Types Of Electrochemical Etching . Chemical etching and electrolytic etching. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. In a typical electrochemical hf etching setup, the top. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. In most cases, an etching process requires one or more chemical reactions to take place. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Here are the main ones: There are two types of etching processes:

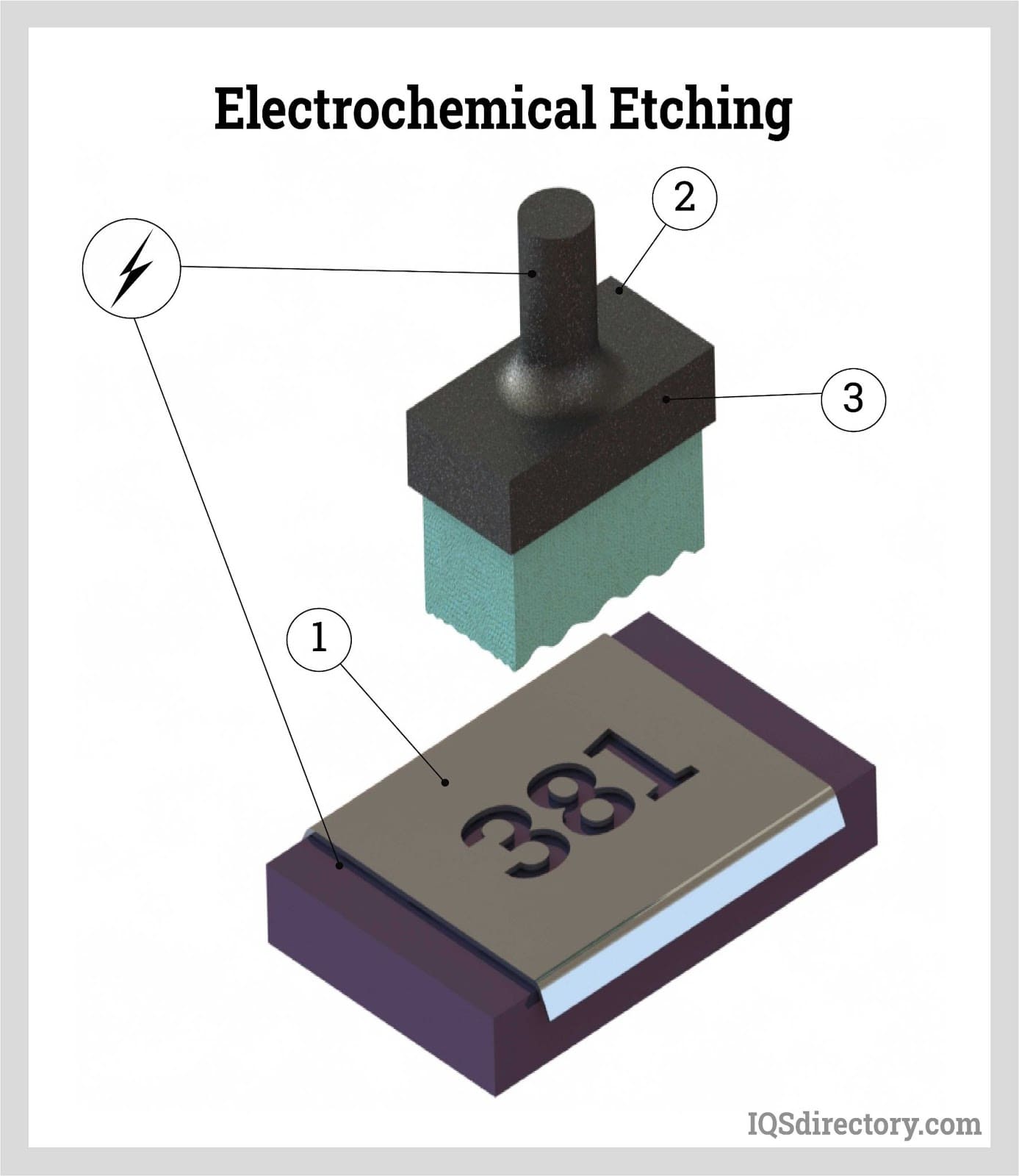

from www.iqsdirectory.com

Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. There are two types of etching processes: Chemical etching and electrolytic etching. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Here are the main ones: For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. In a typical electrochemical hf etching setup, the top.

Marking Machinery What Is It? How Is It Used? Types Of

Types Of Electrochemical Etching Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. In most cases, an etching process requires one or more chemical reactions to take place. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. In a typical electrochemical hf etching setup, the top. Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Here are the main ones: There are two types of etching processes: For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. Chemical etching and electrolytic etching.

From www.researchgate.net

Double cell electrochemical etching setup Download Scientific Diagram Types Of Electrochemical Etching Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. In most cases, an etching process requires one or more chemical reactions to take place. This method includes the emission. Types Of Electrochemical Etching.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Types Of Electrochemical Etching Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. In most cases, an etching process requires one or more chemical reactions to take place. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. Achieving dark marking and white etching results involves switching between. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching setup Electrochemical etching singlecell in a Types Of Electrochemical Etching Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. In a typical electrochemical hf etching setup, the top. Chemical etching and electrolytic etching. In most cases, an etching process requires one or more chemical. Types Of Electrochemical Etching.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation ID1945566 Types Of Electrochemical Etching Here are the main ones: In a typical electrochemical hf etching setup, the top. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon.. Types Of Electrochemical Etching.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Types Of Electrochemical Etching A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. Electrochemical marking and etching are exclusively carried. Types Of Electrochemical Etching.

From www.researchgate.net

Experimental schematic diagram of electrochemical etching of gold Types Of Electrochemical Etching There are two types of etching processes: Here are the main ones: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). In most cases, an etching process requires one or more chemical reactions to take place. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. In a typical. Types Of Electrochemical Etching.

From www.metaletching.org

Stainless Steel Etching Companies Services Types Of Electrochemical Etching Chemical etching and electrolytic etching. Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. This method includes the emission of focused light beams artificially amplified to provide desired results on the. Types Of Electrochemical Etching.

From www.iqsdirectory.com

Metal Etching What Is It? How Does It Work? Types, Uses Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. In a typical electrochemical hf etching setup, the top. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. For isotropic wet etching,. Types Of Electrochemical Etching.

From www.researchgate.net

(a) Schematic illustration of the electrochemical etching approach to Types Of Electrochemical Etching Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). There are two types of etching processes: A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Six types of etching techniques used in 2d materials are discussed,. Types Of Electrochemical Etching.

From www.researchgate.net

The schematic diagram of electrochemical etching bath and laser beam Types Of Electrochemical Etching This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Chemical etching and electrolytic etching. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Electrochemical marking and etching are exclusively. Types Of Electrochemical Etching.

From www.masteretching.com

Chemical Etching Process Etching Information Types Of Electrochemical Etching For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Six types of etching techniques used in. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical Etching Cell . Download Scientific Diagram Types Of Electrochemical Etching Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Electrochemical marking and etching are. Types Of Electrochemical Etching.

From www.researchgate.net

Working principle of the electrochemical etching with a micromachined Types Of Electrochemical Etching Here are the main ones: Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). There are two types. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic diagram of electrochemical etching of the GaN wafer Types Of Electrochemical Etching In a typical electrochemical hf etching setup, the top. In most cases, an etching process requires one or more chemical reactions to take place. There are two types of etching processes: Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. A marking head is used with a. Types Of Electrochemical Etching.

From frgmnt.org

Electrochemical Etching « frgmnt org Types Of Electrochemical Etching Here are the main ones: In a typical electrochemical hf etching setup, the top. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. A marking head is used with a. Types Of Electrochemical Etching.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Types Of Electrochemical Etching A marking head is used with a marking stencil/mask soaked in electrolyte fluid. There are two types of etching processes: Here are the main ones: This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. In most cases, an etching process requires one or more chemical reactions to take place. Achieving. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Types Of Electrochemical Etching Chemical etching and electrolytic etching. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). In a typical electrochemical hf etching setup, the top. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. There are two types of etching. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Types Of Electrochemical Etching Chemical etching and electrolytic etching. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. In a typical electrochemical hf etching setup, the top. There are two types of etching processes: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current. Types Of Electrochemical Etching.

From www.researchgate.net

(a) Scheme of electrochemical etching method. (b) Surface morphologies Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Here are the main ones: In most cases, an etching process requires one or more chemical reactions to take place. A marking. Types Of Electrochemical Etching.

From www.iqsdirectory.com

Marking Machinery What Is It? How Is It Used? Types Of Types Of Electrochemical Etching Chemical etching and electrolytic etching. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. In a typical electrochemical hf etching setup, the top. There are two types of etching processes: In most cases,. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. In most cases, an etching process requires one or more chemical reactions to take place. Chemical etching and electrolytic etching. Here are the main ones: Electrochemical etching is a method that requires an electric current to initiate the. Types Of Electrochemical Etching.

From www.researchgate.net

The electrochemical etching cell setup a schematic diagram b real photo Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Here are the main ones: In most cases, an etching process requires one or more chemical reactions to take place. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal. Types Of Electrochemical Etching.

From link.springer.com

Electrochemical Etching of Tungsten for Fabrication of Sub10nm Tips Types Of Electrochemical Etching Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. In a typical electrochemical hf etching setup, the top. This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. For isotropic wet etching,. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Types Of Electrochemical Etching This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. In most cases, an etching process requires one or more chemical reactions to take place. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. In most cases, an etching process requires one or more chemical reactions to take place. In a typical electrochemical hf etching setup, the top. There are two types of etching processes: Electrochemical etching is a method that requires. Types Of Electrochemical Etching.

From www.researchgate.net

The experimental configuration of the selective electrochemical etching Types Of Electrochemical Etching This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. In a typical electrochemical hf etching setup, the top. In most cases, an etching process requires one or more chemical reactions to take place. There are two types of etching processes: Achieving dark marking and white etching results involves switching between. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Types Of Electrochemical Etching This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. In a typical electrochemical hf etching setup, the top. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Here are the main ones: A marking head is used with a marking stencil/mask soaked in electrolyte fluid. In most. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic representation of PEC etching method. The anode, cathode, and Types Of Electrochemical Etching Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. There are two types of etching processes: Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). This method includes the emission of focused light beams artificially amplified to provide desired. Types Of Electrochemical Etching.

From www.researchgate.net

The electrochemical etching process (A) and obtaining the electrical Types Of Electrochemical Etching In a typical electrochemical hf etching setup, the top. There are two types of etching processes: Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Chemical etching and electrolytic etching. Here are the main ones: In most cases, an etching process. Types Of Electrochemical Etching.

From www.researchgate.net

The electrochemical etching process (A) and obtaining the electrical Types Of Electrochemical Etching There are two types of etching processes: Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common. Types Of Electrochemical Etching.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an Types Of Electrochemical Etching Here are the main ones: For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the most common etchant solvent for silicon. Chemical etching and electrolytic etching. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). Six types of etching techniques used in 2d materials are. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic diagram of the electrochemical etching setup. Download Types Of Electrochemical Etching Chemical etching and electrolytic etching. Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Achieving dark marking and white etching results involves switching between alternating current (ac) and direct current (dc). In a typical electrochemical hf etching setup, the top. For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic representation of the electrochemical etching setup Types Of Electrochemical Etching Here are the main ones: In a typical electrochemical hf etching setup, the top. A marking head is used with a marking stencil/mask soaked in electrolyte fluid. Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. There are two types of etching processes: Electrochemical marking and etching. Types Of Electrochemical Etching.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Types Of Electrochemical Etching Electrochemical marking and etching are exclusively carried out on conductive metal surfaces. Here are the main ones: This method includes the emission of focused light beams artificially amplified to provide desired results on the metal surface. There are two types of etching processes: For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (hna) is the. Types Of Electrochemical Etching.

From www.researchgate.net

Schematic diagram of the electrochemical etching system. Download Types Of Electrochemical Etching In a typical electrochemical hf etching setup, the top. Six types of etching techniques used in 2d materials are discussed, and the mechanism, purpose, and advantages of each technique are explored. Electrochemical etching is a method that requires an electric current to initiate the etching of silicon. Achieving dark marking and white etching results involves switching between alternating current (ac). Types Of Electrochemical Etching.