Ph Boiler In Cement Plant . 70% of clinkerization power consumption) and. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. The system contains a suspension. The reduction in co 2 emission,. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. Isgec is one of the india's largest waste heat recovery boiler manufacturers. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. One cement kiln line requires two ph boilers and one aqc boiler.

from ieepl.com

The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). 70% of clinkerization power consumption) and. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. The system contains a suspension. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Isgec is one of the india's largest waste heat recovery boiler manufacturers. The reduction in co 2 emission,.

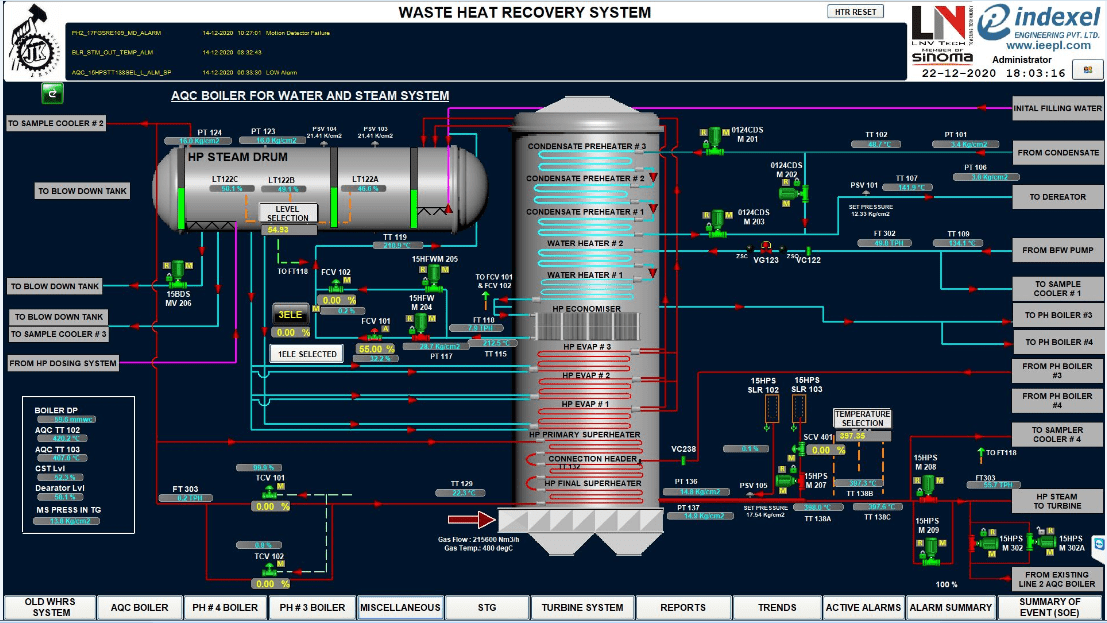

WHRS Indexel Engineering Pvt. Ltd.

Ph Boiler In Cement Plant Isgec is one of the india's largest waste heat recovery boiler manufacturers. Isgec is one of the india's largest waste heat recovery boiler manufacturers. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. The system contains a suspension. The reduction in co 2 emission,. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). One cement kiln line requires two ph boilers and one aqc boiler. 70% of clinkerization power consumption) and. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and.

From www.boiler-units.com

Water Heat CFB Boiler APH Steam Air Preheater In Cement Plant , Tubular Ph Boiler In Cement Plant 1 shows the schematic diagram of the waste heat power generation system for a cement plant. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. One cement kiln line requires two ph boilers and one aqc boiler. Waste heat recovery power plants, contribute significantly, to the electrical energy. Ph Boiler In Cement Plant.

From fortisventures.org

AQC, PH/SP Boiler Fortis Ventures (Private) Limited Ph Boiler In Cement Plant Isgec is one of the india's largest waste heat recovery boiler manufacturers. One cement kiln line requires two ph boilers and one aqc boiler. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx.. Ph Boiler In Cement Plant.

From phtechs.in

ph tech engineering services Ph Boiler In Cement Plant The reduction in co 2 emission,. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%).. Ph Boiler In Cement Plant.

From www.researchgate.net

Heat recovery system with ORC technology in the cement industry typical Ph Boiler In Cement Plant (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The latest generation of cement. Ph Boiler In Cement Plant.

From cementplantparts.com

Boiler Steam Header for Cement Plant AGICO CEMENT Ph Boiler In Cement Plant It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. One cement kiln line requires two ph boilers and one aqc boiler. The reduction in co 2 emission,. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. (whr) boiler steam turbine generator system at. Ph Boiler In Cement Plant.

From hapbco.co

Hapbco Ph Boiler In Cement Plant The reduction in co 2 emission,. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). Isgec is. Ph Boiler In Cement Plant.

From www.designexcel.com

Design Excellence (India) Pvt. Ltd BoilersForCementPlant Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. The system contains a suspension. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The reduction in co 2 emission,. Isgec is one of the india's largest waste heat. Ph Boiler In Cement Plant.

From ieepl.com

WHRS Indexel Engineering Pvt. Ltd. Ph Boiler In Cement Plant Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The system contains a suspension. The reduction in co 2 emission,. One cement kiln line requires two ph boilers and one aqc boiler. 70% of clinkerization power consumption) and. Isgec is one of the india's largest waste heat recovery boiler manufacturers. 1 shows. Ph Boiler In Cement Plant.

From saintwah.en.made-in-china.com

Orc Waste Heat Generation Heat Recovery System Is Used in Cement Plant Ph Boiler In Cement Plant The system contains a suspension. Isgec is one of the india's largest waste heat recovery boiler manufacturers. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. 70% of clinkerization power consumption) and. One cement kiln line requires two ph boilers and one aqc boiler. Waste heat recovery power plants, contribute significantly, to the. Ph Boiler In Cement Plant.

From saintwah.en.made-in-china.com

Orc Waste Heat Generation Heat Recovery System Is Used in Cement Plant Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. The system contains a suspension. The reduction in co 2 emission,. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. One cement kiln line requires two ph boilers and one aqc boiler. Isgec is one of the india's largest waste heat recovery. Ph Boiler In Cement Plant.

From www.indiamart.com

Industrial Parker AQC and PH Boiler, 800065000 Kg/Hr, for Cement Plant Ph Boiler In Cement Plant 1 shows the schematic diagram of the waste heat power generation system for a cement plant. One cement kiln line requires two ph boilers and one aqc boiler. 70% of clinkerization power consumption) and. Isgec is one of the india's largest waste heat recovery boiler manufacturers. Waste heat recovery can provide up to 30 percent of a cement plant’s overall. Ph Boiler In Cement Plant.

From gec.jp

Power Generation by Wasteheat Recovery in Cement Industry JCM The Ph Boiler In Cement Plant One cement kiln line requires two ph boilers and one aqc boiler. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. The latest generation of cement kiln whrpg technology. Ph Boiler In Cement Plant.

From www.cementequipment.org

Fuels in the cement industry INFINITY FOR CEMENT EQUIPMENT Ph Boiler In Cement Plant The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). (whr) boiler steam turbine generator system at an. Ph Boiler In Cement Plant.

From hapbco.co

Hapbco Ph Boiler In Cement Plant (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. One cement kiln. Ph Boiler In Cement Plant.

From fortisventures.org

AQC, PH/SP Boiler Fortis Ventures (Private) Limited Ph Boiler In Cement Plant Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. 70% of clinkerization power consumption) and. The system contains a suspension. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The reduction in co 2 emission,. (whr) boiler steam turbine generator system at an existing. Ph Boiler In Cement Plant.

From martech.com.vn

Application of boiler in cement industry Martech JSC Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The system contains a suspension. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. The reduction in co 2 emission,. Waste heat recovery can provide up to 30. Ph Boiler In Cement Plant.

From www.pinterest.co.uk

Image result for ph boiler and aqc boiler Ph Boiler In Cement Plant It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. The reduction in co 2 emission,. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. Waste. Ph Boiler In Cement Plant.

From dcengineeringindonesia.com

First Pouring Concrete Foundation for Boiler 1 PLTU Sumbagsel1 D & C Ph Boiler In Cement Plant The reduction in co 2 emission,. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. The system contains a suspension. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. Waste heat recovery can provide up to 30 percent. Ph Boiler In Cement Plant.

From civiconcepts.com

Cement Manufacturing A Wet Process With Flow Diagram Ph Boiler In Cement Plant Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). The system contains a suspension. The reduction in co 2 emission,. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc). Ph Boiler In Cement Plant.

From www.triveniturbines.com

Steam Turbine For Cement Industry Triveni Turbines Ph Boiler In Cement Plant The system contains a suspension. One cement kiln line requires two ph boilers and one aqc boiler. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. The reduction in co 2 emission,. Isgec is one. Ph Boiler In Cement Plant.

From www.youtube.com

AQC Boilar// cement plant YouTube Ph Boiler In Cement Plant Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). 1 shows the schematic diagram of the waste heat power generation system for a cement plant. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Isgec is one of the india's largest waste. Ph Boiler In Cement Plant.

From awipl.in

ASSOCIATED WORKS INFRA PVT. LTD. Ph Boiler In Cement Plant Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. The system contains a suspension. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process,. Ph Boiler In Cement Plant.

From idi-tn.com

Precision Boilers for Major Central Plant Project Innovative Design Inc. Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. The reduction in co 2 emission,. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. (whr) boiler steam turbine generator system at an existing cement production plant (pt. Ph Boiler In Cement Plant.

From leomi.in

Advanced Air & Process Gas Flow Monitoring in Cement Plants Ph Boiler In Cement Plant Isgec is one of the india's largest waste heat recovery boiler manufacturers. The system contains a suspension. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. One cement kiln line requires two ph boilers and one aqc boiler. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker. Ph Boiler In Cement Plant.

From www.tradekorea.com

Cement Kiln Waste Heat Boilers in Cement Mill tradekorea Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. One cement kiln line requires two ph boilers and one aqc boiler. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Waste heat recovery power plants, contribute. Ph Boiler In Cement Plant.

From www.researchgate.net

Energy flow chart of the clinker production section of a cement plant Ph Boiler In Cement Plant 70% of clinkerization power consumption) and. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). 1 shows the schematic diagram of the waste heat power generation system for a cement plant. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. One cement kiln line. Ph Boiler In Cement Plant.

From digital-analysis.com

Boiler Blowdown pH Neutralization System. Skid mounted and fully automated. Ph Boiler In Cement Plant Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). One cement kiln line requires two ph boilers and one aqc boiler. 70% of clinkerization power consumption) and. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. Waste heat recovery can provide up to. Ph Boiler In Cement Plant.

From ctp.mi.it

Improving cement industry’s environmental footprint CTP Ph Boiler In Cement Plant The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. The system. Ph Boiler In Cement Plant.

From www.zkg.de

Trends in power generation from waste heat in cement plants Cement Ph Boiler In Cement Plant The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. The system contains a suspension. Isgec is one of the india's largest waste heat recovery boiler manufacturers. One cement kiln line requires two ph boilers and. Ph Boiler In Cement Plant.

From sioux.com

Water Chillers & Boilers for Ready Mix Concrete Batch Plants Sioux Ph Boiler In Cement Plant One cement kiln line requires two ph boilers and one aqc boiler. 70% of clinkerization power consumption) and. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. The reduction in co 2 emission,. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%).. Ph Boiler In Cement Plant.

From www.industrialboilerforsale.com

8 ton Steam Boiler for Tiemen Cement Plant Ph Boiler In Cement Plant (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia, tuban plant) located in tuban, east. The system contains a suspension. The reduction in co 2 emission,. One cement kiln line requires two ph boilers and one aqc boiler. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers. Ph Boiler In Cement Plant.

From www.boiler-units.com

High Temperature Solid Fuel Boiler Steam Air Preheater In Cement Plant Ph Boiler In Cement Plant One cement kiln line requires two ph boilers and one aqc boiler. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). 1 shows the schematic diagram of the waste heat power generation system for a cement plant. (whr) boiler steam turbine generator system at an existing cement production plant (pt semen indonesia,. Ph Boiler In Cement Plant.

From www.isgec.com

ISGEC Waste Heat Recovery Boiler Manufacturers PH boilers AQC boilers Ph Boiler In Cement Plant The system contains a suspension. The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. Waste heat recovery can provide up to 30 percent of a cement plant’s overall electricity needs (approx. 70% of clinkerization power consumption) and. It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber. Ph Boiler In Cement Plant.

From minhquancapital.com

Waste Heat Recovery Power Generator for Cement Plants Minh Quan Ph Boiler In Cement Plant The latest generation of cement kiln whrpg technology organically integrates whrpg with the clinker production line process, and. 1 shows the schematic diagram of the waste heat power generation system for a cement plant. The reduction in co 2 emission,. One cement kiln line requires two ph boilers and one aqc boiler. Waste heat recovery power plants, contribute significantly, to. Ph Boiler In Cement Plant.

From www.isgec.com

High Pressure Industrial Boilers Manufacturer Isgec Ph Boiler In Cement Plant 1 shows the schematic diagram of the waste heat power generation system for a cement plant. The reduction in co 2 emission,. Waste heat recovery power plants, contribute significantly, to the electrical energy saving (to the tune of 25%). It offers waste heat recovery steam pre heater (ph) boilers & after quenching chamber (aqc) boilers for cement plant. Waste heat. Ph Boiler In Cement Plant.