Soldering Structure Definition . Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Such as copper joining in circuit boards and copper pipe joints. Solder is a metal alloy used to create strong permanent bonds; The solder or filler metal is an alloy which is melted. We'll cover a couple of common soldering jobs now: Soldering is a process of joining two or more different types of metals together by melting solder. Its simple design conceals a sophisticated mechanism that ensures. Attachment of one metal to another can be accomplished in three ways:

from www.7pcb.com

Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). The solder or filler metal is an alloy which is melted. Solder is a metal alloy used to create strong permanent bonds; Such as copper joining in circuit boards and copper pipe joints. We'll cover a couple of common soldering jobs now: Its simple design conceals a sophisticated mechanism that ensures. Attachment of one metal to another can be accomplished in three ways: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Soldering is a process of joining two or more different types of metals together by melting solder.

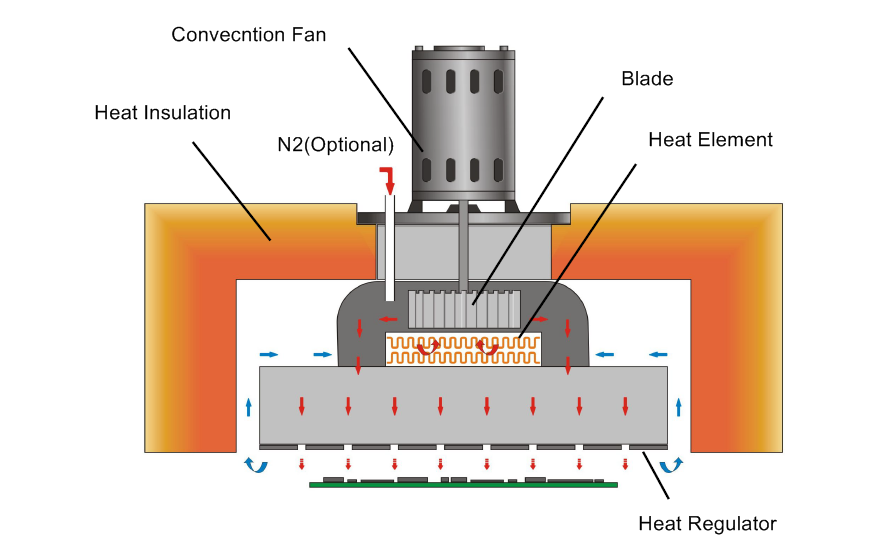

Reflow Soldering Bittele

Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. The solder or filler metal is an alloy which is melted. Attachment of one metal to another can be accomplished in three ways: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. Its simple design conceals a sophisticated mechanism that ensures. We'll cover a couple of common soldering jobs now: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Such as copper joining in circuit boards and copper pipe joints. Solder is a metal alloy used to create strong permanent bonds;

From inchbyinch.de

INCH Technical English soldering station Soldering Structure Definition Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in three ways: We'll cover a couple of common soldering jobs now: The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal, called solder, and. Soldering Structure Definition.

From www.researchgate.net

SEM images of solder joints and preforms. a Microstructure of solder Soldering Structure Definition The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or. Soldering Structure Definition.

From blog.thepipingmart.com

Soldering Steel and Brass What You Need to Know Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Its simple. Soldering Structure Definition.

From www.skillcatapp.com

The Soldering Process in 5 Simple Steps Soldering Structure Definition We'll cover a couple of common soldering jobs now: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Attachment of one metal to another can be accomplished in three ways: Its simple design conceals a sophisticated mechanism that ensures. Solder is a metal alloy used to create strong permanent bonds; Soldering. Soldering Structure Definition.

From web.uvic.ca

Physics 429 Honours Laboratory Soldering Structure Definition Solder is a metal alloy used to create strong permanent bonds; Its simple design conceals a sophisticated mechanism that ensures. Soldering is a process of joining two or more different types of metals together by melting solder. Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in three ways:. Soldering Structure Definition.

From fractory.com

Soldering Explained Definition, Process, Types Fractory Soldering Structure Definition The solder or filler metal is an alloy which is melted. Solder is a metal alloy used to create strong permanent bonds; We'll cover a couple of common soldering jobs now: Its simple design conceals a sophisticated mechanism that ensures. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Such as. Soldering Structure Definition.

From www.mdpi.com

Micromachines Free FullText A New LowTemperature Solder Assembly Soldering Structure Definition The solder or filler metal is an alloy which is melted. We'll cover a couple of common soldering jobs now: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Such as copper joining in circuit boards and copper pipe joints. Solder is a metal alloy used. Soldering Structure Definition.

From www.twi-global.com

What is Soldering? A Full Guide (Meaning, Definition and Types) TWI Soldering Structure Definition We'll cover a couple of common soldering jobs now: Such as copper joining in circuit boards and copper pipe joints. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming. Soldering Structure Definition.

From www.researchgate.net

(a) Schematic structure of solder joint configuration used in this Soldering Structure Definition We'll cover a couple of common soldering jobs now: Solder is a metal alloy used to create strong permanent bonds; Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Such as copper joining in circuit boards and copper pipe joints. Soldering is a process of joining two or more different types. Soldering Structure Definition.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] Soldering Structure Definition We'll cover a couple of common soldering jobs now: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Such as copper joining in circuit boards and copper pipe joints. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming. Soldering Structure Definition.

From www.researchgate.net

Procedure for preparation of a single BGA structure joint by twice Soldering Structure Definition Solder is a metal alloy used to create strong permanent bonds; Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in three ways: The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal, called. Soldering Structure Definition.

From helecu.com

Soldering Explained Definition, Process, Types Fractory (2023) Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in three ways: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to. Soldering Structure Definition.

From www.nj2x.com

NJ2X Soldering 101 Soldering Structure Definition The solder or filler metal is an alloy which is melted. Soldering is a process of joining two or more different types of metals together by melting solder. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Such as copper joining in circuit boards and copper. Soldering Structure Definition.

From adrkurs.pl

Soldering one of the methods of welding Soldering Structure Definition Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. The solder or filler metal is an alloy which is melted. Its simple design conceals a sophisticated mechanism that ensures. Soldering is a process of joining two or more different types of metals together by melting solder.. Soldering Structure Definition.

From www.youtube.com

Using Solder Soldering Basics Soldering for Beginners YouTube Soldering Structure Definition Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal,. Soldering Structure Definition.

From www.researchgate.net

Bonding process description. a Alignment structure of the metal solder Soldering Structure Definition Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. Attachment of one metal to another can be accomplished in three ways: Its simple design conceals a sophisticated mechanism that ensures. Such as copper joining. Soldering Structure Definition.

From www.researchgate.net

Wave Soldering Machine process diagram. Dotted arrows represent the Soldering Structure Definition Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in three ways: Solder is a metal alloy used to create strong permanent bonds; Soldering is a process of joining two or more different types of metals together by melting solder. Soldering is the process of joining metal components together. Soldering Structure Definition.

From www.electronicsandyou.com

Layers of Soldering Iron Tip Electronics Tutorial The Best Soldering Structure Definition The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Its simple design conceals a sophisticated mechanism that ensures. We'll cover a couple of common soldering jobs now: Soldering iron is an essential tool widely used. Soldering Structure Definition.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. The solder or filler metal is an alloy which is melted. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Its simple design conceals a sophisticated mechanism that ensures. We'll cover a couple of. Soldering Structure Definition.

From weldingtroop.com

What Is Soldering? An Indepth Guide [Definition, Types, and Meaning] Soldering Structure Definition Its simple design conceals a sophisticated mechanism that ensures. Soldering is a process of joining two or more different types of metals together by melting solder. We'll cover a couple of common soldering jobs now: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is the process of joining metal. Soldering Structure Definition.

From www.researchgate.net

(a) Schematic structure of solder joint configuration used in this Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. Solder is a metal alloy used to create strong permanent bonds; Attachment of one metal to another can be accomplished in three ways: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is. Soldering Structure Definition.

From www.pcbaaa.com

Why choose wave soldering ? How it works? IBE Electronics Soldering Structure Definition Its simple design conceals a sophisticated mechanism that ensures. The solder or filler metal is an alloy which is melted. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Attachment of one metal to another can be accomplished in three ways: Soldering is a process of joining two or more different. Soldering Structure Definition.

From www.researchgate.net

EDX analysis of solder structure in soldered joint of Al7075/Zn5Al3Cu Soldering Structure Definition We'll cover a couple of common soldering jobs now: Such as copper joining in circuit boards and copper pipe joints. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Attachment of one metal to another can be accomplished in three ways: Its simple design conceals a sophisticated mechanism that ensures. Soldering. Soldering Structure Definition.

From www.tescaglobal.com

What Is Soldering? A Full Guide (Meaning, Definition And Types) Soldering Structure Definition Attachment of one metal to another can be accomplished in three ways: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. We'll cover a couple of common soldering jobs now: The solder or filler metal is an alloy which is melted. Such as copper joining in. Soldering Structure Definition.

From weldingstars.com

Welding, soldering, and brazing. Do you know the difference? Welding Soldering Structure Definition Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. We'll cover a couple of common soldering jobs now: Solder is a metal alloy used to create strong permanent bonds; Attachment of one metal to. Soldering Structure Definition.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components to PCB Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. The solder or filler metal is an alloy which is melted. Solder is a metal alloy used to create strong permanent bonds; Such as copper joining in circuit boards and copper pipe joints. Attachment of one metal to another can be accomplished in. Soldering Structure Definition.

From www.slideshare.net

dental soldering Soldering Structure Definition Its simple design conceals a sophisticated mechanism that ensures. Attachment of one metal to another can be accomplished in three ways: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by. Soldering Structure Definition.

From www.youtube.com

Basic Soldering YouTube Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. We'll cover a couple of common soldering jobs now: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). The solder or filler metal is an alloy which is melted. Its simple design conceals a. Soldering Structure Definition.

From www.electronicsandyou.com

BGA Soldering & Repairing How to Solder Ball Grid Array (BGA) Soldering Structure Definition Soldering is a process of joining two or more different types of metals together by melting solder. Attachment of one metal to another can be accomplished in three ways: The solder or filler metal is an alloy which is melted. Solder is a metal alloy used to create strong permanent bonds; Soldering is the process of joining metal components together. Soldering Structure Definition.

From www.7pcb.com

Reflow Soldering Bittele Soldering Structure Definition Solder is a metal alloy used to create strong permanent bonds; The solder or filler metal is an alloy which is melted. Attachment of one metal to another can be accomplished in three ways: Soldering is a process of joining two or more different types of metals together by melting solder. Soldering is the process of joining metal components together. Soldering Structure Definition.

From accuratepicker.com

Soldering Vs Welding The Ultimate Guideline Soldering Structure Definition Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. Attachment of one metal to another can be accomplished in three ways: Soldering is the process of joining metal components together by melting a filler. Soldering Structure Definition.

From circuitlibraryjurgen.z19.web.core.windows.net

Schematic Diagram Of Soldering Iron Soldering Structure Definition Attachment of one metal to another can be accomplished in three ways: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two. Soldering Structure Definition.

From components101.com

Types of Soldering Iron and How to Select the Right One Soldering Structure Definition We'll cover a couple of common soldering jobs now: The solder or filler metal is an alloy which is melted. Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a. Soldering is a process of joining two or more different types of metals together by melting solder.. Soldering Structure Definition.

From www.techspray.com

Ultimate Guide to Electronic Soldering Techspray Soldering Structure Definition Attachment of one metal to another can be accomplished in three ways: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). The solder or filler metal is an alloy which is melted. We'll cover a couple of common soldering jobs now: Its simple design conceals a sophisticated mechanism that ensures. Solder. Soldering Structure Definition.

From arduinoal.blogspot.com

How Soldering Iron Repair, Connection Diagram and Internal Structure Soldering Structure Definition Attachment of one metal to another can be accomplished in three ways: Soldering iron is an essential tool widely used to attach components and wires on printed circuit boards (pcbs). Soldering is a process of joining two or more different types of metals together by melting solder. Solder is a metal alloy used to create strong permanent bonds; Soldering is. Soldering Structure Definition.