Filler Wire Used In Mig Welding . filler wire is a crucial component in welding. How to choose the right mig wire for a good weld strength. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. The flux inside the wire melts during welding and protects the weld pool from air and contamination. Choosing the right type of mig wire is critical for the. The different types of filler wire for welding include: Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. Hence it is important to. This type of wire has a hollow center filled with flux. Mild steel filler wire is commonly used in welding. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength.

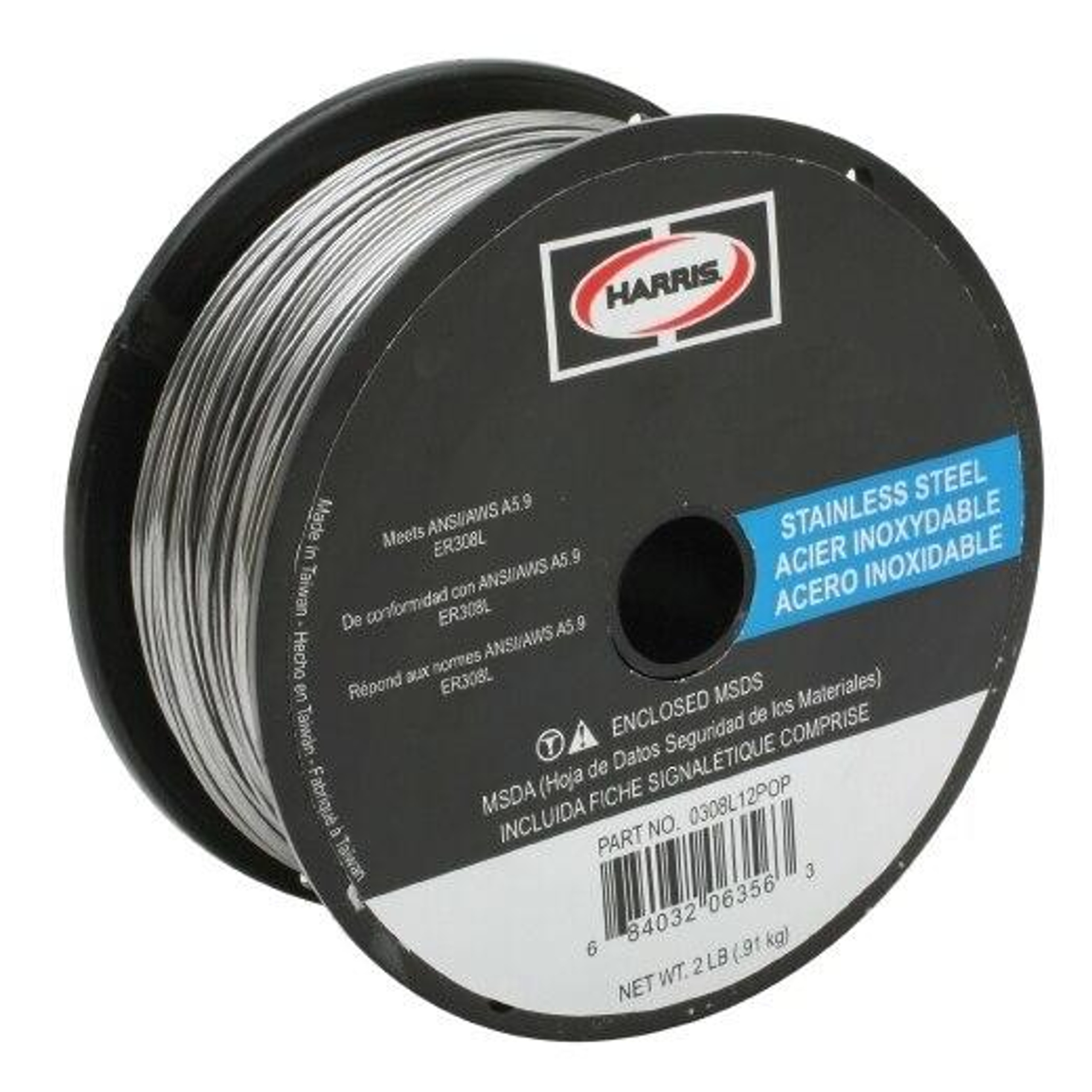

from harrisweldingsupplies.com

Mild steel filler wire is commonly used in welding. The flux inside the wire melts during welding and protects the weld pool from air and contamination. filler wire is a crucial component in welding. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. Choosing the right type of mig wire is critical for the. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. Hence it is important to. The different types of filler wire for welding include:

Harris 309L .035 x 2 lb. Spool Stainless Steel Welding Wire 0309LF2

Filler Wire Used In Mig Welding filler wire is a crucial component in welding. Hence it is important to. filler wire is a crucial component in welding. The flux inside the wire melts during welding and protects the weld pool from air and contamination. Mild steel filler wire is commonly used in welding. The different types of filler wire for welding include: in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. This type of wire has a hollow center filled with flux. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. How to choose the right mig wire for a good weld strength. Choosing the right type of mig wire is critical for the. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position.

From www.hampdon.com.au

5kg 2.4mm ER70S4 Mild Steel TIG Filler Welding Wire Filler Wire Used In Mig Welding The flux inside the wire melts during welding and protects the weld pool from air and contamination. Hence it is important to. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. This type of wire has a hollow center filled with flux. filler wire is a crucial component. Filler Wire Used In Mig Welding.

From www.cwbgroup.org

How is Argon Used in MIG Welding and how do MIG and MAG Welding Differ Filler Wire Used In Mig Welding filler wire is a crucial component in welding. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. How to choose the right mig wire for a good weld strength. Mild steel filler wire is commonly used in welding. Choosing the right type of mig wire is critical for. Filler Wire Used In Mig Welding.

From www.indiamart.com

Adore Stainless steel Mig Welding Filler Wire, For Fabrication at Rs Filler Wire Used In Mig Welding Hence it is important to. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. Choosing the right type of mig wire is critical for the. This. Filler Wire Used In Mig Welding.

From www.hampdon.com.au

5kg 1.6mm ER70S6 Mild Steel TIG Filler Welding Wire Filler Wire Used In Mig Welding filler wire is a crucial component in welding. Mild steel filler wire is commonly used in welding. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. the wire acts as both the filler material and the electrode, making mig welding a. Filler Wire Used In Mig Welding.

From dlx-alloy.en.made-in-china.com

Ernifecr1 Uns N08825 Incoloy 825 Filler Metal MIG Welding Wire 1.2mm 1 Filler Wire Used In Mig Welding Mild steel filler wire is commonly used in welding. Hence it is important to. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. The different types of filler wire for welding include: in mig welding, you can easily join a variety of. Filler Wire Used In Mig Welding.

From weldsmartly.com

The Basics Of Mig Welding [With Detailed Steps & Guide] Filler Wire Used In Mig Welding The flux inside the wire melts during welding and protects the weld pool from air and contamination. The different types of filler wire for welding include: Hence it is important to. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. Choosing the. Filler Wire Used In Mig Welding.

From www.indiamart.com

Adore Stainless steel Mig Welding Filler Wire, For Fabrication at Rs Filler Wire Used In Mig Welding How to choose the right mig wire for a good weld strength. Choosing the right type of mig wire is critical for the. filler wire is a crucial component in welding. The different types of filler wire for welding include: Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint. Filler Wire Used In Mig Welding.

From hunanxunzhuo.en.made-in-china.com

Er308L 0.8mm1.6mm 15kg Stainless Steel Welding Filler MIG Wire China Filler Wire Used In Mig Welding filler wire is a crucial component in welding. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. This type of wire has a hollow center filled with flux. in mig welding, you can easily join a variety of metals, and the type of wire used is determined. Filler Wire Used In Mig Welding.

From wearplatesupplier.en.made-in-china.com

Aws A5.14 Nickel Alloy Inconel 625 Filler Metal MIG Welding Wire Filler Wire Used In Mig Welding Mild steel filler wire is commonly used in welding. This type of wire has a hollow center filled with flux. The different types of filler wire for welding include: The flux inside the wire melts during welding and protects the weld pool from air and contamination. the wire acts as both the filler material and the electrode, making mig. Filler Wire Used In Mig Welding.

From www.indiamart.com

Stainless Steel 308L MIG Filler Wire at Rs 260 SS MIG Welding Wire in Filler Wire Used In Mig Welding the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. Choosing the right type of mig wire is critical for the. This type of wire has a hollow center filled with flux. Hence it is important to. Mild steel filler wire is commonly used. Filler Wire Used In Mig Welding.

From tankiialloy.en.made-in-china.com

MIG/TIG 304/304L/1.4301 welding wire filler metal wire for Coal Scraper Filler Wire Used In Mig Welding Mild steel filler wire is commonly used in welding. Hence it is important to. filler wire is a crucial component in welding. How to choose the right mig wire for a good weld strength. The different types of filler wire for welding include: The flux inside the wire melts during welding and protects the weld pool from air and. Filler Wire Used In Mig Welding.

From www.ebay.com.au

400g Pack 1.6mm 309 Stainless Steel TIG Filler Rods ER309L Filler Wire Used In Mig Welding Hence it is important to. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. the wire acts as both. Filler Wire Used In Mig Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Filler Wire Used In Mig Welding Choosing the right type of mig wire is critical for the. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. How to choose the right mig wire for a good weld strength. Mild steel filler wire is commonly used in welding. . Filler Wire Used In Mig Welding.

From www.indiamart.com

Mild Steel MIG Welding Filler Wire, Thickness 1.2 mm at Rs 125/kg in Filler Wire Used In Mig Welding in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. How to choose the right mig wire. Filler Wire Used In Mig Welding.

From weldingpros.net

MIG Welding Wire Types & Specification Filler Wire Used In Mig Welding Choosing the right type of mig wire is critical for the. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. Mild steel filler wire is commonly used in welding. Hence it is important to. The different types of filler wire for welding. Filler Wire Used In Mig Welding.

From 904dfbe103d50482.en.made-in-china.com

Er5356 MIG Wire Aluminum Welding Wire 5356 Aluminum Alloy MIG Wire Filler Wire Used In Mig Welding This type of wire has a hollow center filled with flux. Mild steel filler wire is commonly used in welding. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. How to choose the right mig wire for a good weld strength. The different types of filler. Filler Wire Used In Mig Welding.

From www.indiamart.com

Aluminium ENAW5183 (TIG, MIG, Filler Metal) Welding Wire Rod at Rs 550 Filler Wire Used In Mig Welding How to choose the right mig wire for a good weld strength. The different types of filler wire for welding include: The flux inside the wire melts during welding and protects the weld pool from air and contamination. Choosing the right type of mig wire is critical for the. filler wire is a crucial component in welding. Choosing the. Filler Wire Used In Mig Welding.

From www.dsenterprises.net

TIG MIG Filler Wires MIG Welding Wire Wholesale Distributor from Pune Filler Wire Used In Mig Welding in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. Mild steel filler wire is commonly used in welding. filler wire is a crucial component in welding. How to choose the right mig wire for a good weld strength. Choosing the right. Filler Wire Used In Mig Welding.

From www.hispanox.com

TIG welding filler wire 1 meter Filler Wire Used In Mig Welding How to choose the right mig wire for a good weld strength. The different types of filler wire for welding include: in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. Mild steel filler wire is commonly used in welding. The flux inside. Filler Wire Used In Mig Welding.

From www.ebay.com

2.4mm Mild Carbon Steel TIG Filler Rods 1kg ER70S4 S4 Welding Wire eBay Filler Wire Used In Mig Welding filler wire is a crucial component in welding. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. The different types of filler wire for welding include: The flux inside the wire melts during welding and protects the weld pool from air and contamination. the most commonly used. Filler Wire Used In Mig Welding.

From dlx-alloy.en.made-in-china.com

C22, B3, B2 Wire Uns N10276 C276 Filler Wire Mesh Alloy C276 Welding Filler Wire Used In Mig Welding Choosing the right type of mig wire is critical for the. Mild steel filler wire is commonly used in welding. This type of wire has a hollow center filled with flux. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. How to. Filler Wire Used In Mig Welding.

From www.ebay.com

2.4mm S6 Mild Carbon Steel TIG Filler Rods 5kg ER70S6 Welding Wire Filler Wire Used In Mig Welding This type of wire has a hollow center filled with flux. The different types of filler wire for welding include: How to choose the right mig wire for a good weld strength. filler wire is a crucial component in welding. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which. Filler Wire Used In Mig Welding.

From www.textronsteelalloys.com

ER1100 TIG / MIG Welding Wire & Filler Rod in 1.6 mm to 4 mm Filler Wire Used In Mig Welding How to choose the right mig wire for a good weld strength. Mild steel filler wire is commonly used in welding. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. This type of wire has a hollow center filled with flux. The different types of filler. Filler Wire Used In Mig Welding.

From www.indiamart.com

MIG Welding Filler Wire at Rs 490/kilogram MIG Welding Wire in Navi Filler Wire Used In Mig Welding Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. Hence it is important to. the wire acts as both. Filler Wire Used In Mig Welding.

From harrisweldingsupplies.com

Harris 309L .035 x 2 lb. Spool Stainless Steel Welding Wire 0309LF2 Filler Wire Used In Mig Welding The flux inside the wire melts during welding and protects the weld pool from air and contamination. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. filler wire is a crucial component in welding. Choosing the right type of mig wire is critical for the. Choosing the right. Filler Wire Used In Mig Welding.

From www.girirajmetals.com

Filler Wires SS & MS Tig Mig Suntech Wires 316L SS Filler Wire Filler Wire Used In Mig Welding the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and has high tensile strength. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. This type of wire has a hollow center filled with flux.. Filler Wire Used In Mig Welding.

From www.zirconiumbar.com

NiCrMo Filler Metal Hastelloy C276 Filler Wire For Mig / Tig Welding Filler Wire Used In Mig Welding the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. filler wire is a crucial component in welding. The different types of filler wire for welding include: Mild steel filler wire is commonly used in welding. Choosing the right filler wire for your welding project relies on several factors,. Filler Wire Used In Mig Welding.

From www.indiamart.com

Stainless Steel 308L MIG Filler Wire at Rs 260 SS MIG Welding Wire in Filler Wire Used In Mig Welding Hence it is important to. Choosing the right type of mig wire is critical for the. The different types of filler wire for welding include: The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled with flux. in mig welding, you can easily. Filler Wire Used In Mig Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Filler Wire Used In Mig Welding The flux inside the wire melts during welding and protects the weld pool from air and contamination. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type. Filler Wire Used In Mig Welding.

From weldcote.com

carbon steel mig wire filler metals Weldcote Welding For WellBeing Filler Wire Used In Mig Welding Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. Hence it is important to. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. filler wire is a crucial component in welding. The flux inside. Filler Wire Used In Mig Welding.

From www.onestopndt.com

Welding with filler wire procedure Filler Wire Used In Mig Welding The flux inside the wire melts during welding and protects the weld pool from air and contamination. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. Choosing the right type of mig wire is critical for the. in mig welding, you can easily join a variety of metals,. Filler Wire Used In Mig Welding.

From www.hampdon.com.au

5kg 3.2mm ER70S2 Mild Steel TIG Filler Welding Wire Rods Filler Wire Used In Mig Welding The different types of filler wire for welding include: the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. filler wire is a crucial component in welding. the most commonly used aluminum mig wires are er5056, a soft wire with good ductility, and er5356, which is harder and. Filler Wire Used In Mig Welding.

From www.pipingmaterial.ae

ER2594 welding wire ER 2594 tig/ filler/ mig wire suppliers Filler Wire Used In Mig Welding filler wire is a crucial component in welding. in mig welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded. This type of wire has a hollow center filled with flux. the wire acts as both the filler material and the electrode, making. Filler Wire Used In Mig Welding.

From www.youtube.com

Filler Wire Specification for Low Alloy and Stainless Steel for GTAW Filler Wire Used In Mig Welding Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. Choosing the right type of mig wire is critical for the. The flux inside the wire melts during welding and protects the weld pool from air and contamination. This type of wire has a hollow center filled. Filler Wire Used In Mig Welding.

From www.marineoutfittings.com

MAG / MIG Welding Filler Material Gas Shielded Wire AWS A5.28 ER80S G Filler Wire Used In Mig Welding filler wire is a crucial component in welding. the wire acts as both the filler material and the electrode, making mig welding a versatile and efficient method. Choosing the right filler wire for your welding project relies on several factors, including the metal type, thickness, joint design, and welding position. How to choose the right mig wire for. Filler Wire Used In Mig Welding.