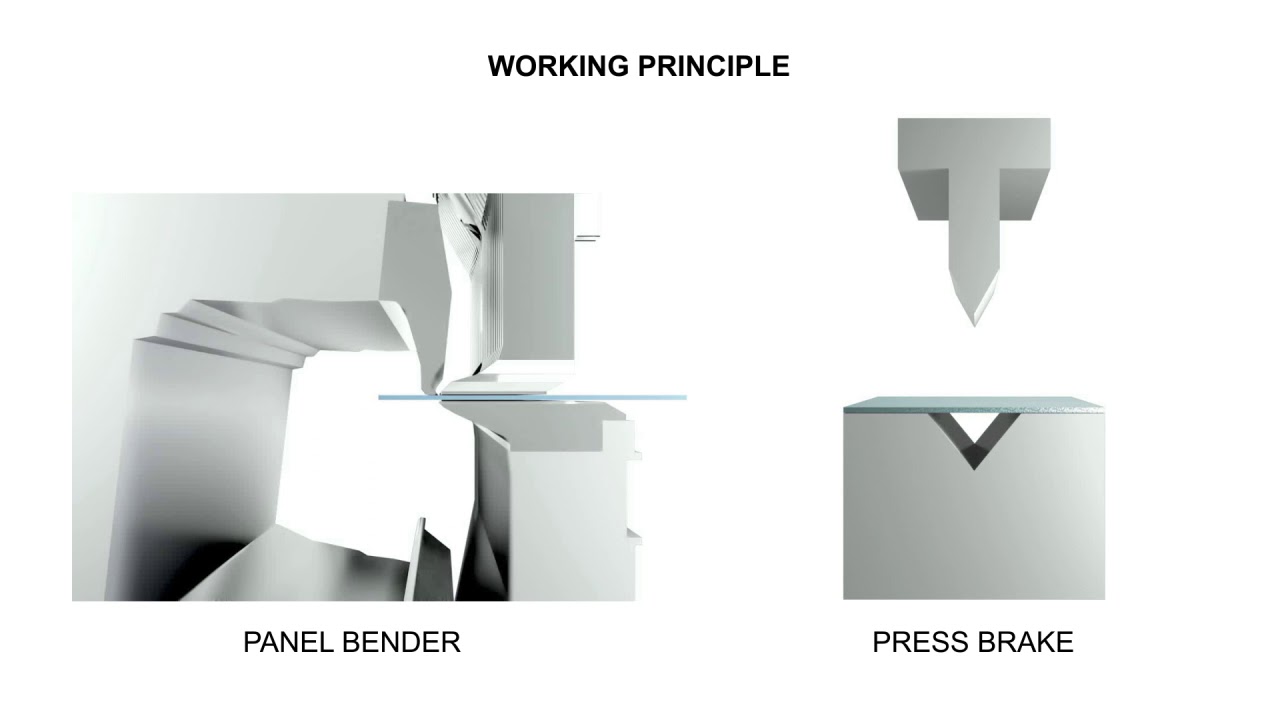

Press Brake Vs Panel Bender . Those differences need to be accounted for. This bender also has two different modes: However, they both have pros and cons. When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Press brakes, high end or low end, cost significantly less than panel benders. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they handle material. Here is a detailed guide to help you choose between the two options. The difference between the panel bender and press brake in the bending process is quite clear. The press brake has an upper die set and a matching lower die set in the form of a v. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. Panel bender and press brake are both used to bend sheet metal in metal fabrication. Both press brake and panel bender machines are excellent options for metal fabrication.

from www.adhmt.com

Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. The difference between the panel bender and press brake in the bending process is quite clear. Both press brake and panel bender machines are excellent options for metal fabrication. However, they both have pros and cons. Those differences need to be accounted for. The press brake has an upper die set and a matching lower die set in the form of a v. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they handle material. Here is a detailed guide to help you choose between the two options. Panel bender and press brake are both used to bend sheet metal in metal fabrication.

Press Brake vs Panel Bender Key Differences ADH Machine Tool

Press Brake Vs Panel Bender When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Both press brake and panel bender machines are excellent options for metal fabrication. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. The press brake has an upper die set and a matching lower die set in the form of a v. Those differences need to be accounted for. Press brakes, high end or low end, cost significantly less than panel benders. This bender also has two different modes: The difference between the panel bender and press brake in the bending process is quite clear. However, they both have pros and cons. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they handle material. Here is a detailed guide to help you choose between the two options. When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Panel bender and press brake are both used to bend sheet metal in metal fabrication.

From www.vigert.com

The Most Comprehensive Pros and Cons of CNC Press Brake vs. NC Press Press Brake Vs Panel Bender Both press brake and panel bender machines are excellent options for metal fabrication. The press brake has an upper die set and a matching lower die set in the form of a v. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend. Press Brake Vs Panel Bender.

From www.adhmt.com

Press Brake vs Panel Bender Key Differences ADH Machine Tool Press Brake Vs Panel Bender This bender also has two different modes: Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. However, they both have pros and cons. Most people reading this are familiar with press brakes, so. Press Brake Vs Panel Bender.

From www.estesdm.com

Panel Benders Vs. Press Brakes Which Is Better And Why? Press Brake Vs Panel Bender This bender also has two different modes: Press brakes, high end or low end, cost significantly less than panel benders. Panel bender and press brake are both used to bend sheet metal in metal fabrication. Both press brake and panel bender machines are excellent options for metal fabrication. Standard, in which the part is automatically fed during the bending sequence. Press Brake Vs Panel Bender.

From reads.alibaba.com

Press Brakes vs. Panel Benders Which Is Right for You? Reads Press Brake Vs Panel Bender Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. Both press brake and panel bender machines are excellent options for metal fabrication. Here is a detailed guide to help you choose between the. Press Brake Vs Panel Bender.

From www.canadianmetalworking.com

Panel bender or automated press brake? Press Brake Vs Panel Bender Here is a detailed guide to help you choose between the two options. The press brake has an upper die set and a matching lower die set in the form of a v. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend. Press Brake Vs Panel Bender.

From reads.alibaba.com

Press Brakes vs. Panel Benders Which Is Right for You? Reads Press Brake Vs Panel Bender Here is a detailed guide to help you choose between the two options. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they. Press Brake Vs Panel Bender.

From www.youtube.com

Salvagnini Panel Bender beats conventional press brake 31 YouTube Press Brake Vs Panel Bender While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they handle material. Both press brake and panel bender machines are excellent options for. Press Brake Vs Panel Bender.

From reads.alibaba.com

Press Brakes vs. Panel Benders Which Is Right for You? Reads Press Brake Vs Panel Bender The press brake has an upper die set and a matching lower die set in the form of a v. However, they both have pros and cons. Both press brake and panel bender machines are excellent options for metal fabrication. The difference between the panel bender and press brake in the bending process is quite clear. Panel bender and press. Press Brake Vs Panel Bender.

From www.wemomachines.com

Press brake, panel bender or automated bending machine? What is the Press Brake Vs Panel Bender Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Here is a detailed guide to help you choose between the two options. The difference between the panel bender and press brake in the bending process. Press Brake Vs Panel Bender.

From www.krrass.com

Panel Bender Machine VS CNC Press Brake Press Brake Vs Panel Bender Those differences need to be accounted for. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. This bender also has two different modes: While press brakes offer versatility and flexibility in bending a wide range. Press Brake Vs Panel Bender.

From www.fabricatingandmetalworking.com

Panel Benders vs. Press Brakes Fabricating and Metalworking Press Brake Vs Panel Bender When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. This bender also has two different modes: However, they both have pros and cons. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend. Press Brake Vs Panel Bender.

From fsmdirect.com

The difference between the press brake and panel bender Press Brake Vs Panel Bender Those differences need to be accounted for. However, they both have pros and cons. When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Panel bender and press brake are both used to bend sheet metal in metal fabrication. This bender also has two different modes: The press. Press Brake Vs Panel Bender.

From www.wemomachines.com

Press brake, Panel Bender or Automated Panel Bending Line? What is the Press Brake Vs Panel Bender This bender also has two different modes: Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Those differences need to be accounted for. Standard, in which the part is automatically fed during the bending sequence. Press Brake Vs Panel Bender.

From www.adhmt.com

Press Brake vs Panel Bender Key Differences ADH Machine Tool Press Brake Vs Panel Bender Here is a detailed guide to help you choose between the two options. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Standard, in which the part is automatically fed during the bending sequence of. Press Brake Vs Panel Bender.

From www.coilandstripequipment.com

New *** Press Brakes and Panel Benders for Sale at Floreani & P... Press Brake Vs Panel Bender Press brakes, high end or low end, cost significantly less than panel benders. Those differences need to be accounted for. The difference between the panel bender and press brake in the bending process is quite clear. The press brake has an upper die set and a matching lower die set in the form of a v. Both press brake and. Press Brake Vs Panel Bender.

From www.estesdm.com

Panel Benders Vs. Press Brakes Which Is Better And Why? Press Brake Vs Panel Bender The press brake has an upper die set and a matching lower die set in the form of a v. This bender also has two different modes: Panel bender and press brake are both used to bend sheet metal in metal fabrication. Both press brake and panel bender machines are excellent options for metal fabrication. Here is a detailed guide. Press Brake Vs Panel Bender.

From www.coilandstripequipment.com

New *** Press Brakes and Panel Benders for Sale at Floreani & P... Press Brake Vs Panel Bender However, they both have pros and cons. This bender also has two different modes: The press brake has an upper die set and a matching lower die set in the form of a v. Panel bender and press brake are both used to bend sheet metal in metal fabrication. Standard, in which the part is automatically fed during the bending. Press Brake Vs Panel Bender.

From www.estesdm.com

Panel Benders Vs. Press Brakes Which Is Better And Why? Press Brake Vs Panel Bender Both press brake and panel bender machines are excellent options for metal fabrication. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they. Press Brake Vs Panel Bender.

From vnoutsourcing.com

Comparison of Panel bender and Press brake VNO Press Brake Vs Panel Bender Both press brake and panel bender machines are excellent options for metal fabrication. However, they both have pros and cons. The press brake has an upper die set and a matching lower die set in the form of a v. The difference between the panel bender and press brake in the bending process is quite clear. Most people reading this. Press Brake Vs Panel Bender.

From www.coilandstripequipment.com

New *** Press Brakes and Panel Benders for Sale at Floreani & P... Press Brake Vs Panel Bender Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. Here is a detailed guide to help you choose between the two options. However, they both have pros and cons. This bender also has. Press Brake Vs Panel Bender.

From www.krrassgroup.com

Panel Benders vs Press Brakes Which is Better and Why? Krrass Machine Press Brake Vs Panel Bender Both press brake and panel bender machines are excellent options for metal fabrication. While press brakes offer versatility and flexibility in bending a wide range of materials and thicknesses, the shape and size of the inside bend radius may vary compared to panel benders or leaf brakes due to differences in process control, tooling, as well as the way they. Press Brake Vs Panel Bender.

From reads.alibaba.com

Press Brakes vs. Panel Benders Which Is Right for You? Reads Press Brake Vs Panel Bender However, they both have pros and cons. This bender also has two different modes: Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. While press brakes offer versatility and flexibility in bending a wide range. Press Brake Vs Panel Bender.

From www.wemomachines.com

Press brake, panel bender or automated bending machine? What is the Press Brake Vs Panel Bender The difference between the panel bender and press brake in the bending process is quite clear. When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Press brakes, high end or low end, cost significantly less than panel benders. While press brakes offer versatility and flexibility in bending. Press Brake Vs Panel Bender.

From fsmdirect.com

Panel benders process on the accuracy on large parts Press Brake Vs Panel Bender Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Both press brake and panel bender machines are excellent options for metal fabrication. Press brakes, high end or low end, cost significantly less than panel benders.. Press Brake Vs Panel Bender.

From www.shen-chong.com

How To Choose? Press Brake Vs Panel Bender SC Machinery Press Brake Vs Panel Bender However, they both have pros and cons. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. The difference between the panel bender and press brake in the bending process is quite clear. Press. Press Brake Vs Panel Bender.

From www.southernfabsales.com

The 3 Types of Bending in Press Brakes Press Brake Vs Panel Bender Both press brake and panel bender machines are excellent options for metal fabrication. Those differences need to be accounted for. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. When a meta fabrication. Press Brake Vs Panel Bender.

From www.thefabricator.com

Press brakes, panel benders, and flat blank calculations Press Brake Vs Panel Bender Here is a detailed guide to help you choose between the two options. Panel bender and press brake are both used to bend sheet metal in metal fabrication. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should. Press Brake Vs Panel Bender.

From www.pinterest.com

The difference between the press brake and panel bender Press brake Press Brake Vs Panel Bender Those differences need to be accounted for. Most people reading this are familiar with press brakes, so the primary thrust of this article will be panel benders, how they compare to press brakes, and why and when you should consider them. Panel bender and press brake are both used to bend sheet metal in metal fabrication. This bender also has. Press Brake Vs Panel Bender.

From www.adhmt.com

Press Brake vs Panel Bender Key Differences ADH Machine Tool Press Brake Vs Panel Bender This bender also has two different modes: Press brakes, high end or low end, cost significantly less than panel benders. The press brake has an upper die set and a matching lower die set in the form of a v. Here is a detailed guide to help you choose between the two options. Panel bender and press brake are both. Press Brake Vs Panel Bender.

From panelbender.salvagnini.co.jp

Press Brake Vs Panel Bender The press brake has an upper die set and a matching lower die set in the form of a v. The difference between the panel bender and press brake in the bending process is quite clear. Panel bender and press brake are both used to bend sheet metal in metal fabrication. Most people reading this are familiar with press brakes,. Press Brake Vs Panel Bender.

From chinaprima.en.made-in-china.com

Operate Automatic Panel Bender Metal Plate Bending Press Brake Machine Press Brake Vs Panel Bender Panel bender and press brake are both used to bend sheet metal in metal fabrication. When a meta fabrication shop switches from a press brake to a panel bender, parts do tend to elongate differently when bent. Those differences need to be accounted for. The press brake has an upper die set and a matching lower die set in the. Press Brake Vs Panel Bender.

From www.adhmt.com

Press Brake vs Panel Bender Key Differences ADH Machine Tool Press Brake Vs Panel Bender Here is a detailed guide to help you choose between the two options. Standard, in which the part is automatically fed during the bending sequence of every side, and press brake mode, in which the sheet is moved manually bend by bend, which is useful for very narrow profiles. Panel bender and press brake are both used to bend sheet. Press Brake Vs Panel Bender.