Flaw Detector Ultrasonic Testing . Imagine a method that can see through solid objects! Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more.

from testindo.co.id

Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more.

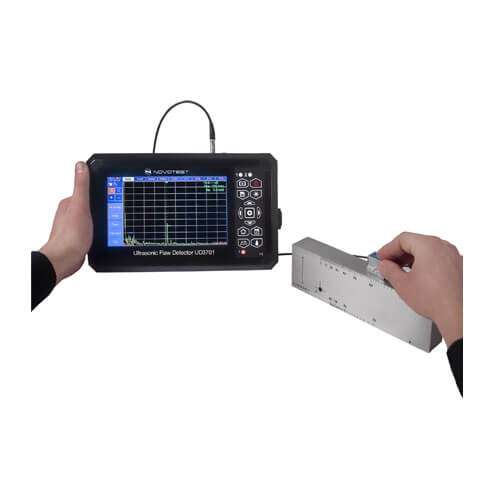

Ultrasonic Flaw Detector NOVOTEST UD3701 TESTINDO.CO.ID

Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more.

From insize.co.id

INSIZE Ultrasonic Flaw Detector UFDT190 (IP65) Frequency; 0.520MHz Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Imagine a method that can see through solid objects! Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic inspection is often used to discover. Flaw Detector Ultrasonic Testing.

From www.advanced-ndt.co.uk

Ultrasonic Flaw Detectors Advanced NDT Ltd Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Imagine a method that can see through solid objects! Ultrasonic inspection is often used to discover and evaluate flaws, measure. Flaw Detector Ultrasonic Testing.

From ut-equipment.blogspot.com

ultrasonic testing equipment Ultrasonic flaw detector Beijing TIME Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate. Flaw Detector Ultrasonic Testing.

From modsonic.com

Ultrasonic Flaw Detection A Complete Guide Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect. Flaw Detector Ultrasonic Testing.

From bdndt.com

Novotest UD2301 Ultrasonic Flaw Detector Price in BD Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries. Flaw Detector Ultrasonic Testing.

From www.dreamstime.com

Ultrasonic Flaw Detector Krautkramer USM 36 at the Plant during Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products. Flaw Detector Ultrasonic Testing.

From www.wewontech.com

Ultrasonic Flaw Detector|Ultrasonic Flaw Testing Equipment Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it. Flaw Detector Ultrasonic Testing.

From www.efficientplantmag.com

Olympus Introduces the Epoch 650 Ultrasonic Flaw Detector Efficient Plant Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Imagine a method that can see through solid objects! Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic testing or monitoring is used during the manufacturing of. Flaw Detector Ultrasonic Testing.

From alat.co.id

Phased Array Ultrasonic Flaw Detector SERI CTS602 Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to. Flaw Detector Ultrasonic Testing.

From www.directindustry.com

Ultrasonic flaw detector UFD 4444D Roop Ultrasonix Ltd portable Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a. Flaw Detector Ultrasonic Testing.

From www.cccme.org.cn

Ultrasonic Flaw Detector (TUD310) Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well. Flaw Detector Ultrasonic Testing.

From ultrainstrument.com

Principle and Characteristics of Ultrasonic Flaw Detection Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however. Flaw Detector Ultrasonic Testing.

From www.shimadzu.com

SHIMADZU CORPORATION Detecting Flaws within Objects Quickly and Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds,. Flaw Detector Ultrasonic Testing.

From www.ndttester.com

Universal Ultrasonic Flaw Detection Equipment , non destructive testing Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds,. Flaw Detector Ultrasonic Testing.

From www.aliexpress.com

Flaw Detection Ultrasonic Testing Equipment Ultrasonic Flaw Detector Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various. Flaw Detector Ultrasonic Testing.

From testrongroup.com

TTD1150 Digital Ultrasonic Flaw Detector Testron Group Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful ndt. Flaw Detector Ultrasonic Testing.

From modsonic.com

History & Evolution of Ultrasonic Flaw Detection Equipment Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic inspection is often used to discover and evaluate flaws, measure. Flaw Detector Ultrasonic Testing.

From testindo.co.id

Ultrasonic Flaw Detector NOVOTEST UD3701 TESTINDO.CO.ID Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries. Flaw Detector Ultrasonic Testing.

From www.katex.co.uk

Ultrasonic Flaw Detector Novotest UD2301 Katex Ltd Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Imagine a method that can see through solid objects! Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Our full range of portable ultrasonic flaw detectors (ut). Flaw Detector Ultrasonic Testing.

From www.metengr.com

Ultrasonic Flaw Inspection — Metallurgical Engineering Services Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched. Flaw Detector Ultrasonic Testing.

From www.tonanasia.com

เครื่องวัดรอยร้าว Ultrasonic Flaw Detector Tonan Asia Autotech Co., Ltd. Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic flaw detection is. Flaw Detector Ultrasonic Testing.

From www.dreamstime.com

Ultrasonic Flaw Detector Krautkramer USM 36 at the Plant during Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem. Flaw Detector Ultrasonic Testing.

From nazahatafuq.com

ultrasonic flaw detection Nazahatafuq Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate. Flaw Detector Ultrasonic Testing.

From www.shutterstock.com

Ultrasonic Flaw Detector Ultrasonic Testing Acoustic Stock Photo (Edit Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology. Flaw Detector Ultrasonic Testing.

From insize.co.id

INSIZE UFDT680 Ultrasonic Flaw Detector (AVG, DAC and TVG display Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic testing or monitoring is used. Flaw Detector Ultrasonic Testing.

From www.tec-science.com

Ultrasonic testing (UT) tecscience Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Imagine a method that. Flaw Detector Ultrasonic Testing.

From ndt-kits.com

UE0040 Ultrasonic Flaw Detector NDTKITS Flaw Detector Ultrasonic Testing Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Imagine a method that can see through solid objects! Ultrasonic testing or monitoring is used during the manufacturing of. Flaw Detector Ultrasonic Testing.

From bdndt.com

NOVOTEST UD3701 Ultrasonic Flaw Detector Price in BD Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Our full range of portable ultrasonic flaw detectors (ut). Flaw Detector Ultrasonic Testing.

From www.yushindt.com

YUSHI YUT2600 ULTRASONIC METAL FLAW DETECTOR Flaw Detector Ultrasonic Testing Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Imagine a method. Flaw Detector Ultrasonic Testing.

From modsonic.com

Operating Principle of Ultrasonic Flaw Detector How They Work? Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities. Flaw Detector Ultrasonic Testing.

From www.huatecgroup.com

Digital Ultrasonic Flaw Detector FD201, UT, ultrasonic testing Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic flaw detection is a powerful nondestructive testing technology and a well established test method in many industries used to measure various materials. Ultrasonic flaw detection is a powerful ndt technology and a well. Flaw Detector Ultrasonic Testing.

From ndt-kits.com

How does Ultrasonic Flaw Detector Works? NDTKITS Flaw Detector Ultrasonic Testing Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Our full range of portable ultrasonic flaw detectors (ut) provides unmatched capabilities for locating discontinuities and other flaws. Imagine a method that can see through solid objects! Ultrasonic testing or monitoring is used during the manufacturing of composites,. Flaw Detector Ultrasonic Testing.

From www.tonanasia.com

NOVOTEST Ultrasonic Flaw Detector UD2301 Mini Tonan Asia Autotech Co Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is. Flaw Detector Ultrasonic Testing.

From www.youtube.com

Portable ultrasonic flaw detector I Proceq Flaw Detector Live YouTube Flaw Detector Ultrasonic Testing Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can seem complex. Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Our full range. Flaw Detector Ultrasonic Testing.

From www.okondt.com

Sonocon BL Portable Ultrasonic Flaw Detector Flaw Detector Ultrasonic Testing Ultrasonic testing or monitoring is used during the manufacturing of composites, welds, metal alloy plate or rolling mill stock products to detect voids, inclusions, and flaws. Ultrasonic inspection is often used to discover and evaluate flaws, measure dimensions, characterize materials, and more. Imagine a method that can see through solid objects! Ultrasonic flaw detection is a powerful ndt technology and. Flaw Detector Ultrasonic Testing.