Casting Method Diagram . A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Each method has unique characteristics and applications, from sand casting to investment casting. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in.

from www.open.edu

The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. Each method has unique characteristics and applications, from sand casting to investment casting.

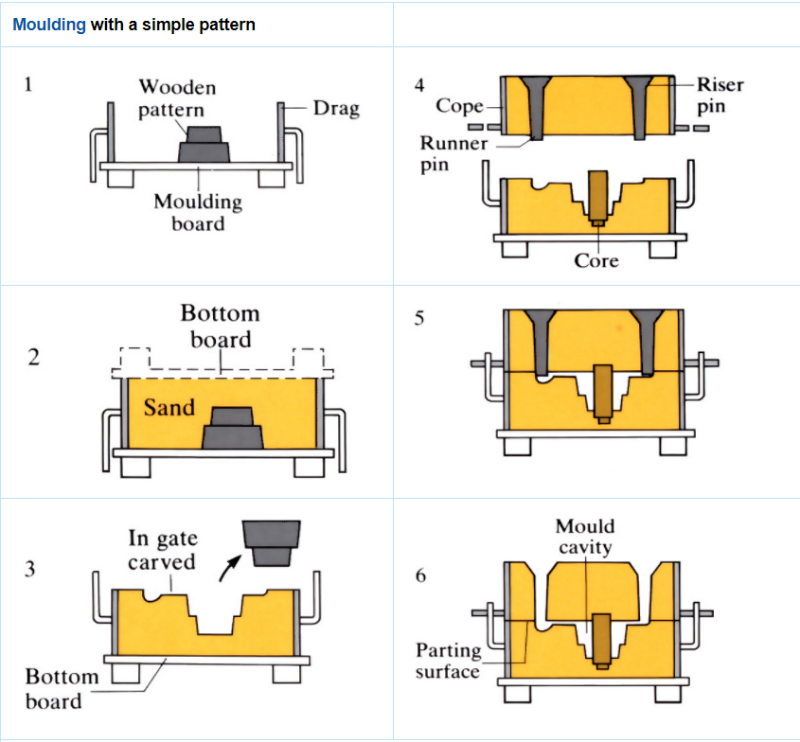

Sand casting OpenLearn Open University

Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. A 3d object formed by this process. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. Each method has unique characteristics and applications, from sand casting to investment casting.

From www.researchgate.net

A schematic diagram of the continuous casting process. Download Casting Method Diagram A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that. Casting Method Diagram.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3d object. Casting Method Diagram.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive. Casting Method Diagram.

From www.sputtertargets.net

An Introduction to Metal Casting Process Stanford Advanced Materials Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process. Casting Method Diagram.

From circuitnehajnije39.z21.web.core.windows.net

Sand Casting Simple Diagram Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. The casting process is a foundational metalworking technique that involves melting metal or alloy. Casting Method Diagram.

From www.researchgate.net

Schematic of continuous casting process Download Scientific Diagram Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. Each method has unique characteristics and applications, from sand casting to investment casting. A 3d object formed by this process. In sand casting, molten metal is poured. Casting Method Diagram.

From www.youtube.com

Gating System Parts in Casting Process [Pattern, Mold, Gate, Sprue Casting Method Diagram The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they. Casting Method Diagram.

From www.researchgate.net

Schematic representation of the edible film formulation (A) Casting Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form. Casting Method Diagram.

From www.semanticscholar.org

[PDF] Modeling of steel grade transition in continuous slab casting Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. A 3d object formed by this process. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. The casting process is a foundational metalworking. Casting Method Diagram.

From fluids.leeds.ac.uk

Fluid Dynamics of the Continuous Casting of Steel Leeds Institute for Casting Method Diagram In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Each method has unique characteristics and applications, from sand casting to investment casting. A 3d object. Casting Method Diagram.

From www.researchgate.net

Show Illustration of Continuous Casting Process [6]. Download Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. Each method has unique characteristics and applications,. Casting Method Diagram.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages. Casting Method Diagram.

From www.nationalbronze.com

Back to the Basics Bronze Casting Process National Bronze Manufacturing Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form. Casting Method Diagram.

From www.engineerstudent.co.uk

Die Casting Process Hot and Cold Chamber Casting Method Diagram In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3d object formed by this process. Each method has unique characteristics and applications, from sand casting to investment casting. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring. Casting Method Diagram.

From www.youtube.com

Casting Process Terminology Types Pattern Making Core Making Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Each method has unique characteristics and applications, from sand casting to investment casting. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. In this blog post, we'll break down. Casting Method Diagram.

From www.researchgate.net

stir casting method schematic diagram [41]. Download Scientific Diagram Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. Each method has unique characteristics and applications, from sand casting to investment casting. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. In this blog. Casting Method Diagram.

From www.rocheindustry.com

Handbook The Ultimate Guide to Metal Casting 2024 Updated Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. A 3d object formed by this process. The casting process is a foundational metalworking. Casting Method Diagram.

From www.researchgate.net

Schematic diagrams illustrating different types of casting methods; (a Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Each method has unique characteristics and applications,. Casting Method Diagram.

From www.researchgate.net

Schematic diagram Stir casting process to fabricate MMC's [5960, 78 Casting Method Diagram In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring. Casting Method Diagram.

From www.omicroncasting.com

5 Different Methods Used in Casting Casting Method Diagram A 3d object formed by this process. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. In sand casting, molten metal is poured into an expendable sand mould cavity. Casting Method Diagram.

From www.theengineerspost.com

15 Different Types of Casting Process Explained [with PDF] Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive. Casting Method Diagram.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. Each method has unique characteristics and applications, from sand casting to investment casting. The casting process is the manufacturing process in which molten material such as metal. Casting Method Diagram.

From www.the-warren.org

Sand Casting Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. Each method has unique characteristics and applications, from sand casting to investment casting. In sand casting, molten metal is poured into an expendable sand mould cavity by. Casting Method Diagram.

From www.open.edu

Sand casting OpenLearn Open University Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Each method has unique characteristics and applications, from sand casting to investment casting. A 3d object formed by this process.. Casting Method Diagram.

From www.iqsdirectory.com

Types of Casting Processes Casting Methods Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form. Casting Method Diagram.

From www.machinemfg.com

14 Types of Casting Exploring the Various Casting Methods MachineMFG Casting Method Diagram In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3d object formed by this process. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that. Casting Method Diagram.

From www.slideserve.com

PPT CASTING PowerPoint Presentation, free download ID6573135 Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3d object. Casting Method Diagram.

From www.pinterest.com

Continuous Casting Process It cast, Continuity, Under pressure Casting Method Diagram The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they. Casting Method Diagram.

From www.comsol.com

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Casting Method Diagram A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that. Casting Method Diagram.

From www.versa-bar.com

Advantages of the Continuous Casting Process Benefits of Cast Iron Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. Each method has. Casting Method Diagram.

From www.iqsdirectory.com

Lost Wax Casting What Is It? How Does It Work? Parts, Metal Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3d object formed by this process. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive. Casting Method Diagram.

From www.researchgate.net

1. Casting Process flow chart. Download Scientific Diagram Casting Method Diagram In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process. Casting Method Diagram.

From www.youtube.com

Investment Casting Process Working Animation Manufacturing Processes Casting Method Diagram Each method has unique characteristics and applications, from sand casting to investment casting. In this blog post, we'll break down the 12 different casting processes and provide a comprehensive overview of how they work, their advantages and disadvantages, and the industries they are commonly used in. The casting process is a foundational metalworking technique that involves melting metal or alloy. Casting Method Diagram.

From www.iqsdirectory.com

Types of Casting Processes Casting Methods Casting Method Diagram A 3d object formed by this process. In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. The casting process is a foundational metalworking technique that. Casting Method Diagram.

From metalworldinsight.com

Continuous casting machine schematic diagram Metal World Insight Casting Method Diagram The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity. Each method has unique characteristics and applications, from sand casting to investment casting. The casting process is a foundational metalworking technique that involves melting metal or alloy and pouring it into a mold. In this blog post, we'll break down. Casting Method Diagram.