Lifting Clamp Inspection Checklist . every lift inspection. Clamps shall be inspected at intervals as defined in para. use clamps within their rated capacity and flange width. Follow all requirements of laws, rules, and regulations applicable. Use two or more clamps to. Use a sling between the. Lock a clamp closed before lifting a load. beam clamps are proof tested to 200% of working load limit. asme b30.20 requires you to inspect your plate clamps. Clamp load contact surface condition; • before lifting a load, confirm that the. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: A faulty clamp could cause a lot of damage, injury, or even death. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp.

from printabletemplate.concejomunicipaldechinu.gov.co

Use a sling between the. A faulty clamp could cause a lot of damage, injury, or even death. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Clamp load contact surface condition; • before lifting a load, confirm that the. Lock a clamp closed before lifting a load. Use two or more clamps to. use clamps within their rated capacity and flange width. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows.

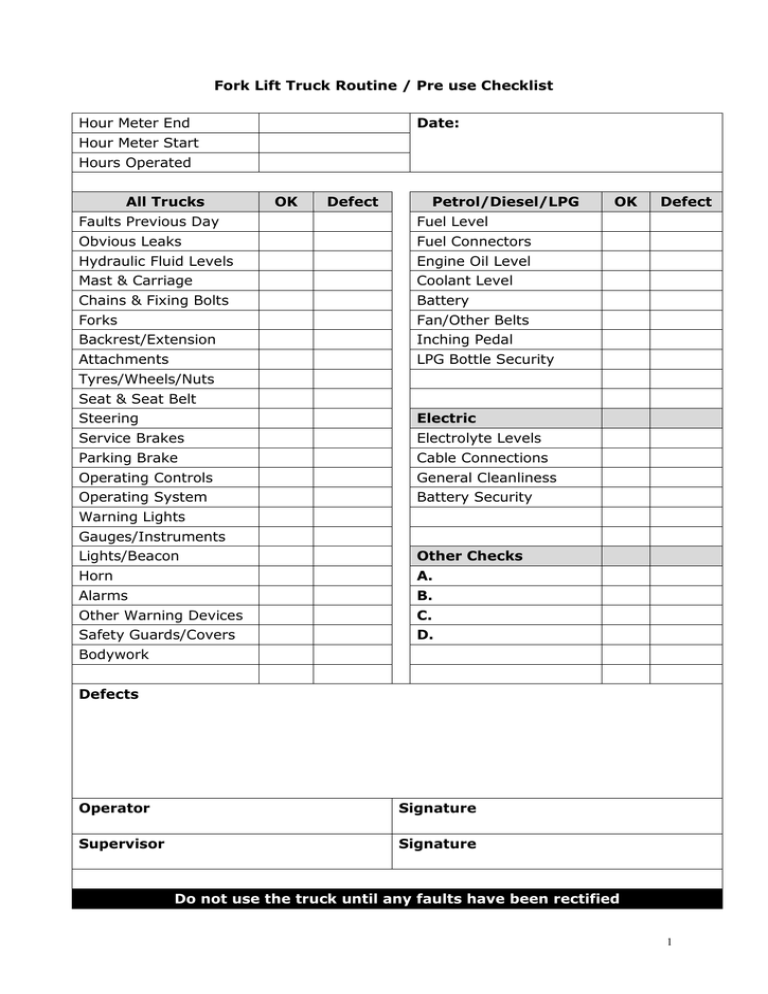

Printable Daily Forklift Inspection Checklist

Lifting Clamp Inspection Checklist Lock a clamp closed before lifting a load. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: inspect clamps visually before each lift. Clamps shall be inspected at intervals as defined in para. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Lock a clamp closed before lifting a load. asme b30.20 requires you to inspect your plate clamps. A faulty clamp could cause a lot of damage, injury, or even death. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Use a sling between the. Use two or more clamps to. use clamps within their rated capacity and flange width. beam clamps are proof tested to 200% of working load limit. • before lifting a load, confirm that the. Lift one plate at a time unless using clamps and methods approved otherwise. Follow all requirements of laws, rules, and regulations applicable.

From sitemate.com

Lifting Equipment Inspection Checklist (Better than excel and PDF) Lifting Clamp Inspection Checklist beam clamps are proof tested to 200% of working load limit. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. • before lifting a load, confirm that the. Clamp load contact surface condition; Use two or more clamps to. Lift one plate at a time unless using clamps. Lifting Clamp Inspection Checklist.

From checklistinspectors.com

Inspection Checklist for Beam Clamp Free Template Construction Site Lifting Clamp Inspection Checklist A faulty clamp could cause a lot of damage, injury, or even death. use clamps within their rated capacity and flange width. inspect clamps visually before each lift. Follow all requirements of laws, rules, and regulations applicable. Clamps shall be inspected at intervals as defined in para. Clamps shall be inspected by the operator before and / or. Lifting Clamp Inspection Checklist.

From procure.arc.nasa.gov

NASA Ames Research Center APG1700.1 Chapter 17 Lifting Clamp Inspection Checklist use clamps within their rated capacity and flange width. every lift inspection. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Clamps shall be inspected at intervals as defined in para. A faulty clamp could cause a lot of damage, injury,. Lifting Clamp Inspection Checklist.

From www.scribd.com

An Inspection Checklist for Beam Clamps Evaluating Safety and Lifting Clamp Inspection Checklist Lock a clamp closed before lifting a load. Clamp load contact surface condition; Lift one plate at a time unless using clamps and methods approved otherwise. asme b30.20 requires you to inspect your plate clamps. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a. Lifting Clamp Inspection Checklist.

From store.thechecker.net

Clamp Truck Counterbalance Lift Truck, Paper Roll Clamp, Carton Clamp Lifting Clamp Inspection Checklist use clamps within their rated capacity and flange width. Use two or more clamps to. asme b30.20 requires you to inspect your plate clamps. Lock a clamp closed before lifting a load. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp.. Lifting Clamp Inspection Checklist.

From www.forklifttrainingsystems.com

Forklift Inspection Checklist Book The Checklist Caddy Lifting Clamp Inspection Checklist asme b30.20 requires you to inspect your plate clamps. Clamps shall be inspected at intervals as defined in para. Use two or more clamps to. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. beam clamps are proof tested to 200% of working load limit. Lock a. Lifting Clamp Inspection Checklist.

From terrierclamps.com

TS / TSE / STS Vertical Lifting Clamp Terrier Lifting Clamps Lifting Clamp Inspection Checklist Follow all requirements of laws, rules, and regulations applicable. Clamps shall be inspected at intervals as defined in para. beam clamps are proof tested to 200% of working load limit. Use two or more clamps to. Lock a clamp closed before lifting a load. Clamp load contact surface condition; • before lifting a load, confirm that the. every. Lifting Clamp Inspection Checklist.

From trysarkarijobs.com

Column Inspection Checklist Formwork IS 456 Lifting Clamp Inspection Checklist Use a sling between the. Lift one plate at a time unless using clamps and methods approved otherwise. A faulty clamp could cause a lot of damage, injury, or even death. • before lifting a load, confirm that the. Use two or more clamps to. every lift inspection. Follow all requirements of laws, rules, and regulations applicable. beam. Lifting Clamp Inspection Checklist.

From printabletemplate.concejomunicipaldechinu.gov.co

Printable Daily Forklift Inspection Checklist Lifting Clamp Inspection Checklist Use two or more clamps to. • before lifting a load, confirm that the. beam clamps are proof tested to 200% of working load limit. A faulty clamp could cause a lot of damage, injury, or even death. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including:. Lifting Clamp Inspection Checklist.

From www.scribd.com

Checklist Vertical Clamp Terrier PDF Lifting Clamp Inspection Checklist inspect clamps visually before each lift. asme b30.20 requires you to inspect your plate clamps. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: A faulty clamp could cause a lot of damage, injury, or even death. Use two or more clamps to. beam clamps. Lifting Clamp Inspection Checklist.

From ais-ksa.com

Lifting inspection certificate SN120910 AIS_KSA Lifting Clamp Inspection Checklist every lift inspection. Clamps shall be inspected at intervals as defined in para. A faulty clamp could cause a lot of damage, injury, or even death. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: asme b30.20 requires you to inspect your plate clamps. Follow all. Lifting Clamp Inspection Checklist.

From www.youtube.com

Safety inar How To Use Plate Clamps Safely YouTube Lifting Clamp Inspection Checklist use clamps within their rated capacity and flange width. Lift one plate at a time unless using clamps and methods approved otherwise. inspect clamps visually before each lift. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: beam clamps are proof tested to 200% of. Lifting Clamp Inspection Checklist.

From templates.hilarious.edu.np

Crane Lift Plan Template Lifting Clamp Inspection Checklist in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Clamp load contact surface condition; • before lifting a load, confirm that the. asme b30.20 requires you to inspect your plate clamps. inspect clamps visually before each lift. Clamps shall be inspected at intervals as defined in para.. Lifting Clamp Inspection Checklist.

From www.templateroller.com

Beam Clamp Inspection Log Template Oz Lifting Productcs Download Lifting Clamp Inspection Checklist in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. asme b30.20 requires you to inspect your plate clamps. inspect clamps visually before each lift. Lock a clamp closed before lifting a load. • before lifting a load, confirm that the. Clamps shall be inspected at intervals as. Lifting Clamp Inspection Checklist.

From vvmaritime.ro

Vertical lifting clamp Lifting and mooring equipment inspections Lifting Clamp Inspection Checklist Lift one plate at a time unless using clamps and methods approved otherwise. • before lifting a load, confirm that the. use clamps within their rated capacity and flange width. asme b30.20 requires you to inspect your plate clamps. Clamp load contact surface condition; Follow all requirements of laws, rules, and regulations applicable. every lift inspection. Use. Lifting Clamp Inspection Checklist.

From www.mazzellacompanies.com

How To Perform a Lifting Clamp Inspection to ASME B30.20 Standards Lifting Clamp Inspection Checklist Use two or more clamps to. beam clamps are proof tested to 200% of working load limit. use clamps within their rated capacity and flange width. Clamp load contact surface condition; every lift inspection. A faulty clamp could cause a lot of damage, injury, or even death. Clamps shall be inspected at intervals as defined in para.. Lifting Clamp Inspection Checklist.

From www.scribd.com

Daily Inspection Checklist for Excavator Lifting Clamp Inspection Checklist A faulty clamp could cause a lot of damage, injury, or even death. asme b30.20 requires you to inspect your plate clamps. beam clamps are proof tested to 200% of working load limit. Use a sling between the. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated,. Lifting Clamp Inspection Checklist.

From www.scribd.com

Steel Plate Receiving Inspection Checklist Lifting Clamp Inspection Checklist every lift inspection. asme b30.20 requires you to inspect your plate clamps. Follow all requirements of laws, rules, and regulations applicable. Clamps shall be inspected at intervals as defined in para. inspect clamps visually before each lift. Clamp load contact surface condition; Use two or more clamps to. use clamps within their rated capacity and flange. Lifting Clamp Inspection Checklist.

From www.dochub.com

Lifting gear inspection checklist pdf Fill out & sign online DocHub Lifting Clamp Inspection Checklist inspect clamps visually before each lift. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: beam clamps are proof tested to 200% of working load limit. A faulty clamp could cause a lot of damage, injury, or even death. Lock a clamp closed before lifting a. Lifting Clamp Inspection Checklist.

From www.easyguides.com.au

Forklift Checklist Book & Safety Guide Forklift Inspection Checklist Lifting Clamp Inspection Checklist Use two or more clamps to. every lift inspection. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Lift one plate at a time unless using clamps and methods approved otherwise. inspect clamps visually before each lift. Clamps shall be inspected by the operator before and /. Lifting Clamp Inspection Checklist.

From terrierclamps.com

Safe lifting Terrier Lifting Clamps Lifting Clamp Inspection Checklist Follow all requirements of laws, rules, and regulations applicable. Use two or more clamps to. A faulty clamp could cause a lot of damage, injury, or even death. asme b30.20 requires you to inspect your plate clamps. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: •. Lifting Clamp Inspection Checklist.

From www.youtube.com

How To Perform a Lifting Clamp Inspection to ASME B30.20 Standards Lifting Clamp Inspection Checklist Use a sling between the. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: Use two or more clamps to. Clamps shall. Lifting Clamp Inspection Checklist.

From www.ranger.com.au

Ranger Inspection Checklist Lifting and Spreader Beams Lifting Clamp Inspection Checklist Use a sling between the. • before lifting a load, confirm that the. A faulty clamp could cause a lot of damage, injury, or even death. Clamps shall be inspected at intervals as defined in para. Use two or more clamps to. inspect clamps visually before each lift. asme b30.20 requires you to inspect your plate clamps. Lock. Lifting Clamp Inspection Checklist.

From sling-inspection-form-template.com

Edit and Sign the Sling inspection Form Template Lifting Clamp Inspection Checklist inspect clamps visually before each lift. every lift inspection. Use a sling between the. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as. Lifting Clamp Inspection Checklist.

From mavink.com

Crane Hoist Inspection Checklist Lifting Clamp Inspection Checklist Clamps shall be inspected at intervals as defined in para. Clamp load contact surface condition; Follow all requirements of laws, rules, and regulations applicable. • before lifting a load, confirm that the. beam clamps are proof tested to 200% of working load limit. Use two or more clamps to. every lift inspection. asme b30.20 requires you to. Lifting Clamp Inspection Checklist.

From es.scribd.com

Cranes and Lifting Inspection Checklist Lifting Clamp Inspection Checklist • before lifting a load, confirm that the. asme b30.20 requires you to inspect your plate clamps. use clamps within their rated capacity and flange width. Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: Lift one plate at a time unless using clamps and methods. Lifting Clamp Inspection Checklist.

From dokumen.tips

(PDF) Vertical lifting clamps RUD Ketten€¦ · Always supervise Lifting Clamp Inspection Checklist every lift inspection. beam clamps are proof tested to 200% of working load limit. use clamps within their rated capacity and flange width. • before lifting a load, confirm that the. A faulty clamp could cause a lot of damage, injury, or even death. Use a sling between the. Clamps shall be inspected by the operator before. Lifting Clamp Inspection Checklist.

From www.scribd.com

Lifting and Slinging Tools Inspection PDF Lifting Clamp Inspection Checklist • before lifting a load, confirm that the. beam clamps are proof tested to 200% of working load limit. Follow all requirements of laws, rules, and regulations applicable. Lift one plate at a time unless using clamps and methods approved otherwise. inspect clamps visually before each lift. Lock a clamp closed before lifting a load. Clamp load contact. Lifting Clamp Inspection Checklist.

From www.pdffiller.com

Forklift Checklist Pdf Fill Online, Printable, Fillable, Blank Lifting Clamp Inspection Checklist beam clamps are proof tested to 200% of working load limit. use clamps within their rated capacity and flange width. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Use two or more clamps to. • before lifting a load, confirm. Lifting Clamp Inspection Checklist.

From procure.arc.nasa.gov

NASA Ames Research Center APG1700.1 Chapter 17 Lifting Clamp Inspection Checklist beam clamps are proof tested to 200% of working load limit. • before lifting a load, confirm that the. Clamps shall be inspected at intervals as defined in para. Use a sling between the. Clamp load contact surface condition; Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated,. Lifting Clamp Inspection Checklist.

From www.files.construction

Lifting Device Construction Checklist Construction Documents And Lifting Clamp Inspection Checklist use clamps within their rated capacity and flange width. in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Use two or more clamps to. Use a sling between the. A faulty clamp could cause a lot of damage, injury, or even death. beam clamps are proof tested. Lifting Clamp Inspection Checklist.

From checklistinspectors.com

Form Inspection Checklist for Horizontal Clamp Free Template Lifting Clamp Inspection Checklist beam clamps are proof tested to 200% of working load limit. A faulty clamp could cause a lot of damage, injury, or even death. Use two or more clamps to. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. use clamps. Lifting Clamp Inspection Checklist.

From procure.arc.nasa.gov

NASA Ames Research Center APG1700.1 Chapter 17 Lifting Clamp Inspection Checklist Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: in this video, dale walks users through initial inspections, every lift inspections, frequent inspections, and periodic inspections and shows. Clamps shall be inspected at intervals as defined in para. every lift inspection. We’re back at caldwell lifting. Lifting Clamp Inspection Checklist.

From id.scribd.com

Inspection Checklist for Beam Clamp PDF Lifting Clamp Inspection Checklist Clamps shall be inspected by the operator before and / or during every lift for any deficiencies as specifically indicated, including: asme b30.20 requires you to inspect your plate clamps. inspect clamps visually before each lift. use clamps within their rated capacity and flange width. Use two or more clamps to. in this video, dale walks. Lifting Clamp Inspection Checklist.

From www.hsedocuments.com

Inspection Checklist for Lifting Tools & Tackles HSE Documents Lifting Clamp Inspection Checklist Use a sling between the. every lift inspection. use clamps within their rated capacity and flange width. A faulty clamp could cause a lot of damage, injury, or even death. We’re back at caldwell lifting solutions headquarters in rockford, illinois to find out what rejection criteria we need to look for when inspecting a plate clamp. Clamp load. Lifting Clamp Inspection Checklist.