Mold For Casting Aluminum . To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Graphite molds can cast iron, steel, and some other. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Look for mold frames online or from specialty metal supply stores. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum.

from blog.faradars.org

Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast.

دایکاست چیست ؟ — دانستنی های مهم درباره ریخته گری تحت فشار فرادرس مجله

Mold For Casting Aluminum To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. Graphite molds can cast iron, steel, and some other. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Look for mold frames online or from specialty metal supply stores. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys.

From www.aluminumingotmold.com

Aluminum Casting Metal Ingot Molds For Nonferrous Metal Non Standard Mold For Casting Aluminum To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold. Mold For Casting Aluminum.

From www.sunrise-metal.com

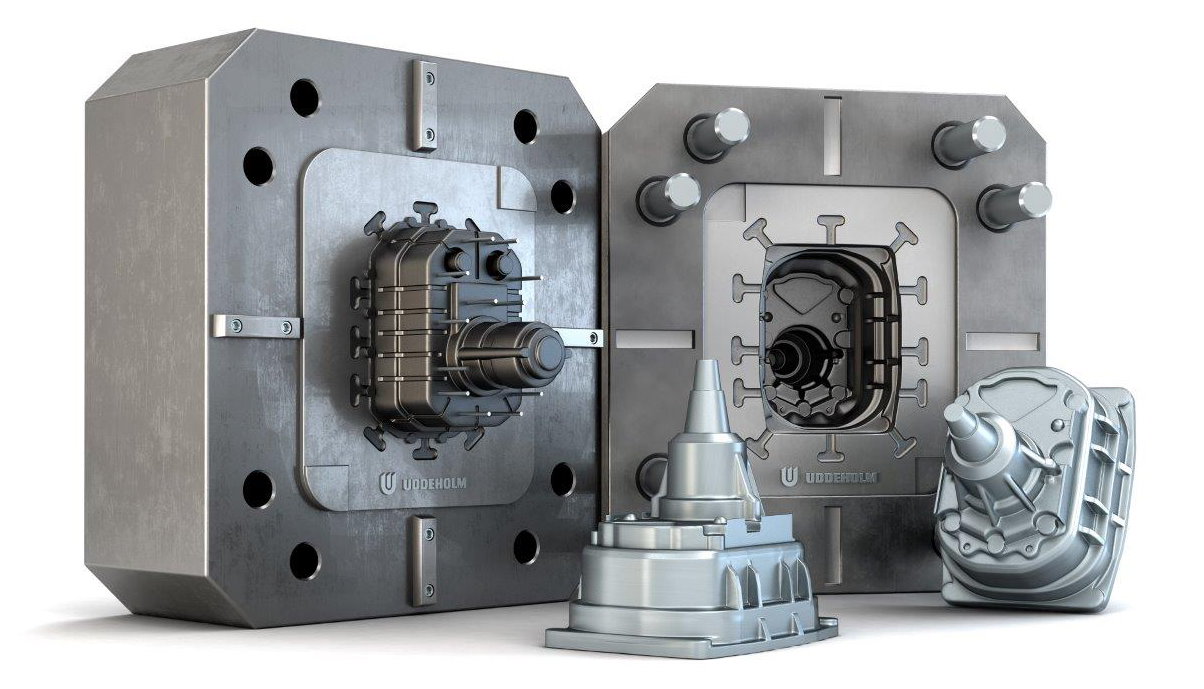

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Mold For Casting Aluminum Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Generally, most. Mold For Casting Aluminum.

From www.museoinclusivo.com

Aluminum Molds Overview of Benefits, Uses and Processes Aluminum Mold For Casting Aluminum This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Graphite molds can cast iron, steel, and some other. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Permanent mold casting is most often used to shape nonferrous metals such as aluminum,. Mold For Casting Aluminum.

From www.diecasting-mould.com

Permanent Mold Casting vs Die Casting vs Sand Casting What is Mold For Casting Aluminum It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Graphite molds can cast iron, steel, and some other. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. The aluminum casting mold’s durability, coupled with its elastic nature, brings. Mold For Casting Aluminum.

From qualityinspection.org

The Die Casting Process, Ingots, & Aluminum Casting [Videos] Mold For Casting Aluminum To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and. Mold For Casting Aluminum.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. To successfully. Mold For Casting Aluminum.

From www.aludiecasting.com

Aluminum die casting mold, Best No. 1 Die Casting Mold Mold For Casting Aluminum To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Permanent mold casting is most often used to shape nonferrous metals such as. Mold For Casting Aluminum.

From unitymanufacture.com

What Is Aluminum Die Casting? Unity Manufacture Mold For Casting Aluminum It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Look for mold. Mold For Casting Aluminum.

From biz6.ru

Особенности и преимущества литейных форм Оборудование для старта Mold For Casting Aluminum The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Make sure. Mold For Casting Aluminum.

From www.sunrise-metal.com

Die Casting Tooling, Design & Manufacturing All Inhouse Mold For Casting Aluminum It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Generally, most. Mold For Casting Aluminum.

From blog.thepipingmart.com

Die Casting vs Mold Casting What's the Difference Mold For Casting Aluminum Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire a mold. Mold For Casting Aluminum.

From www.alibaba.com

Aluminum Die Casting Making As 3d Drawing & Sample Cast Lead Mold Lead Mold For Casting Aluminum Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold. Mold For Casting Aluminum.

From www.museoinclusivo.com

Aluminum Casting Molds An Overview of Design, Manufacturing and Mold For Casting Aluminum Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. It is commonly used to create delicate and detailed elements that exactly match the specifications. Mold For Casting Aluminum.

From www.pinterest.com

Casting Metal Parts into 3D Printed Molds Metal casting, 3d printing Mold For Casting Aluminum Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared. Mold For Casting Aluminum.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Mold For Casting Aluminum It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a. Mold For Casting Aluminum.

From www.aludiecasting.com

Reusable Aluminum Casting Molds China Die Casting Aluminum Die Casting Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Graphite molds can cast iron, steel, and some other. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast.. Mold For Casting Aluminum.

From www.alcirclebiz.com

Aluminium Die Casting Mold Equipment, Shenzhen Camel Die Limited AL Mold For Casting Aluminum Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. This is the process i use to make an aluminum mold in petrobond sand. Mold For Casting Aluminum.

From www.aluminumingotmold.com

Aluminum Casting Metal Ingot Molds Polishing Surface Treatment Mold For Casting Aluminum This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with. Mold For Casting Aluminum.

From www.youtube.com

Pouring Molten Aluminum into a 3D Printed Sand Casting Mold YouTube Mold For Casting Aluminum The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. It. Mold For Casting Aluminum.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Mold For Casting Aluminum This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Graphite molds can cast iron, steel, and some other. Make sure the frame comes in 2 parts and is large enough to hold the object. Mold For Casting Aluminum.

From www.diecastingcompany.com

The Measures To Improve The Life Of AluminumMagnesium Alloy Die Mold For Casting Aluminum Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum.. Mold For Casting Aluminum.

From haoyoumould.en.made-in-china.com

Customized New Aluminum/Zinc Alloy Injection Molds for Automotive Mold For Casting Aluminum Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask). Mold For Casting Aluminum.

From precisecast.com

Aluminum Casting Company American Foundry Rapid Prototyping Mold For Casting Aluminum Graphite molds can cast iron, steel, and some other. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. The aluminum casting mold’s durability, coupled with its elastic. Mold For Casting Aluminum.

From www.gabrian.com

What is Aluminum Die Casting? 5 Things You Need to Know Mold For Casting Aluminum Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Permanent mold casting is most often used to shape nonferrous metals such as aluminum,. Mold For Casting Aluminum.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. It is. Mold For Casting Aluminum.

From sealectplastics.com

The Top 5 Plastic Injection Molding Defects (and How to Solve Them) Mold For Casting Aluminum Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Graphite molds. Mold For Casting Aluminum.

From riversofsteel.com

Aluminum Casting Session — Rivers of Steel Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Generally, most aluminum casting processes involve heating the. Mold For Casting Aluminum.

From www.indiamart.com

Aluminium Mold Casting at best price in Vasai by Shree Maa Engineering Mold For Casting Aluminum This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. It is commonly used to. Mold For Casting Aluminum.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Mold For Casting Aluminum Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. Look for mold frames online or from specialty metal supply stores. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. It is commonly. Mold For Casting Aluminum.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. Graphite molds can cast iron, steel, and some other. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. It is. Mold For Casting Aluminum.

From timberridgedesigns.com

Aluminum Casting At Home DIY Aluminum Foundry & Molds Timber Ridge Mold For Casting Aluminum Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. This is the process i use to make an aluminum mold in petrobond sand for. Mold For Casting Aluminum.

From blog.faradars.org

دایکاست چیست ؟ — دانستنی های مهم درباره ریخته گری تحت فشار فرادرس مجله Mold For Casting Aluminum Look for mold frames online or from specialty metal supply stores. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. Graphite molds can cast iron, steel,. Mold For Casting Aluminum.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Mold For Casting Aluminum Graphite molds can cast iron, steel, and some other. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. To successfully cast metal, you’ll first need to acquire a mold frame. Mold For Casting Aluminum.

From zrxprecision.en.made-in-china.com

OEM Manufacturer Die Casting Mold for Aluminum Die Casting Molds Mold For Casting Aluminum Permanent mold casting is most often used to shape nonferrous metals such as aluminum, magnesium, and copper alloys. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to businesses, paving the way for higher. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood,. Mold For Casting Aluminum.

From www.weld2cast.com

Sand Casting Weld2Cast Mold For Casting Aluminum It is commonly used to create delicate and detailed elements that exactly match the specifications of the original design given. Generally, most aluminum casting processes involve heating the aluminum (and other metal) and pouring them in molten form into a prepared mold with the desired. The aluminum casting mold’s durability, coupled with its elastic nature, brings a competitive edge to. Mold For Casting Aluminum.