Types Of Knurling Plate . Knurling on cylindrical parts, both internal and external, is of three basic patterns: Understanding the essentials of knurling! Straight knurling, or linear knurl, forms linear and parallel. Knurls also have types based on their location: Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. There are four main types of knurling. Explore its types, tools, pros and cons, applications, and the latest innovations in this. These are straight knurling, diamond knurling, left hand and right hand knurling. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Linear knurling linear knurling produces straight, parallel lines on the workpiece. There are two types of knurling, cutting and forming. Three common knurl patterns are: Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes.

from garagegymreviews.com

Three common knurl patterns are: Straight knurling, or linear knurl, forms linear and parallel. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Both of which are knurling processes achieved by pressing the knurl pattern into a. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Understanding the essentials of knurling! These are straight knurling, diamond knurling, left hand and right hand knurling. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Knurling on cylindrical parts, both internal and external, is of three basic patterns: There are two types of knurling, cutting and forming.

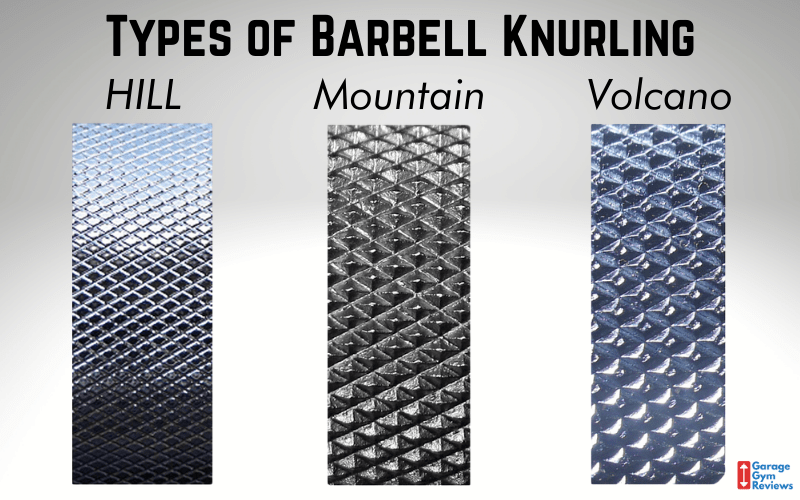

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: There are four main types of knurling. Knurls also have types based on their location: Knurling on cylindrical parts, both internal and external, is of three basic patterns: It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. There are two types of knurling, cutting and forming. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Understanding the essentials of knurling! Straight knurling, or linear knurl, forms linear and parallel. These are straight knurling, diamond knurling, left hand and right hand knurling. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Both of which are knurling processes achieved by pressing the knurl pattern into a.

From www.gdandtbasics.com

Knurling GD&T Basics Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. There are four main types of knurling. Knurls also have types based on their location: Straight knurling, or linear knurl, forms linear and parallel. Knurling on. Types Of Knurling Plate.

From accu-trak.com

General Knurling Information Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. Three common knurl patterns are: It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Straight knurling, or linear knurl, forms linear and parallel. These are straight knurling, diamond knurling, left hand and right hand knurling. Knurling on cylindrical. Types Of Knurling Plate.

From www.boreway.net

Knurling Type Bush Hammer Plate, Bush Hammer Plate With 3 Rollers Types Of Knurling Plate Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. There are two types of knurling, cutting and forming. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Straight knurling, or linear knurl, forms linear and parallel. It’s commonly used to enhance grip and is. Types Of Knurling Plate.

From www.theengineerspost.com

Knurling Operation Definition, Process, Types & Uses [PDF] Types Of Knurling Plate Knurling on cylindrical parts, both internal and external, is of three basic patterns: Explore its types, tools, pros and cons, applications, and the latest innovations in this. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurls also. Types Of Knurling Plate.

From www.youtube.com

knurling operation? Purpose of knurling 5 knurl patterns knurling Types Of Knurling Plate These are straight knurling, diamond knurling, left hand and right hand knurling. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Straight knurling, or linear knurl, forms linear and parallel. There are two types of knurling, cutting and forming. Both of which are knurling. Types Of Knurling Plate.

From www.garagegymreviews.com

What is Barbell Knurling and Why It Matters Garage Gym Reviews Types Of Knurling Plate Understanding the essentials of knurling! Straight knurling, or linear knurl, forms linear and parallel. These are straight knurling, diamond knurling, left hand and right hand knurling. There are two types of knurling, cutting and forming. Both of which are knurling processes achieved by pressing the knurl pattern into a. Explore its types, tools, pros and cons, applications, and the latest. Types Of Knurling Plate.

From fitdominium.com

What is Barbell Knurling And What Type Should I Use? FitDominium Types Of Knurling Plate Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurling on cylindrical parts, both internal and external, is of three basic patterns: There are two types of knurling, cutting and forming. These are straight knurling, diamond knurling, left hand and right hand knurling. Knurls also have types based on. Types Of Knurling Plate.

From www.gdandtbasics.com

Knurling GD&T Basics Types Of Knurling Plate Explore its types, tools, pros and cons, applications, and the latest innovations in this. Understanding the essentials of knurling! There are two types of knurling, cutting and forming. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Both of which are knurling processes achieved by pressing the knurl pattern into a. These are. Types Of Knurling Plate.

From www.tworepcave.com

The 3 Types of Barbell Knurling and What It Means for Your Grip Types Of Knurling Plate Three common knurl patterns are: Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Knurling on cylindrical parts, both internal and external, is of three basic patterns: Both of which are knurling processes. Types Of Knurling Plate.

From garagegymlab.com

Barbell Knurling Everything you Need to Know Garage Gym Lab Types Of Knurling Plate These are straight knurling, diamond knurling, left hand and right hand knurling. Straight knurling, or linear knurl, forms linear and parallel. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Linear knurling linear knurling produces straight, parallel lines on. Types Of Knurling Plate.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Types Of Knurling Plate Knurling on cylindrical parts, both internal and external, is of three basic patterns: Linear knurling linear knurling produces straight, parallel lines on the workpiece. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Both of which are knurling processes achieved by pressing the knurl pattern into a. Explore its types, tools, pros. Types Of Knurling Plate.

From www.scribd.com

Knurling profiles DIN 82 Types Of Knurling Plate Linear knurling linear knurling produces straight, parallel lines on the workpiece. Knurling on cylindrical parts, both internal and external, is of three basic patterns: It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. These are straight knurling, diamond knurling, left hand and right hand knurling. Diamond knurling diamond knurling creates a pattern. Types Of Knurling Plate.

From garagegymreviews.com

What is Barbell Knurling and Why It Matters Garage Gym Reviews Types Of Knurling Plate There are four main types of knurling. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Knurling on cylindrical parts, both internal and external, is of three basic patterns: Knurls also have types based on their location: Three common knurl patterns are: Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to. Types Of Knurling Plate.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. These are straight knurling, diamond knurling, left hand and right hand knurling. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Three common knurl patterns are: There are two types of knurling, cutting and forming. Linear knurling linear. Types Of Knurling Plate.

From www.tworepcave.com

The 3 Types of Barbell Knurling and What It Means for Your Grip Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Understanding the essentials of knurling! Knurling on cylindrical parts, both internal and external, is of three basic patterns: There are two types of knurling, cutting and. Types Of Knurling Plate.

From www.tworepcave.com

The 3 Types of Barbell Knurling and What It Means for Your Grip Types Of Knurling Plate There are two types of knurling, cutting and forming. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Both of which are knurling processes achieved by pressing the knurl pattern into a. Three common knurl patterns are: Knurls also have types based on their location: Straight knurling, or linear knurl, forms linear and parallel. These are straight knurling,. Types Of Knurling Plate.

From mensquats.com

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS Types Of Knurling Plate Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Three common knurl patterns are: Knurling on cylindrical parts, both internal and external, is of three basic patterns: Both of which are knurling processes. Types Of Knurling Plate.

From abettes-culinary.com

How To Make Knurling On Flat Surface? Update New Types Of Knurling Plate It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Explore its types, tools, pros and cons, applications, and the latest innovations in this. Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurling on cylindrical parts, both internal and external, is of three basic patterns: Linear knurling. Types Of Knurling Plate.

From forum.onshape.com

Knurled pattern on a flat surface — Onshape Types Of Knurling Plate There are four main types of knurling. Both of which are knurling processes achieved by pressing the knurl pattern into a. Three common knurl patterns are: It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. There are two types of knurling, cutting and forming. Explore its types, tools, pros and cons, applications,. Types Of Knurling Plate.

From www.cadimensions.com

Knurled Surfaces CADimensions Types Of Knurling Plate Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. There are four main types of knurling. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Straight knurling, or linear knurl,. Types Of Knurling Plate.

From www.practicalmachinist.com

The Basics of Knurling Practical Machinist Practical Machinist Types Of Knurling Plate Explore its types, tools, pros and cons, applications, and the latest innovations in this. There are four main types of knurling. Understanding the essentials of knurling! Knurls also have types based on their location: Straight knurling, or linear knurl, forms linear and parallel. Both of which are knurling processes achieved by pressing the knurl pattern into a. These are straight. Types Of Knurling Plate.

From www.pinterest.com

Knurling.jpg (720×1200) Patterns & Textures Pinterest Patterns Types Of Knurling Plate Understanding the essentials of knurling! There are two types of knurling, cutting and forming. There are four main types of knurling. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Knurling on cylindrical parts, both internal and external, is of three basic patterns: Both of which are knurling processes achieved by pressing the. Types Of Knurling Plate.

From www.theengineerspost.com

Knurling Operation Definition, Process, Types & Uses [PDF] Types Of Knurling Plate Knurls also have types based on their location: Explore its types, tools, pros and cons, applications, and the latest innovations in this. There are two types of knurling, cutting and forming. Three common knurl patterns are: Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurling on cylindrical parts,. Types Of Knurling Plate.

From www.boreway.net

Knurling Type Bush Hammer Plate, Bush Hammer Plate With 3 Rollers Types Of Knurling Plate Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. There are two types of knurling, cutting and forming. Three common knurl patterns are: Explore its types, tools, pros and cons, applications, and the latest innovations in this. Straight knurling, or linear knurl, forms linear and parallel. Linear knurling linear knurling produces straight, parallel. Types Of Knurling Plate.

From mensquats.com

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS Types Of Knurling Plate Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. These are straight knurling, diamond knurling, left hand and right hand knurling. There are two types of knurling, cutting and forming. Knurling on cylindrical parts, both internal and external, is of three basic patterns: There are four main types of. Types Of Knurling Plate.

From www.boreway.net

Knurling Type Bush Hammer Plate, Bush Hammer Plate With 3 Rollers Types Of Knurling Plate It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Knurling on cylindrical parts, both internal and external, is of three basic patterns: Knurling is done to increase the friction on a surface, and is typically performed. Types Of Knurling Plate.

From hackaday.com

How To Achieve Knurling On A Flat Surface Hackaday Types Of Knurling Plate Explore its types, tools, pros and cons, applications, and the latest innovations in this. There are two types of knurling, cutting and forming. Knurls also have types based on their location: Both of which are knurling processes achieved by pressing the knurl pattern into a. Straight knurling, or linear knurl, forms linear and parallel. Three common knurl patterns are: Linear. Types Of Knurling Plate.

From www.tworepcave.com

The 3 Types of Barbell Knurling and What It Means for Your Grip Types Of Knurling Plate Both of which are knurling processes achieved by pressing the knurl pattern into a. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Knurls also have types based on their location: There are two types of knurling, cutting and forming. Straight knurling, or linear knurl, forms linear and parallel.. Types Of Knurling Plate.

From accu-trak.com

General Knurling Information Types Of Knurling Plate Straight knurling, or linear knurl, forms linear and parallel. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Explore its types, tools, pros and cons, applications, and the latest innovations in this. There are two types of knurling, cutting and forming. There are four main types of knurling. Knurling is done to increase the friction on a surface,. Types Of Knurling Plate.

From fractory.com

Knurling Explained What Is it, Methods & Applications Fractory Types Of Knurling Plate Explore its types, tools, pros and cons, applications, and the latest innovations in this. Understanding the essentials of knurling! Both of which are knurling processes achieved by pressing the knurl pattern into a. These are straight knurling, diamond knurling, left hand and right hand knurling. There are four main types of knurling. Knurls also have types based on their location:. Types Of Knurling Plate.

From www.micoope.com.gt

Knurling—What It Is, How It Works, And Why We Don't Do It, 48 OFF Types Of Knurling Plate Straight knurling, or linear knurl, forms linear and parallel. There are two types of knurling, cutting and forming. These are straight knurling, diamond knurling, left hand and right hand knurling. Understanding the essentials of knurling! Knurling on cylindrical parts, both internal and external, is of three basic patterns: Knurls also have types based on their location: There are four main. Types Of Knurling Plate.

From www.boreway.net

Knurling Type Bush Hammer Plate, Bush Hammer Plate With 3 Rollers Types Of Knurling Plate There are four main types of knurling. Knurls also have types based on their location: Knurling on cylindrical parts, both internal and external, is of three basic patterns: Explore its types, tools, pros and cons, applications, and the latest innovations in this. These are straight knurling, diamond knurling, left hand and right hand knurling. Both of which are knurling processes. Types Of Knurling Plate.

From www.youtube.com

How to Model Different Types of Knurling Profiles Blender3D YouTube Types Of Knurling Plate Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Understanding the essentials of knurling! There are two types of knurling, cutting and forming. These are straight knurling, diamond knurling, left hand and right hand knurling. Linear knurling linear knurling produces straight, parallel lines on the workpiece. Three common knurl patterns are: Knurls also. Types Of Knurling Plate.

From www.indiamart.com

ALU ALU KNURLING PLATE, Packaging Type Pharmaceutical, Capacity Same Types Of Knurling Plate There are two types of knurling, cutting and forming. Diamond knurling diamond knurling creates a pattern of diagonal lines that intersect to form diamond shapes. Explore its types, tools, pros and cons, applications, and the latest innovations in this. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and pliers. Straight knurling, or linear. Types Of Knurling Plate.

From leadrp.net

Understanding What Is Knurling And Its Comprehensive Guide LEADRP Types Of Knurling Plate Knurls also have types based on their location: Straight knurling, or linear knurl, forms linear and parallel. There are four main types of knurling. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. It’s commonly used to enhance grip and is often seen on hand tools like wrenches and. Types Of Knurling Plate.