End Mill Spindle Speed Chart . For milling, turning, drilling, grooving, and parting off. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. Surface feet per minute factor x 4 = ___ ? formula for computing spindle speed is. The most important aspect of milling with end mills is to run the tool at. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. the best online speeds and feeds calculator. milling speed and feed calculator. end mill feeds and speeds: 2) start with a middle/average value for. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. 1) select your material in the iso colored chart with respect to material description.

from mungfali.com

Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. 1) select your material in the iso colored chart with respect to material description. end mill feeds and speeds: 2) start with a middle/average value for. milling speed and feed calculator. formula for computing spindle speed is. For milling, turning, drilling, grooving, and parting off. The most important aspect of milling with end mills is to run the tool at. 2) start with a middle/average value for. the best online speeds and feeds calculator.

Lathe Surface Speed Chart

End Mill Spindle Speed Chart end mill feeds and speeds: 2) start with a middle/average value for. the best online speeds and feeds calculator. 2) start with a middle/average value for. end mill feeds and speeds: For milling, turning, drilling, grooving, and parting off. Surface feet per minute factor x 4 = ___ ? milling speed and feed calculator. The most important aspect of milling with end mills is to run the tool at. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. 1) select your material in the iso colored chart with respect to material description. 1) select your material in the iso colored chart with respect to material description. formula for computing spindle speed is. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter End Mill Spindle Speed Chart 1) select your material in the iso colored chart with respect to material description. Surface feet per minute factor x 4 = ___ ? For milling, turning, drilling, grooving, and parting off. formula for computing spindle speed is. the best online speeds and feeds calculator. The most important aspect of milling with end mills is to run. End Mill Spindle Speed Chart.

From dat.perueduca.edu.pe

Hss Drill Speeds And Feeds Chart Pdf Printable Templates Free End Mill Spindle Speed Chart 1) select your material in the iso colored chart with respect to material description. formula for computing spindle speed is. The most important aspect of milling with end mills is to run the tool at. 1) select your material in the iso colored chart with respect to material description. Surface feet per minute factor x 4 =. End Mill Spindle Speed Chart.

From mavink.com

Brookfield Spindle Factor Chart End Mill Spindle Speed Chart end mill feeds and speeds: milling speed and feed calculator. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. formula for computing spindle speed is. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time. End Mill Spindle Speed Chart.

From gcodetutor.com

Calculating spindle speeds Machine Shop Maths End Mill Spindle Speed Chart the best online speeds and feeds calculator. For milling, turning, drilling, grooving, and parting off. end mill feeds and speeds: 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. The most important aspect of milling with end mills is to run the tool at. Determine. End Mill Spindle Speed Chart.

From mungfali.com

Cutting Speeds And Feeds Chart End Mill Spindle Speed Chart For milling, turning, drilling, grooving, and parting off. end mill feeds and speeds: 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. milling speed and feed calculator. formula. End Mill Spindle Speed Chart.

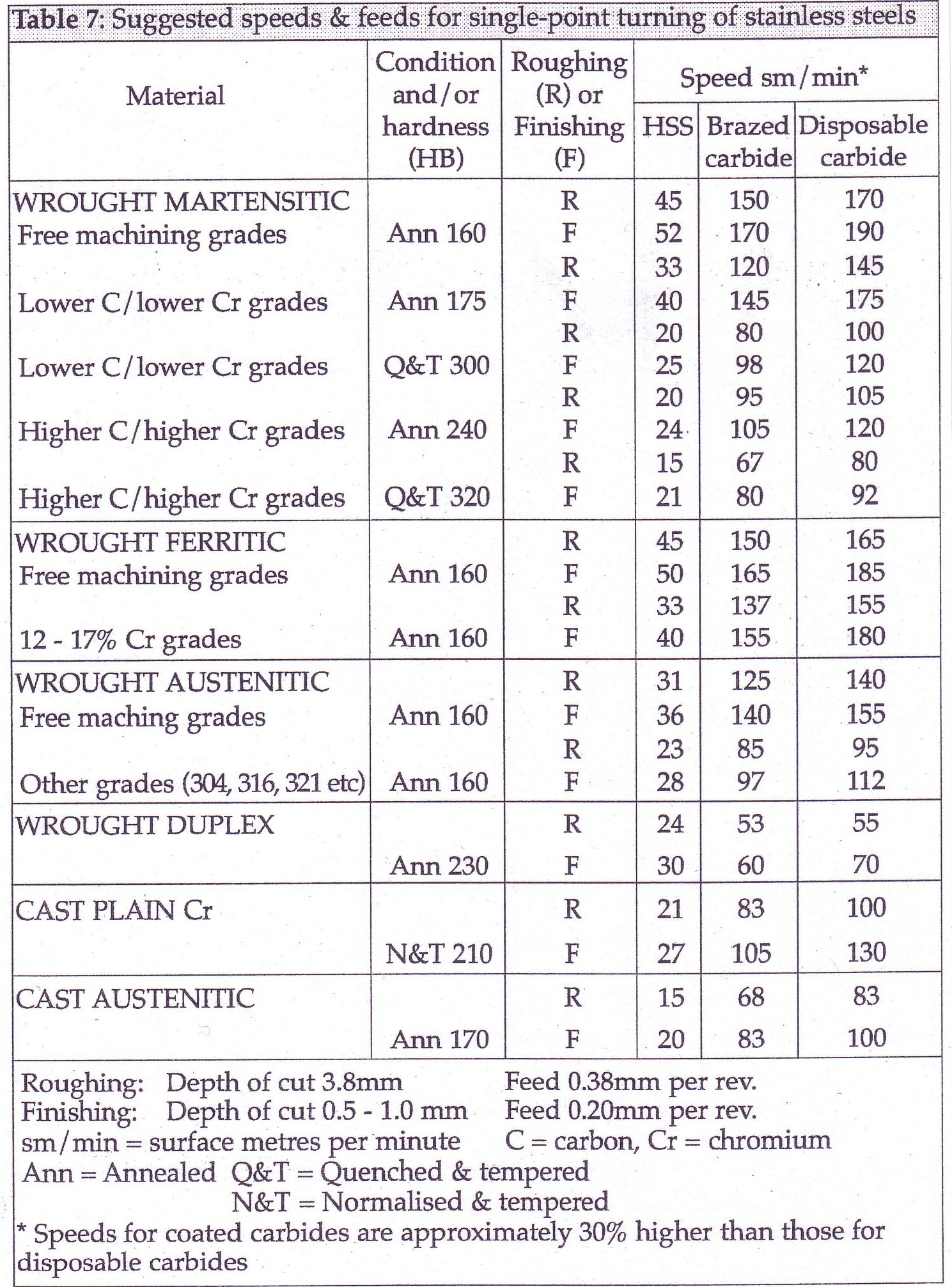

From bssa.org.uk

Speeds and feeds for turning stainless steels British Stainless Steel End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? 2) start with a middle/average value for. The most important aspect of milling with end mills is to run the tool at. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. formula for computing spindle speed. End Mill Spindle Speed Chart.

From www.pinterest.com

End Mill Speed Feed Chart When you plan to learn wood working End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? formula for computing spindle speed is. 2) start with a middle/average value for. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. the best online speeds and feeds calculator. 2) start with a middle/average value for. milling speed and feed. End Mill Spindle Speed Chart.

From www.slideserve.com

PPT CNC Tooling PowerPoint Presentation, free download ID219776 End Mill Spindle Speed Chart 2) start with a middle/average value for. For milling, turning, drilling, grooving, and parting off. The most important aspect of milling with end mills is to run the tool at. end mill feeds and speeds: 1) select your material in the iso colored chart with respect to material description. Determine the spindle speed (rpm) and feed rate (ipm). End Mill Spindle Speed Chart.

From www.edwoodcrafting.com

CNC Speed/Feed Calculator EdwoodCrafting End Mill Spindle Speed Chart Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. Surface feet per minute factor x 4 = ___ ? 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. Determine the spindle speed for. End Mill Spindle Speed Chart.

From machiningtool.blogspot.co.uk

Machining Milling Metric Cutting speed calculation End Mill Spindle Speed Chart 1) select your material in the iso colored chart with respect to material description. Surface feet per minute factor x 4 = ___ ? Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. formula for computing spindle speed is. 2) start with a middle/average. End Mill Spindle Speed Chart.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice End Mill Spindle Speed Chart formula for computing spindle speed is. 2) start with a middle/average value for. The most important aspect of milling with end mills is to run the tool at. 1) select your material in the iso colored chart with respect to material description. milling speed and feed calculator. Determine the spindle speed for turning, milling, drilling, and reaming. End Mill Spindle Speed Chart.

From gcodetutor.com

Calculating spindle speeds Machine Shop Maths End Mill Spindle Speed Chart 2) start with a middle/average value for. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. Surface feet per minute factor x 4 = ___ ? end mill feeds and speeds: For milling, turning, drilling, grooving, and parting off. 2) start with a middle/average value for. the best online speeds and. End Mill Spindle Speed Chart.

From mungfali.com

HSS Speeds And Feeds Chart End Mill Spindle Speed Chart formula for computing spindle speed is. The most important aspect of milling with end mills is to run the tool at. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description.. End Mill Spindle Speed Chart.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Spindle Speed Chart the best online speeds and feeds calculator. end mill feeds and speeds: 2) start with a middle/average value for. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. milling speed and feed calculator. 1) select your material in the iso colored chart with respect to material description. The most. End Mill Spindle Speed Chart.

From ar.inspiredpencil.com

End Mill Speed Chart End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? the best online speeds and feeds calculator. 1) select your material in the iso colored chart with respect to material description. milling speed and feed calculator. formula for computing spindle speed is. 2) start with a middle/average value for. Determine the spindle speed for turning, milling,. End Mill Spindle Speed Chart.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter End Mill Spindle Speed Chart 2) start with a middle/average value for. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. The most important aspect of milling with end mills is to run the tool at. the best online speeds and feeds calculator. For milling, turning, drilling, grooving, and parting off.. End Mill Spindle Speed Chart.

From mungfali.com

Cutting Speeds And Feeds Chart End Mill Spindle Speed Chart milling speed and feed calculator. end mill feeds and speeds: For milling, turning, drilling, grooving, and parting off. The most important aspect of milling with end mills is to run the tool at. Surface feet per minute factor x 4 = ___ ? the best online speeds and feeds calculator. 2) start with a middle/average value for.. End Mill Spindle Speed Chart.

From onlinesupply.ca

Skookum End Mills End Mill Spindle Speed Chart end mill feeds and speeds: The most important aspect of milling with end mills is to run the tool at. the best online speeds and feeds calculator. formula for computing spindle speed is. 1) select your material in the iso colored chart with respect to material description. 2) start with a middle/average value for. Determine the. End Mill Spindle Speed Chart.

From edwardr777.github.io

Speeds And Feeds Chart End Mill Spindle Speed Chart formula for computing spindle speed is. the best online speeds and feeds calculator. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. 1) select your material in the iso colored chart with respect to material description. milling speed and feed calculator. . End Mill Spindle Speed Chart.

From mungfali.com

Milling Speed Chart End Mill Spindle Speed Chart formula for computing spindle speed is. 1) select your material in the iso colored chart with respect to material description. end mill feeds and speeds: 2) start with a middle/average value for. The most important aspect of milling with end mills is to run the tool at. Determine the spindle speed (rpm) and feed rate (ipm) for. End Mill Spindle Speed Chart.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere End Mill Spindle Speed Chart 1) select your material in the iso colored chart with respect to material description. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. The most important aspect of milling with end mills is to run the tool at. end mill feeds and speeds: formula for computing spindle speed is. Surface. End Mill Spindle Speed Chart.

From mollybarrett.z13.web.core.windows.net

Speed And Feed Chart For Milling End Mill Spindle Speed Chart Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. 1) select your material in the iso colored chart with respect to material description. 1) select your material in the iso colored chart with respect to material description. 2) start with a middle/average value for. The most important aspect of milling with. End Mill Spindle Speed Chart.

From mungfali.com

CNC Speed Feed Chart End Mill Spindle Speed Chart For milling, turning, drilling, grooving, and parting off. end mill feeds and speeds: Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. 1) select your material in the. End Mill Spindle Speed Chart.

From www.pinterest.com

(2) METRIC drill press speed chart WoodworkingTools Essential End Mill Spindle Speed Chart Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. 2) start with a middle/average value for. the best online speeds and feeds calculator. formula for computing spindle speed is. milling speed and feed calculator. 1) select your material in the iso colored. End Mill Spindle Speed Chart.

From mungfali.com

HSS Speeds And Feeds Chart End Mill Spindle Speed Chart 2) start with a middle/average value for. Surface feet per minute factor x 4 = ___ ? For milling, turning, drilling, grooving, and parting off. 1) select your material in the iso colored chart with respect to material description. 1) select your material in the iso colored chart with respect to material description. end mill feeds and. End Mill Spindle Speed Chart.

From encyclopedia.pub

HighSpeed Motorized Spindles of CNC Machine Tools Encyclopedia MDPI End Mill Spindle Speed Chart 1) select your material in the iso colored chart with respect to material description. 1) select your material in the iso colored chart with respect to material description. The most important aspect of milling with end mills is to run the tool at. 2) start with a middle/average value for. milling speed and feed calculator. Determine the. End Mill Spindle Speed Chart.

From michael-parrish.com

Craftsman 103.23141 (100 series) Drill Press Restoration [part 1 End Mill Spindle Speed Chart For milling, turning, drilling, grooving, and parting off. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. milling speed and feed calculator. 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. end mill feeds and speeds: The most. End Mill Spindle Speed Chart.

From shiba.ns-tool.com

Calculation for Cutting Speed, Spindle Speed and Feed NS TOOL CO.,LTD. End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? the best online speeds and feeds calculator. milling speed and feed calculator. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. For milling, turning, drilling, grooving, and parting off. 2) start with a middle/average. End Mill Spindle Speed Chart.

From www.jbcnc.se

ATC Spindles Milling Spindles and accessories ATC Spindle 24000rpm End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? For milling, turning, drilling, grooving, and parting off. 1) select your material in the iso colored chart with respect to material description. the best online speeds and feeds calculator. The most important aspect of milling with end mills is to run the tool at. formula for computing. End Mill Spindle Speed Chart.

From mungfali.com

End Mill Speed And Feed Chart End Mill Spindle Speed Chart end mill feeds and speeds: formula for computing spindle speed is. The most important aspect of milling with end mills is to run the tool at. Surface feet per minute factor x 4 = ___ ? Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. the best online speeds and. End Mill Spindle Speed Chart.

From www.v1engineering.com

MPCNC Speeds and Feeds Chart V1 Engineering End Mill Spindle Speed Chart milling speed and feed calculator. 1) select your material in the iso colored chart with respect to material description. end mill feeds and speeds: the best online speeds and feeds calculator. For milling, turning, drilling, grooving, and parting off. Surface feet per minute factor x 4 = ___ ? 2) start with a middle/average value for.. End Mill Spindle Speed Chart.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Spindle Speed Chart 2) start with a middle/average value for. The most important aspect of milling with end mills is to run the tool at. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. 1) select your material in the iso colored chart with respect to material description.. End Mill Spindle Speed Chart.

From quoteimg.com

drill press speed chart Quotes End Mill Spindle Speed Chart 2) start with a middle/average value for. 1) select your material in the iso colored chart with respect to material description. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a given cut. The most important aspect of milling with end mills is to run the tool at.. End Mill Spindle Speed Chart.

From bamil.lewisburgdistrictumc.org

carbide end mill speed and feed chart Bamil End Mill Spindle Speed Chart Surface feet per minute factor x 4 = ___ ? end mill feeds and speeds: formula for computing spindle speed is. 1) select your material in the iso colored chart with respect to material description. The most important aspect of milling with end mills is to run the tool at. the best online speeds and feeds. End Mill Spindle Speed Chart.

From mungfali.com

Lathe Surface Speed Chart End Mill Spindle Speed Chart end mill feeds and speeds: 2) start with a middle/average value for. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed. formula for computing spindle speed is. 1) select your material in the iso colored chart with respect to material description. milling speed and feed calculator. Determine the spindle. End Mill Spindle Speed Chart.