Chiller Evaporator Tube Leak . So check there’s nothing blocking this. water leaks in chiller systems. Check around your system for signs of this and top up if needed. This could be down to a low refrigerant charge. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. They usually come from places like the drain line or the condensate pan. Don’t forget to check for leaks as well. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. Water leaks can happen in chiller systems. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns.

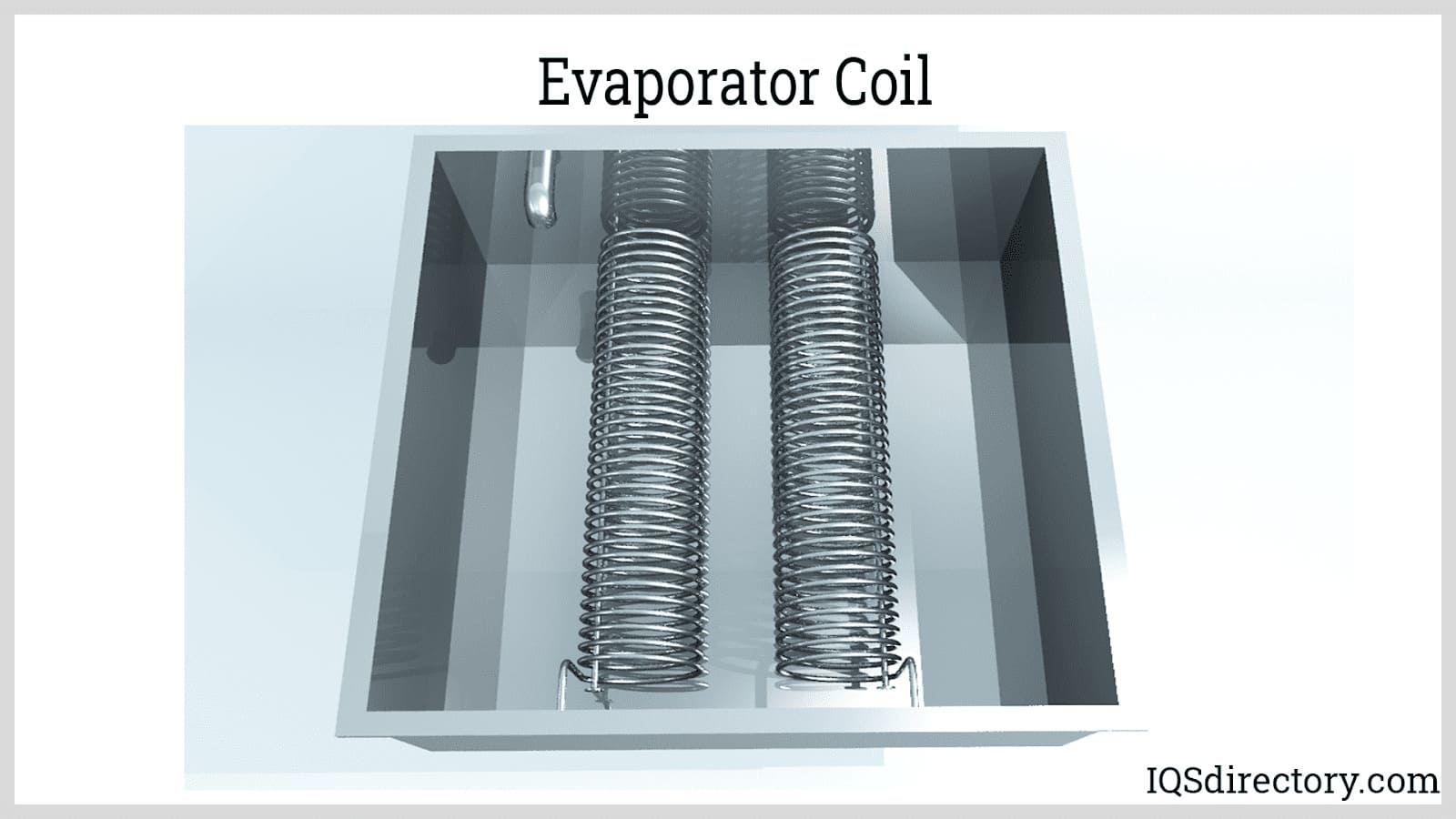

from www.iqsdirectory.com

Water leaks can happen in chiller systems. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. This could be down to a low refrigerant charge. So check there’s nothing blocking this. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. water leaks in chiller systems. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. Don’t forget to check for leaks as well.

Water Chiller What Is It? How Does It Work? Types, Uses

Chiller Evaporator Tube Leak Don’t forget to check for leaks as well. Don’t forget to check for leaks as well. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. They usually come from places like the drain line or the condensate pan. So check there’s nothing blocking this. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. Check around your system for signs of this and top up if needed. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. This could be down to a low refrigerant charge. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. Water leaks can happen in chiller systems. water leaks in chiller systems.

From www.facebook.com

🛠🛠Repair FUJIDENZO Upright Chiller ISSUE Evaporator internal leak 😄Mabilisang re Coil na lang Chiller Evaporator Tube Leak This could be down to a low refrigerant charge. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. Water leaks can happen in chiller systems. Check around your system for signs of this and. Chiller Evaporator Tube Leak.

From theengineeringmindset.com

Chiller Evaporators Explained The Engineering Mindset Chiller Evaporator Tube Leak the most common issue for low pressure is going to be a dirty or an obstructed evaporator. So check there’s nothing blocking this. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns.. Chiller Evaporator Tube Leak.

From www.iqsdirectory.com

Water Chiller What Is It? How Does It Work? Types, Uses Chiller Evaporator Tube Leak Water leaks can happen in chiller systems. This could be down to a low refrigerant charge. They usually come from places like the drain line or the condensate pan. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. we have a carrier chiller model 19xl5858 (r134a) in. Chiller Evaporator Tube Leak.

From faservice.net

chiller inspection for leaks Chiller Evaporator Tube Leak once every two or three years for your chiller or three to five years for your evaporator should be sufficient. This could be down to a low refrigerant charge. So check there’s nothing blocking this. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. The procedures. Chiller Evaporator Tube Leak.

From www.youtube.com

Pinpointing a Refrigerant Leak in a Ductless Evaporator Coil YouTube Chiller Evaporator Tube Leak They usually come from places like the drain line or the condensate pan. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. So check there’s nothing blocking this. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445. Chiller Evaporator Tube Leak.

From www.youtube.com

How to Pinpoint Leaky Tubes In Chillers, Condensers, HVAC Heat Exchangers & Other Pressure Chiller Evaporator Tube Leak This could be down to a low refrigerant charge. They usually come from places like the drain line or the condensate pan. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. Water leaks can happen in chiller systems. Don’t forget to check for leaks as well. we have a carrier. Chiller Evaporator Tube Leak.

From www.youtube.com

ChillerTube leak detection test YouTube Chiller Evaporator Tube Leak Don’t forget to check for leaks as well. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. the most common issue for low pressure is. Chiller Evaporator Tube Leak.

From www.banksindustrial.com

Chiller repair and maintenance that will save you money Chiller Evaporator Tube Leak to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. They usually come from places like the drain line or the condensate pan. Check around your system for signs of this and top up if needed. Water leaks can happen in chiller systems. Leaks in the chiller’s refrigerant. Chiller Evaporator Tube Leak.

From hvactechguide.com

Chiller components & their working HVAC & Engineering Chiller Evaporator Tube Leak So check there’s nothing blocking this. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. water leaks in chiller systems. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. Don’t forget to check for leaks as well. Check around your system for. Chiller Evaporator Tube Leak.

From www.facebook.com

🛠🛠Repair FUJIDENZO Upright Chiller ISSUE Evaporator internal leak 😄Mabilisang re Coil na lang Chiller Evaporator Tube Leak Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. we have a carrier chiller model. Chiller Evaporator Tube Leak.

From www.mekasmart.club

Chiller System Design and Control Chiller Evaporator Tube Leak Check around your system for signs of this and top up if needed. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. water leaks in chiller systems. They usually come from places like the drain line or the condensate pan. So check there’s nothing blocking this.. Chiller Evaporator Tube Leak.

From www.facebook.com

🛠🛠Repair FUJIDENZO Upright Chiller ISSUE Evaporator internal leak 😄Mabilisang re Coil na lang Chiller Evaporator Tube Leak The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. So check there’s nothing blocking this. Don’t forget to check for leaks as well. This could be down to a low refrigerant charge. They usually come from places like the drain line or the condensate pan. to hold the refrigerant inside. Chiller Evaporator Tube Leak.

From maximuschillers.com

Fgas Chiller Leak Testing Maximus Chillers Be the best Chiller Evaporator Tube Leak to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. the most common issue for low pressure is going to be a dirty or an obstructed. Chiller Evaporator Tube Leak.

From www.youtube.com

Chiller evaporator connection with flexible bellows YouTube Chiller Evaporator Tube Leak we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. Check around your system. Chiller Evaporator Tube Leak.

From www.diychatroom.com

Evaporator Coil Leak Repair DIY Home Improvement Forum Chiller Evaporator Tube Leak water leaks in chiller systems. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. They usually come from places like the drain line or the condensate pan. So check there’s nothing blocking this.. Chiller Evaporator Tube Leak.

From maximuschillers.com

Chiller Tube Cleaning Chiller Condensers & Evaporators Chiller Evaporator Tube Leak Don’t forget to check for leaks as well. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. So check there’s nothing blocking this. Check around your system for signs of this and top up if needed. Water leaks can happen in chiller systems. we have a carrier chiller model 19xl5858. Chiller Evaporator Tube Leak.

From www.njreliablecoatings.com

Heat Exchanger & HVAC Chiller Tube Sheet Repair Services New Jersey Chiller Evaporator Tube Leak to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. once every two or three years for your chiller or three to five years for your. Chiller Evaporator Tube Leak.

From www.youtube.com

How To Repair Leaked Refrigerator's Evaporator Coil YouTube Chiller Evaporator Tube Leak we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. Water leaks can happen in chiller systems. So check there’s nothing blocking this. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. Check around your system for signs of this. Chiller Evaporator Tube Leak.

From www.youtube.com

HVAC Service Call (small chiller water leak) YouTube Chiller Evaporator Tube Leak The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. Don’t forget to check for leaks as well. Check around your system for signs of this and top up if needed. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. once every. Chiller Evaporator Tube Leak.

From www.youtube.com

Chiller and Condenser Tube Cleaning System by Innovas Technologies YouTube Chiller Evaporator Tube Leak They usually come from places like the drain line or the condensate pan. This could be down to a low refrigerant charge. Check around your system for signs of this and top up if needed. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. Water leaks can happen in chiller systems.. Chiller Evaporator Tube Leak.

From www.mdpi.com

Applied Sciences Free FullText Measurement Method and Experimental Analysis of Liquid Chiller Evaporator Tube Leak water leaks in chiller systems. Water leaks can happen in chiller systems. This could be down to a low refrigerant charge. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. Don’t forget to check for leaks as well. the most common issue for low pressure is going to be a dirty or an. Chiller Evaporator Tube Leak.

From electricalworkbook.com

What is Chiller? Types, Function & Applications ElectricalWorkbook Chiller Evaporator Tube Leak to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. So check there’s nothing blocking this. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. The procedures in this document have proven to be a “best practice” when leak. Chiller Evaporator Tube Leak.

From www.youtube.com

centrifugal chiller evaporator tube cleaning YouTube Chiller Evaporator Tube Leak water leaks in chiller systems. They usually come from places like the drain line or the condensate pan. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. Don’t forget to check for leaks as well. This could be down to a low refrigerant charge. we have a carrier chiller. Chiller Evaporator Tube Leak.

From www.youtube.com

Leakage in chiller evaporator 2 YouTube Chiller Evaporator Tube Leak Water leaks can happen in chiller systems. They usually come from places like the drain line or the condensate pan. So check there’s nothing blocking this. Don’t forget to check for leaks as well. The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. This could be down to a low refrigerant. Chiller Evaporator Tube Leak.

From usaborescopes.com

USA Borescopes Borescope Chiller Tube Inspections Chiller Evaporator Tube Leak we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. Don’t forget to check for leaks as well. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. So check there’s nothing blocking this. Check around your. Chiller Evaporator Tube Leak.

From www.apexengineeringproducts.com

Chiller Cleaning Chiller Maintenance Apex Engineering Chiller Evaporator Tube Leak water leaks in chiller systems. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. the most common issue for low pressure is going to. Chiller Evaporator Tube Leak.

From www.dreamstime.com

Focus On The Condenser Tube, Cleaning Chiller Condenser Tubes With Brushs Condenser Tubes Chiller Evaporator Tube Leak Check around your system for signs of this and top up if needed. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. Water leaks can happen in chiller systems. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. to hold the refrigerant. Chiller Evaporator Tube Leak.

From maximuschillers.com

Process chiller service to a refrigerant leak on a flooded evaporator Chiller Evaporator Tube Leak The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. water leaks in chiller systems. to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator. Chiller Evaporator Tube Leak.

From northeastcoil.com

Chiller Tube Cleaning Northeast Coil Chiller Evaporator Tube Leak to hold the refrigerant inside the evaporator shell and ensure it doesn’t leak, a metal plate is welded to each end. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. Don’t forget to check for leaks as well. Check around your system for signs of this and top up if needed. They usually come. Chiller Evaporator Tube Leak.

From repairmachinehatch.z5.web.core.windows.net

How To Fix Evap Leak Chiller Evaporator Tube Leak the most common issue for low pressure is going to be a dirty or an obstructed evaporator. This could be down to a low refrigerant charge. we have a carrier chiller model 19xl5858 (r134a) in which 8 nos evaporator tubes leaked out of total 445 tubes. once every two or three years for your chiller or three. Chiller Evaporator Tube Leak.

From www.youtube.com

EP005 Centrifugal Water Chiller Evaporator YouTube Chiller Evaporator Tube Leak So check there’s nothing blocking this. Water leaks can happen in chiller systems. Check around your system for signs of this and top up if needed. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. This could be down to a low refrigerant charge. Leaks in the chiller’s. Chiller Evaporator Tube Leak.

From www.senho-chiller.com

Difference of Chiller Evaporators丨Senho Chiller Chiller Evaporator Tube Leak Water leaks can happen in chiller systems. Don’t forget to check for leaks as well. This could be down to a low refrigerant charge. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. water leaks in chiller systems. They usually come from places like the drain line or the condensate. Chiller Evaporator Tube Leak.

From www.vrcoolertech.com

What Causes Leaks In Evaporator Coils? News Changzhou Vrcoolertech Refrigeration Co.,Ltd Chiller Evaporator Tube Leak Don’t forget to check for leaks as well. This could be down to a low refrigerant charge. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. once every two or three years for your chiller or. Chiller Evaporator Tube Leak.

From www.youtube.com

Hydrostatic Test chilled water/ Pressure Leak test YouTube Chiller Evaporator Tube Leak The procedures in this document have proven to be a “best practice” when leak checking an absorption unit. Check around your system for signs of this and top up if needed. once every two or three years for your chiller or three to five years for your evaporator should be sufficient. we have a carrier chiller model 19xl5858. Chiller Evaporator Tube Leak.

From oceanstateac.com

What Causes Evaporator Coil Leaks and How to Prevent Them Chiller Evaporator Tube Leak This could be down to a low refrigerant charge. water leaks in chiller systems. They usually come from places like the drain line or the condensate pan. the most common issue for low pressure is going to be a dirty or an obstructed evaporator. Leaks in the chiller’s refrigerant circuit can lead to reduced efficiency and environmental concerns.. Chiller Evaporator Tube Leak.