Spot Weld Sizes . Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. there are 4 variables to consider with resistance spot welding; spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. It is a type of resistance welding process. spot welding is a crucial technique in manufacturing, but how much do you really know about it? The process involves the application of heat and pressure to create a weld at specific points. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. Pressure, weld time, current, and tip. what is spot welding? If the sheets are steel, the resistance to the. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes.

from weldguru.com

these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. Pressure, weld time, current, and tip. It is a type of resistance welding process. The process involves the application of heat and pressure to create a weld at specific points. spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. spot welding is a crucial technique in manufacturing, but how much do you really know about it? there are 4 variables to consider with resistance spot welding; the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current.

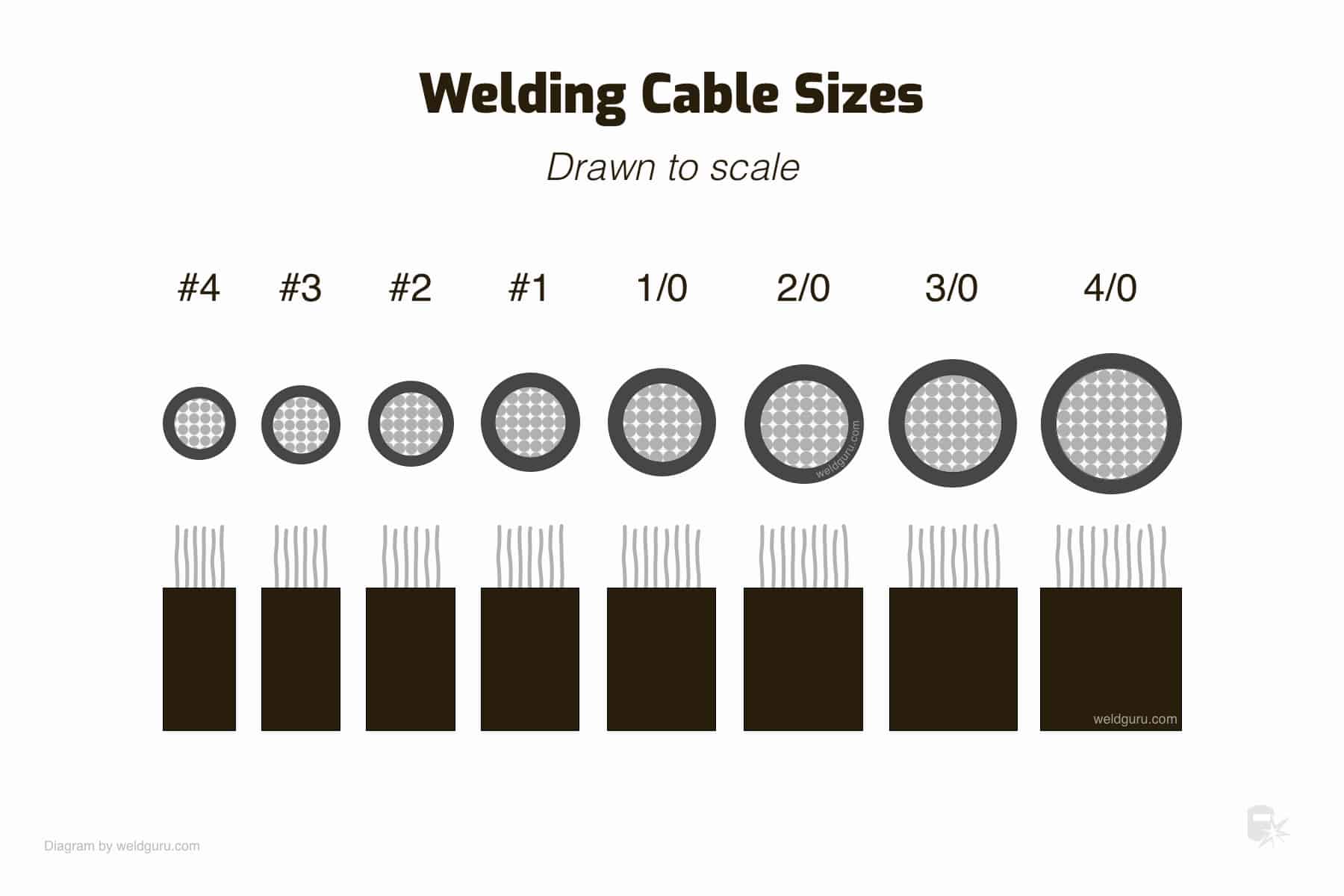

Welding Cable Size Guide Charts & Tips for the Right Choice

Spot Weld Sizes the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. Pressure, weld time, current, and tip. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. If the sheets are steel, the resistance to the. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. what is spot welding? spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. there are 4 variables to consider with resistance spot welding; spot welding is a crucial technique in manufacturing, but how much do you really know about it? in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. It is a type of resistance welding process. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. The process involves the application of heat and pressure to create a weld at specific points. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding.

From weldfaqs.com

Common Weld Types Fillet, Groove, Plug, Slot, Spot & Seam Weld Weld Faqs Spot Weld Sizes spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. the resistance spot welding (rsw) process is often. Spot Weld Sizes.

From weaversteelweld.com

Pipe Size Chart Weaver Steel Welding Spot Weld Sizes If the sheets are steel, the resistance to the. there are 4 variables to consider with resistance spot welding; the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot. Spot Weld Sizes.

From ahssinsights.org

Spot Welds Fatigue Strength AHSS Guidelines Spot Weld Sizes spot welding is a crucial technique in manufacturing, but how much do you really know about it? the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. Pressure, weld time, current, and tip. The process involves the application of heat and pressure to create a weld. Spot Weld Sizes.

From www.howtoresistanceweld.info

What is the formula to calculate nugget diameter in resistance welding Spot Weld Sizes what is spot welding? in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. If the sheets are steel, the resistance to the. these general guidelines can be used. Spot Weld Sizes.

From www.eng-tips.com

Fillet Weld Size Based On Plate Thick Structural engineering general Spot Weld Sizes the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. It is a type of resistance welding process. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. spot welding is a. Spot Weld Sizes.

From www.cruxweld.com

Understanding the Welding Symbols [Explained with Diagrams] cruxweld Spot Weld Sizes spot welding is a crucial technique in manufacturing, but how much do you really know about it? these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. Pressure, weld time, current, and tip. spot welding (or resistance spot welding [1]) is a type of electric resistance welding used. Spot Weld Sizes.

From www.slideserve.com

PPT Welding Representation PowerPoint Presentation, free download Spot Weld Sizes in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. there are 4 variables to consider with resistance spot welding; these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. the resistance spot welding (rsw) process is often used as a model. Spot Weld Sizes.

From ahssinsights.org

Spot Weld Strength Improvement by PWHT AHSS Guidelines Spot Weld Sizes The process involves the application of heat and pressure to create a weld at specific points. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. If the sheets are steel, the resistance to the. in summary, spot welding involves clamping metal sheets between electrodes, passing. Spot Weld Sizes.

From aviationandaccessories.tpub.com

TABLE 221. TYPICAL MACHINE SETTINGS, MINIMUM SPACING AND NUGGET Spot Weld Sizes spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. If the sheets are steel, the resistance to the. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. . Spot Weld Sizes.

From ahssinsights.org

Resistance Spot Welding Archives Page 4 of 5 AHSS Guidelines Spot Weld Sizes If the sheets are steel, the resistance to the. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. The process involves the application of heat and pressure to create a weld at specific points. It is a type of resistance welding process. Pressure, weld time, current, and tip. spot welding is a. Spot Weld Sizes.

From spotweldinc.com

Seam Welders Spot Weld, Inc. Spot Weld Sizes spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. there are 4 variables to consider with resistance spot welding; spot. Spot Weld Sizes.

From www.onestopndt.com

fillet weld Spot Weld Sizes what is spot welding? spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. there are 4 variables to consider with. Spot Weld Sizes.

From marinerspointpro.com

Spot Welding Marinerspoint Pro Spot Weld Sizes what is spot welding? these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. spot welding is a crucial technique in manufacturing, but how. Spot Weld Sizes.

From www.leisto.com

Spot Welding Electrode's Tip, Spot Welding Tip, Micro Welding Tip Spot Weld Sizes spot welding is a crucial technique in manufacturing, but how much do you really know about it? spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. the tables listed here contain data from bs en iso 14373:2015, the standard relating. Spot Weld Sizes.

From blog.thepipingmart.com

Spot Welding vs Projection Welding What's the Difference Spot Weld Sizes The process involves the application of heat and pressure to create a weld at specific points. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. Figure 1 shows a standard resistance spot welding. Spot Weld Sizes.

From www.slideserve.com

PPT Welding Joints, Positions, and Symbols PowerPoint Presentation Spot Weld Sizes in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. Pressure, weld time, current, and tip. spot welding is a crucial technique in manufacturing, but how much do you really know about it? what is spot welding? The process involves the application of heat and pressure to create a weld at specific. Spot Weld Sizes.

From www.slideserve.com

PPT Economical Guidelines for Design of Structural Steel PowerPoint Spot Weld Sizes there are 4 variables to consider with resistance spot welding; It is a type of resistance welding process. If the sheets are steel, the resistance to the. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. spot welding is a crucial technique in manufacturing,. Spot Weld Sizes.

From www.howtoresistanceweld.info

Spot Welding HowTo Resistance Weld Spot Weld Sizes spot welding is a crucial technique in manufacturing, but how much do you really know about it? It is a type of resistance welding process. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. The process involves the application of heat and pressure to create a weld at. Spot Weld Sizes.

From spotweldinc.com

SetUp Guides Spot Weld, Inc. Spot Weld Sizes in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. what is spot welding? the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of. Spot Weld Sizes.

From www.howtoresistanceweld.info

What is the pitch between Arc and Spot welding? HowTo Resistance Weld Spot Weld Sizes the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. there are 4 variables to consider with resistance spot welding; spot. Spot Weld Sizes.

From blog.thepipingmart.com

How to Spot Weld Stainless Steel A Complete Guide Spot Weld Sizes Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. these general guidelines can be used to approximate which parameters can be. Spot Weld Sizes.

From blog.thepipingmart.com

How to Spot Weld with Sheet Metal A Complete Guide Spot Weld Sizes spot welding is a crucial technique in manufacturing, but how much do you really know about it? the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. The process involves the application of heat and pressure to create a weld at specific points. in summary,. Spot Weld Sizes.

From weldguru.com

Welding Cable Size Guide Charts & Tips for the Right Choice Spot Weld Sizes there are 4 variables to consider with resistance spot welding; the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. spot welding is a crucial technique in manufacturing, but how much do you really know about it? the resistance spot welding (rsw) process is. Spot Weld Sizes.

From www.lowcostwelder.com

Spot welding parameters setting optimal values for spotwelding Spot Weld Sizes the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. It is a type of resistance welding process. spot welding is a crucial technique in manufacturing, but how much do. Spot Weld Sizes.

From www.youtube.com

Spot Welding Basics YouTube Spot Weld Sizes If the sheets are steel, the resistance to the. what is spot welding? Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding. Spot Weld Sizes.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Spot Weld Sizes If the sheets are steel, the resistance to the. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. It is a type of resistance welding process. in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. the resistance. Spot Weld Sizes.

From studycampuslemann.z19.web.core.windows.net

Welding Wire Gauge Chart Spot Weld Sizes If the sheets are steel, the resistance to the. there are 4 variables to consider with resistance spot welding; in summary, spot welding involves clamping metal sheets between electrodes, passing a high electric current. the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. Figure. Spot Weld Sizes.

From slidetodoc.com

CHAPTER 22 WELDING REPRESENTATION 1 IMPORTANCE OF THE Spot Weld Sizes Pressure, weld time, current, and tip. The process involves the application of heat and pressure to create a weld at specific points. If the sheets are steel, the resistance to the. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. spot welding is a. Spot Weld Sizes.

From ahssinsights.org

Spot Welds Fatigue Strength AHSS Guidelines Spot Weld Sizes these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. spot welding is a crucial technique in manufacturing, but how much do you really know about it? what is spot welding? there are 4 variables to consider with resistance spot welding; in summary, spot welding involves. Spot Weld Sizes.

From slidetodoc.com

WELD JOINT GEOMETERY AND WELDING SYMBOLS Terminology Definitions Spot Weld Sizes The process involves the application of heat and pressure to create a weld at specific points. the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. what is spot welding? spot welding (or resistance spot welding [1]) is a type of electric resistance welding used. Spot Weld Sizes.

From www.researchgate.net

Conventional solid spot welding electrodes used in the study Spot Weld Sizes If the sheets are steel, the resistance to the. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply force and pass current through the sheets being welded. It is a type of resistance welding process. there are 4 variables to consider with resistance spot welding; the resistance spot welding (rsw) process is. Spot Weld Sizes.

From dxorkmqso.blob.core.windows.net

Welding Rods Guide at Demetrius Carlson blog Spot Weld Sizes the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. there are 4 variables to consider with resistance spot welding; these general guidelines can be used to approximate which parameters can be used to begin the resistance spot welding. spot welding is a crucial. Spot Weld Sizes.

From nissho-astec.com

Spot Welding NISSHO ASTEC CO., LTD. Spot Weld Sizes The process involves the application of heat and pressure to create a weld at specific points. spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which. spot welding is a crucial technique in manufacturing, but how much do you really know about. Spot Weld Sizes.

From exohyurxw.blob.core.windows.net

Welding Parameters For Gmaw at Maurita Martin blog Spot Weld Sizes the resistance spot welding (rsw) process is often used as a model to explain the fundamental concepts behind most resistance welding processes. Pressure, weld time, current, and tip. The process involves the application of heat and pressure to create a weld at specific points. Figure 1 shows a standard resistance spot welding arrangement in which two copper electrodes apply. Spot Weld Sizes.

From workshopinsider.com

Welding Symbols Guide to Reading Weld Symbols Spot Weld Sizes If the sheets are steel, the resistance to the. there are 4 variables to consider with resistance spot welding; the tables listed here contain data from bs en iso 14373:2015, the standard relating to spot welding of low carbon steels, both. these general guidelines can be used to approximate which parameters can be used to begin the. Spot Weld Sizes.