Belt Feeder Drawing . A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. Belt feeders are used to feed many types. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. They are commonly used when material that is either stockpiled or. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. The profile of the material on the belt is known, the bulk.

from designscad.com

The profile of the material on the belt is known, the bulk. They are commonly used when material that is either stockpiled or. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. Belt feeders are used to feed many types. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing.

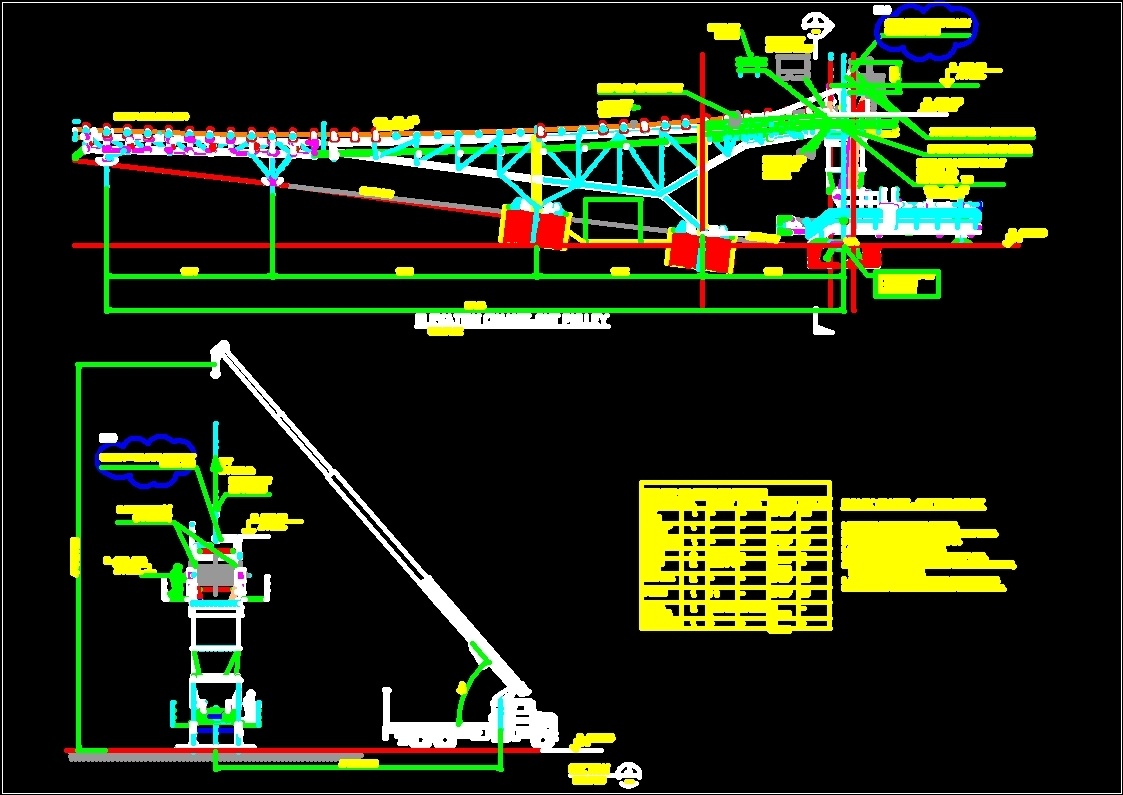

Conveyor Belt DWG Detail for AutoCAD • Designs CAD

Belt Feeder Drawing Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Belt feeders are used to feed many types. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. The profile of the material on the belt is known, the bulk. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. They are commonly used when material that is either stockpiled or. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation.

From feeco.com

Belt Feeders Belt Feeder Drawing They are commonly used when material that is either stockpiled or. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of. Belt Feeder Drawing.

From designscad.com

Conveyor Belt Feeder DWG Block for AutoCAD • Designs CAD Belt Feeder Drawing The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. They are commonly used when material that is either stockpiled. Belt Feeder Drawing.

From www.youtube.com

belt weigh feeder main parts and working principle YouTube Belt Feeder Drawing In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. They are commonly used when material that is either stockpiled or. Belt feeders are devices that require little space, they are. Belt Feeder Drawing.

From drawing.rjuuc.edu.np

Conveyor Belt Drawing Drawing.rjuuc.edu.np Belt Feeder Drawing In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. The key to proper belt feeder design is to ensure increasing capacity along the length of the. Belt Feeder Drawing.

From alldrawings.ru

Feeder Conveyor Download drawings, blueprints, Autocad blocks, 3D Belt Feeder Drawing The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. They are commonly. Belt Feeder Drawing.

From www.pinterest.com

Corrugated Sidewall Belt Conveyor, Sidewall Belt Conveyor, Steep Belt Feeder Drawing A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. It is also important that the. Belt Feeder Drawing.

From statesengineeringinc.com

Belt Conveyors • States Engineering Belt Feeder Drawing Belt feeders are used to feed many types. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Belt feeders are devices that require little space, they are not expensive and,. Belt Feeder Drawing.

From feeco.com

Belt Feeders Belt Feeder Drawing Belt feeders are used to feed many types. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. In this article, we discuss proper belt feeder design technique. Belt Feeder Drawing.

From www.machineryshops.com

Overall structure diagram of feeder (MY90*2), Overall structure diagram Belt Feeder Drawing A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Download 2d and 3d cad drawings to assist. Belt Feeder Drawing.

From www.dakotafab.com

Belt Feeders DAKOTA FABRICATING INC. Belt Feeder Drawing In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design. Belt Feeder Drawing.

From www.sedic.be

Belt feeders SEDIC Belt Feeder Drawing Belt feeders are used to feed many types. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing.. Belt Feeder Drawing.

From www.cdmsys.com

Drag Chain Conveyors CDM Systems, Inc. Belt Feeder Drawing The profile of the material on the belt is known, the bulk. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. They are commonly used when material that is either stockpiled or. Belt feeders are used to feed many types. It is. Belt Feeder Drawing.

From www.sepor.com

Belt Feeders Sepor, Inc Belt Feeder Drawing The profile of the material on the belt is known, the bulk. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. They. Belt Feeder Drawing.

From www.smlease.com

Mechanical Design of the Rotary Feeder on Cartoners Belt Feeder Drawing The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. The profile of the material on the belt is known,. Belt Feeder Drawing.

From www.researchgate.net

Drawing of typical conveyorbelt (headdown deposit ) feeders, i.e Belt Feeder Drawing Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. They are commonly used when material that is either stockpiled or. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size. Belt Feeder Drawing.

From designscad.com

Conveyor Belt DWG Detail for AutoCAD • Designs CAD Belt Feeder Drawing Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. Belt feeders are used to feed many types. They are commonly used when material that is either stockpiled or. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two. Belt Feeder Drawing.

From constructioncrushers.tpub.com

Figure 90. Feeder conveyor belt under scraper, exploded view. Belt Feeder Drawing Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. The profile of the material on the belt is known, the bulk. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that. Belt Feeder Drawing.

From bulknet.com.au

Belt Feeders & Belt Conveyors Belt Feeder Drawing Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Belt feeders are used to feed many types. A more accurate method of predicting. Belt Feeder Drawing.

From bulknet.com.au

Belt Feeders & Belt Conveyors Belt Feeder Drawing It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. The profile of the material on the belt is known, the bulk. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into. Belt Feeder Drawing.

From bwsinclair.com

Belt Conveyors and Feeders B.W. Sinclair Inc Belt Feeder Drawing Belt feeders are used to feed many types. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. The profile of the material on the belt is known,. Belt Feeder Drawing.

From www.vibrating-machine.com

Belt Feeders Basics, 2 Control Methods,Top 4 Benefits Belt Feeder Drawing Belt feeders are used to feed many types. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. They are commonly used when material that is either stockpiled or. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion. Belt Feeder Drawing.

From www.umaengineers.com

BELT FEEDERS Belt Feeder Drawing Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered. Belt Feeder Drawing.

From feeco.com

Belt Feeders Belt Feeder Drawing It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. In this article, we discuss proper belt feeder design technique so. Belt Feeder Drawing.

From bloodmagicminecrafttutorial.blogspot.com

belt feeder hopper design bloodmagicminecrafttutorial Belt Feeder Drawing Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. The profile of the material on. Belt Feeder Drawing.

From engineeringdl.com

Belt Feeder SolidWorks Mechanical Engineering Design Library Belt Feeder Drawing Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. In this article, we discuss proper belt feeder design. Belt Feeder Drawing.

From www.modelit.net.au

Belt Feeder, Isolation Gate & Transition Chute ModelIT (WA) Pty Ltd Belt Feeder Drawing Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle size to prevent blockage. Belt feeders are used to feed many types.. Belt Feeder Drawing.

From www.youtube.com

what is weigh feeder and how weigh feeder work YouTube Belt Feeder Drawing Belt feeders are used to feed many types. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and conveyor belt systems into your light industrial manufacturing. A more accurate. Belt Feeder Drawing.

From fashiondesignerworking.blogspot.com

belt feeder hopper design fashiondesignerworking Belt Feeder Drawing Belt feeders are used to feed many types. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. It is also important that the. Belt Feeder Drawing.

From engineeringdl.com

Belt Feeder SolidWorks Mechanical Engineering Design Library Belt Feeder Drawing They are commonly used when material that is either stockpiled or. Having determined the belt feeder infeed and the interface to the upstream process, the basic feeder design can proceed. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence. Belt Feeder Drawing.

From foundations.martin-eng.com

Trackmounted conveyor idlers allow easy service Martin Engineering Belt Feeder Drawing Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. They are commonly used when material that is either stockpiled or. It is also important that the clearance between the belt and frond end of the outlet be at least 1.5 to two times the largest particle. Belt Feeder Drawing.

From www.scribd.com

GA Drawing Hopper 60 Cu MTR With Belt Feeder PDF Belt Feeder Drawing Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow while feeding. In this article, we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers. It is also important that the clearance between the belt and frond end of the outlet be. Belt Feeder Drawing.

From engineeringdl.com

Belt Feeder SolidWorks Mechanical Engineering Design Library Belt Feeder Drawing They are commonly used when material that is either stockpiled or. Belt feeders are used to feed many types. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Download 2d and 3d cad drawings to assist in integrating vibratory feeder bowls and. Belt Feeder Drawing.

From www.bibliocad.com

Conveyor belt feeder in AutoCAD CAD download (473.88 KB) Bibliocad Belt Feeder Drawing The profile of the material on the belt is known, the bulk. The key to proper belt feeder design is to ensure increasing capacity along the length of the bin outlet by providing expansion in both plan and elevation. Belt feeders are devices that require little space, they are not expensive and, most importantly, they do not interrupt material flow. Belt Feeder Drawing.

From instrumentationtools.com

What is a Weigh Feeder? Instrumentation Tools Belt Feeder Drawing They are commonly used when material that is either stockpiled or. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. Belt feeders are used to feed many types. Download 2d and 3d cad drawings to assist in. Belt Feeder Drawing.

From www.modelit.net.au

Belt Feeder, Isolation Gate & Transition Chute ModelIT (WA) Pty Ltd Belt Feeder Drawing They are commonly used when material that is either stockpiled or. A more accurate method of predicting feeder loads is clearly needed, (3), but there is also considered to be a complementary need for an understanding of the factors that influence the load. The key to proper belt feeder design is to ensure increasing capacity along the length of the. Belt Feeder Drawing.