Insert Tool Mold . Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. For example, in the automotive industry, insert. These specialized components, designed to be embedded. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process.

from pascotool.com

The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. These specialized components, designed to be embedded. Placing the insert within the mold cavity occurs before molten plastic injection. For example, in the automotive industry, insert. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability.

Insert Molding Pasco Tool & Plastics Inc.

Insert Tool Mold But what exactly is insert. These specialized components, designed to be embedded. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. Placing the insert within the mold cavity occurs before molten plastic injection.

From www.ace-mold.com

What is an insert mold? 4 Best Practices for Perfect Mold Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. For example, in the automotive industry, insert. Insert molding is ideal for parts requiring the. Insert Tool Mold.

From www.youtube.com

Injection Mold Split Insert YouTube Insert Tool Mold For example, in the automotive industry, insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Consequently, on cooling, the insert becomes a permanent plastic part. Placing the insert within the mold cavity occurs before molten plastic injection. These specialized components, designed to be embedded. Insert molding is ideal for parts. Insert Tool Mold.

From www.tritechtool.com

Case Study, Insert Molding Tri Tech Tool Insert Tool Mold But what exactly is insert. These specialized components, designed to be embedded. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Placing the insert within the mold cavity occurs before molten plastic. Insert Tool Mold.

From www.petermanfirm.com

Injection Molding 101 How It Works Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. But what exactly is insert. Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. The insert molding works wonders for. Insert Tool Mold.

From teampti.com

Anatomy of a Mold PTI Plastic Injection Molding Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. For example, in the automotive industry, insert. But what exactly is insert.. Insert Tool Mold.

From www.hardwareinterviews.fyi

Basics of Compression Molding Consumer Hardware Guide Hardware FYI Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. These specialized components, designed to be embedded. Insert molding is ideal. Insert Tool Mold.

From www.moldtoolsteel.com

Plastic Mold Inserts Easy Cutting 1.2085 Mold Tool Steel Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. For example, in the automotive industry, insert. These specialized components, designed to be embedded. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Placing the insert within. Insert Tool Mold.

From www.mold-and-tool.com

Injection Molding Inserts Mold and Tool Insert Tool Mold The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Consequently, on cooling, the insert becomes a permanent plastic part. For example, in the automotive industry, insert. Placing the insert within the mold cavity occurs before molten plastic injection. These specialized components, designed to be embedded. Insert molding is ideal for parts. Insert Tool Mold.

From www.sitech-corp.com

Silicone Molding Methods Advantages of Injection Molding Silicone Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Consequently, on cooling, the insert becomes a permanent plastic part. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. But. Insert Tool Mold.

From pascotool.com

Insert Molding Pasco Tool & Plastics Inc. Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. These specialized components, designed to be embedded. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. For example, in the automotive industry, insert. Injection. Insert Tool Mold.

From www.plastopialtd.com

Insert Injection Molding Plastopia Insert Tool Mold Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. These specialized components, designed to be embedded. For. Insert Tool Mold.

From www.youtube.com

Injection Molding 101 Insert Molding YouTube Insert Tool Mold For example, in the automotive industry, insert. These specialized components, designed to be embedded. Consequently, on cooling, the insert becomes a permanent plastic part. Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. But what exactly is insert. The. Insert Tool Mold.

From texasinjectionmolding.com

Mold Makers, Tool and Die Craftsman Texas Injection Molding Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Placing the insert within the mold cavity occurs before molten plastic injection. But what exactly is insert. Consequently, on cooling, the insert becomes a permanent plastic part. Insert molding is ideal for parts requiring the integration of metal and plastic, providing. Insert Tool Mold.

From www.uidearp.com

Rapid Tooling and Rapid Injection Molding Their Importance and Insert Tool Mold Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. But what exactly is insert. Placing the insert within the mold cavity occurs before molten plastic injection. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability.. Insert Tool Mold.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Insert Tool Mold Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Placing the insert within the mold cavity occurs before molten plastic injection. The insert molding works. Insert Tool Mold.

From cekekmaf.blob.core.windows.net

Dimensions In Tooling at Ricky Jackson blog Insert Tool Mold But what exactly is insert. For example, in the automotive industry, insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Consequently, on cooling, the insert becomes a permanent plastic part. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Insert. Insert Tool Mold.

From www.youtube.com

Insert Moulding YouTube Insert Tool Mold Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. For example, in the automotive. Insert Tool Mold.

From fyofrllkb.blob.core.windows.net

How To Make Mold For Injection Molding at Sarah Thompson blog Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. But what exactly is insert. Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry,. Insert Tool Mold.

From www.injectionmould.org

The slider for plastic injection mold Insert Tool Mold But what exactly is insert. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. These specialized components, designed to be embedded. Consequently, on cooling, the insert becomes a permanent plastic part. Placing the insert within the mold cavity occurs before molten plastic injection. Insert molding is ideal for parts requiring. Insert Tool Mold.

From wkplastics.com

mold spare parts custom mold components cavity and core inserts Insert Tool Mold Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. For example, in the automotive industry, insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. These specialized components, designed to be embedded. Insert molding is ideal for parts requiring the integration of metal and plastic,. Insert Tool Mold.

From molds-manufacturing.com

Insert Molding Tools Mold Maker WIT MOLD LIMITED Insert Tool Mold These specialized components, designed to be embedded. For example, in the automotive industry, insert. But what exactly is insert. Consequently, on cooling, the insert becomes a permanent plastic part. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Placing the insert within the mold cavity occurs before molten plastic injection. Insert. Insert Tool Mold.

From www.pinterest.com

This mold was built for a large tier one automotive supplier. The part Insert Tool Mold But what exactly is insert. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Placing the insert within the mold cavity occurs before molten plastic injection. These specialized components, designed to be embedded. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and. Insert Tool Mold.

From www.mold-and-tool.com

Mold Core Insert Mold and Tool Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Consequently, on cooling, the insert becomes a permanent plastic part. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. But. Insert Tool Mold.

From an-prototype.com

Insert Molding Services Injection Molding ANPrototype Insert Tool Mold The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. Placing the. Insert Tool Mold.

From www.tiptopmolds.com

Consider the Advantages of the 2Step Slider Mold Injection Tip Top Insert Tool Mold These specialized components, designed to be embedded. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. Insert molding is ideal for parts requiring the integration of metal and plastic,. Insert Tool Mold.

From plasticmouldmanufacturers.weebly.com

Category Custom Molds My SiteMichiana Global Mold Insert Tool Mold For example, in the automotive industry, insert. Placing the insert within the mold cavity occurs before molten plastic injection. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. These specialized components, designed to be embedded. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the. Insert Tool Mold.

From kehuimold.com

Precision Mold ToolKehui Mold Co., Limited Insert Tool Mold Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. Placing the insert within the mold cavity occurs before molten plastic injection. Injection mold tooling, also called injection molding dies or molds, are specialized tools. Insert Tool Mold.

From www.midmould.com

Mold Inserts, mold Components,Mold Insert Tool Mold But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. These specialized. Insert Tool Mold.

From molds-manufacturing.com

Insert Molding Tools Mold Maker WIT MOLD LIMITED Insert Tool Mold These specialized components, designed to be embedded. But what exactly is insert. For example, in the automotive industry, insert. Consequently, on cooling, the insert becomes a permanent plastic part. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools. Insert Tool Mold.

From info.crescentind.com

Cooling Methods and Design in Injection Molding Insert Tool Mold Consequently, on cooling, the insert becomes a permanent plastic part. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. These specialized components, designed to be embedded. Injection mold tooling, also called injection molding. Insert Tool Mold.

From www.mold-and-tool.com

Plastic Insert Molding Mold and Tool Insert Tool Mold Placing the insert within the mold cavity occurs before molten plastic injection. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Insert molding is ideal for parts. Insert Tool Mold.

From www.researchgate.net

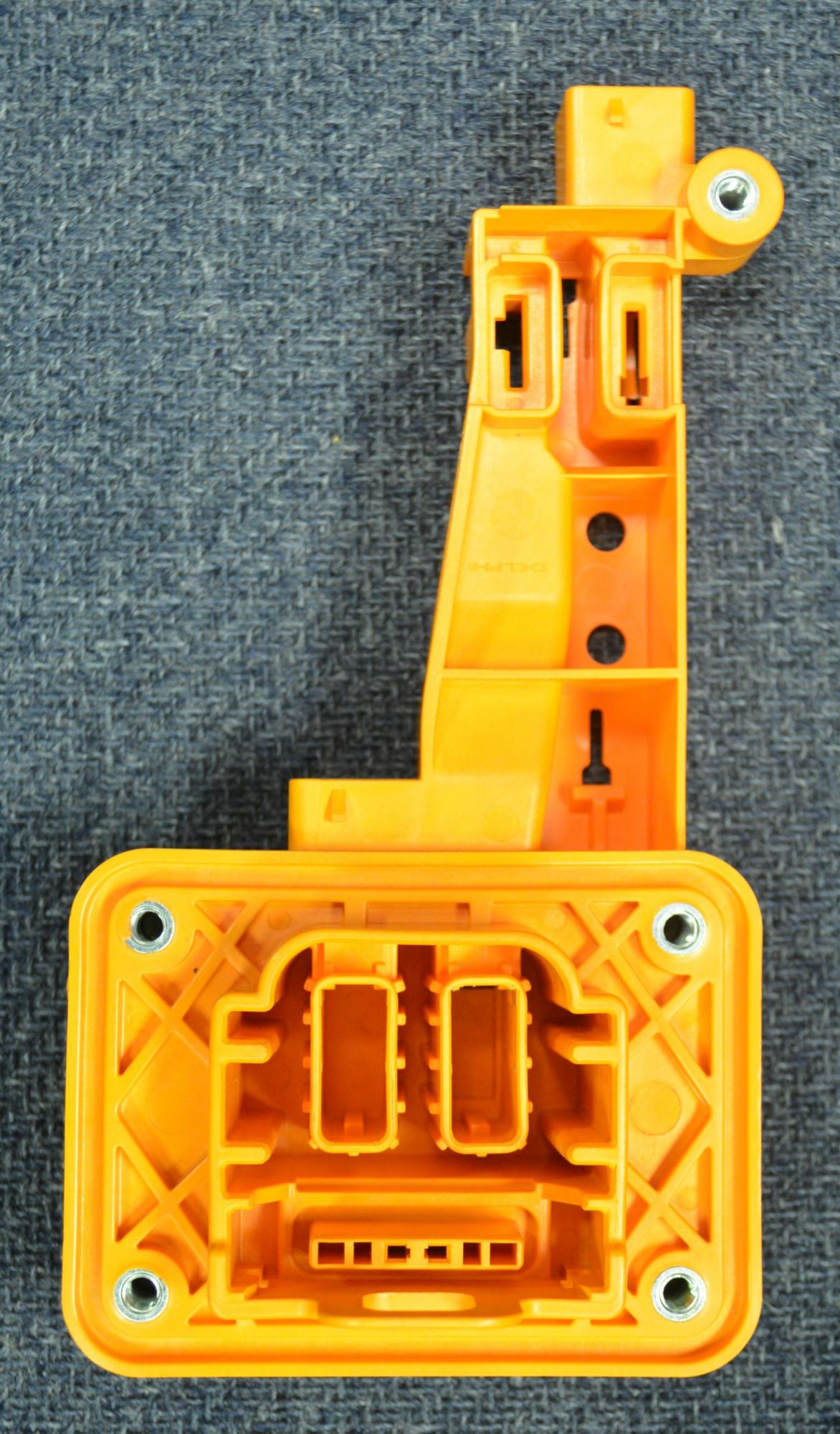

Injection molding tool insert for the pedal system Download Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Consequently, on cooling, the insert becomes a permanent plastic part. But what exactly is insert. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. Placing the insert within the mold cavity occurs. Insert Tool Mold.

From www.rapiddirect.com

What Is Insert Molding? Process, Applications & Considerations Insert Tool Mold Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability.. Insert Tool Mold.

From www.acomold.com

The Science of Insert Molding A Comprehensive Overview Insert Tool Mold The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Insert molding is ideal for parts requiring the integration of metal and plastic, providing enhanced strength and durability. But what exactly is insert. For example, in the automotive industry, insert. These specialized components, designed to be embedded. Consequently, on cooling, the insert. Insert Tool Mold.

From www.kaysun.com

Insert Molding How to Ensure Consistent Insert Tool Mold Consequently, on cooling, the insert becomes a permanent plastic part. Injection mold tooling, also called injection molding dies or molds, are specialized tools needed for the injection molding process. But what exactly is insert. The insert molding works wonders for devices like catheters, pacemakers, and surgical tools, ensuring precision, biocompatibility, and durability. Insert molding is ideal for parts requiring the. Insert Tool Mold.