How To Design Welds . In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Specify the smallest weld acceptable for both service and fabrication; Welding design is the process of planning and creating the layout, dimensions, and. How to weld the connections. Fillet welds are always designed on the basis of shear stress on the throat (a). Design the component to be welded by the most cost effective process;

from welditu.com

Specify the smallest weld acceptable for both service and fabrication; • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. How to weld the connections. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Fillet welds are always designed on the basis of shear stress on the throat (a). A weld joint of the type that will require the minimum amount of weld metal shall be selected. Design the component to be welded by the most cost effective process; Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. Welding design is the process of planning and creating the layout, dimensions, and.

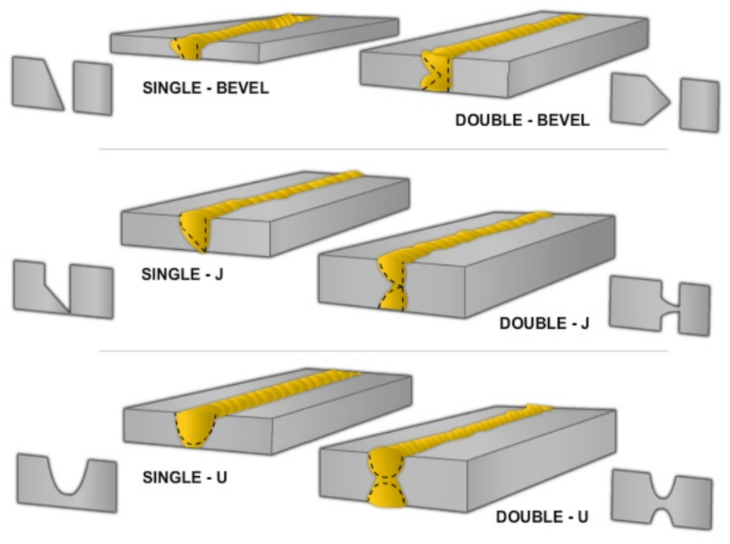

Guide to Welding Joint Types and Parts WelditU

How To Design Welds A weld joint of the type that will require the minimum amount of weld metal shall be selected. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Welding design is the process of planning and creating the layout, dimensions, and. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. How to weld the connections. Specify the smallest weld acceptable for both service and fabrication; Fillet welds are always designed on the basis of shear stress on the throat (a). • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Design the component to be welded by the most cost effective process;

From boilersinfo.com

A Guide to Designing Welds How To Design Welds Design the component to be welded by the most cost effective process; Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding design is the process of planning and creating the layout, dimensions, and. In. How To Design Welds.

From inchbyinch.de

INCH Technical English weld types How To Design Welds At the heart of welded connection design lies the understanding of stress distribution and material behaviour. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Welding design is the process of planning and creating the layout, dimensions,. How To Design Welds.

From engineersfield.com

Weld Joint and Weld Types Engineersfield How To Design Welds Welding design is the process of planning and creating the layout, dimensions, and. How to weld the connections. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. • structural welding is a process by which. How To Design Welds.

From hgg-group.com

Tubular welding terms, the basics HGG 3D Profiling Specialists How To Design Welds Specify the smallest weld acceptable for both service and fabrication; Fillet welds are always designed on the basis of shear stress on the throat (a). At the heart of welded connection design lies the understanding of stress distribution and material behaviour. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations,. How To Design Welds.

From weldguru.com

Parts of A Weld Weld Components with Diagram Weld Guru How To Design Welds In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Design the component to be welded by the most cost effective process; Welding design is the process of planning and creating the layout, dimensions, and. How to weld. How To Design Welds.

From engineeringdrawingbasics.com

Dimensioning of welds Engineering Drawing Basics How To Design Welds Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding design is the process of planning and creating the layout, dimensions, and. How to weld the connections. Design the component to be welded by the. How To Design Welds.

From weldinghelmetgenius.com

Welding Blueprints Guide How to Read, Interpret and Use Welding How To Design Welds Specify the smallest weld acceptable for both service and fabrication; Fillet welds are always designed on the basis of shear stress on the throat (a). At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding design is the process of planning and creating the layout, dimensions, and. • structural welding is a process. How To Design Welds.

From www.pinterest.de

21 Satisfyingly Beautiful Welds That Are Basically Works Of Art How To Design Welds Specify the smallest weld acceptable for both service and fabrication; Fillet welds are always designed on the basis of shear stress on the throat (a). Design the component to be welded by the most cost effective process; How to weld the connections. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld.. How To Design Welds.

From www.mem50212.com

Weld Design How To Design Welds Specify the smallest weld acceptable for both service and fabrication; A weld joint of the type that will require the minimum amount of weld metal shall be selected. How to weld the connections. Welding design is the process of planning and creating the layout, dimensions, and. Design the component to be welded by the most cost effective process; • structural. How To Design Welds.

From weldingboss.com

How to Read Welding Blueprints How To Design Welds In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. How to weld. How To Design Welds.

From www.weldingis.com

Types Of Welding Joints Design and Welding Symbols How To Design Welds Welding design is the process of planning and creating the layout, dimensions, and. Fillet welds are always designed on the basis of shear stress on the throat (a). How to weld the connections. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. A weld joint of the type that will require the minimum. How To Design Welds.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide How To Design Welds Specify the smallest weld acceptable for both service and fabrication; At the heart of welded connection design lies the understanding of stress distribution and material behaviour. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. Fillet welds are always designed on the basis of. How To Design Welds.

From engineersfield.com

Weld Type and Weld Joint Configuration Engineersfield How To Design Welds Fillet welds are always designed on the basis of shear stress on the throat (a). How to weld the connections. Design the component to be welded by the most cost effective process; • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. Specify the smallest. How To Design Welds.

From savree.com

Flange Welds and NDT Explained saVRee How To Design Welds In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. How to weld. How To Design Welds.

From www.instructables.com

Basic Welding 8 Steps Instructables How To Design Welds How to weld the connections. Specify the smallest weld acceptable for both service and fabrication; In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Design the component to be welded by the most cost effective process; Fillet. How To Design Welds.

From weldingpros.net

Types of Welding Joints Different Welds and Styles How To Design Welds A weld joint of the type that will require the minimum amount of weld metal shall be selected. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. How. How To Design Welds.

From welditu.com

Guide to Welding Joint Types and Parts WelditU How To Design Welds How to weld the connections. Specify the smallest weld acceptable for both service and fabrication; At the heart of welded connection design lies the understanding of stress distribution and material behaviour. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Welding design is the process of planning and creating the layout,. How To Design Welds.

From safeworkmethodofstatement.com

Understanding the Welding Symbols in Engineering Drawings Safe Work How To Design Welds Fillet welds are always designed on the basis of shear stress on the throat (a). Welding design is the process of planning and creating the layout, dimensions, and. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices.. How To Design Welds.

From www.roadkillcustoms.com

Chapter 6 Welding Techniques Roadkill Customs How To Design Welds A weld joint of the type that will require the minimum amount of weld metal shall be selected. Design the component to be welded by the most cost effective process; Specify the smallest weld acceptable for both service and fabrication; Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. Welding design. How To Design Welds.

From www.youtube.com

Features of Complete Weld Butt Weld Fillet Weld YouTube How To Design Welds Welding design is the process of planning and creating the layout, dimensions, and. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Design the component to be welded by the most cost effective process; How to weld. How To Design Welds.

From welditu.com

Main Types of Welds Used in Welding WelditU How To Design Welds • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. Design the component to be welded by the most cost effective process; In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en. How To Design Welds.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... How To Design Welds At the heart of welded connection design lies the understanding of stress distribution and material behaviour. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Specify the smallest weld acceptable for both service and fabrication; Welding design. How To Design Welds.

From www.cruxweld.com

Understanding the Welding Symbols [Explained with Diagrams] cruxweld How To Design Welds Fillet welds are always designed on the basis of shear stress on the throat (a). How to weld the connections. • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. Specify the smallest weld acceptable for both service and fabrication; In this article, we review. How To Design Welds.

From www.masterseries.com

How to design web to flange welds in plate girders? MasterSeries How To Design Welds At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as. How To Design Welds.

From www.cruxweld.com

Understanding the Welding Symbols [Explained with Diagrams] cruxweld How To Design Welds Design the component to be welded by the most cost effective process; • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. Fillet welds are always designed. How To Design Welds.

From weldingzilla.com

How to Read Welding Blueprints Like a Pro How To Design Welds Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. How to weld the connections. Welding design is the process of planning and creating the layout, dimensions, and. Fillet welds are always designed on the basis of shear stress on the throat (a). A weld joint of the type that will require. How To Design Welds.

From kinetictechllc.com

Everything You Need to Know About Welding Positioners A Comprehensive How To Design Welds A weld joint of the type that will require the minimum amount of weld metal shall be selected. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. How to weld the connections. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode. How To Design Welds.

From rileylaw.z19.web.core.windows.net

Dimensions Of A Weld How To Design Welds Design the component to be welded by the most cost effective process; • structural welding is a process by which the parts that are to be connected are heated and fused, with supplementary molten metal at the. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding symbols are basically a shorthand language. How To Design Welds.

From thenavalarch.com

Designing Fillet Welds for Symmetrical Joint Sections TheNavalArch How To Design Welds In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding design is the process of planning and creating the layout, dimensions,. How To Design Welds.

From weldingzilla.com

How to Read Welding Blueprints Like a Pro How To Design Welds Design the component to be welded by the most cost effective process; In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. At the heart of welded connection design lies the understanding of stress distribution and material behaviour.. How To Design Welds.

From www.howtoresistanceweld.info

Design HowTo Resistance Weld How To Design Welds Specify the smallest weld acceptable for both service and fabrication; In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Welding design is the process of planning and creating the layout, dimensions, and. A weld joint of the. How To Design Welds.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT How To Design Welds Welding design is the process of planning and creating the layout, dimensions, and. Specify the smallest weld acceptable for both service and fabrication; At the heart of welded connection design lies the understanding of stress distribution and material behaviour. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode. How To Design Welds.

From www.steelconn.uk

Fillet weld design two methods How To Design Welds In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. At the heart of welded connection design lies the understanding of stress distribution and material behaviour. Welding symbols are basically a shorthand language that allows the engineer or. How To Design Welds.

From weldinginsider.com

Understanding the Basic Welding Symbols How To Design Welds Welding symbols are basically a shorthand language that allows the engineer or designer to clearly indicate the weld. Welding design is the process of planning and creating the layout, dimensions, and. A weld joint of the type that will require the minimum amount of weld metal shall be selected. Design the component to be welded by the most cost effective. How To Design Welds.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT How To Design Welds At the heart of welded connection design lies the understanding of stress distribution and material behaviour. How to weld the connections. In this article, we review the design of welded connections, exploring their key design principles, common types, and considerations, with eurocode 3 (en 1993) serving as our primary reference for best practices. Welding design is the process of planning. How To Design Welds.