What Causes Flash Gas . This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity casting defects and causes. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting.

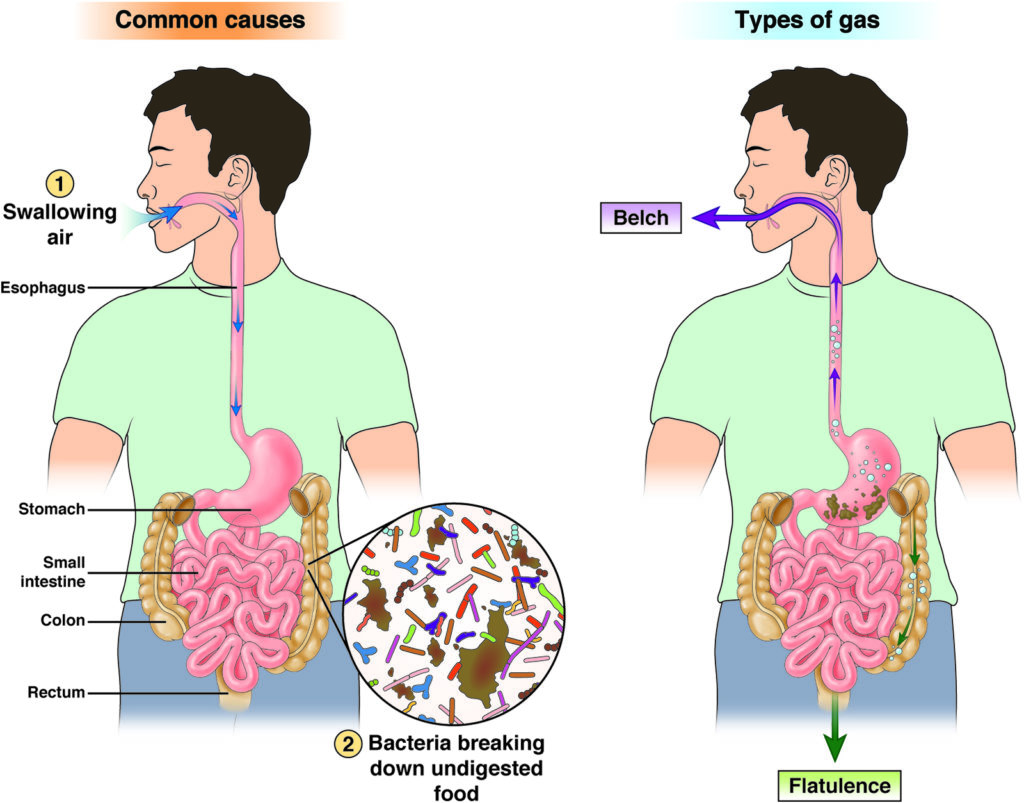

from patient.gastro.org

A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity casting defects and causes. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure.

Gas AGA GI Patient Center

What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Gas porosity casting defects and causes. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass.

From www.slideserve.com

PPT Pressure Enthalpy without Tears PowerPoint Presentation, free What Causes Flash Gas Gas porosity casting defects and causes. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The true. What Causes Flash Gas.

From www.researchgate.net

COP vs. flash gas bypass system (a) normal operation (b) heat recovery What Causes Flash Gas Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity casting defects and causes. A metering device can cause flash gas by creating a pressure drop in the refrigerant.. What Causes Flash Gas.

From www.youtube.com

Flash Gas and Vapor Recovery YouTube What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device. What Causes Flash Gas.

From blog.storemasta.com.au

Examples of flammable liquids and their flash points What Causes Flash Gas Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. A metering device can cause flash gas by creating a pressure drop in the refrigerant. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas porosity occurs when the metal traps gas (most. What Causes Flash Gas.

From www.researchgate.net

Applying guidewords to parameters for the low pressure flash gas What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity casting defects and causes. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Flash gas. What Causes Flash Gas.

From contendo.ca

Flash Gas SAGD Oil Sands Online Training Contendo What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity casting defects and causes. The true. What Causes Flash Gas.

From www.researchgate.net

(PDF) A study of LNG processes to determine the effect of end flash What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device. What Causes Flash Gas.

From iigas.com

Gas Flash Back & Its Causes International Industrial Gases Ltd What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas porosity casting defects and causes. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Flash. What Causes Flash Gas.

From flashgas.com

Propane Safety Tips Flash Gas Order Gas in a FLASH What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The. What Causes Flash Gas.

From www.refrigeration-engineer.com

Flash Gas What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Gas porosity casting defects and causes. Flash. What Causes Flash Gas.

From contendo.ca

Flash Gas SAGD Oil Sands Online Training Contendo What Causes Flash Gas Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity casting defects and. What Causes Flash Gas.

From flashgas.com

Propane Safety Tips Flash Gas Order Gas in a FLASH What Causes Flash Gas The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. A metering device can cause flash gas by creating a pressure drop in the refrigerant. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure. What Causes Flash Gas.

From contendo.ca

Flash Gas SAGD Oil Sands Online Training Contendo What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Flash. What Causes Flash Gas.

From www.researchgate.net

b). The circulating flash gas is fed on the 13 th stage. Due to the What Causes Flash Gas Gas porosity casting defects and causes. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen. What Causes Flash Gas.

From www.cbsnews.com

What causes flash floods and why are they so dangerous? CBS News What Causes Flash Gas A metering device can cause flash gas by creating a pressure drop in the refrigerant. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. The flash gas. What Causes Flash Gas.

From www.youtube.com

Lecture 18 RAC Intercooling Flash Gas Removal YouTube What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in. What Causes Flash Gas.

From patient.gastro.org

Gas AGA GI Patient Center What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity casting defects and causes. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash. What Causes Flash Gas.

From flashgas.com

Flash Gas is a Better Propane Delivery Service than Cynch Flash Gas What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. Gas porosity casting defects and causes. Flash gas occurs when the liquid refrigerant inside a refrigeration system is. What Causes Flash Gas.

From flashgas.com

Flash Gas Thrives with PayArc A Fresh Start After Stripe's "High Risk What Causes Flash Gas Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. A metering device can cause flash gas by creating a pressure drop in the refrigerant. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas porosity casting defects and causes. The flash gas generation causes rapid. What Causes Flash Gas.

From flashgas.com

How to Optimize Your Home Gas Consumption with Flash Gas Flash Gas What Causes Flash Gas The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Gas porosity casting defects and causes. This pressure drop. What Causes Flash Gas.

From www.slideserve.com

PPT Refrigeration Systems PowerPoint Presentation, free download ID What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas. What Causes Flash Gas.

From www.youtube.com

L 09 Two Stage Compression System With Flash Gas Removal Applied What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. Gas porosity occurs when. What Causes Flash Gas.

From www.researchgate.net

Simple P&ID for flash gas injection (a) and parallel compression (b What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or. What Causes Flash Gas.

From www.laurenrenlund.com

9 Common Causes of Gas and How to Avoid Them Lauren Renlund MPH RD What Causes Flash Gas The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The. What Causes Flash Gas.

From contendo.ca

Flash Gas SAGD Oil Sands Online Training Contendo What Causes Flash Gas Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. This pressure drop causes the. What Causes Flash Gas.

From www.slideserve.com

PPT Refrigeration Systems PowerPoint Presentation, free download ID What Causes Flash Gas Gas porosity casting defects and causes. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight glass. This pressure drop causes the refrigerant to rapidly change from a liquid. What Causes Flash Gas.

From chemicalengineeringguy.com

Applications of Flash Distillation in the Industry ChemEngGuy What Causes Flash Gas The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity casting defects and causes. A metering device can cause flash gas by creating a pressure drop in the refrigerant. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. The true. What Causes Flash Gas.

From www.everydayhealth.com

What Is Excessive Gas? Digestive Health Center What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. A metering device can cause flash gas by creating a pressure drop in the refrigerant. The true liquid line “flash gas” issues are cases where you have. What Causes Flash Gas.

From www.researchgate.net

Flash gas from the flash drum and LV0036 opening overhaul scheduled What Causes Flash Gas The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. This pressure drop causes the refrigerant. What Causes Flash Gas.

From www.researchgate.net

All the possible causes for the 'more inlet flo', to the Flash Gas What Causes Flash Gas The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Gas porosity casting defects and causes. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. A. What Causes Flash Gas.

From www.slideserve.com

PPT Refrigeration Systems PowerPoint Presentation, free download ID What Causes Flash Gas This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. Gas porosity casting defects and causes. A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity occurs. What Causes Flash Gas.

From flashgas.com

Why Flash Gas is the Better Choice Over AmeriGas for Propane Delivery What Causes Flash Gas A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. Gas porosity casting defects and causes. The true liquid line. What Causes Flash Gas.

From elviselt.blogspot.com

What Is Flash Point Of A Fuel / How To Test Flash Point The What Causes Flash Gas A metering device can cause flash gas by creating a pressure drop in the refrigerant. Gas porosity occurs when the metal traps gas (most often nitrogen, oxygen or hydrogen) during casting. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. Flash gas occurs when the liquid refrigerant inside a. What Causes Flash Gas.

From www.researchgate.net

Schematic of the system provided with suction of the flash gas from the What Causes Flash Gas Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop in pressure. The true liquid line “flash gas” issues are cases where you have measurable subcooling at the condenser coil outlet but still see, hear, or measure boiling/flashing refrigerant in the liquid line before the metering device or see it in a sight. What Causes Flash Gas.

From flashgas.com

How does Flash Gas Work Flash Gas Order Gas in a FLASH What Causes Flash Gas Gas porosity casting defects and causes. The flash gas generation causes rapid reduction of the refrigerant mass flow rate passing through the expansion device and the. This pressure drop causes the refrigerant to rapidly change from a liquid to a gas, which is. Flash gas occurs when the liquid refrigerant inside a refrigeration system is subjected to a sudden drop. What Causes Flash Gas.