What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why . What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. How strong is a tack. How do you tack weld with a stick welder? tack welding is real welding, even if the welds are deposited in separate short beads. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. how to make a tack weld. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality.

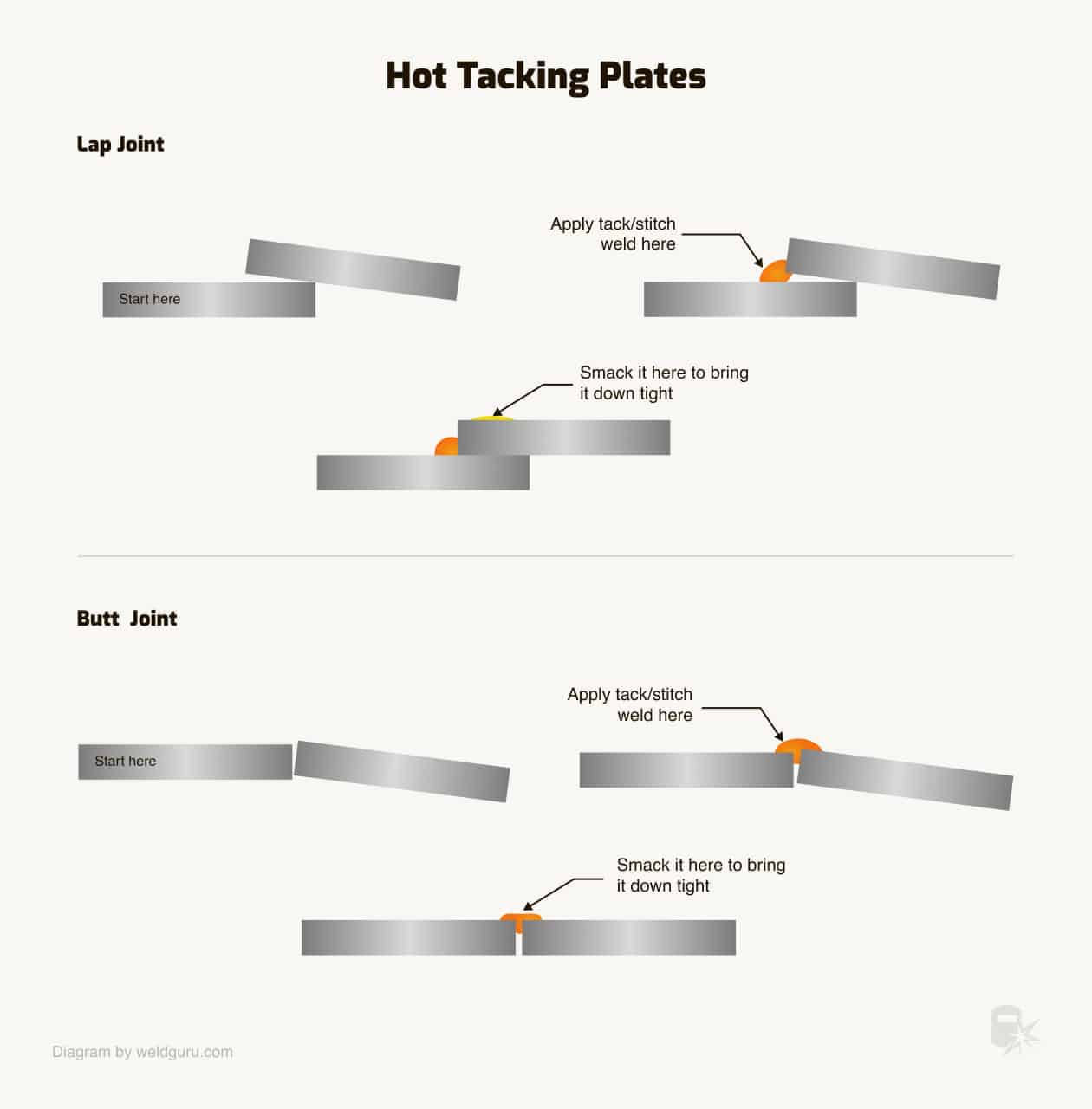

from weldguru.com

it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. tack welding is real welding, even if the welds are deposited in separate short beads. What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. How do you tack weld with a stick welder? tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. how to make a tack weld. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. How strong is a tack. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the.

What is Tack Welding & When to Use It

What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. How do you tack weld with a stick welder? How strong is a tack. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. What is the difference between spot welding and tack welding? other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. Most of the 225 to 300 amps stick welders are capable of handling. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. tack welding is real welding, even if the welds are deposited in separate short beads. how to make a tack weld.

From waterwelders.com

What is Tack Welding? Understanding it Thoroughly WaterWelders What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. How strong is a tack. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. How do you tack. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.youtube.com

Fcaw set up volts,ampereswelding YouTube What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. What is the difference between spot welding and tack welding? how to. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxobykcoh.blob.core.windows.net

Gas Used In Mig Welding Process at Norma White blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why tack welding is real welding, even if the welds are deposited in separate short beads. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. Most of the 225 to 300 amps stick welders are capable of handling. How do you tack weld with a. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.pinterest.com.au

Handler 210 Weld Setup and Parts Information Chart Welding table What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. Most of the 225 to 300 amps stick welders are capable of handling. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a.. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.rapiddirect.com

什么是点焊? 了解其目的和重要性 What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. How strong is a tack. How do you tack weld with a. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From inchbyinch.de

INCH Technical English weld types What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. tack welding is an integral component of welding. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From blog.thepipingmart.com

Tack Weld vs Fillet Weld What's the Difference What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why Most of the 225 to 300 amps stick welders are capable of handling. how to make a tack weld. tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. tack welding is real welding, even if the welds are deposited in separate short beads. it is essential. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From blog.thepipingmart.com

Tack Welding vs Spot Welding What’s the Difference? What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. What is the difference between spot welding and tack welding? tack. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From leaderland.academy

What Is Tack Welding? Understanding Its Purpose And, 46 OFF What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why tack welding is real welding, even if the welds are deposited in separate short beads. Most of the 225 to 300 amps stick welders are capable of handling. What is the difference between spot welding and tack welding? How do you tack weld with a stick welder? you select the amperage of a stick welding rod by setting. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxozifamx.blob.core.windows.net

Stick Welding Rod Amperage Chart at Terry Fox blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why How do you tack weld with a stick welder? tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. tack welding is real welding, even if the welds are deposited in separate short beads. What is the difference between spot welding and tack welding? Most of the 225 to. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxocnvbsq.blob.core.windows.net

How To Weld Wire Without Welder at Christine Lopez blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. tack welding is real welding, even if the welds are deposited in separate short beads. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.vrogue.co

How To Read Blueprints For Welding vrogue.co What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why How do you tack weld with a stick welder? tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. Most of the 225 to 300 amps stick welders are capable of handling. What is the difference between spot welding and tack welding? other issues that can arise from an. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From weldinginsider.com

What Is Tack Welding and How is it Used When Fabricating Projects? What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. Most of the 225 to 300 amps stick welders are capable of handling. tack welding is real welding, even if the welds. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From schematiciroknivs.z4.web.core.windows.net

Weld Cross Section Diagram What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. how to make a tack weld. How strong is a tack. How do you tack weld with a stick welder? it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From partdiagramaminabakery5v.z14.web.core.windows.net

Basic Welding Symbols Chart What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why Most of the 225 to 300 amps stick welders are capable of handling. How do you tack weld with a stick welder? What is the difference between spot welding and tack welding? you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. tack welding is. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From blog.thepipingmart.com

What is Tack Welding? Uses and Working What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why how to make a tack weld. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. tack welding is an integral component of. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From blog.thepipingmart.com

Spot Welding vs Tack Welding What's the Difference What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why how to make a tack weld. tack welding is real welding, even if the welds are deposited in separate short beads. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. other issues that can arise from an improper tack weld include cracking. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.builder.id

Tack Welding, Kelebihan dan Kelemahan Pengelasan Tack What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. how to make a tack weld. How do you tack weld with a stick welder? tack welding is real welding, even if the welds are deposited in separate short beads. tack welding is an. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From weldlover.com

What is a Tack Weld? Definition, importance and proper usage. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. tack welding is an integral component of welding. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxoguabhu.blob.core.windows.net

Welding Symbols Download at Candy Smith blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. you select the amperage of a stick welding rod by setting. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From waterwelders.com

What is Tack Welding? Understanding it Thoroughly WaterWelders What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. how to make a tack weld. tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. tack welding is real welding, even if the welds. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From in.pinterest.com

What is tack welding? Welding, How to apply, Tack What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? tack welding is real welding, even if the welds are deposited in separate short beads. how to make a tack weld. How do you tack weld with a stick welder? other issues that can arise from an improper tack weld include cracking in the final weld, the. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From blog.thepipingmart.com

Advantages and Disadvantages Tack Welding What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. tack welding is real welding, even if the welds are deposited in separate short beads. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.slideshare.net

Types20of20 Welding[1] What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. how to make a tack weld. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. Most of the 225 to 300 amps stick. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From exoykcuqs.blob.core.windows.net

Types Of Welding For Steel at Henry b blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. tack welding is real welding, even if the welds. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.youtube.com

How To Tack Weld Like A Pro YouTube What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. How strong is a tack. Most of the 225 to 300 amps stick welders are capable of handling. How do you tack weld with a stick welder? you. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From exohyurxw.blob.core.windows.net

Welding Parameters For Gmaw at Maurita Martin blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why How do you tack weld with a stick welder? other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the.. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From weldguru.com

What is Tack Welding & When to Use It What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why Most of the 225 to 300 amps stick welders are capable of handling. What is the difference between spot welding and tack welding? How strong is a tack. tack welding is real welding, even if the welds are deposited in separate short beads. it is essential to use the appropriate welding technique and adjust the amperage accordingly to. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From weldguru.com

What is Tack Welding & When to Use It What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why how to make a tack weld. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. How strong. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From weldguru.com

What is Tack Welding & When to Use It What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why how to make a tack weld. tack welding is an integral component of welding that serves as a temporary hold before final welding is performed. tack welding is real welding, even if the welds are deposited in separate short beads. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From waterwelders.com

What is Tack Welding? Understanding it Thoroughly WaterWelders What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why How do you tack weld with a stick welder? How strong is a tack. What is the difference between spot welding and tack welding? Most of the 225 to 300 amps stick welders are capable of handling. other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes,. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.vrogue.co

Types Of Welding Positions 1g 2g 3g 4g 5g 6g6gr Joint vrogue.co What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why other issues that can arise from an improper tack weld include cracking in the final weld, the formation of dents or holes, overly hard areas, a. it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. how to make a tack weld. How strong is a tack.. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxogzbgfa.blob.core.windows.net

Can I Weld Stainless Steel With A Wire Feed Welder at Bill Krahn blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why how to make a tack weld. tack welding is real welding, even if the welds are deposited in separate short beads. you select the amperage of a stick welding rod by setting it high enough to get the best penetration and fusion for the. Most of the 225 to 300 amps stick welders are capable of handling.. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From www.theweldingmaster.com

Different Types of Welds in Welding What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why What is the difference between spot welding and tack welding? it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. Most of the 225 to 300 amps stick welders are capable of handling. you select the amperage of a stick welding rod by setting it high enough to. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.

From dxosrnjtq.blob.core.windows.net

Gas Metal Reactions In Welding at Kathy Fredrick blog What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why How do you tack weld with a stick welder? What is the difference between spot welding and tack welding? it is essential to use the appropriate welding technique and adjust the amperage accordingly to achieve the desired weld quality. tack welding is real welding, even if the welds are deposited in separate short beads. you select the. What Is The Recommended Set-Up Of Welding Amperes For Tack Weld Why.