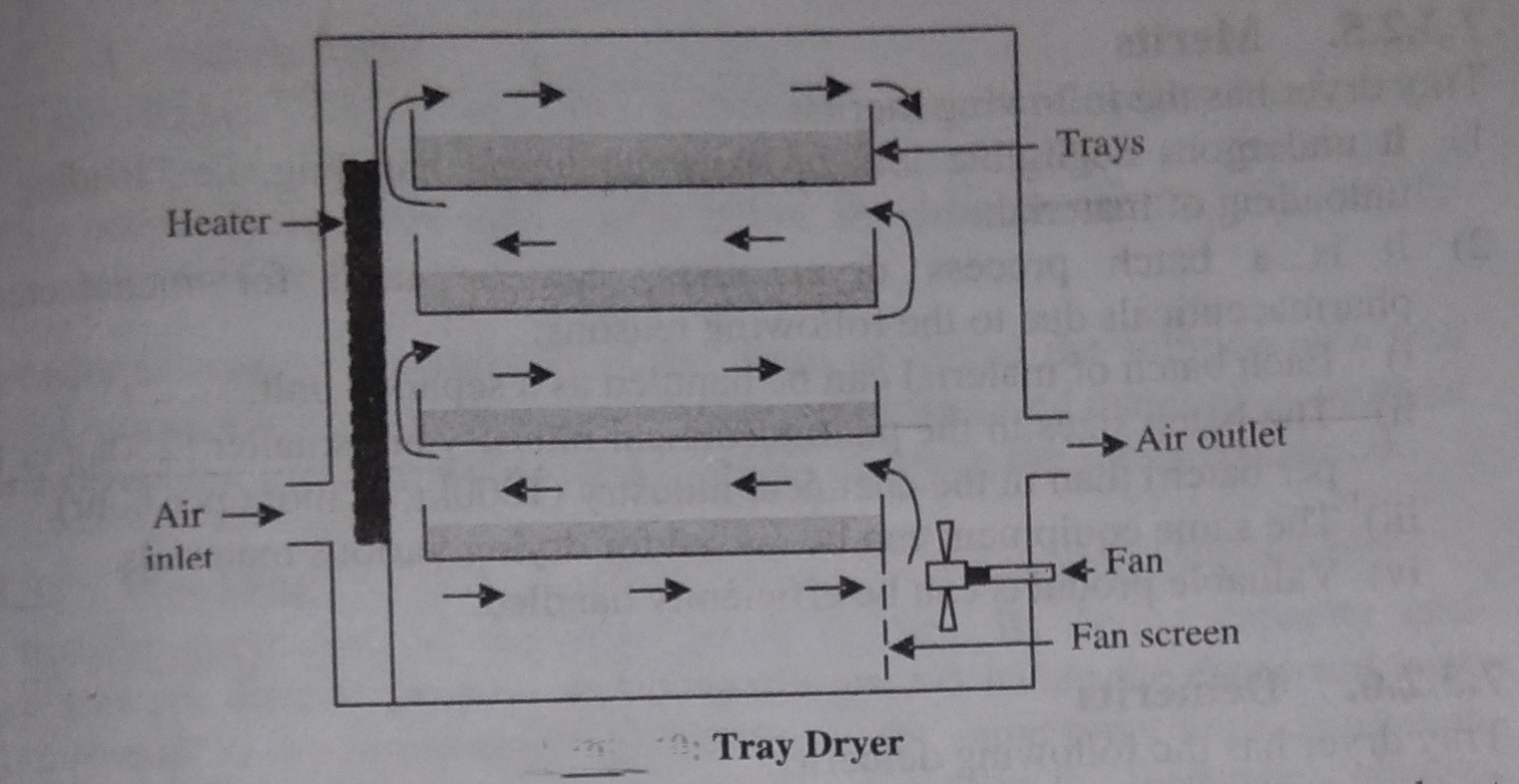

Tray Dryer Schematic Diagram . Schematic of a typical batch dryer is shown in figure 2.1. Case study for experimental design project. Schematic diagram of tray drier [13]. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Mathematical modelling of a laboratory drying process: This chapter contains sections titled: Tray dryers usually operate in batch mode, use racks to hold product and circulate. It describes batch and continuous dryers. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Heat transfer occurs via convection as hot air. Working principle of tray dryer. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids.

from pharmacymcqshayeque.blogspot.com

This chapter contains sections titled: It describes batch and continuous dryers. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Case study for experimental design project. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic diagram of tray drier [13]. Mathematical modelling of a laboratory drying process: Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Working principle of tray dryer. Schematic of a typical batch dryer is shown in figure 2.1.

Tray Dryers and Drum Dryers

Tray Dryer Schematic Diagram Case study for experimental design project. This chapter contains sections titled: Schematic diagram of tray drier [13]. Case study for experimental design project. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Heat transfer occurs via convection as hot air. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Working principle of tray dryer. Schematic of a typical batch dryer is shown in figure 2.1. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. It describes batch and continuous dryers. Mathematical modelling of a laboratory drying process: This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids.

From schematicpartduo.z4.web.core.windows.net

Schematic Diagram Of Tray Dryer Tray Dryer Schematic Diagram Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic of a typical batch dryer is shown in figure 2.1. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Working principle of tray dryer. Tray drying is a batch process where hot air is passed. Tray Dryer Schematic Diagram.

From www.universaldryingsystems.com

Home Universal Drying Systems Tray Dryer Schematic Diagram Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. This chapter contains sections titled: It describes batch and continuous dryers. Heat transfer occurs via convection as hot air. Schematic of a typical batch dryer is shown in figure 2.1. Working principle of tray dryer. Mathematical modelling of a laboratory drying process: This document discusses. Tray Dryer Schematic Diagram.

From www.researchgate.net

Schematic diagram of tray dryer Download Scientific Diagram Tray Dryer Schematic Diagram Schematic diagram of tray drier [13]. Schematic of a typical batch dryer is shown in figure 2.1. Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. This chapter contains sections titled: This document discusses various types of drying equipment and processes used to remove moisture from. Tray Dryer Schematic Diagram.

From pharmasciences.in

Fluidized Bed Dryer FBD Principle, Working Process Tray Dryer Schematic Diagram Mathematical modelling of a laboratory drying process: This chapter contains sections titled: Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Heat transfer occurs via convection as hot air. Schematic diagram of tray drier [13]. The principle involved in tray dryer is forced convection where hot. Tray Dryer Schematic Diagram.

From www.researchgate.net

The schematic drawing of the retractable tray dryer (RtD). Download Tray Dryer Schematic Diagram Schematic diagram of tray drier [13]. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Working principle of tray dryer. Tray drying is a batch process where hot air is passed. Tray Dryer Schematic Diagram.

From electricalworkbook.com

What is Tray Dryer? Working Principle, Construction, Diagram Tray Dryer Schematic Diagram This chapter contains sections titled: Heat transfer occurs via convection as hot air. Schematic of a typical batch dryer is shown in figure 2.1. Mathematical modelling of a laboratory drying process: Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic diagram of tray drier [13]. Working principle of tray dryer. It describes batch and. Tray Dryer Schematic Diagram.

From www.youtube.com

Drying part 5 Tray dryer YouTube Tray Dryer Schematic Diagram Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Schematic diagram of tray drier [13]. This chapter contains sections titled: Working principle of tray dryer. Heat transfer occurs via convection as hot air. The principle involved in tray dryer is forced convection where hot air is. Tray Dryer Schematic Diagram.

From circuitcodeyokoya.z22.web.core.windows.net

Dryer Schematic Diagram Tray Dryer Schematic Diagram Schematic diagram of tray drier [13]. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Mathematical modelling of a laboratory drying process: Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Case study for experimental design. Tray Dryer Schematic Diagram.

From pharmacyscope.com

Vacuum Dryer Principle, Construction, Working And More Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. It describes batch and continuous dryers. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. This chapter contains sections titled: Schematic diagram of tray drier [13]. Schematic. Tray Dryer Schematic Diagram.

From hutco.com

Hutchinson & Company Drying Tray Dryer Schematic Diagram Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Mathematical modelling of a laboratory drying process: Schematic diagram of tray drier [13]. Schematic of a typical batch dryer is shown in figure 2.1. This document discusses various types of drying equipment and processes used to remove. Tray Dryer Schematic Diagram.

From www.researchgate.net

Schematic diagram of the vacuum dryer 1. Drying chamber; 2. Vacuum Tray Dryer Schematic Diagram This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. This chapter contains sections titled: Mathematical modelling of a laboratory drying process: Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Heat transfer occurs via convection as hot air. Tray dryers usually operate in batch. Tray Dryer Schematic Diagram.

From www.zslceq.com

Hopper Dryer Operation Instructions Hot Air Hopper Dryer LCEQ Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Case study for experimental design project. Schematic of a typical batch dryer is shown. Tray Dryer Schematic Diagram.

From localrevive.com

Components, Types, Applications and Advantages (2022) Tray Dryer Schematic Diagram This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Heat transfer occurs via convection as hot air. Working principle of tray dryer. This chapter contains sections titled: Case study for experimental design project. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Tray dryers. Tray Dryer Schematic Diagram.

From pharmacymcqshayeque.blogspot.com

Tray Dryers and Drum Dryers Tray Dryer Schematic Diagram Mathematical modelling of a laboratory drying process: Heat transfer occurs via convection as hot air. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Case study for experimental design project. Schematic diagram of tray drier. Tray Dryer Schematic Diagram.

From www.pinterest.com

10+ Images of Simple Tray dryer, Tray dryer diagram, Tray dryer Tray Dryer Schematic Diagram Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Case study for experimental design project. It describes batch and continuous dryers. Tray dryers usually operate in batch. Tray Dryer Schematic Diagram.

From www.researchgate.net

Schematic representation of tray dryer. Download Scientific Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. Working principle of tray dryer. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Case study for experimental design project. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Schematic of a typical batch dryer is. Tray Dryer Schematic Diagram.

From mrappliance.mastersamuraitech.com

Whirlpool Dryer Schematic Tray Dryer Schematic Diagram It describes batch and continuous dryers. Schematic diagram of tray drier [13]. Working principle of tray dryer. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic of a typical batch dryer is shown in figure 2.1. Mathematical modelling of a laboratory drying process: Heat transfer occurs via convection as hot air. Tray drying is. Tray Dryer Schematic Diagram.

From www.researchgate.net

A schematic diagram of the multitray dryer and a focusing view of a Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic diagram of tray drier [13]. Case study for experimental design project. Tray drying is a batch process where. Tray Dryer Schematic Diagram.

From www.chemengonline.com

Batch Drying With Vacuum Contact Dryers Chemical Engineering Page 1 Tray Dryer Schematic Diagram This chapter contains sections titled: Case study for experimental design project. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. It describes batch and continuous dryers. The principle involved in tray dryer is forced convection where hot air is circulated. Tray Dryer Schematic Diagram.

From electricalworkbook.com

What is Vacuum Dryer? Working Principle, Construction, Diagram Tray Dryer Schematic Diagram Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Tray drying is a batch process where. Tray Dryer Schematic Diagram.

From solutionpharmacy.in

Construction and Working of Tray Dryer Solution Parmacy Tray Dryer Schematic Diagram Tray dryers usually operate in batch mode, use racks to hold product and circulate. It describes batch and continuous dryers. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Tray drying is a batch process. Tray Dryer Schematic Diagram.

From www.basilius.com

Material Drying 101 Basilius Inc. Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. Schematic diagram of tray drier [13]. Mathematical modelling of a laboratory drying process: Schematic of a typical batch dryer is shown in figure 2.1. It describes batch and continuous dryers. This chapter contains sections titled: This document discusses various types of drying equipment and processes used to remove moisture from foods and. Tray Dryer Schematic Diagram.

From www.chemicalslearning.com

Tray dryer Construction and Working Principle and Advantages Tray Dryer Schematic Diagram Tray dryers usually operate in batch mode, use racks to hold product and circulate. Mathematical modelling of a laboratory drying process: Heat transfer occurs via convection as hot air. Schematic of a typical batch dryer is shown in figure 2.1. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Working. Tray Dryer Schematic Diagram.

From www.researchgate.net

A schematic diagram of the tray dryer (a) and a tray (b) in the Tray Dryer Schematic Diagram It describes batch and continuous dryers. Schematic diagram of tray drier [13]. Tray dryers usually operate in batch mode, use racks to hold product and circulate. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Mathematical modelling of a laboratory drying process: Case study for experimental design project. Schematic of. Tray Dryer Schematic Diagram.

From www.pinterest.com

10+ Images of Simple Tray dryer, Tray dryer diagram, Tray dryer Tray Dryer Schematic Diagram Heat transfer occurs via convection as hot air. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Schematic diagram of tray drier [13]. Tray drying is a batch process where hot air is passed over. Tray Dryer Schematic Diagram.

From circuitenginebloggs.z21.web.core.windows.net

Dryer Schematic Wiring Tray Dryer Schematic Diagram It describes batch and continuous dryers. Mathematical modelling of a laboratory drying process: Schematic of a typical batch dryer is shown in figure 2.1. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Schematic diagram of tray drier [13]. Heat transfer occurs via convection as hot air. This document discusses. Tray Dryer Schematic Diagram.

From manuallibrarypablo.z13.web.core.windows.net

Schematic Diagram Of Tray Dryer Tray Dryer Schematic Diagram Case study for experimental design project. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. Schematic. Tray Dryer Schematic Diagram.

From learnaboutpharma.com

Tray Dryer Principle, Construction, Working, Uses, Advantages and Tray Dryer Schematic Diagram The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic diagram of tray drier [13]. Water vapours formed, mix with the circulating air and are eliminated through the outlet provided. This document discusses various types of. Tray Dryer Schematic Diagram.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Schematic Diagram Tray dryers usually operate in batch mode, use racks to hold product and circulate. Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Schematic diagram of tray drier [13]. Schematic of a typical batch dryer is shown in figure 2.1. Working principle of tray dryer. The. Tray Dryer Schematic Diagram.

From learnaboutpharma.com

Tray Dryer Principle, Construction, Working, Uses, Advantages and Tray Dryer Schematic Diagram The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Heat transfer occurs via convection as hot air. Schematic of a typical batch dryer is shown in figure 2.1. Working principle of tray dryer. This chapter contains sections titled: Schematic diagram of tray drier [13]. Water vapours formed, mix with the. Tray Dryer Schematic Diagram.

From www.youtube.com

Vacuum tray dryer(VTD) working principle,MOCs,Sizes,Utilities,Safety Tray Dryer Schematic Diagram Mathematical modelling of a laboratory drying process: The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. Heat transfer occurs via convection as hot air. Schematic of a typical batch dryer is shown in figure 2.1. It describes batch and continuous dryers. This document discusses various types of drying equipment and. Tray Dryer Schematic Diagram.

From www.iqsdirectory.com

Types of Dryers Components, Types, Applications and Advantages Tray Dryer Schematic Diagram Case study for experimental design project. This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Tray dryers usually operate in batch mode, use racks to hold product and circulate. Schematic diagram of tray drier [13]. Mathematical modelling of a laboratory drying process: The principle involved in tray dryer is forced. Tray Dryer Schematic Diagram.

From www.youtube.com

Drying Tray Dryer working principle Drum Dryer working principle Tray Dryer Schematic Diagram Mathematical modelling of a laboratory drying process: Tray drying is a batch process where hot air is passed over solid materials arranged on trays to remove water or other liquids. Case study for experimental design project. Working principle of tray dryer. It describes batch and continuous dryers. This chapter contains sections titled: This document discusses various types of drying equipment. Tray Dryer Schematic Diagram.

From www.researchgate.net

Schematic diagram of tray dryer (Armfield Ltd., Ringwood, UK Tray Dryer Schematic Diagram Mathematical modelling of a laboratory drying process: This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. Heat transfer occurs via convection as hot air. Case study for experimental design project. This chapter contains sections titled: Water vapours formed, mix with the circulating air and are eliminated through the outlet provided.. Tray Dryer Schematic Diagram.

From www.simplepharmanotes.com

Tray Dryers. Tray Dryer Schematic Diagram This document discusses various types of drying equipment and processes used to remove moisture from foods and other materials. The principle involved in tray dryer is forced convection where hot air is circulated continuously over the wet material. This chapter contains sections titled: Schematic diagram of tray drier [13]. Working principle of tray dryer. It describes batch and continuous dryers.. Tray Dryer Schematic Diagram.