What Are Carbide Inserts . Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. there are many parameters to consider when choosing a turning insert. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. learn how to identify indexable inserts and insert shapes. Cutter body ranges from dia25mm to dia200mm. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Learn how to read the ansi insert code system & download.

from www.icarbide.com

Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. there are many parameters to consider when choosing a turning insert. Learn how to read the ansi insert code system & download. learn how to identify indexable inserts and insert shapes. Cutter body ranges from dia25mm to dia200mm.

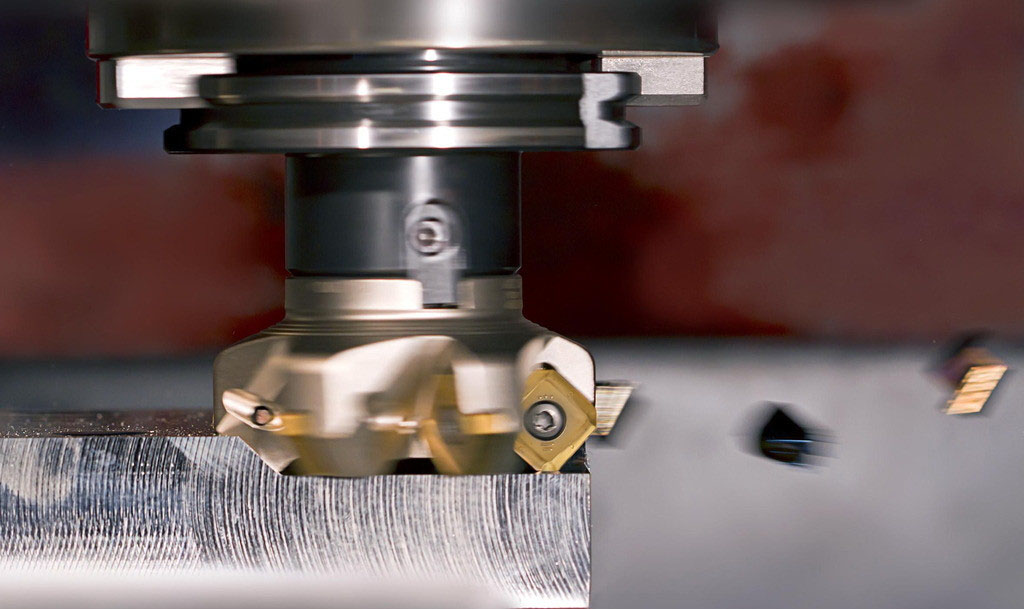

SEKT1204 AFNN IG101 CARBIDE INSERT MILL INSERTS 45 DEGREE icarbide

What Are Carbide Inserts Learn how to read the ansi insert code system & download. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm to dia200mm. Learn how to read the ansi insert code system & download. learn how to identify indexable inserts and insert shapes. there are many parameters to consider when choosing a turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts What Are Carbide Inserts Cutter body ranges from dia25mm to dia200mm. Learn how to read the ansi insert code system & download. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing.. What Are Carbide Inserts.

From www.shop-apt.co.uk

TNMG 160404 MMN M250 Carbide Inserts for Turning PVD Coated for What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Cutter body ranges from dia25mm to. What Are Carbide Inserts.

From www.shop-apt.co.uk

VCGT 110304 FS US05 Carbide Turning Inserts for Finishing High What Are Carbide Inserts one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. there are many parameters to consider when choosing a turning insert. Regardless of component size, material or design, the carbide insert grade you use can. What Are Carbide Inserts.

From cdbp2009.en.made-in-china.com

China Carbide Inserts (WNMG080408) China Carbide Inserts, Tungsten What Are Carbide Inserts Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm. What Are Carbide Inserts.

From www.shop-apt.co.uk

TCMT 110204 TF XM25 Carbide Inserts for Turning PVD Coated for What Are Carbide Inserts learn how to identify indexable inserts and insert shapes. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Cutter body ranges from dia25mm to dia200mm. . What Are Carbide Inserts.

From www.icarbide.com

SEKT1204 AFNN IG101 CARBIDE INSERT MILL INSERTS 45 DEGREE icarbide What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Learn how to read the ansi insert code system & download. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. learn how to identify indexable inserts and insert shapes. Regardless of component size, material or. What Are Carbide Inserts.

From www.shop-apt.co.uk

APMT 160412 UM25 Carbide Inserts for Milling PVD Coated for General Use What Are Carbide Inserts inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Learn how to read the ansi insert code system & download. Cutter body ranges from dia25mm to dia200mm. Regardless of component size, material or design, the carbide. What Are Carbide Inserts.

From www.shop-apt.co.uk

SCMT 120408 MPN PC35 Carbide Inserts for Turning CVD Coated for What Are Carbide Inserts learn how to identify indexable inserts and insert shapes. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability. What Are Carbide Inserts.

From www.icarbide.com

VCGT130302 IG101 CARBIDE INSERT TURNING INSERTS PACK OF 10 icarbide What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. there are many parameters to consider when choosing a turning insert. Cutter body ranges from dia25mm to dia200mm. Regardless of component size, material or design, the. What Are Carbide Inserts.

From www.icarbide.com

High Performance Carbide Inserts icarbide What Are Carbide Inserts there are many parameters to consider when choosing a turning insert. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm to dia200mm. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. learn how to identify indexable inserts. What Are Carbide Inserts.

From www.amazon.ca

10pcs CNC Carbide Insert Cutter Indexable Lathe Milling Inserts Turning What Are Carbide Inserts there are many parameters to consider when choosing a turning insert. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carefully select insert geometry, insert grade,. What Are Carbide Inserts.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. there are many parameters. What Are Carbide Inserts.

From www.shop-apt.co.uk

VCMT 110304 FM M250 Carbide Inserts for Turning PVD Coated for Finshing What Are Carbide Inserts Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability. What Are Carbide Inserts.

From www.shop-apt.co.uk

VBMT 160404 MP DP25A Carbide Inserts for Turning MTCVD Coated for What Are Carbide Inserts inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. there are many parameters to consider when choosing a turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Learn how to read the ansi insert code system & download. Cutter body ranges from. What Are Carbide Inserts.

From www.accuromm.com

Custom Carbide Inserts Exceptional Quality Accuromm USA What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Learn how to read the ansi insert code system & download. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. there are many parameters to consider when choosing a turning insert. learn how to. What Are Carbide Inserts.

From www.carbidetoolinserts.com

CVD Coated Carbide Cutting Inserts , High Strength Square Carbide Inserts What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. learn how to identify indexable inserts and insert shapes. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. there are many parameters to consider when choosing a turning insert. Learn how to read. What Are Carbide Inserts.

From mewsaws.com

Shop MewSaws What Are Carbide Inserts learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm to dia200mm.. What Are Carbide Inserts.

From www.shop-apt.co.uk

CNMG 190612 GS US15 Carbide Turning Inserts PVD Coated for Medium to What Are Carbide Inserts Cutter body ranges from dia25mm to dia200mm. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Learn how to read the ansi insert code system & download. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge.. What Are Carbide Inserts.

From www.shop-apt.co.uk

VCGT 160404 AK101 Carbide Inserts for Turning Ground and Polished for What Are Carbide Inserts Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. learn how to identify indexable inserts and insert shapes. there are many parameters to consider. What Are Carbide Inserts.

From www.cnccarbideinserts.com

Copper Alloy Aluminum Inserts , Tungsten Carbide Inserts DCGT11T308AL What Are Carbide Inserts Cutter body ranges from dia25mm to dia200mm. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. there are many parameters to consider when choosing a. What Are Carbide Inserts.

From www.grainger.com

METABO Carbide Insert, Size 11mm, 4 Edges, PK10 49EX47SQ4 Carbide What Are Carbide Inserts learn how to identify indexable inserts and insert shapes. Cutter body ranges from dia25mm to dia200mm. there are many parameters to consider when choosing a turning insert. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Learn how to read the ansi insert code system. What Are Carbide Inserts.

From www.amazon.com

Carbide Inserts CNC Lathe Insert Blade APMT 1135 What Are Carbide Inserts Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm. What Are Carbide Inserts.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco What Are Carbide Inserts learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Cutter body ranges from dia25mm to dia200mm. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. there are many parameters to consider when choosing a. What Are Carbide Inserts.

From ovienterprises.com

Carbide Insert Ovienterprises What Are Carbide Inserts inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Learn how to read the ansi insert code system & download. Regardless of component size, material or. What Are Carbide Inserts.

From www.shop-apt.co.uk

DCMT 11T302 FM M250 Carbide Inserts for Turning PVD Coated for Finshing What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Cutter body ranges from dia25mm to dia200mm. inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. there are many parameters to consider when choosing a turning insert. Learn how to read the ansi insert code. What Are Carbide Inserts.

From www.cnccarbideinserts.com

SCGT120408AL Carbide Inserts For Turning Aluminum With Ultrafine What Are Carbide Inserts Learn how to read the ansi insert code system & download. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. learn how to identify indexable inserts and insert shapes. Cutter body ranges from dia25mm. What Are Carbide Inserts.

From www.shop-apt.co.uk

CNMG 190608 MD DP25 Carbide Inserts for Turning MTCVD Coated for Steel What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. there are many parameters to consider when choosing a turning insert. one crucial aspect of cnc turning is the use of carbide inserts, which have. What Are Carbide Inserts.

From www.aliexpress.com

10pcs Carbide Inserts APKT1604PDFR MA3 H01 Insert with Corrosion What Are Carbide Inserts one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm to dia200mm. Learn how to read the ansi insert code system & download. learn how to identify indexable inserts and insert shapes. there are many parameters to consider when choosing a. What Are Carbide Inserts.

From www.aliexpress.com

10pcs Carbide Inserts DCMT070204 YBC251 Carbide Insert For Lathe What Are Carbide Inserts Cutter body ranges from dia25mm to dia200mm. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Learn how to read the ansi insert code system & download. inserts with tough carbide grades and sharper. What Are Carbide Inserts.

From www.shop-apt.co.uk

CNMG 120408 MMN M250 Carbide Inserts for Turning PVD Coated for What Are Carbide Inserts inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Learn how to read the ansi insert code system & download. learn how to identify indexable inserts and insert shapes. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. Regardless of component size, material or. What Are Carbide Inserts.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco What Are Carbide Inserts Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. there are many parameters to consider when choosing a turning insert. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm. What Are Carbide Inserts.

From www.shop-apt.co.uk

SNMG 120408 GM UM25A Carbide Inserts for Turning PVD Coated for Steel What Are Carbide Inserts Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Cutter body ranges from dia25mm to dia200mm. Learn how to read the ansi insert code system & download. Regardless of component size, material or design, the. What Are Carbide Inserts.

From www.icarbide.com

APMT1135 M2 CARBIDE INSERT MILL INSERTS icarbide What Are Carbide Inserts one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Learn how to read the ansi insert. What Are Carbide Inserts.

From www.acarbide.com

Carbide Inserts AGrade Carbide What Are Carbide Inserts one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size,. there are many parameters to consider when choosing a turning insert. Regardless of component size, material or design, the carbide insert grade you use can. What Are Carbide Inserts.

From www.shop-apt.co.uk

WNMG 080408 GP DP25 Carbide Inserts for Turning MTCVD Coated for Steel What Are Carbide Inserts one crucial aspect of cnc turning is the use of carbide inserts, which have revolutionized the efficiency and performance of cutting. Learn how to read the ansi insert code system & download. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. inserts with tough carbide grades. What Are Carbide Inserts.