Solder Flux Material . Without it, achieving clean, strong solder joints would be challenging, if not impossible. As with solder, there are several types of flux, each with key uses and some limitations. — flux is an indispensable auxiliary material in the smt soldering process. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. This article investigates types of flux commonly used in. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of.

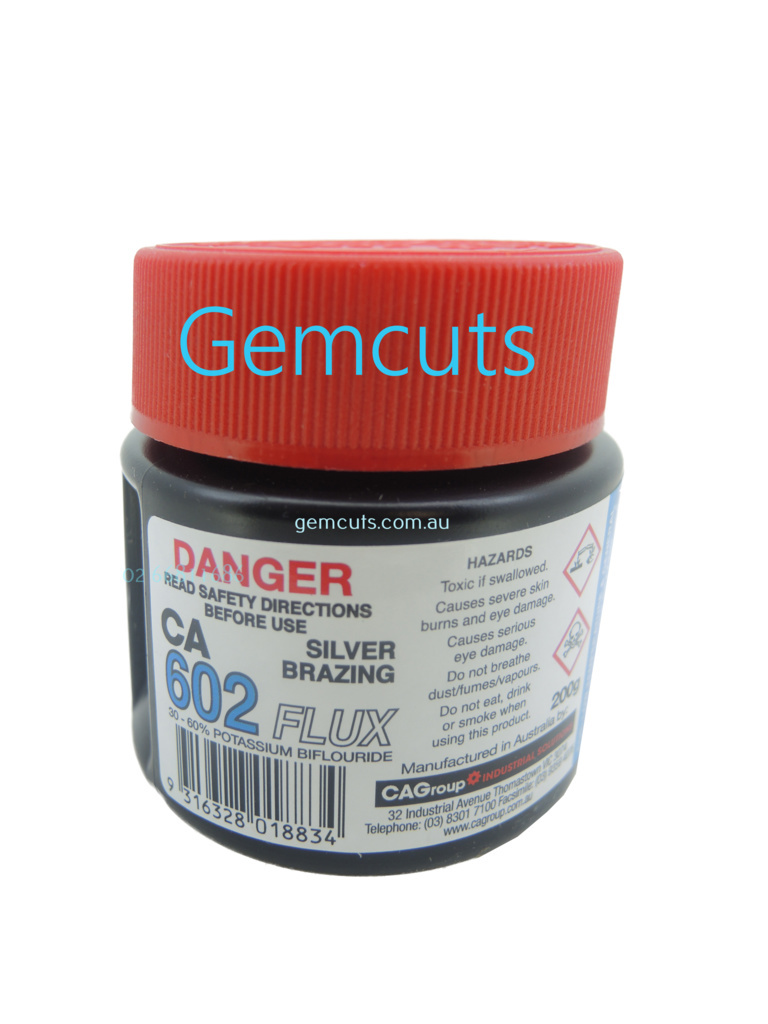

from www.gemcuts.com.au

flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. This article investigates types of flux commonly used in. Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. — flux is an indispensable auxiliary material in the smt soldering process. As with solder, there are several types of flux, each with key uses and some limitations.

EziWeld Soldering Flux 602

Solder Flux Material As with solder, there are several types of flux, each with key uses and some limitations. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. As with solder, there are several types of flux, each with key uses and some limitations. This article investigates types of flux commonly used in. — flux is an indispensable auxiliary material in the smt soldering process. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. Without it, achieving clean, strong solder joints would be challenging, if not impossible.

From soldersandfluxes.co.uk

Solders & Fluxes About Us Soldering product in convenient sizes Solder Flux Material Without it, achieving clean, strong solder joints would be challenging, if not impossible. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux is an indispensable auxiliary material in. Solder Flux Material.

From www.aliexpress.com

Dental lab laboratory material Ney borax solder flux solderingin Teeth Solder Flux Material This article investigates types of flux commonly used in. As with solder, there are several types of flux, each with key uses and some limitations. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux remains on the surface of the metal while you're. Solder Flux Material.

From www.omniamfg.com

Choosing the Right Solder Alloy and Flux — Omnia MFG Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. As with solder, there are several types of flux, each with key uses and some limitations. — flux is an indispensable auxiliary material in the smt soldering process. In wave soldering, flux and solder are. Solder Flux Material.

From resources.altium.com

Types of PCB Soldering and the Assembly Process Blog Altium Designer Solder Flux Material Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux is an indispensable auxiliary material in the smt soldering process. This article investigates types of flux commonly used in. In wave soldering, flux and solder are used separately, while. Solder Flux Material.

From www.walmart.com

Soldering Paste Flux 50 Gram Box Helpful in Smooth Solder Flow Solder Flux Material This article investigates types of flux commonly used in. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow. Solder Flux Material.

From www.aliexpress.com

Lead Free Tin Silver Solder Wire Flux 1.8 3 Silver 0.8mm Speaker DIY Solder Flux Material Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. This article investigates types of flux commonly used in. — a tapestry of compounds, soldering flux comprises rosin. Solder Flux Material.

From www.aliexpress.com

High Quality bga solder flux/paste RMA UV100 Lead Free Soldering Solder Flux Material — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides,. Solder Flux Material.

From agdop.weebly.com

Solder flux agdop Solder Flux Material As with solder, there are several types of flux, each with key uses and some limitations. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. — flux is an indispensable auxiliary material in the smt soldering process. Without it, achieving. Solder Flux Material.

From www.aliexpress.com

50g100gSolidRosinSolderPasteFluxPasteMaterialHighPurityFor Solder Flux Material In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. — flux remains on the surface of the metal while you're soldering,. Solder Flux Material.

From www.indiamart.com

Noel Chemical White Solder Flux Material Composition Rosin and Wax at Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux is an indispensable auxiliary material in the smt soldering process. As with solder, there are several types of flux, each. Solder Flux Material.

From www.digitaltrends.com

How to Solder A Complete Noob's Guide to Melting Metal Digital Trends Solder Flux Material This article investigates types of flux commonly used in. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. As with solder, there are several types of flux, each with key uses and some limitations. Without it, achieving clean, strong solder joints would be challenging, if. Solder Flux Material.

From www.walmart.com

Mgaxyff MCNUV50 Paste Flux Soldering Tin Flux Electric Soldering Iron Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. As with solder, there are several types of flux, each with key. Solder Flux Material.

From zhongshi-soldering.en.made-in-china.com

Low Temperature Solder Paste LED Material Tin Soldering Paste Flux for Solder Flux Material — flux is a crucial ingredient in successfully soldering electronic components to a pcb. Without it, achieving clean, strong solder joints would be challenging, if not impossible. This article investigates types of flux commonly used in. As with solder, there are several types of flux, each with key uses and some limitations. — flux is an indispensable auxiliary. Solder Flux Material.

From alexnld.com

KSS S800 10CC Solder Paste Flux Soldering Paste with Needle for Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. — flux is an indispensable auxiliary material in the smt soldering process. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high. Solder Flux Material.

From www.weldingsupply.com.au

EZIWELD FLUX 602 SILVER SOLDER 200G QWS Welding Supply Solutions Solder Flux Material — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. Without it, achieving clean, strong solder joints would be challenging, if not impossible. In wave soldering, flux and solder are used separately, while in reflow. Solder Flux Material.

From www.aliexpress.com

(1.76oz/50g) Solid Rosin Paste Solder Flux 50g Welding Rosin Soldering Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux remains on the surface of the metal while you're soldering,. Solder Flux Material.

From www.aliexpress.com

Lead Free Tin Silver Solder Wire Flux 2.0 Silver 0.8mm Speaker DIY Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. This article investigates types of flux commonly used in. — flux remains on the surface. Solder Flux Material.

From www.electronicsandyou.com

What is Solder Flux How to Use Flux in Soldering Solder Flux Material — flux is a crucial ingredient in successfully soldering electronic components to a pcb. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to. Solder Flux Material.

From www.solderconnection.com

Solder Materials Solder Connection Solders & Fluxes Solder Flux Material — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux is an indispensable auxiliary material in the smt soldering process. — flux remains on the surface of the metal while you're soldering, which. Solder Flux Material.

From www.youtube.com

What is Solder Flux? Soldering Basics YouTube Solder Flux Material — flux is an indispensable auxiliary material in the smt soldering process. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. Without it, achieving clean, strong solder joints would be. Solder Flux Material.

From www.hampdon.com.au

EZI Weld 801 Soft Soldering Flux 250ml Jar Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. — a tapestry of compounds, soldering flux. Solder Flux Material.

From www.aliexpress.com

PCB electric solder material 1pcs*Colophony soldering flux with 1pcs Solder Flux Material Without it, achieving clean, strong solder joints would be challenging, if not impossible. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. — flux is an indispensable auxiliary material in the smt soldering process. This article investigates types of flux commonly used in. — flux remains on. Solder Flux Material.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Solder Flux Material — flux is an indispensable auxiliary material in the smt soldering process. As with solder, there are several types of flux, each with key uses and some limitations. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. In wave soldering, flux and solder are used separately, while in. Solder Flux Material.

From szvital.eu

Highquality soldering materials Vital New Material Solder Flux Material As with solder, there are several types of flux, each with key uses and some limitations. — flux is an indispensable auxiliary material in the smt soldering process. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. — flux is a crucial ingredient in successfully soldering electronic. Solder Flux Material.

From www.bracon.co.uk

45gm 'Fluxur' Precious/NonPrecious Soldering Flux Solder General Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux is an indispensable auxiliary material in. Solder Flux Material.

From exomeicia.blob.core.windows.net

Solder Flux Type at Jose Jacobs blog Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. Without it, achieving clean, strong solder joints would be. Solder Flux Material.

From www.macdermidalpha.com

Solder Flux MacDermid Alpha Solder Flux Material — flux is an indispensable auxiliary material in the smt soldering process. As with solder, there are several types of flux, each with key uses and some limitations. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing. Solder Flux Material.

From www.gemcuts.com.au

EziWeld Soldering Flux 602 Solder Flux Material — flux is an indispensable auxiliary material in the smt soldering process. flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. This article investigates types of flux commonly used in. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating. Solder Flux Material.

From zhongshi-soldering.en.made-in-china.com

Solder Flux Rosin Wire PCB Repairing Solder Wire China Welder and Solder Flux Material flux is a chemical compound that helps prepare the metal surfaces for soldering by removing oxides, promoting wetting, and enhancing the flow of. Without it, achieving clean, strong solder joints would be challenging, if not impossible. This article investigates types of flux commonly used in. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating. Solder Flux Material.

From zhongshi-soldering.en.made-in-china.com

LeadFree Solder Wire 0.5mm2.0mm FluxCore Solder 100g Sn99.3cu0.7 Solder Flux Material — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon heating. Without it, achieving clean, strong solder joints would be challenging, if not impossible. In wave soldering, flux and solder are used separately, while in reflow soldering, flux is used as an important part of solder paste. — flux is. Solder Flux Material.

From wonderfulengineering.com

10 Best Soldering Wires For Engineers And Hobbyists Solder Flux Material As with solder, there are several types of flux, each with key uses and some limitations. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. In. Solder Flux Material.

From www.scribd.com

951 Soldering Flux Data Sheet PDF Soldering Solder Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. Without it, achieving clean, strong solder joints would be challenging, if not impossible. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent cleansing prowess upon. Solder Flux Material.

From news.thomasnet.com

Page not found News Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. As with solder, there are several types of flux, each with key uses and some limitations. — a tapestry of compounds, soldering flux comprises rosin or organic acids instigating their potent. Solder Flux Material.

From dccwiki.com

Solder and Flux for DCC Applications Solder Flux Material — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. — flux is a crucial ingredient in successfully soldering electronic components to a pcb. — flux is an indispensable auxiliary material in the smt soldering process. As with solder, there. Solder Flux Material.

From www.solderconnection.com

Solder Materials Solder Connection Solders & Fluxes Solder Flux Material Without it, achieving clean, strong solder joints would be challenging, if not impossible. — flux is an indispensable auxiliary material in the smt soldering process. — flux remains on the surface of the metal while you're soldering, which prevents additional oxides from forming due to the high heat of the soldering process. flux is a chemical compound. Solder Flux Material.