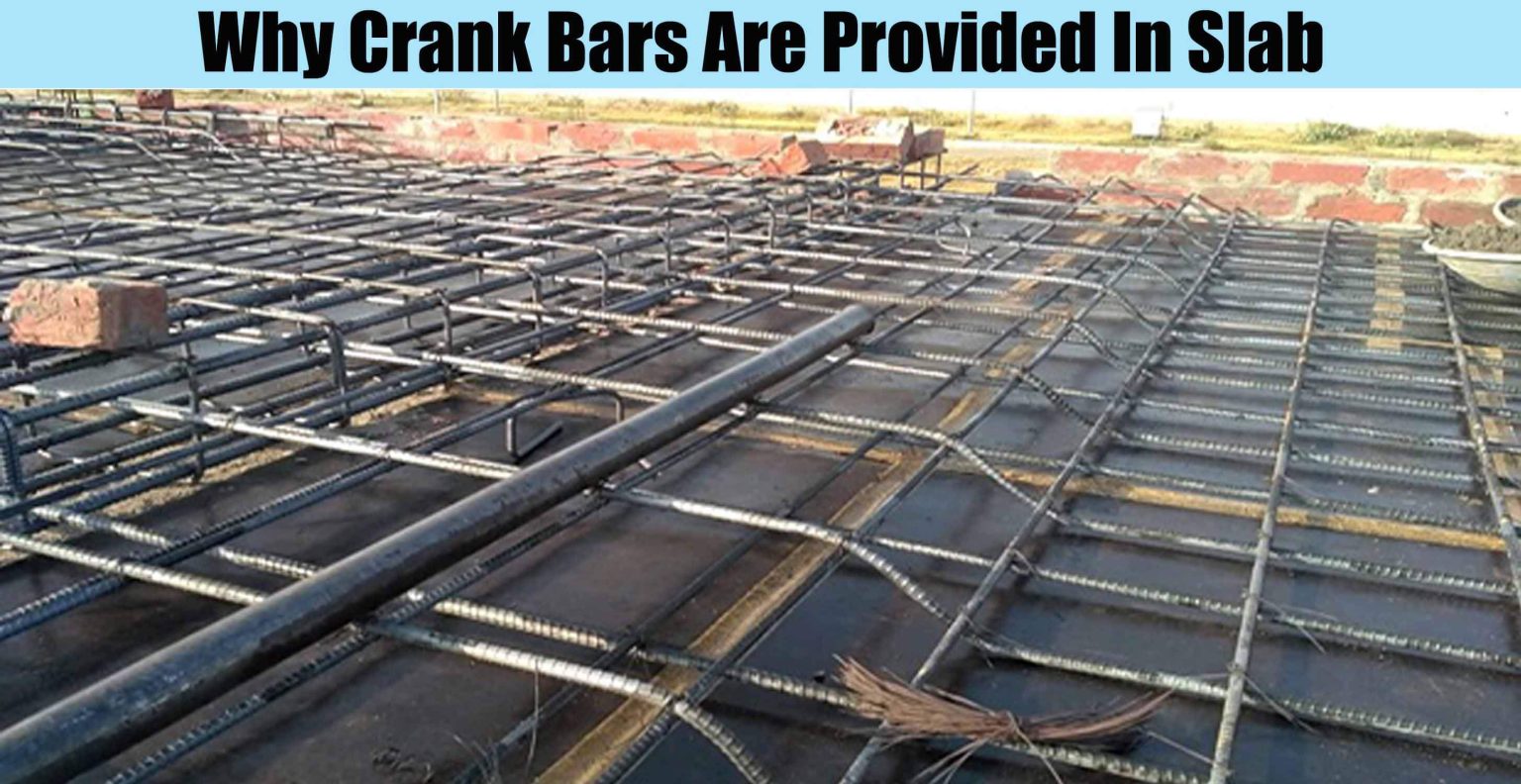

Crank Bar Meaning . When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. When these bars are provided, the strength and deformation capacity Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). A crank bar is provided to make rcc slab safe from compressive stresses. Crank bars are provided to make the steel available at both top and bottom reinforcement. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. A crank bar is provided to secure the rcc slab from compression stresses. Types of slabs that require crank bars. Crank bars are particularly important in: They are placed carefully to.

from engineeringdiscoveries.com

Crank bars are provided to make the steel available at both top and bottom reinforcement. They are placed carefully to. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. Types of slabs that require crank bars. A crank bar is provided to make rcc slab safe from compressive stresses. A crank bar is provided to secure the rcc slab from compression stresses. When these bars are provided, the strength and deformation capacity Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Crank bars are particularly important in:

Why Crank Bars Are Provided In Slab Engineering Discoveries

Crank Bar Meaning Crank bars are provided to make the steel available at both top and bottom reinforcement. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Crank bars are provided to make the steel available at both top and bottom reinforcement. A crank bar is provided to secure the rcc slab from compression stresses. A crank bar is provided to make rcc slab safe from compressive stresses. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. When these bars are provided, the strength and deformation capacity Types of slabs that require crank bars. They are placed carefully to. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Crank bars are particularly important in:

From www.youtube.com

Practical Video How to Provide Crank Bar in Slab , Beam Crank Bar Crank Bar Meaning They are placed carefully to. Types of slabs that require crank bars. Crank bars are provided to make the steel available at both top and bottom reinforcement. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. A crank bar is provided to secure. Crank Bar Meaning.

From www.youtube.com

Why Crank Bars Provide in Beam Bent Up Bars in Beam YouTube Crank Bar Meaning When these bars are provided, the strength and deformation capacity They are placed carefully to. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Crank bars. Crank Bar Meaning.

From www.civilclick.com

Why Crank Bars are Provided in slabs, Beams ? Civil Click Crank Bar Meaning A crank bar is provided to make rcc slab safe from compressive stresses. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. They are placed carefully to. When these bars are provided, the strength and deformation capacity of slabs. Crank Bar Meaning.

From engineeringinfohub.com

Why Using The Crank Bar In Slab Column RCC Beam Engineering Crank Bar Meaning Types of slabs that require crank bars. They are placed carefully to. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Crank/bent bars are used in. Crank Bar Meaning.

From engineeringdiscoveries.com

Why Crank Bars Are Provided In Slab Engineering Discoveries Crank Bar Meaning Crank bars are particularly important in: When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at. Crank Bar Meaning.

From www.youtube.com

Why and where we provide crank bars in Beams YouTube Crank Bar Meaning They are placed carefully to. Crank bars are particularly important in: A crank bar is provided to make rcc slab safe from compressive stresses. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Since the steel is required only where the positive and. Crank Bar Meaning.

From dailycivil.com

What Is Crank Bar & Why Crank Bars Are Provided In Slab Crank Bar Meaning Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. Crank bars are provided to make the steel available at both top and bottom reinforcement. Since the steel is required only where the positive and negative moments are created, crank. Crank Bar Meaning.

From civilmint.com

Crank Bar In Beam, Slab And Column Why It Is Provided Crank Bar Meaning Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. A crank bar is provided to make rcc slab safe from compressive stresses. Crank bars are provided to make the steel available at both top and bottom reinforcement. Since the. Crank Bar Meaning.

From www.youtube.com

Extra Rods in Beam Crank Bars Details in Floor Beam Contraction Crank Bar Meaning Crank bars are provided to make the steel available at both top and bottom reinforcement. Crank bars are particularly important in: Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. A crank bar is provided to make rcc slab. Crank Bar Meaning.

From www.youtube.com

What is Crank Bar in Slab Practical Video on Site Crank Bar Method Crank Bar Meaning A crank bar is provided to secure the rcc slab from compression stresses. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. They are placed carefully to. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging). Crank Bar Meaning.

From www.pinterest.ph

a diagram showing how to use the crank bar Crank Bar Meaning A crank bar is provided to make rcc slab safe from compressive stresses. Crank bars are particularly important in: Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. Since the steel is required only where the positive and negative. Crank Bar Meaning.

From engineeringinfohub.com

Why Using The Crank Bar In Slab Column RCC Beam Engineering Crank Bar Meaning Crank bars are provided to make the steel available at both top and bottom reinforcement. A crank bar is provided to secure the rcc slab from compression stresses. Crank bars are particularly important in: Types of slabs that require crank bars. Since the steel is required only where the positive and negative moments are created, crank rods are provided in. Crank Bar Meaning.

From www.youtube.com

How to Calculate Cutting Length Of bend Up ( Crank )Bar in hindi full Crank Bar Meaning Crank bars are particularly important in: Types of slabs that require crank bars. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. When these bars are provided, the strength and deformation capacity Since the steel is required only where the positive and negative. Crank Bar Meaning.

From www.youtube.com

Why Crank Bars are Use in RCC Beam? Civil Engineering Videos YouTube Crank Bar Meaning When these bars are provided, the strength and deformation capacity When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Types of slabs that require crank bars. Crank bars are particularly important in: Crank bars are provided to make the steel available at both. Crank Bar Meaning.

From dndconstruction.blogspot.com

Why Crank Bars / Bentup Bars are Provided in Slabs/Beams Crank Bar Meaning When these bars are provided, the strength and deformation capacity Crank bars are provided to make the steel available at both top and bottom reinforcement. They are placed carefully to. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,.. Crank Bar Meaning.

From www.youtube.com

Crank bars in 3D view crank bars in beams why crank bars are Crank Bar Meaning Types of slabs that require crank bars. Crank bars are particularly important in: They are placed carefully to. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end. Crank Bar Meaning.

From www.youtube.com

What Are Crank Bars? Why Crank Bars Are Provided In Slabs, Beams? YouTube Crank Bar Meaning Types of slabs that require crank bars. A crank bar is provided to secure the rcc slab from compression stresses. They are placed carefully to. When these bars are provided, the strength and deformation capacity Crank bars are provided to make the steel available at both top and bottom reinforcement. Since the steel is required only where the positive and. Crank Bar Meaning.

From civilguidelines.com

Crank Bars are Provided In Slab and Why Crank Bar Meaning When these bars are provided, the strength and deformation capacity Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such. Crank Bar Meaning.

From www.youtube.com

Derivation of 1.42D in Bent Up Bar What is 1.42D in Crank Bar YouTube Crank Bar Meaning When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. They are placed carefully to. Types of slabs that require crank bars. A crank bar is provided to secure the rcc slab from compression stresses. Crank bars are provided to make the steel available. Crank Bar Meaning.

From www.youtube.com

WHY CRANK BARS ARE PROVIDED IN BEAMS CRANKED BAR WITH 3D ANIMATION Crank Bar Meaning Crank bars are particularly important in: When these bars are provided, the strength and deformation capacity When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Since the steel is required only where the positive and negative moments are created, crank rods are provided. Crank Bar Meaning.

From engineeringdiscoveries.com

Why Crank Bars Are Provided In Slab Engineering Discoveries Crank Bar Meaning They are placed carefully to. When these bars are provided, the strength and deformation capacity Crank bars are provided to make the steel available at both top and bottom reinforcement. Types of slabs that require crank bars. A crank bar is provided to make rcc slab safe from compressive stresses. A crank bar is provided to secure the rcc slab. Crank Bar Meaning.

From engineeringdiscoveries.com

What Are The Reasons To Use Cranked Bars In A Slab? Engineering Crank Bar Meaning A crank bar is provided to make rcc slab safe from compressive stresses. Types of slabs that require crank bars. A crank bar is provided to secure the rcc slab from compression stresses. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar. Crank Bar Meaning.

From www.youtube.com

What is Crank Bar Why We Provide Crank Bar In Slab Bent Up Bar In Crank Bar Meaning They are placed carefully to. Types of slabs that require crank bars. Crank bars are particularly important in: Crank bars are provided to make the steel available at both top and bottom reinforcement. A crank bar is provided to make rcc slab safe from compressive stresses. Since the steel is required only where the positive and negative moments are created,. Crank Bar Meaning.

From civilmint.com

Crank Bar In Beam, Slab And Column Why It Is Provided Crank Bar Meaning A crank bar is provided to secure the rcc slab from compression stresses. Crank bars are particularly important in: When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Types of slabs that require crank bars. They are placed carefully to. When these bars. Crank Bar Meaning.

From www.youtube.com

How to calculate Cutting Length of crank bar YouTube Crank Bar Meaning When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. A crank bar is provided to make rcc slab safe from compressive stresses. A crank bar is provided to secure the rcc slab from compression stresses. They are placed carefully to. Types of slabs. Crank Bar Meaning.

From www.youtube.com

What is 0.42H in Crank Bar / Cutting length f Crank Bar BY CIVIL GURUJI Crank Bar Meaning A crank bar is provided to secure the rcc slab from compression stresses. When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a. Crank Bar Meaning.

From civilmint.com

Crank Bar In Beam, Slab And Column Why It Is Provided Crank Bar Meaning Types of slabs that require crank bars. When these bars are provided, the strength and deformation capacity Crank bars are particularly important in: Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. A crank bar is provided to make. Crank Bar Meaning.

From www.youtube.com

How To Calculate Inclined Length Of Bend Up Bar (Crank Bar). YouTube Crank Bar Meaning Types of slabs that require crank bars. A crank bar is provided to make rcc slab safe from compressive stresses. They are placed carefully to. Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist the shear force at the supports,. When these bars are provided,. Crank Bar Meaning.

From www.youtube.com

Continuous Beam Reinforcement according to Crank Bars or Bent Up Bars Crank Bar Meaning A crank bar is provided to secure the rcc slab from compression stresses. Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Crank bars are provided. Crank Bar Meaning.

From www.youtube.com

What is crank Bar why we provide it Basic Topic for civil Engineers Crank Bar Meaning When these bars are provided, the strength and deformation capacity Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). They are placed carefully to. A crank. Crank Bar Meaning.

From dailyengineering.com

What Are Crank Bars? Why Crank Bars Are Provided In Slabs, Beams Crank Bar Meaning Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Types of slabs that require crank bars. Crank/bent bars are used in the slab on top of. Crank Bar Meaning.

From www.youtube.com

Why is the crank bar important in columns and beams Vital role of Crank Bar Meaning When these bars are provided, the strength and deformation capacity Crank bars are provided to make the steel available at both top and bottom reinforcement. A crank bar is provided to make rcc slab safe from compressive stresses. Crank bars are particularly important in: When these bars are provided, the strength and deformation capacity of slabs with bent up bars. Crank Bar Meaning.

From www.youtube.com

Why we use Crank Bar in Beam and Slab YouTube Crank Bar Meaning When these bars are provided, the strength and deformation capacity of slabs with bent up bars compared to slabs without bent up bars is sufficiently increased. When these bars are provided, the strength and deformation capacity Crank/bent bars are used in the slab on top of the reinforcements to resist negative (hogging) moment at the supports of the slab, resist. Crank Bar Meaning.

From www.lceted.com

What is Crank Bars? Why its provided in Slab? lceted institute Crank Bar Meaning They are placed carefully to. Crank bars are particularly important in: Since the steel is required only where the positive and negative moments are created, crank rods are provided in such a way that the same steel bar can be used for both positive (mid of the slab) and negative moment area (end supports). Crank/bent bars are used in the. Crank Bar Meaning.

From www.youtube.com

CRANK SHAFT CRANK THROWN CRANK WEB FUNCTION OF CRANK SHAFT Crank Bar Meaning A crank bar is provided to make rcc slab safe from compressive stresses. A crank bar is provided to secure the rcc slab from compression stresses. Crank bars are provided to make the steel available at both top and bottom reinforcement. Types of slabs that require crank bars. They are placed carefully to. When these bars are provided, the strength. Crank Bar Meaning.