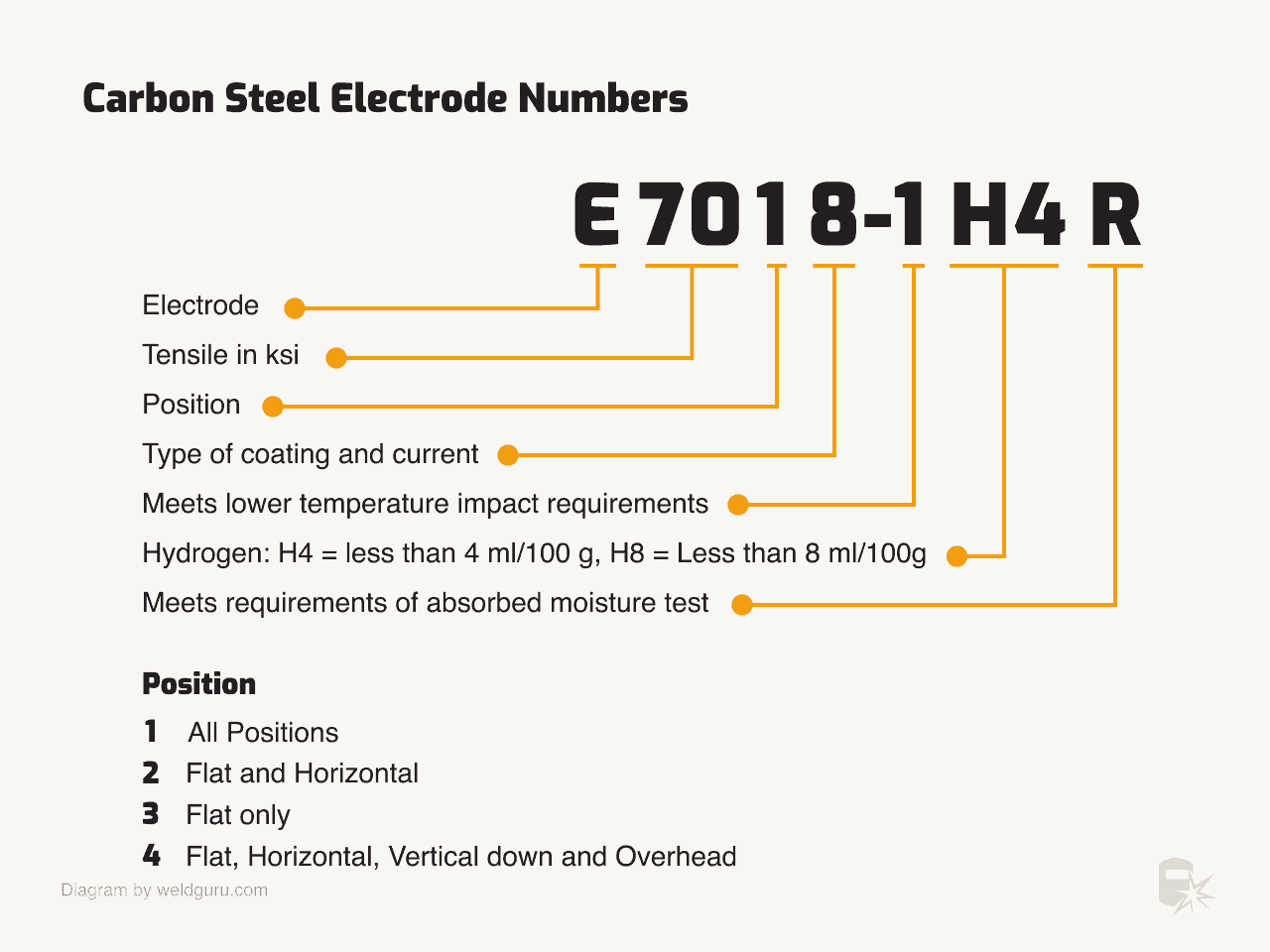

Welding Rod Electrode Classifications . Mild steel coated electrodes low alloy steel coated electrodes. when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. You may have noticed it imprinted. to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct the welding current.” this means that the product can be used in the electrod form or rod form (typically cut lengths of solid rod for the gtaw process). this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. The main three groups are:

from weldguru.com

electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. Typically, welding electrode types are made of a metal alloy that matches or. this specification prescribes the requirements for classification of bare solid stainless steel electrodes (both as. this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. the american welding society’s specifications are most widely used for specifying bare welding rod and electrode wires. let’s take a look at how this works and what it means for three commonly used welding rods: mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. the smaw electrodes are grouped based on their flux coating type into three groups;

Welding Rod Numbers Explained What Do They Mean?

Welding Rod Electrode Classifications when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct the welding current.” this means that the product can be used in the electrod form or rod form (typically cut lengths of solid rod for the gtaw process). mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. The welding industry has adopted the american welding society’s classification number series for welding rod. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. let’s take a look at how this works and what it means for three commonly used welding rods: The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. Mild steel coated electrodes low alloy steel coated electrodes. The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. You may have noticed it imprinted. the american welding society’s specifications are most widely used for specifying bare welding rod and electrode wires.

From yeowchuan.com.my

How to read the Welding Electrode Classifications on Coating Welding Rod Electrode Classifications mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. Mild steel coated electrodes low alloy steel coated electrodes. this specification. Welding Rod Electrode Classifications.

From www.wcwelding.com

Arc Welding Rods Guide Welding Rod Electrode Classifications The main three groups are: this specification prescribes the requirements for classification of bare solid stainless steel electrodes (both as. Typically, welding electrode types are made of a metal alloy that matches or. let’s take a look at how this works and what it means for three commonly used welding rods: The numbers in the classification refer to. Welding Rod Electrode Classifications.

From leniran.blogspot.com

Welding Consumables Welding Rod Electrode Classifications let’s take a look at how this works and what it means for three commonly used welding rods: Mild steel coated electrodes low alloy steel coated electrodes. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. The welding industry has adopted the american welding society’s classification number series for welding rod. . Welding Rod Electrode Classifications.

From weldguru.com

Welding Electrode Chart and Selection Weld Guru Welding Rod Electrode Classifications The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. You may have noticed it imprinted. The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. this specification prescribes the requirements for classification of bare stainless steel electrodes (both. Welding Rod Electrode Classifications.

From www.walmart.com

400A Welding Electrode Holder Arc Mma Arc Welding Rod Electrode Clamp Welding Rod Electrode Classifications The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. when you pick. Welding Rod Electrode Classifications.

From dxozsrbtx.blob.core.windows.net

Types Of Electrodes For Welding at Todd Tilley blog Welding Rod Electrode Classifications this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. The numbers in the classification refer. Welding Rod Electrode Classifications.

From www.koviwelding.com

Welding Electrode Classification Welding Rod Electrode Classifications to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. this specification prescribes the requirements for classification of. Welding Rod Electrode Classifications.

From weldingrodshub.com

Types Of Welding Rods, Which One is Best Comprehensive Guide Welding Rod Electrode Classifications You may have noticed it imprinted. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct the. Welding Rod Electrode Classifications.

From www.weldfabworld.com

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World Welding Rod Electrode Classifications You may have noticed it imprinted. The welding industry has adopted the american welding society’s classification number series for welding rod. let’s take a look at how this works and what it means for three commonly used welding rods: Typically, welding electrode types are made of a metal alloy that matches or. electrode welding, or stick welding, uses. Welding Rod Electrode Classifications.

From www.scribd.com

Comparison Chart Electrode Stainless Steel Welding Welding Rod Electrode Classifications to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. they are designed to melt and provide filler material during the welding process. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct. Welding Rod Electrode Classifications.

From compare-bear.com

Welding Rods for Stick Welding The Definitive Electrode Guide (2019) Welding Rod Electrode Classifications The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. they are designed to melt and provide filler material during the welding process. the e in carbon steel welding rod. Welding Rod Electrode Classifications.

From www.walmart.com

E6013 3/32" 1/8" 5/32" Premium Arc Welding Rods Carbon Steel Electrode Welding Rod Electrode Classifications mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. You may have noticed it imprinted. to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. this specification prescribes the requirements for classification of bare solid stainless steel electrodes (both as. The american welding society (aws) numbering. Welding Rod Electrode Classifications.

From www.mfvideobrazil.com

Welding Rod Chart Classification, 51 OFF Welding Rod Electrode Classifications The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in. Welding Rod Electrode Classifications.

From brokeasshome.com

welding electrode classifications table Welding Rod Electrode Classifications north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between. Welding Rod Electrode Classifications.

From www.youtube.com

Welding Tips_ Electrode Classifications E7018,6010,7024 ..etc YouTube Welding Rod Electrode Classifications north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. electrode welding, or stick welding, uses electrode rods covered in a flux, each of. Welding Rod Electrode Classifications.

From weldguru.com

Welding Rod Numbers Explained What Do They Mean? Welding Rod Electrode Classifications the smaw electrodes are grouped based on their flux coating type into three groups; north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. The welding industry has adopted the american welding society’s classification number series for welding rod. to help classify the electrodes, the american welding society (aws) has developed the popular “e”. Welding Rod Electrode Classifications.

From www.hobartbrothers.com

Basics of AWS Filler Metal and Electrode Classification Welding Rod Electrode Classifications The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. this specification prescribes the requirements for classification of bare solid stainless steel electrodes (both as. when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. north america’s. Welding Rod Electrode Classifications.

From mechanicalinventions.blogspot.ca

Types Welding Electrodes explained Non consumableConsumable Welding Rod Electrode Classifications the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding. Welding Rod Electrode Classifications.

From www.weldingcity.com

3/32" x 12" WeldingCity® E309L16 Stainless Steel Stick Welding Welding Rod Electrode Classifications Mild steel coated electrodes low alloy steel coated electrodes. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. the smaw electrodes are grouped based on their flux coating type into three groups; the american. Welding Rod Electrode Classifications.

From brokeasshome.com

welding electrode classifications table Welding Rod Electrode Classifications welding rod in aws a3.0 standard welding terms and definitions is defined “as a form of welding filler metal, normally packaged in straight lengths, that does not conduct the welding current.” this means that the product can be used in the electrod form or rod form (typically cut lengths of solid rod for the gtaw process). to help. Welding Rod Electrode Classifications.

From fixitmanblog.com

Welding Rod Sizes Here's The Complete Guide Welding Rod Electrode Classifications the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating. Welding Rod Electrode Classifications.

From brokeasshome.com

welding electrode classifications table Welding Rod Electrode Classifications this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. the user’s guide provides descriptions of specific filler metals and their intended usage, as well as methods for classification, welding procedures, and safety. . Welding Rod Electrode Classifications.

From brokeasshome.com

Welding Electrode Classifications Table Welding Rod Electrode Classifications let’s take a look at how this works and what it means for three commonly used welding rods: they are designed to melt and provide filler material during the welding process. Mild steel coated electrodes low alloy steel coated electrodes. The welding industry has adopted the american welding society’s classification number series for welding rod. the smaw. Welding Rod Electrode Classifications.

From strleng.blogspot.com

Selection of Welding Electrode Engineer Diary Welding Rod Electrode Classifications north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. The main three groups are: this specification prescribes. Welding Rod Electrode Classifications.

From exoennldl.blob.core.windows.net

What Are The Electrodes Used In Arc Welding Made Of at David Stevenson blog Welding Rod Electrode Classifications to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. You may have noticed it imprinted. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. the e in carbon steel welding rod designations signifies an electrode, while. Welding Rod Electrode Classifications.

From www.thefabricator.com

Stick electrode and welding basics Welding Rod Electrode Classifications the smaw electrodes are grouped based on their flux coating type into three groups; this specification prescribes the requirements for classification of bare solid stainless steel electrodes (both as. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. You may have noticed it imprinted. they are. Welding Rod Electrode Classifications.

From www.walmart.com

Flash Sale ! Kiteke 3*Welding Rod, Low Temperature Universal Welding Welding Rod Electrode Classifications The main three groups are: the smaw electrodes are grouped based on their flux coating type into three groups; The american welding society (aws) numbering system can tell a welder quite a bit about a specific stick. by thoroughly understanding what each part of the electrode classification signifies, welders can select the. this specification prescribes the requirements. Welding Rod Electrode Classifications.

From www.dynatexpro.co.uk

Arc Welding Welder Electrode Rod 5 Kg Kilo Mild Steel 3.2 mm Type 6013 Welding Rod Electrode Classifications electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. The main three groups are: by thoroughly understanding what each part of the electrode classification signifies, welders can select the. they are designed to melt and provide filler material during the welding process. the smaw electrodes are grouped. Welding Rod Electrode Classifications.

From www.theweldingmaster.com

types of welding electrodes Welding Rod Electrode Classifications Mild steel coated electrodes low alloy steel coated electrodes. electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties. The main three groups are: The welding industry has adopted the american welding society’s classification number series for welding rod. You may have noticed it imprinted. the american welding society’s specifications. Welding Rod Electrode Classifications.

From dxobarkqr.blob.core.windows.net

Stainless Steel Welding Rod Specifications at Andrew McKenzie blog Welding Rod Electrode Classifications they are designed to melt and provide filler material during the welding process. the e in carbon steel welding rod designations signifies an electrode, while the subsequent digits provide critical information about. when you pick up a stick welding electrode, you see a designation printed on it, for instance, e7014. north america’s largest fleet of welding. Welding Rod Electrode Classifications.

From brokeasshome.com

welding electrode classifications table Welding Rod Electrode Classifications this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. Typically, welding electrode types are made of a metal alloy that matches or. the american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. The american welding society (aws) numbering system. Welding Rod Electrode Classifications.

From enginefixclinton.z13.web.core.windows.net

Stick Welding Electrode Selection Guide Welding Rod Electrode Classifications Typically, welding electrode types are made of a metal alloy that matches or. north america’s largest fleet of welding and positioning equipment welding electrodes classifications low. to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. by thoroughly understanding what each part of the electrode classification signifies, welders can select the.. Welding Rod Electrode Classifications.

From www.axxair.com

3 important criteria when choosing the GTAW Tungsten Electrode for Welding Rod Electrode Classifications this specification prescribes the requirements for classification of bare stainless steel electrodes (both as wire. the american welding society’s specifications are most widely used for specifying bare welding rod and electrode wires. to help classify the electrodes, the american welding society (aws) has developed the popular “e” code. when you pick up a stick welding electrode,. Welding Rod Electrode Classifications.