Polishing Process Simulation . This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after.

from www.semanticscholar.org

Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves.

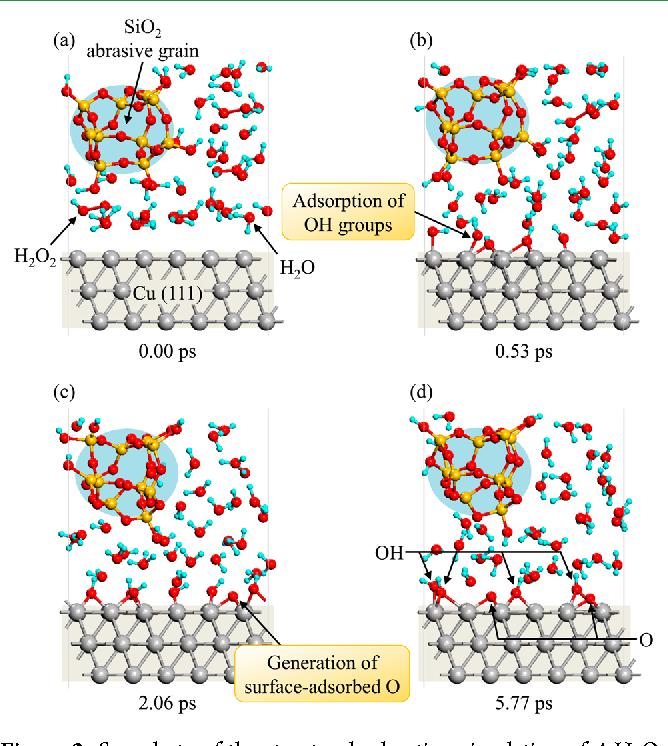

Atomistic Mechanisms of Chemical Mechanical Polishing of a Cu Surface

Polishing Process Simulation Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This research aims to establish a finite element analysis model of the polishing.

From www.mdpi.com

Micromachines Free FullText Uniform Polishing Method of Spherical Polishing Process Simulation Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This research aims to establish a finite element analysis model of the polishing. This. Polishing Process Simulation.

From www.slideserve.com

PPT Tutorial on Chemical Mechanical Polishing (CMP) PowerPoint Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and. Polishing Process Simulation.

From pubs.acs.org

New Atomistic Insights on the Chemical Mechanical Polishing of Silica Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This research aims to establish a finite element analysis model of the polishing. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which. Polishing Process Simulation.

From www.mdpi.com

Materials Free FullText Subsurface Damage in Polishing Process of Polishing Process Simulation This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From blog.thepipingmart.com

What is Metal Polishing? Process and Types Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which. Polishing Process Simulation.

From www.mdpi.com

Applied Sciences Free FullText Simulation and Experimental Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From www.youtube.com

Polishing Process Simulation YouTube Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. This. Polishing Process Simulation.

From www.semanticscholar.org

Atomistic Mechanisms of Chemical Mechanical Polishing of a Cu Surface Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From www.researchgate.net

Simulation results of the polishing tool Download Scientific Diagram Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This. Polishing Process Simulation.

From www.researchgate.net

(PDF) Subsurface Damage in Polishing Process of Silicon Carbide Ceramic Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From www.mdpi.com

Fluids Free FullText Towards an Understanding of Multiphase Fluid Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp). Polishing Process Simulation.

From www.researchgate.net

The schematic of the polishing principle Download Scientific Diagram Polishing Process Simulation This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. This research aims to establish a finite element analysis model of the polishing. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly. Polishing Process Simulation.

From www.researchgate.net

Shear thickening polishing (STP) method for ultraprecision machining Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic. Polishing Process Simulation.

From www.helandermetal.com

The Basics of Metal Polishing Helander Polishing Process Simulation Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Based. Polishing Process Simulation.

From www.hitachizosen.co.jp

Polishing Eqipment and Precision Polishing Process Hitachi Zosen Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. This. Polishing Process Simulation.

From roboticom.it

SandRob the applications of the finishing robotic system in the Polishing Process Simulation This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From www.horiba.com

Semiconductor Processing Chemical Mechanical Planarization Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This research aims to establish a finite element analysis model of the polishing. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of. Polishing Process Simulation.

From www.cambridge.org

A review on chemical and mechanical phenomena at the wafer interface Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria. Polishing Process Simulation.

From www.researchgate.net

Structure simulation process of polishing cloth. a Simulation process Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This paper provides a literature review on. Polishing Process Simulation.

From alltechapp.com

The 10 Best Chemical Process Simulation Software Packages For Chemical Polishing Process Simulation This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This research aims to establish a finite element analysis model of the polishing. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of. Polishing Process Simulation.

From ieeexplore.ieee.org

Modeling Of Chemical Mechanical Polishing Process For Threedimensional Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This research aims to establish a finite element analysis model of the polishing. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and. Polishing Process Simulation.

From www.researchgate.net

(PDF) A novel multijet polishing process and tool for highefficiency Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate. Polishing Process Simulation.

From cncmf.com

What is the Polishing Process and its Application and Working Principle Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which. Polishing Process Simulation.

From howtorobot.com

Polishing Robots Automating the Finishing Process HowToRobot Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which. Polishing Process Simulation.

From roboticom.it

SandRob the applications of the finishing robotic system in the Polishing Process Simulation Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic. Polishing Process Simulation.

From www.researchgate.net

(PDF) Simulation of abrasive polishing process of single crystal Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of. Polishing Process Simulation.

From www.mdpi.com

Applied Sciences Free FullText ContactAreaChangeable CMP Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria. Polishing Process Simulation.

From deepforest.substack.com

A Deep Dive into Chip Manufacturing Front End of Line (FEOL) Basics Polishing Process Simulation Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite element analysis model of the polishing. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Based. Polishing Process Simulation.

From www.stahli.com

Stähli Polishing Polishing Process Simulation Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Based on the reconstructed texture features and initial topography, a stratified method is proposed. Polishing Process Simulation.

From www.researchgate.net

(PDF) Development of a multijet polishing process for inner surface Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. This research aims to establish a finite element analysis. Polishing Process Simulation.

From www.researchgate.net

Polishing process and ventilation arrangement of the polishing system Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. Amorphous and zinc blende structures atoms are. Polishing Process Simulation.

From www.youtube.com

Chemo Mechanical Polishing (CMP) Process YouTube Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and. Polishing Process Simulation.

From www.researchgate.net

Fiber based polishing process map Download Scientific Diagram Polishing Process Simulation Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Reactive molecular dynamics simulations have been used to simulate the chemical mechanical polishing (cmp) process of silica glass surfaces with the ceria (111) and (100) surfaces, which are predominantly found in ceria nanoparticles. This research aims to establish a finite. Polishing Process Simulation.

From www.researchgate.net

Simplified polishing process model. (a) Compliant rotary tool; (b) hard Polishing Process Simulation This research aims to establish a finite element analysis model of the polishing. This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. Amorphous and zinc blende structures atoms are extruded and. Polishing Process Simulation.

From www.researchgate.net

a (1) The Procedure of polishing surface and coating thereafter. (2 Polishing Process Simulation This paper provides a literature review on the fundamental mechanisms of the plasma electrolytic polishing process and discusses. Amorphous and zinc blende structures atoms are extruded and deformed within the grooves. Based on the reconstructed texture features and initial topography, a stratified method is proposed to simulate the rough surface after. This research aims to establish a finite element analysis. Polishing Process Simulation.