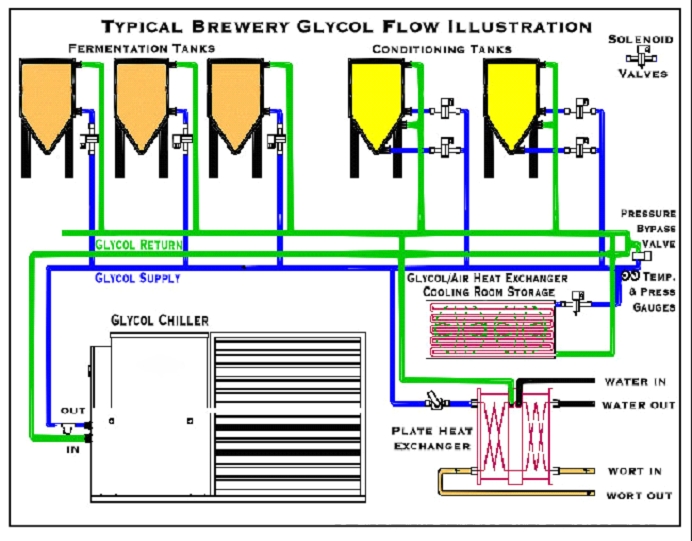

Glycol Piping Diagram . This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Glycol cooling control leads to a more. Most process chiller application being deployed today use two types of glycol. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. It provides a comprehensive overview of. (your plumbing contractor or pipe supplier can help you, or simply take the. 1) figure out the estimated capacity of your systems piping. It will also address how the controls work to provide the proper system pressure. Ethylene glycol (e.g) and propylene glycol. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process.

from www.probrewer.com

Most process chiller application being deployed today use two types of glycol. It provides a comprehensive overview of. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. 1) figure out the estimated capacity of your systems piping. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. Ethylene glycol (e.g) and propylene glycol. (your plumbing contractor or pipe supplier can help you, or simply take the. It will also address how the controls work to provide the proper system pressure. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Glycol cooling control leads to a more.

Everything you wanted to know about glycol

Glycol Piping Diagram It provides a comprehensive overview of. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Most process chiller application being deployed today use two types of glycol. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Glycol cooling control leads to a more. 1) figure out the estimated capacity of your systems piping. It will also address how the controls work to provide the proper system pressure. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. Ethylene glycol (e.g) and propylene glycol. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. (your plumbing contractor or pipe supplier can help you, or simply take the. It provides a comprehensive overview of.

From www.eaglebayrefrigeration.com

Glycol Piping Design Glycol Piping Diagram It provides a comprehensive overview of. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It will also address how the controls work to provide the proper system pressure. (your plumbing. Glycol Piping Diagram.

From www.vrogue.co

Diagram Glycol System Piping Diagrams Mydiagram Onlin vrogue.co Glycol Piping Diagram This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Most process chiller application being deployed today use two types of glycol. It will also address how the controls work to provide the proper system pressure. It provides a comprehensive overview of. 1) figure out the estimated capacity. Glycol Piping Diagram.

From mungfali.com

Glycol System Piping Diagrams Glycol Piping Diagram It provides a comprehensive overview of. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Glycol cooling control leads to a more. Ethylene glycol (e.g) and propylene glycol. 1) figure out the estimated capacity of your systems piping. (your plumbing contractor or pipe supplier can help you, or simply. Glycol Piping Diagram.

From www.vrogue.co

Diagram Glycol System Piping Diagrams Mydiagram Onlin vrogue.co Glycol Piping Diagram This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. 1) figure out the estimated capacity of your systems piping. Ethylene glycol (e.g) and propylene glycol. Glycol cooling control leads to a more. It provides a comprehensive overview of. The glycol chiller system diagram is a visual representation. Glycol Piping Diagram.

From www.homebrewtalk.com

DIY Glycol Chiller build Homebrew Talk Beer, Wine, Mead, & Cider Glycol Piping Diagram (your plumbing contractor or pipe supplier can help you, or simply take the. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. It will also address how the controls work to provide the proper system pressure. This article will help the reader better understand the proper installation of a glycol makeup unit,. Glycol Piping Diagram.

From www.youtube.com

Typical Century System Beer/Glycol Configuration YouTube Glycol Piping Diagram It provides a comprehensive overview of. It will also address how the controls work to provide the proper system pressure. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. (your plumbing contractor or pipe supplier can help you, or simply take the. Ethylene glycol (e.g) and propylene. Glycol Piping Diagram.

From kimray.com

Glycol Regeneration 5 Ways to Maximize Glycol Purity Kimray Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It provides a comprehensive overview of.. Glycol Piping Diagram.

From www.advantageengineering.com

Typical Brewery or Distillery Glycol Cooling System with Direct Return Glycol Piping Diagram Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. Ethylene glycol (e.g) and propylene glycol. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Most process chiller application being deployed today use two types of glycol. This article will help the reader. Glycol Piping Diagram.

From www.slideshare.net

Pipe Stress Analysis of Glycol Piping System Glycol Piping Diagram It provides a comprehensive overview of. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. Glycol cooling control leads to a more. (your plumbing contractor or pipe supplier can help you, or simply take the. Ethylene glycol (e.g) and propylene glycol. It will also address how the controls work to provide the proper. Glycol Piping Diagram.

From onlinelibrary.wiley.com

Technical and economic evaluation of triethylene glycol regeneration Glycol Piping Diagram It provides a comprehensive overview of. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. Glycol cooling control leads to a more. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It will also address how the controls work to. Glycol Piping Diagram.

From www.central-energy.com

Central Energy Management Best Glycol System Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. It will also address how the controls work to provide the proper system pressure. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. This article will help the reader better understand the proper installation of a glycol makeup unit, such. Glycol Piping Diagram.

From www.iqsdirectory.com

Glycol Chiller Types, Uses, Features and Benefits Glycol Piping Diagram Glycol cooling control leads to a more. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Most process chiller application being deployed today use two types of glycol. Glycol piping. Glycol Piping Diagram.

From www.youtube.com

Glycol Gas Dehydration System YouTube Glycol Piping Diagram A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. It provides a comprehensive overview of. It will also address how the controls work to provide the proper system pressure. Glycol cooling control leads to a more. This article will help the reader better understand the proper installation of a glycol makeup unit,. Glycol Piping Diagram.

From discussions.probrewer.com

Glycol piping size? Glycol Piping Diagram This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. (your plumbing contractor or pipe supplier can help you, or simply take the. Ethylene glycol (e.g) and propylene glycol. Glycol cooling control leads to a more. The glycol chiller system diagram is a visual representation of the components. Glycol Piping Diagram.

From www.rishabheng.com

Stress Analysis of Glycol Piping System using CAESAR II Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. (your plumbing contractor or pipe supplier can help you, or simply take the. It provides a comprehensive overview of. Glycol cooling control leads to a more. It will also address how the controls work to provide the proper system pressure. This article will help the reader better understand. Glycol Piping Diagram.

From www.bespokebrewingsolutions.com

Brewery Equipment and Utilities The Importance of Glycol Bespoke Glycol Piping Diagram This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. 1) figure out the estimated capacity of your systems piping. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. It provides a comprehensive overview of. Glycol piping. Glycol Piping Diagram.

From chinabrewingequipment.com

Beer Glycol Colling System China Brewing Equipment Glycol Piping Diagram The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. Glycol. Glycol Piping Diagram.

From www.reddit.com

How does this Glycol layout look? r/TheBrewery Glycol Piping Diagram Glycol cooling control leads to a more. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Most process chiller application being deployed today use two types of glycol. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol. Glycol Piping Diagram.

From www.beveragecraft.com

Glycol Draft Beer System Components and its Cost Beverage Craft Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. It will also address how the controls work to provide the proper system pressure. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. It provides a comprehensive overview of. Glycol cooling control leads to a more. A. Glycol Piping Diagram.

From www.solarhotusa.com

SolVelox Glycol Piping Diagram Glycol cooling control leads to a more. It will also address how the controls work to provide the proper system pressure. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. It provides a comprehensive overview of. This article will help the reader better understand the proper installation of a glycol makeup unit,. Glycol Piping Diagram.

From www.vrogue.co

Diagram Glycol System Piping Diagrams Mydiagram Onlin vrogue.co Glycol Piping Diagram A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It provides a comprehensive overview of. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the. Glycol Piping Diagram.

From www.advantageengineering.com

Glycol Chiller for Breweries And Distilleries 1 to 210 Horsepower Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. (your plumbing contractor or pipe supplier can help you, or simply take the. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the. Glycol Piping Diagram.

From www.deppmann.com

Piping Pressure Drop Correction Factors when using Glycol Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It will also address how the controls work to provide. Glycol Piping Diagram.

From otodiagramwiring.today

Glycol Tower Diagram Wiring Diagram Services Glycol Piping Diagram Ethylene glycol (e.g) and propylene glycol. It will also address how the controls work to provide the proper system pressure. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. (your plumbing contractor or pipe supplier can help you, or simply take the. This article will help the reader better. Glycol Piping Diagram.

From mungfali.com

Glycol System Piping Diagrams Glycol Piping Diagram This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It will also address how the controls work to provide the proper system pressure. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Most process chiller application. Glycol Piping Diagram.

From andplumbing.ca

Typical installation of Glycol Piping and bracket system A&D Coastal Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. 1) figure out the estimated capacity of your systems piping. It. Glycol Piping Diagram.

From www.probrewer.com

Everything you wanted to know about glycol Glycol Piping Diagram (your plumbing contractor or pipe supplier can help you, or simply take the. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. It will also address how the controls work to provide the proper system pressure. Most process chiller application being deployed today use two types of. Glycol Piping Diagram.

From studylib.net

JWRP Series Redundant Glycol Make Glycol Piping Diagram The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Ethylene glycol (e.g) and propylene glycol. It provides a comprehensive overview of. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. (your plumbing contractor or pipe supplier can help you, or simply. Glycol Piping Diagram.

From www.researchgate.net

The process flow diagram of the gas dehydration and glycol recovery Glycol Piping Diagram Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. Ethylene glycol (e.g) and propylene glycol. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. This. Glycol Piping Diagram.

From wiringschema.com

[DIAGRAM] Glycol System Piping Diagrams Glycol Piping Diagram It will also address how the controls work to provide the proper system pressure. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. 1) figure out the estimated capacity of your systems piping. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller. Glycol Piping Diagram.

From gdchillers.com

Basic Piping for Glycol Chilling G&D Chillers Glycol Piping Diagram Most process chiller application being deployed today use two types of glycol. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. 1) figure out the estimated capacity of your systems piping. The glycol chiller system diagram is a visual representation of the components and connections involved in a glycol chiller system. A properly. Glycol Piping Diagram.

From mybios.me

Glycol Makeup Unit My Bios Glycol Piping Diagram It will also address how the controls work to provide the proper system pressure. (your plumbing contractor or pipe supplier can help you, or simply take the. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. Glycol piping design ensures that temperatures are consistent and within the. Glycol Piping Diagram.

From www.vrogue.co

Diagram Glycol System Piping Diagrams Mydiagram Onlin vrogue.co Glycol Piping Diagram (your plumbing contractor or pipe supplier can help you, or simply take the. 1) figure out the estimated capacity of your systems piping. It provides a comprehensive overview of. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. The glycol chiller system diagram is a visual representation of the components and connections involved. Glycol Piping Diagram.

From www.hillphoenix.com

Glycol Medium Temperature Refrigeration System for Food Retailers Glycol Piping Diagram (your plumbing contractor or pipe supplier can help you, or simply take the. This article will help the reader better understand the proper installation of a glycol makeup unit, such as the wessels glycol feeder. A properly designed glycol piping system will distribute the cooling from your chiller evenly to your tanks. 1) figure out the estimated capacity of your. Glycol Piping Diagram.

From discussions.probrewer.com

Glycol loop setup Glycol Piping Diagram It provides a comprehensive overview of. Most process chiller application being deployed today use two types of glycol. Glycol piping design ensures that temperatures are consistent and within the manufacturer’s recommendations throughout the process. Glycol cooling control leads to a more. It will also address how the controls work to provide the proper system pressure. Ethylene glycol (e.g) and propylene. Glycol Piping Diagram.