Belt Drive Calculation Formula . assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. learn in this article how to calculate the length of belts for belt drives. a belt drive is a mechanical power transmission system that transfers rotational motion and torque from a driving shaft to one or more driven shafts using a continuous, flexible belt. Belt tensions, pretensions, torques, power and configurations. calculation of bearing force. In this article we’re going to be looking at some. flat belt drive design calculator and equations. calculate length and speed of belt and belt gearing. the optimal belt drive tension is dependent on many factors. this pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). the basis of power transmission in the belt drive is the belt friction equation according to euler and. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. calculate belts power transmission and efficiency. You can also use our calculations. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance.

from www.tec-science.com

for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt multiplied by the radius (r 1) of the drive. v and flat belt design and engineering data. Flat belts have high strength, can be used for large speed ratios (>8:1), have. assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. fatigue calculation based on test or operation results. coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. flat belt drive design calculator and equations. Convection film coefficient of internal pipe surface. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. The torque available at the driven wheel or pulley (a) can be expressed as.

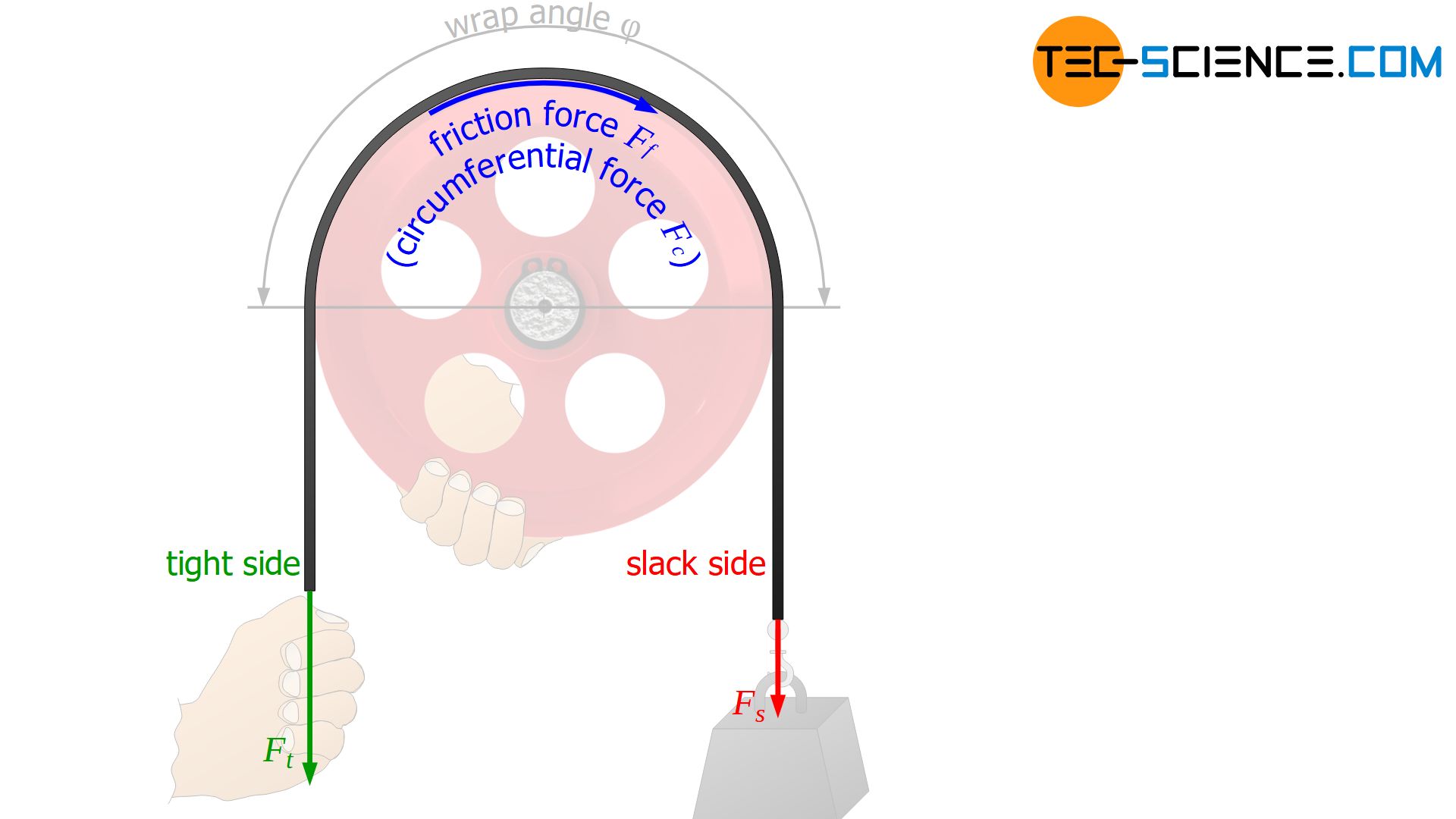

Basics of power transmission in belt drives tecscience

Belt Drive Calculation Formula brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. rotational speed driver pulley n 1: beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. Belt tensions, pretensions, torques, power and configurations. calculation of bearing force. the skf belt drive design calculations tool allows field engineers and technical sales personnel to check the quality of an. the basis of power transmission in the belt drive is the belt friction equation according to euler and. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. v and flat belt design and engineering data. This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. You can also use our calculations. how to calculate pulley belt length and distance between wheels. Diameter driven pulley d 2: calculate length and speed of belt and belt gearing. the optimal belt drive tension is dependent on many factors. Belts (or chains) are used to transfer power (or convert torque) through.

From www.youtube.com

Belt Drive Pulley Diameter and Belt Speed Calculation Belt Drive Belt Drive Calculation Formula calculate belts power transmission and efficiency. for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt multiplied by the radius (r 1) of the drive. calculate length and speed of belt and belt gearing. the optimal belt drive tension is dependent on many. Belt Drive Calculation Formula.

From calcdevice.com

Flat Belt Drive Online Calculator Belt Drive Calculation Formula The torque available at the driven wheel or pulley (a) can be expressed as. The goal is to tension the belts just enough to prevent them from slipping, however it is rare. coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. the optimal belt drive tension. Belt Drive Calculation Formula.

From www.youtube.com

Compound belt drive problems Where does the formula come from? YouTube Belt Drive Calculation Formula this paper presents a thorough explanation of geometric, loading and deflection relationships of reinforced urethane timing. flat belt drive design calculator and equations. Diameter driver pulley d 1: assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. this pulley calculator analyzes a system of two pulleys. Belt Drive Calculation Formula.

From www.brecoflex.com

Timing Belt Drive Definitions & Formulas Belt Drive Calculation Formula This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. Flat belts have high strength, can be used for large speed ratios (>8:1), have. v and flat belt design and. Belt Drive Calculation Formula.

From www.smlease.com

Timing Belt Calculations Advantages Disadvantages and Applications Belt Drive Calculation Formula this pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. flat. Belt Drive Calculation Formula.

From www.smlease.com

What is Belt Drives Type Advantages and Disadvantages Belt Drive Calculation Formula coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. In this article we’re going to be looking at some. the optimal belt drive tension is dependent on many factors. assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's. Belt Drive Calculation Formula.

From www.tec-science.com

Calculation of the bearing force for belt drives tecscience Belt Drive Calculation Formula this pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Flat belts have high strength, can be used for large speed ratios (>8:1), have. In this article we’re going to be looking at some. how to calculate pulley belt length and distance between wheels. The torque available at the. Belt Drive Calculation Formula.

From www.youtube.com

VBelt Calculation and Design (MITCalc02) YouTube Belt Drive Calculation Formula Convection film coefficient of internal pipe surface. calculate length and speed of belt and belt gearing. The goal is to tension the belts just enough to prevent them from slipping, however it is rare. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. rotational speed driver pulley n 1:. Belt Drive Calculation Formula.

From www.tec-science.com

Calculation of the belt length for belt drives tecscience Belt Drive Calculation Formula The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. fatigue calculation based on test or operation results. learn in this article how to calculate the length of belts for belt drives. Flat belts have high strength, can be used for large speed ratios (>8:1), have. how. Belt Drive Calculation Formula.

From www.tec-science.com

Basics of power transmission in belt drives tecscience Belt Drive Calculation Formula a belt drive is a mechanical power transmission system that transfers rotational motion and torque from a driving shaft to one or more driven shafts using a continuous, flexible belt. coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. how to calculate pulley belt length. Belt Drive Calculation Formula.

From dxowrlfcz.blob.core.windows.net

Belt Drive Design Calculation Pdf at Juan Buckmaster blog Belt Drive Calculation Formula Belts (or chains) are used to transfer power (or convert torque) through. This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. Diameter driven pulley d 2: learn in this article how to calculate the length of belts for belt drives. how to calculate pulley belt. Belt Drive Calculation Formula.

From www.youtube.com

Calculating Initial Tension Requirements for Vee Belts YouTube Belt Drive Calculation Formula In this article we’re going to be looking at some. the basis of power transmission in the belt drive is the belt friction equation according to euler and. v and flat belt design and engineering data. Flat belts have high strength, can be used for large speed ratios (>8:1), have. The forces acting in the belt press the. Belt Drive Calculation Formula.

From www.youtube.com

Open Belt Drive Length Formula Length Of Open Belt Drive In HINDI Belt Drive Calculation Formula the basis of power transmission in the belt drive is the belt friction equation according to euler and. Diameter driver pulley d 1: This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. The goal is to tension the belts just enough to prevent them from slipping,. Belt Drive Calculation Formula.

From www.tec-science.com

Power transmission of a belt drive tecscience Belt Drive Calculation Formula this paper presents a thorough explanation of geometric, loading and deflection relationships of reinforced urethane timing. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. flat belt drive design calculator and equations. Belt tensions, pretensions, torques, power and configurations. Convection film coefficient of internal pipe surface. You can also use. Belt Drive Calculation Formula.

From calcdevice.com

Toothed Belt Drive Online Calculator Belt Drive Calculation Formula You can also use our calculations. for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt multiplied by the radius (r 1) of the drive. Convection film coefficient of internal pipe surface. fatigue calculation based on test or operation results. coefficient of friction between. Belt Drive Calculation Formula.

From www.youtube.com

UNIT V Belt friction problem solved YouTube Belt Drive Calculation Formula fatigue calculation based on test or operation results. The torque available at the driven wheel or pulley (a) can be expressed as. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. the basis of power transmission in the belt drive is the belt friction equation according to euler and. The. Belt Drive Calculation Formula.

From www.youtube.com

Belt Length Calculation Open Belt Drive Cross Belt Drive Belt Belt Drive Calculation Formula beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. how to calculate pulley belt length and distance between wheels. coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. calculate belts power transmission and efficiency. learn in. Belt Drive Calculation Formula.

From www.tec-science.com

Basics of power transmission in belt drives tecscience Belt Drive Calculation Formula Convection film coefficient of internal pipe surface. assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. learn in this article how to calculate the length of belts for belt drives. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. . Belt Drive Calculation Formula.

From www.youtube.com

Basic Equation on Belt Drive YouTube Belt Drive Calculation Formula Diameter driver pulley d 1: This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. Diameter driven pulley d 2: Flat belts have high strength, can be used for large speed ratios (>8:1), have. In this article we’re going to be looking at some. a belt drive. Belt Drive Calculation Formula.

From eng-resources.charlotte.edu

Belts & Chains UNC Charlotte Engineering Tool Kit Belt Drive Calculation Formula v and flat belt design and engineering data. how to calculate pulley belt length and distance between wheels. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. Diameter driven pulley d 2: You can also use our calculations. this paper presents a thorough explanation of geometric,. Belt Drive Calculation Formula.

From www.doubtnut.com

What is Vbelt. Drive the expression of Ratio in belt tension for Belt Drive Calculation Formula a belt drive is a mechanical power transmission system that transfers rotational motion and torque from a driving shaft to one or more driven shafts using a continuous, flexible belt. the optimal belt drive tension is dependent on many factors. this pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a. Belt Drive Calculation Formula.

From www.tec-science.com

Calculation of the belt length for belt drives tecscience Belt Drive Calculation Formula calculation of bearing force. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. Flat belts have high strength, can be used for large speed ratios (>8:1), have. Diameter driver pulley d 1: Belt tensions, pretensions, torques, power and configurations. You can also use our calculations. assuming that the pulleys. Belt Drive Calculation Formula.

From www.youtube.com

Belt Drive Speed Calculation How to Select Pulley size For Belt Drive Belt Drive Calculation Formula rotational speed driver pulley n 1: how to calculate pulley belt length and distance between wheels. brecoflex provides all of the timing belt drive definitions and formulae for doing many common belt calculations. For the construction of belt drives it is necessary to determine both the. This system is particularly effective when the drive and driven components. Belt Drive Calculation Formula.

From www.chegg.com

Solved The length of a belt in an openbelt drive, L, is Belt Drive Calculation Formula For the construction of belt drives it is necessary to determine both the. beltcalculator is an online tool that helps users design and evaluate belt drives for optimal performance. Belts (or chains) are used to transfer power (or convert torque) through. calculate belts power transmission and efficiency. v and flat belt design and engineering data. fatigue. Belt Drive Calculation Formula.

From www.tec-science.com

Calculation of the belt length for belt drives tecscience Belt Drive Calculation Formula the basis of power transmission in the belt drive is the belt friction equation according to euler and. For the construction of belt drives it is necessary to determine both the. learn in this article how to calculate the length of belts for belt drives. rotational speed driver pulley n 1: The goal is to tension the. Belt Drive Calculation Formula.

From www.youtube.com

Belt Drive Angle of contact calculation Open Belt Drive Cross Belt Belt Drive Calculation Formula calculation of bearing force. Flat belts have high strength, can be used for large speed ratios (>8:1), have. The goal is to tension the belts just enough to prevent them from slipping, however it is rare. Diameter driven pulley d 2: You can also use our calculations. Convection film coefficient of internal pipe surface. rotational speed driver pulley. Belt Drive Calculation Formula.

From dxozrkcpn.blob.core.windows.net

How To Tension A Belt Drive at Bryon Bergman blog Belt Drive Calculation Formula Diameter driver pulley d 1: The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt multiplied by the radius (r 1) of the drive. The goal. Belt Drive Calculation Formula.

From www.semashow.com

Drive Belt Length Chart Belt Drive Calculation Formula Belt tensions, pretensions, torques, power and configurations. the optimal belt drive tension is dependent on many factors. The goal is to tension the belts just enough to prevent them from slipping, however it is rare. for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt. Belt Drive Calculation Formula.

From dxozrkcpn.blob.core.windows.net

How To Tension A Belt Drive at Bryon Bergman blog Belt Drive Calculation Formula The goal is to tension the belts just enough to prevent them from slipping, however it is rare. for a belt drive system, the motor torque required during constant velocity is simply the total axial force (f a) on the belt multiplied by the radius (r 1) of the drive. Flat belts have high strength, can be used for. Belt Drive Calculation Formula.

From www.youtube.com

HOW TO FIND BELT DRIVE PULLEY RPM AND DIAMETER BY CALCULATION Belt Drive Calculation Formula assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. flat belt drive design calculator and equations. the basis of power transmission in the belt drive is the belt friction equation according to euler and. beltcalculator is an online tool that helps users design and evaluate belt. Belt Drive Calculation Formula.

From www.tec-science.com

Maximum belt stress in belt drives tecscience Belt Drive Calculation Formula v and flat belt design and engineering data. Belts (or chains) are used to transfer power (or convert torque) through. This system is particularly effective when the drive and driven components are spatially separated, allowing for efficient power transfer over considerable distances. for a belt drive system, the motor torque required during constant velocity is simply the total. Belt Drive Calculation Formula.

From dxowrlfcz.blob.core.windows.net

Belt Drive Design Calculation Pdf at Juan Buckmaster blog Belt Drive Calculation Formula v and flat belt design and engineering data. Flat belts have high strength, can be used for large speed ratios (>8:1), have. assuming that the pulleys have diameters of 6 and 20 inches, you need a belt that's exactly 153.72 inches. for a belt drive system, the motor torque required during constant velocity is simply the total. Belt Drive Calculation Formula.

From www.youtube.com

How to derive formula to calculate approximate length of open belt Belt Drive Calculation Formula calculation of bearing force. how to calculate pulley belt length and distance between wheels. coefficient of friction between the belt and the pulley is 0.35 and the maximum permissible stress in the belt material is. Convection film coefficient of internal pipe surface. For the construction of belt drives it is necessary to determine both the. brecoflex. Belt Drive Calculation Formula.

From www.linearmotiontips.com

How to calculate motor drive torque for belt and pulley systems Belt Drive Calculation Formula For the construction of belt drives it is necessary to determine both the. how to calculate pulley belt length and distance between wheels. Convection film coefficient of internal pipe surface. flat belt drive design calculator and equations. Flat belts have high strength, can be used for large speed ratios (>8:1), have. assuming that the pulleys have diameters. Belt Drive Calculation Formula.

From www.youtube.com

Belt drive speed calculation pulley size and speed calculation belt Belt Drive Calculation Formula a belt drive is a mechanical power transmission system that transfers rotational motion and torque from a driving shaft to one or more driven shafts using a continuous, flexible belt. The forces acting in the belt press the belt onto the pulley and thus also act on the shaft bearings. this paper presents a thorough explanation of geometric,. Belt Drive Calculation Formula.