What Is Bend Radius Sheet Metal . bend radii & minimum bend sizes. Here are a few key concepts to know about designing for sheet metal. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). It is most economical to use a single bend radius throughout the design, but if necessary,. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. — in steel between 0.5 and 0.8 in. Below is xometry’s minimum bend radius reference table which is based on theoretical. Brackets, covers, cabinets, chassis, electrical. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — what is the right bend radius for sheet metal? sheet metal bend radius guidelines.

from dxohfuetc.blob.core.windows.net

Brackets, covers, cabinets, chassis, electrical. It is most economical to use a single bend radius throughout the design, but if necessary,. Below is xometry’s minimum bend radius reference table which is based on theoretical. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. Here are a few key concepts to know about designing for sheet metal. — what is the right bend radius for sheet metal? — in steel between 0.5 and 0.8 in. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. sheet metal bend radius guidelines.

Sheet Metal Bend Radius Tolerance at Wade Breeden blog

What Is Bend Radius Sheet Metal — in steel between 0.5 and 0.8 in. bend radii & minimum bend sizes. Below is xometry’s minimum bend radius reference table which is based on theoretical. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Here are a few key concepts to know about designing for sheet metal. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. It is most economical to use a single bend radius throughout the design, but if necessary,. — what is the right bend radius for sheet metal? — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. — in steel between 0.5 and 0.8 in. sheet metal bend radius guidelines. Brackets, covers, cabinets, chassis, electrical.

From www.youtube.com

Making a Radius Bending Fixture for Sheetmetal YouTube What Is Bend Radius Sheet Metal Here are a few key concepts to know about designing for sheet metal. bend radii & minimum bend sizes. Brackets, covers, cabinets, chassis, electrical. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness. What Is Bend Radius Sheet Metal.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog What Is Bend Radius Sheet Metal — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — in steel between 0.5 and 0.8 in. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius. What Is Bend Radius Sheet Metal.

From metalmaq.shop

Metal sheet bending table What Is Bend Radius Sheet Metal Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical. — what is. What Is Bend Radius Sheet Metal.

From aaronconnolly.z19.web.core.windows.net

Aluminum Sheet Metal Bend Radius What Is Bend Radius Sheet Metal It is most economical to use a single bend radius throughout the design, but if necessary,. sheet metal bend radius guidelines. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — what is the right bend radius for sheet metal? sheet metal bend radius. What Is Bend Radius Sheet Metal.

From www.thefabricator.com

Minimum inside sheet metal bend radius vs what's What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. — in steel between 0.5 and 0.8 in. — what is the right bend radius for sheet metal? sheet metal bend radius guidelines. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. It is most economical to. What Is Bend Radius Sheet Metal.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange What Is Bend Radius Sheet Metal — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — what is the right bend radius for sheet metal? It is most economical to use a single bend radius throughout the design, but if necessary,. sheet metal bend radius guidelines. Brackets, covers, cabinets, chassis, electrical.. What Is Bend Radius Sheet Metal.

From mungfali.com

Sheet Metal Bend Radius What Is Bend Radius Sheet Metal Here are a few key concepts to know about designing for sheet metal. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum. What Is Bend Radius Sheet Metal.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the. What Is Bend Radius Sheet Metal.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices (Updated for 2023) ASM What Is Bend Radius Sheet Metal — what is the right bend radius for sheet metal? Brackets, covers, cabinets, chassis, electrical. Here are a few key concepts to know about designing for sheet metal. Below is xometry’s minimum bend radius reference table which is based on theoretical. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for. What Is Bend Radius Sheet Metal.

From mavink.com

Sheet Metal Minimum Bend Radius Chart What Is Bend Radius Sheet Metal Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with. What Is Bend Radius Sheet Metal.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe What Is Bend Radius Sheet Metal Brackets, covers, cabinets, chassis, electrical. It is most economical to use a single bend radius throughout the design, but if necessary,. bend radii & minimum bend sizes. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Here are a few key concepts to know about designing for sheet. What Is Bend Radius Sheet Metal.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart What Is Bend Radius Sheet Metal sheet metal bend radius guidelines. It is most economical to use a single bend radius throughout the design, but if necessary,. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Here are a few key concepts to know about designing for sheet metal. bend radii & minimum. What Is Bend Radius Sheet Metal.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart What Is Bend Radius Sheet Metal sheet metal bend radius guidelines. — in steel between 0.5 and 0.8 in. Here are a few key concepts to know about designing for sheet metal. bend radii & minimum bend sizes. Brackets, covers, cabinets, chassis, electrical. It is most economical to use a single bend radius throughout the design, but if necessary,. Thick, grade 350 and. What Is Bend Radius Sheet Metal.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study What Is Bend Radius Sheet Metal Brackets, covers, cabinets, chassis, electrical. Below is xometry’s minimum bend radius reference table which is based on theoretical. — what is the right bend radius for sheet metal? — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — bending is a stamping process that uses. What Is Bend Radius Sheet Metal.

From skill-lync.com

What is Sheet Metal? How to Design a Sheet Metal Bend Radius? What Is Bend Radius Sheet Metal — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. — what is the right bend radius for sheet metal? sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. It is most economical. What Is Bend Radius Sheet Metal.

From exovyzyec.blob.core.windows.net

Aluminium Sheet Metal Bend Radius at Jeffrey Crane blog What Is Bend Radius Sheet Metal sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. bend radii & minimum bend sizes. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. sheet metal bend radius guidelines. Thick, grade. What Is Bend Radius Sheet Metal.

From www.javelin-tech.com

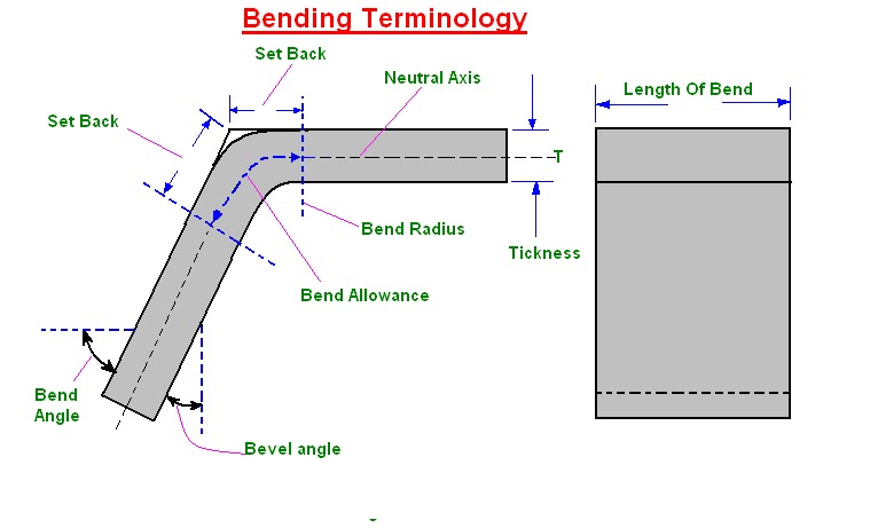

Learn Sheet Metal Design Terminology including Bend Deduction What Is Bend Radius Sheet Metal Brackets, covers, cabinets, chassis, electrical. Here are a few key concepts to know about designing for sheet metal. sheet metal bend radius guidelines. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — what is the right bend radius for sheet metal? Below is xometry’s. What Is Bend Radius Sheet Metal.

From unitymanufacture.com

How To Bend A Radius In Sheet Metal? Unity Manufacture What Is Bend Radius Sheet Metal — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Below is xometry’s minimum bend radius reference table which is based on theoretical. — in steel between 0.5 and 0.8 in. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending. What Is Bend Radius Sheet Metal.

From www.machinemfg.com

Bend Radius Chart (Steel, Aluminum & Copper) MachineMFG What Is Bend Radius Sheet Metal — what is the right bend radius for sheet metal? sheet metal bend radius guidelines. Here are a few key concepts to know about designing for sheet metal. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — bending is a stamping process that. What Is Bend Radius Sheet Metal.

From tipseri.com

How to calculate the bending radius for sheet metal? Tipseri What Is Bend Radius Sheet Metal — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. It is most economical to use a single bend radius throughout the design, but if necessary,. Below is xometry’s minimum bend radius reference table which is based on theoretical. Brackets, covers, cabinets, chassis, electrical. sheet metal bend. What Is Bend Radius Sheet Metal.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec What Is Bend Radius Sheet Metal — what is the right bend radius for sheet metal? Brackets, covers, cabinets, chassis, electrical. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. It is most economical to use a single bend radius throughout the design, but if necessary,. Here are a few key concepts to know. What Is Bend Radius Sheet Metal.

From www.tbkmetal.com

5 Things To Consider When Using The Proper Sheet Metal Bend Radius For What Is Bend Radius Sheet Metal — in steel between 0.5 and 0.8 in. Below is xometry’s minimum bend radius reference table which is based on theoretical. Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate,. What Is Bend Radius Sheet Metal.

From www.rocheindustry.com

The Basics of Bending Sheet Metal You Should Know What Is Bend Radius Sheet Metal Here are a few key concepts to know about designing for sheet metal. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure 1). bend radii & minimum bend sizes. —. What Is Bend Radius Sheet Metal.

From www.researchgate.net

The sheet metal stretchbending with bending radius R die (a) the What Is Bend Radius Sheet Metal — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. Here are a few key concepts to know about designing for sheet metal. Below is xometry’s minimum bend. What Is Bend Radius Sheet Metal.

From dxohfuetc.blob.core.windows.net

Sheet Metal Bend Radius Tolerance at Wade Breeden blog What Is Bend Radius Sheet Metal sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. Brackets, covers, cabinets, chassis, electrical. bend radii & minimum bend sizes. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending. What Is Bend Radius Sheet Metal.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange What Is Bend Radius Sheet Metal — what is the right bend radius for sheet metal? sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. Brackets, covers, cabinets, chassis, electrical. Below is xometry’s minimum bend radius reference table which is based on theoretical. bend radii & minimum bend. What Is Bend Radius Sheet Metal.

From materialschoollavonne.z21.web.core.windows.net

Bend Radius Chart Sheet Metal What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. sheet metal bend radius guidelines. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. — in steel between 0.5 and 0.8 in. — dfm advice like bend radius best practices helps to ensure that. What Is Bend Radius Sheet Metal.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe What Is Bend Radius Sheet Metal — in steel between 0.5 and 0.8 in. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. It is most economical to use a single bend radius throughout the design, but if necessary,. sheet metal bend radius is an essential factor to consider during metal. What Is Bend Radius Sheet Metal.

From www.krrass.com

How Sheet Metal Bend Radius is Calculated What Is Bend Radius Sheet Metal sheet metal bend radius guidelines. bend radii & minimum bend sizes. It is most economical to use a single bend radius throughout the design, but if necessary,. Here are a few key concepts to know about designing for sheet metal. — dfm advice like bend radius best practices helps to ensure that part designs are optimized for. What Is Bend Radius Sheet Metal.

From mavink.com

Steel Bend Radius Chart What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. Below is xometry’s minimum bend radius reference table which is based on theoretical. — in steel between 0.5 and 0.8 in. Brackets, covers, cabinets, chassis, electrical. — what is the right bend radius for sheet metal? — dfm advice like bend radius best practices helps to ensure that part designs. What Is Bend Radius Sheet Metal.

From classcampustommie.z21.web.core.windows.net

Sheet Metal Bend Radius Chart What Is Bend Radius Sheet Metal — dfm advice like bend radius best practices helps to ensure that part designs are optimized for quick, accurate, and cost. Below is xometry’s minimum bend radius reference table which is based on theoretical. sheet metal bend radius guidelines. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or. What Is Bend Radius Sheet Metal.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart What Is Bend Radius Sheet Metal sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. — what is the right bend radius for sheet metal? — in steel between 0.5 and 0.8 in. bend radii & minimum bend sizes. sheet metal bend radius guidelines. It is. What Is Bend Radius Sheet Metal.

From id.pinterest.com

Engineering First Principles (engineering_first_principles) en What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. It is most economical to use a single bend radius throughout the design, but if necessary,. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s 3.75 times the material thickness (see figure. What Is Bend Radius Sheet Metal.

From mungfali.com

Stainless Steel Bend Radius Chart What Is Bend Radius Sheet Metal Here are a few key concepts to know about designing for sheet metal. — what is the right bend radius for sheet metal? — bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and. sheet metal bend radius guidelines. It is most economical to use a single bend radius. What Is Bend Radius Sheet Metal.

From www.indiamart.com

MS Sheet Metal Radius Bending, Bend Radius 3D at Rs 15/kg in Ahmedabad What Is Bend Radius Sheet Metal bend radii & minimum bend sizes. sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. Brackets, covers, cabinets, chassis, electrical. Below is xometry’s minimum bend radius reference table which is based on theoretical. — in steel between 0.5 and 0.8 in. It. What Is Bend Radius Sheet Metal.