacturing.

From www.researchgate.net

Illustration of the directed energy deposition (DED) process; the Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. Suboptimal. Gas Analysis Additive Manufacturing.

From www.futura-sciences.com

Fabrication additive métallique le rôle du gaz Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This. Gas Analysis Additive Manufacturing.

From www.hidenanalytical.com

The Basics of Process Gas Analysis in Chemical Vapor Deposition Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications. Gas Analysis Additive Manufacturing.

From press.siemens.com

Additive Manufacturing Siemens uses innovative technology to produce Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which. Gas Analysis Additive Manufacturing.

From uwm.edu

Vaccum SystemsResidual Gas Analysis Advanced Analysis Facility Gas Analysis Additive Manufacturing This paper offers a condensed review of energy. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications. Gas Analysis Additive Manufacturing.

From www.gasworld.com

Additive manufacturing and industrial gases Additive manufacturing Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This. Gas Analysis Additive Manufacturing.

From www.youtube.com

Dissolved Gas Analysis made easy using Transformer Oil Gas Analyzer Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. This paper offers. Gas Analysis Additive Manufacturing.

From www.researchgate.net

Classification of additive manufacturing processes, adapted from [35 Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. In this study, a monitoring system was developed to collect the weld pool images in the additive. Gas Analysis Additive Manufacturing.

From www.extorr.com

Introduction to Residual Gas Analyzers Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal. Gas Analysis Additive Manufacturing.

From www.engineerlive.com

Gas analysis more powerful as technology advances Engineer Live Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of the implications. Gas Analysis Additive Manufacturing.

From videos.emerson.com

Natural Gas Quality Analysis Using Rosemount 700XA Gas Chromatograph Gas Analysis Additive Manufacturing Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. Suboptimal. Gas Analysis Additive Manufacturing.

From thermalprocessing.com

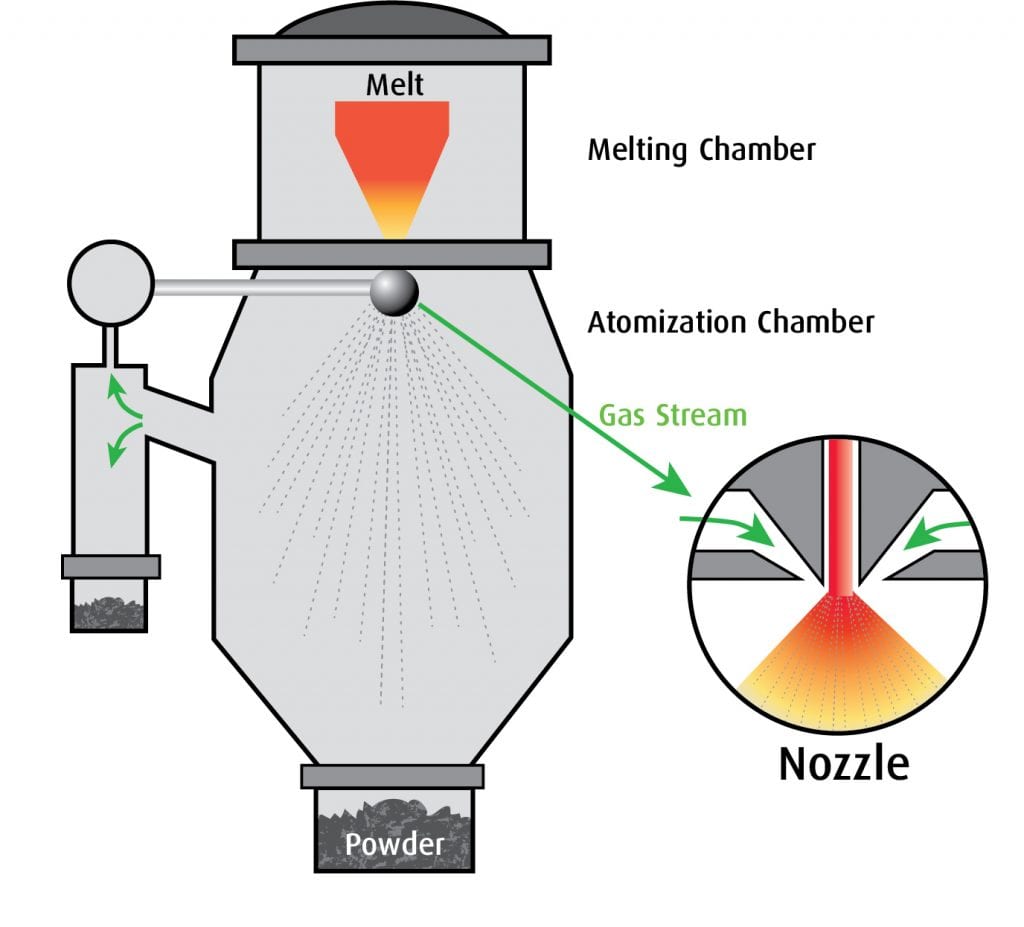

Additive manufacturing and gas technology applications Thermal Gas Analysis Additive Manufacturing Suboptimal process parameters and entrapped gas content in powder feedstock are two factors that can induce porosity in. Shielding gas, metal vapors, and gases trapped inside powders during atomization can result in gas porosity, which is known to. In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to.. Gas Analysis Additive Manufacturing.

From www.metal-am.com

CFD simulation for metal Additive Manufacturing Applications in laser Gas Analysis Additive Manufacturing In this study, a monitoring system was developed to collect the weld pool images in the additive manufacturing on line, and to. This paper offers a condensed review of energy. However, the energy consumption inherent in am processes necessitates an understanding of the implications for energy efficiency. Suboptimal process parameters and entrapped gas content in powder feedstock are two factors. Gas Analysis Additive Manufacturing.