Bearing Oil Lubrication System . These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication is essential to prevent premature ball bearing failure. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine.

from favpng.com

When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Probably the most critical factor in maintaining operating conditions, the lubricant.

Oil Automatic Lubrication System Lubricant Bearing, PNG, 569x762px, Oil

Bearing Oil Lubrication System Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and.

From cullen-has-burgess.blogspot.com

Car Engine Lubrication System CullenhasBurgess Bearing Oil Lubrication System Probably the most critical factor in maintaining operating conditions, the lubricant. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that. Bearing Oil Lubrication System.

From senazh.com

Automatic bearing lubrication system for the baler from the Bearing Oil Lubrication System Probably the most critical factor in maintaining operating conditions, the lubricant. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing. Bearing Oil Lubrication System.

From themechanicalengineering.com

Different Types of Lubrication System in Detail [Notes & PDF] Bearing Oil Lubrication System When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds. Bearing Oil Lubrication System.

From rbcbearings.in

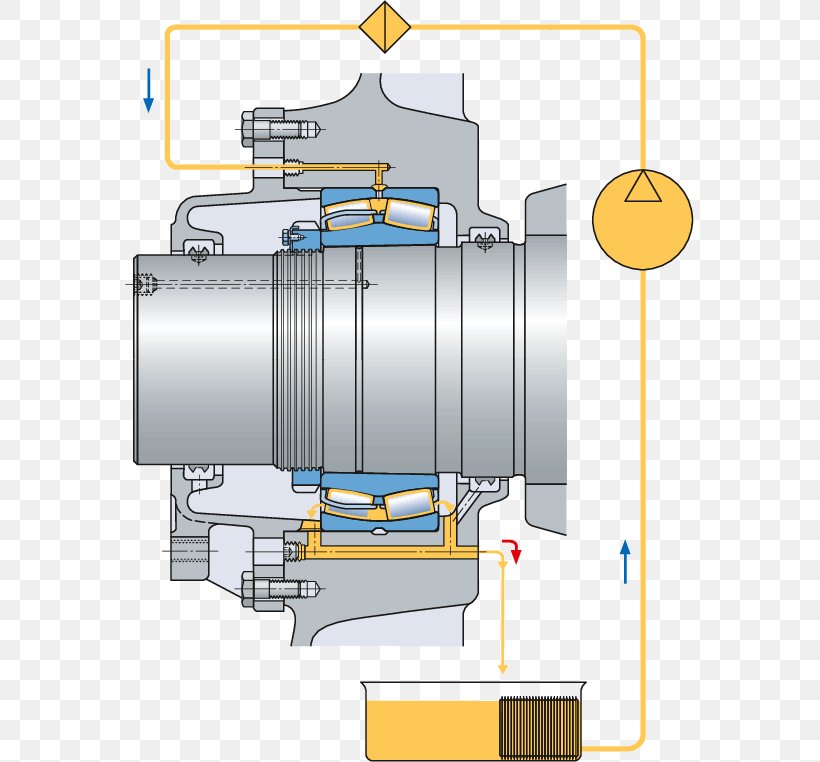

Oil circulation lubrication systems RBC Bearings Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Lubrication is essential to prevent premature ball bearing failure. When selecting the most appropriate oil lubrication. Bearing Oil Lubrication System.

From favpng.com

Oil Automatic Lubrication System Lubricant Bearing, PNG, 569x762px, Oil Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings,. Bearing Oil Lubrication System.

From www.plantengineering.com

Plant Engineering Understanding lubrication from the bearing’s Bearing Oil Lubrication System Probably the most critical factor in maintaining operating conditions, the lubricant. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. This highly effective solution improves lubricant flow and. Bearing Oil Lubrication System.

From informacionpublica.svet.gob.gt

How To Lubricate Your Bearings Bearing Oil Lubrication System When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Probably the most critical factor in maintaining operating conditions, the lubricant. Designed primarily to cool and lubricate highly stressed bearings in nearly every. Bearing Oil Lubrication System.

From spencerengineering.com

Mine Hoist Bearing Lubrication Systems W.G. Spencer Engineering Inc. Bearing Oil Lubrication System When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Probably the most critical factor in maintaining operating. Bearing Oil Lubrication System.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication is essential to prevent premature ball bearing failure. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing. Bearing Oil Lubrication System.

From www.lubetechnologies.com

ILC AUTOMATIC LUBRICATION SYSTEMS LUBRICATION TECHNOLOGIES Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Probably the most critical factor in maintaining operating conditions, the lubricant. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Lubrication is essential to prevent. Bearing Oil Lubrication System.

From koyo.jtekt.co.jp

Purpose and method of lubrication Basic Bearing Knowledge Koyo Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Lubrication. Bearing Oil Lubrication System.

From www.ybcomponents.co.uk

Bearing Lubrication Oil or Grease? Y B Components Bearing Oil Lubrication System Probably the most critical factor in maintaining operating conditions, the lubricant. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Designed primarily to cool and lubricate highly stressed bearings in nearly every. Bearing Oil Lubrication System.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 1 Pumps & Systems Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Lubrication is essential to prevent premature ball bearing failure.. Bearing Oil Lubrication System.

From blog.slsbearings.com

The Importance of Lubrication in Bearings and Other Components Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication is essential to prevent premature ball bearing. Bearing Oil Lubrication System.

From www.youtube.com

TURBOCHARGER LUBRICATION SYSTEMSELF LUBRICATION INDEPENDENT Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Lubrication is essential to prevent premature ball bearing failure.. Bearing Oil Lubrication System.

From www.youtube.com

Pump bearing housing lubrication YouTube Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Probably the most critical factor in maintaining operating conditions, the lubricant.. Bearing Oil Lubrication System.

From www.indiamart.com

Bearing Lubrication Systems Centralized Oil Lubrication System Bearing Oil Lubrication System These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. When selecting the most appropriate oil lubrication method for a. Bearing Oil Lubrication System.

From dieselship.com

Turbocharger bearing lubrication system DieselShip Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Lubrication is essential to prevent premature ball bearing failure. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. When selecting the most appropriate oil lubrication method for a. Bearing Oil Lubrication System.

From ritmindustry.com

Oil lubrication system / centralized / for bearings RITM Industry Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. Probably the most critical factor in maintaining operating conditions, the lubricant. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate. Bearing Oil Lubrication System.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Bearing Oil Lubrication System When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. Probably the most critical factor in maintaining operating. Bearing Oil Lubrication System.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of. Bearing Oil Lubrication System.

From www.bearingtips.com

When should I use solid film lubricants? Bearing Tips Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery. Bearing Oil Lubrication System.

From www.mining.com

SKF superprecision bearing lubrication unit Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. Probably. Bearing Oil Lubrication System.

From www.marineengineersknowledge.com

STERN TUBE LUBRICATION SYSTEM Marine engineers knowledge Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication is essential to prevent premature ball bearing failure. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. When selecting the. Bearing Oil Lubrication System.

From www.marineengineersknowledge.com

Lets understand about main engine lubrication system Marine engineers Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Probably the most critical factor in maintaining operating conditions, the lubricant. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. For larger machines. Bearing Oil Lubrication System.

From www.machinerylubrication.com

Selecting the Correct Lubricant for Bearing Applications Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. This highly effective solution. Bearing Oil Lubrication System.

From precisionlubrication.com

How to Properly Lubricate a Rolling Element Bearing Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at. Bearing Oil Lubrication System.

From www.youtube.com

How to Properly Lubricate a Plain Linear Bearing YouTube Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. This. Bearing Oil Lubrication System.

From www.maintworld.com

Bearing Lubrication Best Practices What to Know and Mistakes to Avoid Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements. Bearing Oil Lubrication System.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 2 Bearing Oil Lubrication System Probably the most critical factor in maintaining operating conditions, the lubricant. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. When selecting the most appropriate. Bearing Oil Lubrication System.

From www.theengineerspost.com

8 Different Parts of Lubrication System with [Diagrams & PDF] Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. When selecting the most appropriate oil lubrication. Bearing Oil Lubrication System.

From smbbearings.blogspot.com

SMB Bearings Ltd Blog Bearing Lubrication the importance of Bearing Oil Lubrication System This highly effective solution improves lubricant flow and reduces frictional heating in the bearings, enabling them to operate at speeds up to. Probably the most critical factor in maintaining operating conditions, the lubricant. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. Designed primarily to cool and. Bearing Oil Lubrication System.

From advancedfluidsystems.com

Lubrication Unit Trunnion Bearing High Pressure Bearing Oil Lubrication System For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating. Bearing Oil Lubrication System.

From reliabilityweb.com

Reliabilityweb Understanding Bearing Housing Protection and Reliable Bearing Oil Lubrication System Lubrication is essential to prevent premature ball bearing failure. Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine. For larger machines and production lines, lincoln offers systems to lubricate hundreds of bearings that pump directly from refinery drums or bulk. When selecting the most appropriate oil lubrication method for a bearing arrangement, the following. Bearing Oil Lubrication System.

From favpng.com

Lubrication Oil Bearing Lubricant Colmar, PNG, 746x599px, Lubrication Bearing Oil Lubrication System When selecting the most appropriate oil lubrication method for a bearing arrangement, the following application requirements should be. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and. Lubrication is essential to prevent premature ball bearing failure. This highly effective solution improves lubricant flow and reduces frictional heating in the bearings,. Bearing Oil Lubrication System.