Stainless Steel Sheet Minimum Bend Radius . Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. These are general guidelines, and it’s. The grain can be seen by. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. We go beyond the general rules of sheet metal. Minimum hole distance and minimum flange distance. We’ve broken down our minimum bend radii into two values: In steel between 0.5 and 0.8 in. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back.

from www.approvedsheetmetal.com

For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. We go beyond the general rules of sheet metal. We’ve broken down our minimum bend radii into two values: A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Minimum hole distance and minimum flange distance. These are general guidelines, and it’s.

Sheet Metal Bend Radius Best Practices Approved Sheet Metal

Stainless Steel Sheet Minimum Bend Radius The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. In steel between 0.5 and 0.8 in. The grain can be seen by. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Minimum hole distance and minimum flange distance. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. These are general guidelines, and it’s. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. We’ve broken down our minimum bend radii into two values: We go beyond the general rules of sheet metal.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: Minimum hole distance and minimum flange distance. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. The grain can be seen by. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. These. Stainless Steel Sheet Minimum Bend Radius.

From www.chegg.com

Consider the chart “Minimum Bend Radius for Maximum Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Thick, grade 350 and 400 may have a. Stainless Steel Sheet Minimum Bend Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices Approved Sheet Metal Stainless Steel Sheet Minimum Bend Radius In steel between 0.5 and 0.8 in. We go beyond the general rules of sheet metal. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. These are general guidelines, and it’s. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. The tables. Stainless Steel Sheet Minimum Bend Radius.

From www.machinemfg.com

How to determine the bending radius of sheet metal? MachineMfg Stainless Steel Sheet Minimum Bend Radius In steel between 0.5 and 0.8 in. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. These are general guidelines, and it’s. The grain can be seen by. We go beyond the general rules of sheet metal.. Stainless Steel Sheet Minimum Bend Radius.

From www.youtube.com

Common sheet metal design Basic rules or guidelines Minimum Bend Stainless Steel Sheet Minimum Bend Radius We go beyond the general rules of sheet metal. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. The grain can be seen by. The tables below show bend radii. Stainless Steel Sheet Minimum Bend Radius.

From mavink.com

Steel Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary.. Stainless Steel Sheet Minimum Bend Radius.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Stainless Steel Sheet Minimum Bend Radius Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. We go beyond the general rules of sheet metal. We’ve broken down our minimum bend radii into two values: Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring. Stainless Steel Sheet Minimum Bend Radius.

From classcampustommie.z21.web.core.windows.net

Sheet Metal Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius These are general guidelines, and it’s. Minimum hole distance and minimum flange distance. We’ve broken down our minimum bend radii into two values: For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. In steel between 0.5 and 0.8 in. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or. Stainless Steel Sheet Minimum Bend Radius.

From www.vrogue.co

Steel Bend Radius Chart vrogue.co Stainless Steel Sheet Minimum Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.. Stainless Steel Sheet Minimum Bend Radius.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Stainless Steel Sheet Minimum Bend Radius A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is. Stainless Steel Sheet Minimum Bend Radius.

From mavink.com

Steel Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius Minimum hole distance and minimum flange distance. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. The grain can be seen by. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend. Stainless Steel Sheet Minimum Bend Radius.

From civildigital.com

Everything about Bar Bending Schedule BBS Terms & Rules CivilDigital Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. In steel between 0.5 and 0.8 in. We’ve broken down our minimum bend radii into two values: Minimum hole distance and minimum flange distance. The grain. Stainless Steel Sheet Minimum Bend Radius.

From www.thefabricator.com

Minimum inside sheet metal bend radius vs what's Stainless Steel Sheet Minimum Bend Radius Minimum hole distance and minimum flange distance. We’ve broken down our minimum bend radii into two values: Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. We go beyond. Stainless Steel Sheet Minimum Bend Radius.

From mungfali.com

Stainless Steel Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. In steel between 0.5 and 0.8 in. Minimum hole distance and minimum flange distance. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. These are. Stainless Steel Sheet Minimum Bend Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. In steel between 0.5 and 0.8. Stainless Steel Sheet Minimum Bend Radius.

From www.rapiddirect.com

Bending Stainless Steel Tubing Effective Processes and Considerations Stainless Steel Sheet Minimum Bend Radius Minimum hole distance and minimum flange distance. We go beyond the general rules of sheet metal. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. In steel between 0.5 and 0.8 in. The tables below show bend radii and minimum bend sizes for materials. Stainless Steel Sheet Minimum Bend Radius.

From mungfali.com

Stainless Steel Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. In steel between 0.5 and 0.8 in. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 ×. Stainless Steel Sheet Minimum Bend Radius.

From www.mech4study.com

Different Sheet Metal Bending Process Mech4study Stainless Steel Sheet Minimum Bend Radius We go beyond the general rules of sheet metal. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend. Stainless Steel Sheet Minimum Bend Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. We go beyond the general rules of sheet metal. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or. Stainless Steel Sheet Minimum Bend Radius.

From www.plateroller.com

Calculate the minimum bend radius of sheet metal/steel plate Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked. Stainless Steel Sheet Minimum Bend Radius.

From www.vrogue.co

Bend Radius Chart For Steel vrogue.co Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. In steel between 0.5 and 0.8 in. These are general guidelines, and it’s. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the. Stainless Steel Sheet Minimum Bend Radius.

From mavink.com

Sheet Metal Bend Chart Stainless Steel Sheet Minimum Bend Radius A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always. Stainless Steel Sheet Minimum Bend Radius.

From cadinfield.com

Sheet Metal Fabrication Fundamental Cad Infield Stainless Steel Sheet Minimum Bend Radius These are general guidelines, and it’s. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078. Stainless Steel Sheet Minimum Bend Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. We’ve broken down our minimum bend radii into two values: In steel between 0.5 and 0.8 in. Bend allowance (ba) ba = [ (0.017453 × inside. Stainless Steel Sheet Minimum Bend Radius.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Minimum hole distance and minimum flange distance. In steel between 0.5 and 0.8 in. The grain can be. Stainless Steel Sheet Minimum Bend Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Stainless Steel Sheet Minimum Bend Radius Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. We go beyond the general rules of sheet metal. In steel between 0.5 and 0.8 in. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. We’ve broken. Stainless Steel Sheet Minimum Bend Radius.

From www.thefabricator.com

How to predict an air formed inside bend radius with precision Stainless Steel Sheet Minimum Bend Radius A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while. Stainless Steel Sheet Minimum Bend Radius.

From www.thefabricator.com

Analyzing the kfactor in sheet metal bending Stainless Steel Sheet Minimum Bend Radius Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. These are general guidelines, and it’s. For thicknesses up to 3 mm, a minimum bend radius of 1.5t is proposed. In steel between 0.5 and 0.8 in. We go beyond the general rules of sheet metal. We’ve broken down our. Stainless Steel Sheet Minimum Bend Radius.

From metalmaq.shop

Metal sheet bending table Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: In steel between 0.5 and 0.8 in. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. These are general guidelines, and it’s. Thick, grade 350 and 400 may have a minimum bend radius of. Stainless Steel Sheet Minimum Bend Radius.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Stainless Steel Sheet Minimum Bend Radius We’ve broken down our minimum bend radii into two values: The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. These are general guidelines, and it’s. In steel between 0.5 and 0.8 in. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse. Stainless Steel Sheet Minimum Bend Radius.

From www.approvedsheetmetal.com

Sheet Metal Bend Radius Best Practices (Updated for 2024) ASM Stainless Steel Sheet Minimum Bend Radius Minimum hole distance and minimum flange distance. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. We go beyond the general rules of sheet metal. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal.. Stainless Steel Sheet Minimum Bend Radius.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Stainless Steel Sheet Minimum Bend Radius Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 × material thickness)] × bend angle, which is always complementary. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. We go beyond the general rules of sheet metal. The grain can be seen by. A typical recommendation is 1t. Stainless Steel Sheet Minimum Bend Radius.

From forum.woodenboat.com

Cutting and shaping .1875" thick 316 stainless steel Stainless Steel Sheet Minimum Bend Radius A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. The grain can be seen by. In steel between 0.5 and 0.8 in. For thicknesses up to. Stainless Steel Sheet Minimum Bend Radius.

From www.latten.net

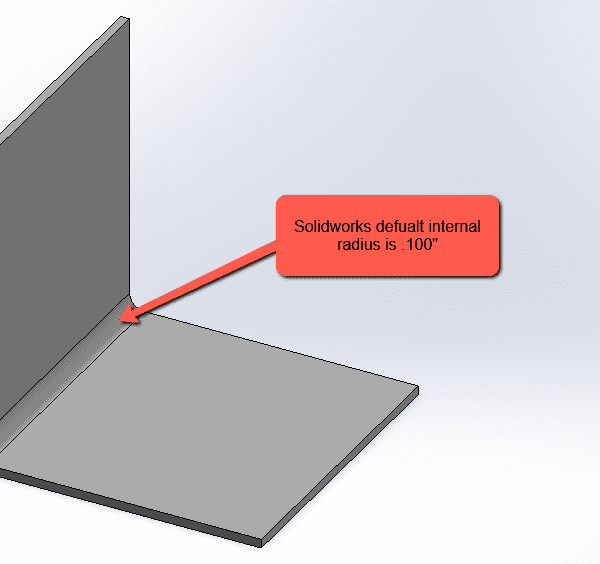

Bend radius / SolidWorks / more brackets Sling2 Stainless Steel Sheet Minimum Bend Radius The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. Minimum hole distance and minimum flange distance. Bend allowance (ba) ba = [ (0.017453 × inside radius) + (0.0078 ×. Stainless Steel Sheet Minimum Bend Radius.

From www.researchgate.net

The sheet metal stretchbending with bending radius R die (a) the Stainless Steel Sheet Minimum Bend Radius The grain can be seen by. We go beyond the general rules of sheet metal. Minimum hole distance and minimum flange distance. Thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius. Stainless Steel Sheet Minimum Bend Radius.