Cereal Manufacturing . depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. in this guide, we will explore the various types of cereal processing equipment, key features of modern. The preparation of the grain is the first step, regardless of the type of finished product. Since cereal is a food intended for human. Most functional foods and ready to eat food products utilize similar technologies for production. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. every step in the manufacturing of breakfast cereal is carefully monitored for quality. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast.

from www.cyfoodtruck.com

depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. every step in the manufacturing of breakfast cereal is carefully monitored for quality. Most functional foods and ready to eat food products utilize similar technologies for production. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. in this guide, we will explore the various types of cereal processing equipment, key features of modern. Since cereal is a food intended for human. The preparation of the grain is the first step, regardless of the type of finished product. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet.

Corn flakes breakfast cereal manufacturing plant machine Wholesale

Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. in this guide, we will explore the various types of cereal processing equipment, key features of modern. Most functional foods and ready to eat food products utilize similar technologies for production. Since cereal is a food intended for human. every step in the manufacturing of breakfast cereal is carefully monitored for quality. The preparation of the grain is the first step, regardless of the type of finished product. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast.

From www.alibaba.com

Automatic Corn Chips Breakfast Cereal Manufacturing Machine High Yield Cereal Manufacturing Most functional foods and ready to eat food products utilize similar technologies for production. in this guide, we will explore the various types of cereal processing equipment, key features of modern. depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. imarc group’s report, titled “breakfast cereal manufacturing. Cereal Manufacturing.

From www.thequint.com

US Cereal Manufacturing Giant Kellogg to Split Into 3 Independent Companies Cereal Manufacturing in this guide, we will explore the various types of cereal processing equipment, key features of modern. every step in the manufacturing of breakfast cereal is carefully monitored for quality. The preparation of the grain is the first step, regardless of the type of finished product. the most common cereal processes include dry milling (wheat and rye),. Cereal Manufacturing.

From www.alibaba.com

Ce Certificate Expand Cereal Machine Buy Expanding Cereal Machine Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. in this guide, we will explore the various types of cereal processing equipment, key features of modern. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. depending on the kind of cereal, several production procedures are. Cereal Manufacturing.

From loyalfoodmachine.com

Nutritional Cereals Bars Making Machine Manufacturing Process Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. every step in the manufacturing of breakfast cereal is carefully monitored for quality. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy. Cereal Manufacturing.

From www.alibaba.com

Cereal Bar Production Line Buy Puffed Rice Granola Cereal Bar Cereal Manufacturing in this guide, we will explore the various types of cereal processing equipment, key features of modern. depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. The preparation of the grain is the first step, regardless of the type of finished product. Most functional foods and ready to. Cereal Manufacturing.

From www.youtube.com

Automatic modern forming machine MMC200 cereal bar / cereal bar Cereal Manufacturing Most functional foods and ready to eat food products utilize similar technologies for production. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. Since cereal is a food intended for human. every step in the manufacturing of breakfast cereal is carefully monitored for quality. in this guide, we will. Cereal Manufacturing.

From www.ecvv.com

cereal manufacturing line from China Manufacturer, Manufactory, Factory Cereal Manufacturing Most functional foods and ready to eat food products utilize similar technologies for production. in this guide, we will explore the various types of cereal processing equipment, key features of modern. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. our capabilities and knowledge of food manufacturing equipment cover virtually every kind. Cereal Manufacturing.

From leaderfoodmachine.en.made-in-china.com

Corn Flakes Making Machine Corn Flakes Manufacturing Process Cereal Cereal Manufacturing the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. in this guide, we will explore the various types of cereal processing equipment, key features of modern. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. imarc group’s report, titled “breakfast cereal manufacturing plant. Cereal Manufacturing.

From www.mdpi.com

Foods Free FullText Modelling Processes and Products in the Cereal Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. Since cereal is a food intended for human. every step in the manufacturing of breakfast cereal is carefully monitored for quality. The preparation of the grain is the first step, regardless of the type of finished product. in. Cereal Manufacturing.

From huakefoodmachine.en.made-in-china.com

Intelligent Automatic Industrial Breakfast Cereal Corn Flakes Cereal Manufacturing every step in the manufacturing of breakfast cereal is carefully monitored for quality. The preparation of the grain is the first step, regardless of the type of finished product. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. in this guide, we will explore the various types of cereal processing equipment, key. Cereal Manufacturing.

From www.darin.cn

What are the key components of a breakfast cereal manufacturing Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. Since cereal is a food intended for human. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. our breakfast cereal production systems offer you flexibility,. Cereal Manufacturing.

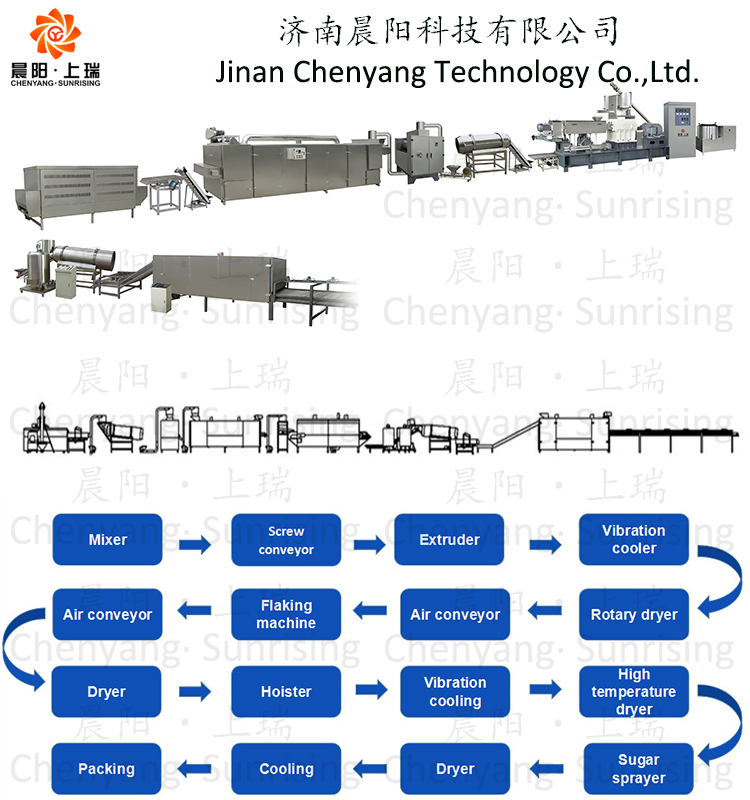

From chenyangtech.en.made-in-china.com

China Manufacturing Breakfast Cereal Corn Flakes Processing Line Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. Since cereal is a food intended for human. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: Most functional. Cereal Manufacturing.

From www.bakerperkins.com

Cereal Processing Equipment And Manufacturing Baker Perkins Cereal Manufacturing our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. every step in the manufacturing of breakfast cereal is carefully monitored for quality. Most functional foods and ready to eat food products utilize similar technologies for production. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. in. Cereal Manufacturing.

From sudaneseyha.net

Automatic High Capacity Nutritional Powder Baby Food Cereal Processing Cereal Manufacturing the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. Since cereal is a food intended for human. every step in the manufacturing of breakfast cereal is carefully monitored for quality. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. our capabilities and knowledge. Cereal Manufacturing.

From www.researchgate.net

The processing of cereal. Download Scientific Diagram Cereal Manufacturing our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. every step in the manufacturing of breakfast cereal is carefully monitored for quality. Most functional foods and ready to eat food products utilize similar technologies for production. the. Cereal Manufacturing.

From www.youtube.com

Breakfast cereal food production line YouTube Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: every step in the manufacturing of breakfast cereal is carefully monitored for quality. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy. Cereal Manufacturing.

From loyalfoodmachine.com

What Machines Does The Breakfast Cereal Production Line Include? Cereal Manufacturing Since cereal is a food intended for human. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: our breakfast cereal production systems offer. Cereal Manufacturing.

From www.alamy.com

Cereal manufacturing Stock Videos & Footage HD and 4K Video Clips Alamy Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. Most functional foods and ready to eat food products utilize similar technologies for production. every step in the manufacturing of breakfast cereal is carefully monitored for quality. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024:. Cereal Manufacturing.

From www.foth.com

Cereal Production Optimization with Capital Execution Team FOTH Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: every step in the manufacturing of breakfast cereal is carefully monitored for quality. depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of. Cereal Manufacturing.

From loyalfoodprocessingline.com

Stable PreFormtion Corn Flakes Manufacturing Cereal Production Line Cereal Manufacturing our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: The preparation of the grain is the first step, regardless of the type of finished product. in. Cereal Manufacturing.

From loyalfoodmachine.com

Nutritional Cereals Bars Making Machine Manufacturing Process Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: in this guide, we will explore the various types of cereal processing equipment, key features of modern. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. depending on the kind of cereal, several production procedures are used, such as flaked,. Cereal Manufacturing.

From jnmtmachine.en.made-in-china.com

Breakfast Cereal Crispy Corn Flakes Extruder Machine Manufacturing Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. every step in the manufacturing of breakfast cereal is carefully monitored for quality.. Cereal Manufacturing.

From www.bakerperkins.com

Cereal Processing Equipment And Manufacturing Baker Perkins Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: The preparation of the grain is the first step, regardless of the type of finished product. depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. Since cereal is a food intended for human. in this guide,. Cereal Manufacturing.

From www.alamy.com

Kellogs cereal, an American multinational food manufacturing company Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. every step in the manufacturing of breakfast cereal is carefully monitored for quality. the most common cereal processes include dry milling (wheat and. Cereal Manufacturing.

From www.linkedin.com

Baby Cereal Food Manufacturing Project Report 2023 Plant Setup, Cost Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. every step in the manufacturing of breakfast cereal is carefully. Cereal Manufacturing.

From uflcereals.blogspot.com

Universal Foods Limited Breakfast Cereal CEREAL MANUFACTURING PROCESS Cereal Manufacturing in this guide, we will explore the various types of cereal processing equipment, key features of modern. our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. Since cereal is a food intended for human. every step in the manufacturing of breakfast cereal is carefully monitored for quality. The preparation of the grain. Cereal Manufacturing.

From www.buhlergroup.com

Breakfast Cereal Manufacturing Solutions Bühler Group Cereal Manufacturing depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. every step in the manufacturing of breakfast cereal is carefully monitored for quality. imarc group’s report, titled “breakfast cereal manufacturing. Cereal Manufacturing.

From www.raymondtravel.co.uk

Used EXTRUDED BREAKFAST CEREAL PRODUCTION LINE for Sale at Raymond Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. Most functional foods and ready to eat food products utilize similar technologies for production. every step in the manufacturing of breakfast cereal is carefully monitored. Cereal Manufacturing.

From www.linkedin.com

Cereal Flour Manufacturing Plant Project Report 2024 Comprehensive Cereal Manufacturing in this guide, we will explore the various types of cereal processing equipment, key features of modern. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. Since cereal is a food intended for human. The preparation of the grain is the first step, regardless of the type of finished product.. Cereal Manufacturing.

From www.alamy.com

Cereal warehouse and agroprocessing and manufacturing plant for Cereal Manufacturing our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. Most functional foods and ready to eat food products utilize similar technologies for production. the most common cereal processes include dry milling (wheat and rye), pearling (rice, oat, and barley), wet. in this guide, we will explore the various types of cereal processing. Cereal Manufacturing.

From fscl.co.uk

cerealproduction FSC Food Sector Construction Cereal Manufacturing Since cereal is a food intended for human. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. Most functional foods and ready to eat food products utilize similar technologies for production. The preparation of the grain is the first step, regardless of the type of finished product. imarc group’s report, titled “breakfast cereal. Cereal Manufacturing.

From www.pinterest.com

Rare look inside General Mills cereal factory General mills cereal Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: our capabilities and knowledge of food manufacturing equipment cover virtually every kind of breakfast. Most functional foods and ready to eat food products utilize similar technologies for production. The preparation of the grain is the first step, regardless of the type of finished product. our breakfast. Cereal Manufacturing.

From www.cyfoodtruck.com

Corn flakes breakfast cereal manufacturing plant machine Wholesale Cereal Manufacturing The preparation of the grain is the first step, regardless of the type of finished product. Since cereal is a food intended for human. in this guide, we will explore the various types of cereal processing equipment, key features of modern. every step in the manufacturing of breakfast cereal is carefully monitored for quality. depending on the. Cereal Manufacturing.

From www.extruderfoodmachine.com

China Expanded Cereal Manufacturing Equipment Manufacturers, Suppliers Cereal Manufacturing in this guide, we will explore the various types of cereal processing equipment, key features of modern. our breakfast cereal production systems offer you flexibility, efficiency, longevity and optimized energy use. depending on the kind of cereal, several production procedures are used, such as flaked, puffed, shredded, and so on. imarc group’s report, titled “breakfast cereal. Cereal Manufacturing.

From www.moisttech.com

Moisture Measurement in Cereal Moist Tech Cereal Manufacturing imarc group’s report, titled “breakfast cereal manufacturing plant project report 2024: Most functional foods and ready to eat food products utilize similar technologies for production. Since cereal is a food intended for human. The preparation of the grain is the first step, regardless of the type of finished product. in this guide, we will explore the various types. Cereal Manufacturing.