Blind Hole Engineering Drawing . This is a complete guide to the types of holes found in machining. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Cnc milling machines are used to make blind holes by running a thread milling cycle. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. In this guide you’ll learn: Blind holes are used in engineering to measure residual stresses. What the difference is between. The different types of holes used in machining. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. Thru holes get drilled all the way through a.

from cad.onshape.com

This is a complete guide to the types of holes found in machining. The different types of holes used in machining. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. What the difference is between. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. In this guide you’ll learn: Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and.

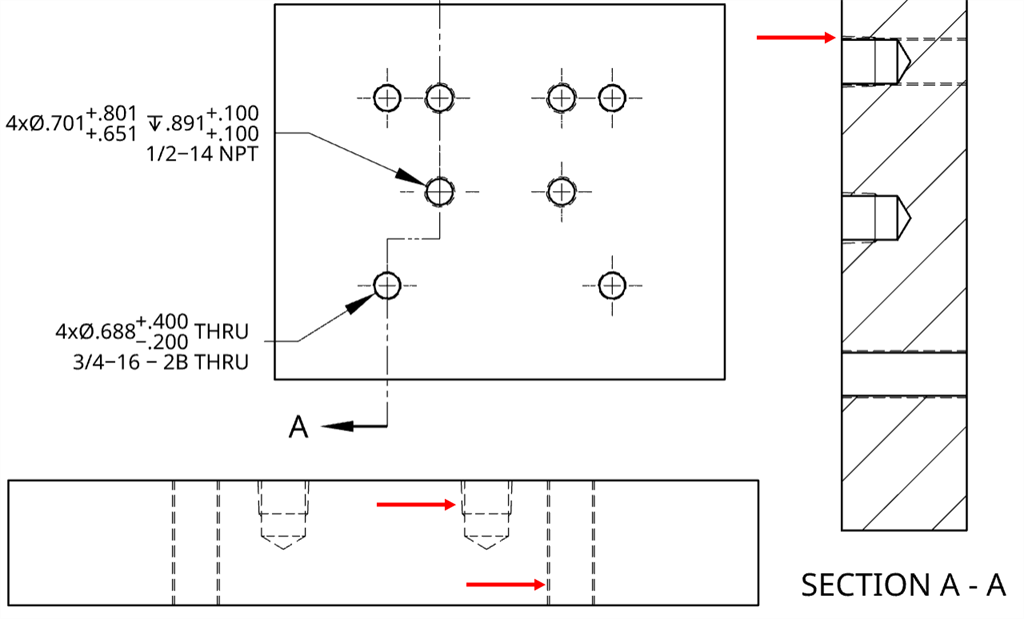

Hole/Thread Callout

Blind Hole Engineering Drawing Cnc milling machines are used to make blind holes by running a thread milling cycle. The different types of holes used in machining. Cnc milling machines are used to make blind holes by running a thread milling cycle. In this guide you’ll learn: Thru holes get drilled all the way through a. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. What the difference is between. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. This is a complete guide to the types of holes found in machining. Blind holes are used in engineering to measure residual stresses. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part.

From www.xometry.com

7 Tips to Help You Design for CNC Machining Xometry Blind Hole Engineering Drawing In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. The different types of holes used in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Blind. Blind Hole Engineering Drawing.

From www.mcgill.ca

Principles of Dimensioning Engineering Design McGill University Blind Hole Engineering Drawing Blind holes are used in engineering to measure residual stresses. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. In this guide you’ll learn: The different types of holes used in machining. This is a complete guide to the types of holes found in machining. Blind holes are holes that. Blind Hole Engineering Drawing.

From www.machinistguides.com

Blind Holes All About Machinist Guides Blind Hole Engineering Drawing Thru holes get drilled all the way through a. Cnc milling machines are used to make blind holes by running a thread milling cycle. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. In engineering drawing and machining, a blind hole (also known as a pocket. Blind Hole Engineering Drawing.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Engineering Drawing To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The different types of holes used in machining. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Thru holes get drilled all. Blind Hole Engineering Drawing.

From www.slideserve.com

PPT Holes In AutoCAD PowerPoint Presentation, free download ID5331488 Blind Hole Engineering Drawing The different types of holes used in machining. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. In. Blind Hole Engineering Drawing.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Engineering Drawing In this guide you’ll learn: What the difference is between. This is a complete guide to the types of holes found in machining. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. To specify a blind hole requires listing the diameter of the hole and a. Blind Hole Engineering Drawing.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Engineering Drawing This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The different types of holes used in machining. What the difference is between. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. This is a complete guide. Blind Hole Engineering Drawing.

From www.vrogue.co

Dimensioning Hole Patterns vrogue.co Blind Hole Engineering Drawing What the difference is between. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. This section explores the different types of holes. Blind Hole Engineering Drawing.

From www.innova-systems.co.uk

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems Blind Hole Engineering Drawing This is a complete guide to the types of holes found in machining. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. What. Blind Hole Engineering Drawing.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] Blind Hole Engineering Drawing What the difference is between. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This is a complete guide to the types of holes found in machining. Blind holes are used in engineering to measure residual stresses. Cnc milling machines are used to make blind holes by running a thread. Blind Hole Engineering Drawing.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Engineering Drawing Blind holes are used in engineering to measure residual stresses. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the. Blind Hole Engineering Drawing.

From www.coursehero.com

[Solved] Using appropriate sketch explain method to drill a blind hole Blind Hole Engineering Drawing This is a complete guide to the types of holes found in machining. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Thru holes get drilled all the way through a. The depth can be controlled by directly specifying the depth of the hole or by identifying the. Blind Hole Engineering Drawing.

From www.slideshare.net

Engineering Drawing Chapter 11 thread fastener Blind Hole Engineering Drawing To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The different types of holes used in machining. Blind holes are used in engineering to measure residual stresses. What the difference is between. Thru holes get drilled all the way through a. This section explores the different types of holes commonly. Blind Hole Engineering Drawing.

From olson-engineering.weebly.com

Hole Activity ENGINEERING AND DESIGN Blind Hole Engineering Drawing To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. The different types of holes used in machining. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. This article will explore what a blind hole is, how. Blind Hole Engineering Drawing.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Blind Hole Engineering Drawing Cnc milling machines are used to make blind holes by running a thread milling cycle. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. This is a complete guide to the types of holes found in machining. Blind holes are used. Blind Hole Engineering Drawing.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Blind Hole Engineering Drawing This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Blind holes are used in engineering to measure residual stresses. The different types of holes used. Blind Hole Engineering Drawing.

From www.eng-tips.com

Depth of crosshole Drafting Standards, GD&T & Tolerance Analysis Blind Hole Engineering Drawing In this guide you’ll learn: This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Cnc milling machines are used to make blind holes by running a thread milling cycle. This is a complete guide to the types of holes found in machining. What the difference is between. In. Blind Hole Engineering Drawing.

From prototool.com

Blind Holes and Through Holes in Design Blind Hole Engineering Drawing Blind holes are used in engineering to measure residual stresses. To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. This is a complete guide to the types of holes. Blind Hole Engineering Drawing.

From www.wevolver.com

Everything you need to know about Injection Molded Holes Blind Hole Engineering Drawing In this guide you’ll learn: Blind holes are used in engineering to measure residual stresses. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Blind. Blind Hole Engineering Drawing.

From www.youtube.com

TYPES OF HOLES MECHANICAL DESIGN MACHINE DRAWING YouTube Blind Hole Engineering Drawing What the difference is between. This is a complete guide to the types of holes found in machining. The different types of holes used in machining. Blind holes are used in engineering to measure residual stresses. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. To. Blind Hole Engineering Drawing.

From www.youtube.com

Dimensioning Hole Depth YouTube Blind Hole Engineering Drawing The different types of holes used in machining. Thru holes get drilled all the way through a. Cnc milling machines are used to make blind holes by running a thread milling cycle. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. In engineering drawing and machining, a blind. Blind Hole Engineering Drawing.

From adkinsfricaunt.blogspot.com

How to Draw Threaded Hole in Autocad 2d Adkins Fricaunt Blind Hole Engineering Drawing The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. What the difference is between. This is a complete guide to the types of holes found in machining. Thru holes get drilled all the way through a. Cnc milling machines are used to make blind holes by. Blind Hole Engineering Drawing.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole Engineering Drawing In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Blind holes are used in engineering to measure residual stresses. Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the. Blind Hole Engineering Drawing.

From toolsjoint.com

3 Types of Screw Holes You Need to Know Tools Joint Blind Hole Engineering Drawing In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Blind holes are used in engineering to measure residual stresses. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will. Blind Hole Engineering Drawing.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Engineering Drawing What the difference is between. Cnc milling machines are used to make blind holes by running a thread milling cycle. Thru holes get drilled all the way through a. Blind holes are used in engineering to measure residual stresses. The different types of holes used in machining. In engineering drawing and machining, a blind hole (also known as a pocket. Blind Hole Engineering Drawing.

From e1304.blogspot.com

ENGR1304 Orthographic (Multiview) projections Blind Hole Engineering Drawing Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. In this guide you’ll learn: This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Thru holes get drilled all the way through a. The different. Blind Hole Engineering Drawing.

From www.slideserve.com

PPT Engineering Graphics PowerPoint Presentation ID7068169 Blind Hole Engineering Drawing To specify a blind hole requires listing the diameter of the hole and a dimension to control the depth. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. This is a complete guide to the types of holes found in machining. What the difference is between. The depth. Blind Hole Engineering Drawing.

From cad.onshape.com

Hole/Thread Callout Blind Hole Engineering Drawing Blind holes are used in engineering to measure residual stresses. In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. The. Blind Hole Engineering Drawing.

From www.youtube.com

Quick Tips Hole Callout In Solidworks YouTube Blind Hole Engineering Drawing Blind holes are used in engineering to measure residual stresses. In this guide you’ll learn: The different types of holes used in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. Cnc milling machines are used to make blind holes by running a thread milling. Blind Hole Engineering Drawing.

From www.chegg.com

(Interpreting an Engineering Drawing) Calculate the Blind Hole Engineering Drawing In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Thru holes get drilled all the way through a. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. The different. Blind Hole Engineering Drawing.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Blind Hole Engineering Drawing In engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness or length of the workpiece. Thru holes get drilled all the way through a. This article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. This section. Blind Hole Engineering Drawing.

From leadrp.net

Engineering Drawing Basics And Tips For Beginners LEADRP Rapid Blind Hole Engineering Drawing What the difference is between. Thru holes get drilled all the way through a. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. This is a complete guide to the types of holes found in machining. This article will explore what a blind hole is, how. Blind Hole Engineering Drawing.

From mavink.com

Engineering Drawing Hole Symbols Blind Hole Engineering Drawing Blind holes are holes that get drilled or milled to a specified depth but do not go all the way through the part. Cnc milling machines are used to make blind holes by running a thread milling cycle. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. Thru. Blind Hole Engineering Drawing.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Blind Hole Engineering Drawing This is a complete guide to the types of holes found in machining. Blind holes are used in engineering to measure residual stresses. Thru holes get drilled all the way through a. What the difference is between. This section explores the different types of holes commonly used in engineering, with a focus on counterbored holes, countersunk holes, and. In this. Blind Hole Engineering Drawing.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole Engineering Drawing The different types of holes used in machining. The depth can be controlled by directly specifying the depth of the hole or by identifying the amount of material that will remain. This is a complete guide to the types of holes found in machining. Blind holes are holes that get drilled or milled to a specified depth but do not. Blind Hole Engineering Drawing.